Documente Academic

Documente Profesional

Documente Cultură

Dowhole Tools - Slickline

Încărcat de

Adonis SaidlerDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Dowhole Tools - Slickline

Încărcat de

Adonis SaidlerDrepturi de autor:

Formate disponibile

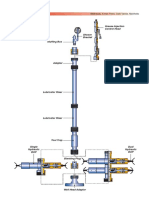

Slickline Downhole Basic Tools Data Sheets

Slickline Services

DATA DHT-01.00

Table of Contents

Slickline Downhole Basic Tools Data Sheets ............................................................. 1

Rope Socket Pear Drop Type........................................................................................................................3

Wireline Stem Weight Bars...........................................................................................................................4

Wireline Knuckle Joint...................................................................................................................................5

Wireline Swivel Joint......................................................................................................................................6

Wireline Adapters...........................................................................................................................................7

Wireline Link Jar Spang.............................................................................................................................8

Wireline Tube Jar...........................................................................................................................................9

Wireline Hydraulic Jar.................................................................................................................................10

Wireline Spring Jar......................................................................................................................................11

Gauge Cutters..............................................................................................................................................12

Blind Box.......................................................................................................................................................13

Impression Block.........................................................................................................................................14

Wireline Magnet...........................................................................................................................................15

Fluted Centralizer........................................................................................................................................16

GR Adapter...................................................................................................................................................17

GS Pulling Tool............................................................................................................................................18

JU Running/Pulling Tool.............................................................................................................................19

JD Running/Pulling tool..............................................................................................................................20

R Running/ Pulling Tool..........................................................................................................................21

S Running/ Pulling Tool...........................................................................................................................22

X Running Tool............................................................................................................................................23

B Shifting Tool.............................................................................................................................................24

Sand Pump Bailer........................................................................................................................................25

Sample Bailer...............................................................................................................................................26

Hydrostatic Bailer........................................................................................................................................27

Wireline Cutter.............................................................................................................................................28

GO Devil........................................................................................................................................................29

Solid Wire Finder.........................................................................................................................................30

Wire Grab.....................................................................................................................................................31

Shock Absorber............................................................................................................................................32

Spring Centralizer........................................................................................................................................33

Scratcher/Brush...........................................................................................................................................34

Slickline Services

DATA DHT-01.00

Rope Socket Pear Drop Type

The Pear Drop Rope Sockets are used to attach

wireline to the tool string and are predominately

used with wireline sizes from 0.092 to 0.160

dependent on size.

The Rope Socket assembly consists of a body with

an external fishing neck, sleeve and a brass wedge

(pear drop) which is grooved to accommodate the

wire and comes complete with a securing grub

screw

Applications

Used as a method of connecting the Slickline to

the tool string, from wire sizes from 0.108 up to

0.160

Features

Assembly consists of a body with external fishing

neck, sleeve and brass wedge (pear drop)

The pear drop is grooved to accommodate the

wire and comes complete with a securing grub

screw

The more pull applied on the Slickline, the more

the pear drop pulls into the sleeve giving a tighter

grip on the Slickline

Benefits

Pear drop sockets are ordered to suit the wire size

being deployed

Simple, low maintenance design

Size (in.)

1-1/2

1-7/8

1-7/8

2-1/8

2-1/2

Max. OD (in.)

1.500

1.875

1.875

2.125

2.500

Rope socket

F/N OD (in.)

1.375

1.750

1.750

1.750

2.312

Thread Conn. Box (in. TPI)

1-1/16 - 10 UN

15/16 - 10 UN

1-1/16 - 10 UN

1-1/16 - 10 UN

1-9/16 - 10 UN

Wire size (in.)

0.092 / 0.108

0.092 / 0.125

0.092 / 0.125

0.092 / 0.125

0.092 / 0.125

Slickline Services

DATA DHT-01.00

Wireline Stem Weight Bars

The Wireline Stem/Weight Bars, sometimes referred

to as sinker bars, are designed to serve two

purposes.

Firstly they are the weight required to overcome

forces created by well pressure and the size of cable

used and secondly they are the mass required to

deliver impacts when setting or pulling devices in

the wellbore

Applications

As with the conventional stem, however Lead

Filled stem is heavier per ft. giving increased tool

string weight when required without increasing

length or OD

Features

Provides the weight required to overcome forces

created by well pressure and the size of the cable

Creates the mass required to deliver impacts

when setting or pulling devices in the wellbore

Supplied with standard pin and box connections

complete with fishing necks

Benefits

Available in various diameter and lengths

Overcomes well pressures

Wireline Stems

Size (Inch)

Max. OD (inch)

F/N OD (inch)

Thread Connection

1-1/2

1-7/8

2-1/8

2-1/2

1.500

1.875

2.125

2.500

1.375

1.750

1.750

2.312

15/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

1-9/16-10 UN

Slickline Services

DATA DHT-01.00

Wireline Knuckle Joint

The Knuckle Joint is designed to provide flexibility

within the wireline tool string. One or more Knuckle

Joints can be inserted into the tool string at the

operators discretion, to meet operational

requirements

Applications

Knuckle Joints are used to add flexibility within the

tool string and are particularly effective within

deviated well bores

Features

Can be inserted into the tool string at operators

discretion

Works most effectively when situated below the

jar to provide angular movement between the tool

string and the running/pulling tool

Available in various diameters

Benefits

Provides flexibility within the wireline tool string

Meets operational requirements

Size (inch)

1-1/8

1-1/4

1-1/2

1-7/8

2-1/8

2-1/2

Wireline Knuckle Joints

Max. OD (inch)

F/N OD (inch)

1.125

1.250

1.500

1.875

2.125

2.500

0.875

1.187

1.375

1.750

1.750

2.312

Thread Connection

Pin X Box (in. TPI)

5/8-11 UNC

15/16-10 UN

15/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

1-9/16-10 UN

Slickline Services

DATA DHT-01.00

Wireline Swivel Joint

The Swivel Joint is a wireline accessory used to

minimize the effect of line twist caused by

subsurface devices being run. The Swivel Joint has

a bearing incorporated into its design and is used

to minimize rotation whilst running tubing or casing

caliper surveys.

The Swivel Joint has a double fish neck feature and

standard pin and box threads.

Applications

The swivel joint is a tool string accessory that is

incorporated to minimize the effect of any potential

wire twist caused by downhole conditions or devices

being run. The Swivel is commonly run when

running braided cable

Features

Ensures free rotation of downhole tool string

assemblies

Capable of withstanding high impact forces

Suitable for use with the latest generation of high

impact jars

Reduces the build of torque in the tool strong

Benefits

Free rotation even when the tool string is held in

significant tension

Minimizing the buildup of torque reduces

potential damage being cause to the wireline stand

Swivel Joints

Size (inch)

1.500

1.875

2.500

F/N OD (inch)

1.375

1.750

2.313

Connection Thread (inch TPI)

15/16-10 UN

1-1/16-10 UN

1-9/16-10 UN

Slickline Services

DATA DHT-01.00

Wireline Adapters

The Wireline Crossover are used to connect two tool

string items with different threads.

Quick Lock Connection provide a fast safe and strong

method of attaching and releasing tools by hand. The

male half is mated with the female half, then rotated

through 90 deg. Whereon a spring loaded spade in

the female section engages a slot in the male

section and locks the assembly in place. It is released

by pushing upon the spring and rotating again through

90 deg.

Applications

Wireline crossovers are used to connect two tool

string items with different threads and sizes

Lift subs are used to make up the tool string in a safe

manner

Features

All crossovers are supplied with a fishing neck

Can supply the following variations pin to box, pin

to pin or box to box

Benefits

Flexible

Crossovers

Max. OD (inch)

F/N OD(inch)

1.750

2.312

2.312

2.312

1.750

2.312

1.750

1.750

2.312

2.312

1.750

2.312

Thread Conn. Pin (in. TPI)

1-1/16-10

1-1/16-10

1-1/16-10

1-1/16-10

1-3/16-10

1-3/16-10

Thread Conn. Box (in. TPI)

UN

UN

UN

UN

UN

UN

15/16-10 UN

15/16-10 UN

1-3/16-10 UN

1-9/16-10 UN

15/16-10 UN

1-9/16-10 UN

Sucker Rod Threads & Quick Lock Connections

Thread / QLS Yield Strength

Design Tensile* Strength

Design Shear* Strength

Ultimate

15/16-10 SRT

1-1/16-10 SRT

1-1/2 QLS

1-7/8 QLS & 2-1/8 QLS

47584 lbs.

63910 lbs.

51128 lbs.

77605 lbs.

68475 lbs.

79888 lbs.

60258 lbs.

74409 lbs.

72966 lbs.

96600 lbs.

77700 lbs.

119000 lbs.

Slickline Services

DATA DHT-01.00

Wireline Link Jar Spang

The Wireline Link Jars, often referred to as spang

jars or mechanical jars, are designed to act like a

sliding hammer, utilizing the weight of the stem bars

located immediately above, to convey powerful

jarring impacts.

Upward and downward impacts (jarring actions) are

achieved by controlling the direction and speed of

the wireline at surface.

Applications

Spang Jars or Mechanical Jars are used in both

standard intervention operations and can be used in

fishing operations. The jars, combined with the

added weight of the stem, give a high impact force

downhole when setting or pulling flow control

devices. The operator can manipulate the jars using

the directional control lever in the Wireline unit

Features

Designed to act like a sliding hammer by utilizing

the weight of the steam bars to convey a powerful

jarring action

Jarring actions are controlled by the direction and

speed of the wireline at surface

Available in various diameters and stroke lengths

Benefits

Controlled jarring actions

Wireline Link Jars

Size (inch)

1

1-1/4

1-1/2

1-1/2

1-7/8

1-7/8

2-1/8

2-1/2

Max. OD (inch)

1.000

1.250

1.500

1.500

1.875

1.875

2.125

2.500

F/N OD (inch)

0.875

1.187

1.375

1.375

1.750

1.750

1.750

2.312

Thread Conn. Pin X Box (in. TPI)

5/8-11 UNC

15/16-10 UN

15/16-10 UN

15/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

1-9/16-10 UN

Stroke

20

30

20

30

20

30

30

24

Slickline Services

DATA DHT-01.00

Wireline Tube Jar

The Tubular Wireline Jars are designed to act like a

siding hammer, utilizing the weight of the stem bars

located immediately above, to convey powerful

jarring impacts.

Upward and downward impacts (jarring actions) are

achieved by controlling the direction and speed of

the wireline at surface

Applications

Tubular Jars are most commonly used during

fishing operations where the possibility of Wire or

other debris could impede the jar action of

conventional mechanical jars. As the Tubular jar

action is contained within an outer housing, there is

less chance of losing jarring action whilst downhole

Features

Used effectively during fishing operations when the

jarring action could be impeded by wire, debris etc.

Used effectively when the tool string is being

deployed during large tubing and casing

Available in various diameters and stroke lengths

Benefits

The jarring action is contained within an outer

body allowing its effective use in wellbores that may

contain debris

Wireline Tubular Jars

Size (inch)

Max. OD (inch)

F/N OD (inch)

1-1/4

1-1/2

1-1/2

1-7/8

1-7/8

2-1/8

2-1/8

1.250

1.500

1.500

1.875

1.875

2.125

2.125

1.187

1.375

1.375

1.750

1.750

1.750

1.750

Thread Conn. Pin X Box (in. TPI)

15/16-10 UN

15/16-10 UN

15/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

Stroke

30

20

30

20

30

20

30

Slickline Services

DATA DHT-01.00

Wireline Hydraulic Jar

The Wireline Hydraulic Jar are used for jarring when

difficulty is face to obtain good jarring action

with Mechanical Jars, particularly due to

deviated wells or wells with highly viscous fluids.

These jars provide only up stroke and are run

between stem and Mechanical Jar.

Applications

Hydraulic Jars are used for jarring when difficulty

is faced when attempting to obtain a good jar action

with mechanical jars, particularly when in deviated

wells or wells that contain highly viscous fluids.

Hydraulic jars only provide an upwards jarring stroke

and are run above the mechanical jars and below

the stem

Features

Delivers a controlled upward impact load during

wireline operations

The closed hydraulic system makes it possible for

the jarring action to be controlled

Available in various diameters and supplied with

standard pin by box connections complete with

fishing necks

Benefits

Controls the jarring action from very light impact

to substantial force

Wireline Hydraulic Jars

Size (inch)

Max. OD (inch)

F/N OD (inch)

Thread Conn. Pin X Box (in. TPI)

Stroke

1-1/8

1-1/4

1-1/2

1-3/4

2-1/8

1.125

1.250

1.500

1.750

2.125

0.875

1.187

1.375

1.375

1.750

5/8-11 UNC

15/16-10 UN

15/16-10 UN

1-1/16-10 UN

1-3/16-10 UN

6.750

9.250

9.187

10.000

11.625

Slickline Services

DATA DHT-01.00

Wireline Spring Jar

The Spring Jar is designed to impact a very high

impact load to a tool string without excessive jarring

action, With a reasonably short tool string, an

upward pull on the wireline compresses the jar

spring until such time as the inner ring has moved

up enough to allow the balls to move in from the

external ring allowing the jar to fire.

Applications

Spring Jars provide an upward jarring action and

are commonly run with mechanical jars on either

standard intervention operations, or fishing

operations. Spring jars are run above the mechanical

jars and below the stem

Features

Design to impact a tool string with a greater load

without excessive jarring actions

Benefits

Reduces excessive jarring actions

Wireline Spring Jars

Size (inch)

Max. OD (inch)

F/N OD (inch)

Thread Conn. Pin X Box (in. TPI)

Setting

1-3/4

2-1/8

1.750

2.125

1.375

1.750

1-1/16-10 UN

1-3/16-10 UN

400-700

400-700

Slickline Services

DATA DHT-01.00

Gauge Cutters

The Gauge Cutter are run in hole before running sub

surface equipment. Gauge/Paraffin Cutters are used

to check if sub surface equipment can pass freely

thru tubing & there are no obstructions and to locate

top of nipple. The bottom of Gauge/Paraffin Cutter is

suitable to cut paraffin, scale and any other obstacles

in tubing.

Applications

Gauge Cutters are run in hole before running sub

surface equipment

Gauge Cutters are used to check if sub

surface equipment can pass freely thru tubing &

there are no obstructions and to locate top of nipple

The bottom of Gauge Cutter is suitable to cut

paraffin, scale and any other obstacles in tubing.

Features

Short bar with a machined bore extending up the

center

Elongated windows for fluid by pass

Upset gauge ring on the bottom is sized for

application

Large bevel cut to provide a scraping edge

Industry standard thread connection complete with

finishing neck

Benefits

Gauge and scrape clean paraffin, wax and other

debris from inside the wall of the completion tubing

string

Ensures there is no impeding matter before running

Tubing Gauge / Paraffin Cutters

OD Range (inch)*

F/N OD (inch)

Thread Connection Pin (in. TPI)

0.905 1.575

1.655 2.265

2.323 2.520

2.598 2.953

2.992 3.900

5.750 6.151

0.875

1.375

1.375

1.750

2.312

2.312

5/8-11 UNC

15/16-10 UN

15/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

1-9/16-10 UN

Slickline Services

DATA DHT-01.00

Blind Box

The Blind Box are used when heavy downward

jarring is required to dislodge a fish or push

something down the hole. Bottom surface of Blind

Box is flat and hardened to reduce wear and

damage.

Applications

Blind Boxes are used when heavy downward

jarring is required to dislodge a fish or push

something down the hole

The Bottom surface of Blind Box is flat and

hardened to reduce wear and damage

Features

Solid bar with a flat hardened bottom end and a

standard thread connection with fishing neck on top

Benefits

Jars an obstruction downward through the tubing

strong to a position which cause the least

inconvenience

Breaking the wireline at the rope socket, allowing

the wire to be retrieved

Blind Boxes

OD Range (inch)*

F/N OD (inch)

1.187 1.250

1.625 1.375

2.625 2.750

3.500 4.625

5.250 5.750

1.187

1.375

1.750

2.312

2.312

Thread Connection Pin (in. TPI)

15/16-10 UN

15/16-10 UN

1-1/16-10 UN

1-9/16-10 UN

1-9/16-10 UN

Slickline Services

DATA DHT-01.00

Impression Block

The Impression Block are used during fishing

operations to check the shape / size of the top of

fish and to determine tool appropriate for fishing

operation. Lead is filled within body of Impression

Block and a pin is fixed thru body of Impression

Block and lead to stabilize lead within body.

Applications

Impression Blocks are used during fishing

operations to check the shape / size of the top of

fish and to determine the appropriate tool for the

fishing operation. Lead is filled within body of

Impression

Block and a pin is fixed thru body of Impression

Block and lead to stabilize lead within body

Features

Steel Cylinder with an open bottom end filled with

soft lead

Top end has an industry standard thread

connection complete with fishing neck

Available in various diameters

Benefits

Allows the operator to take an impression of

unknown objects in the tubing string

This impression helps the operator select the tool

for the next operation

Impression Blocks

OD Range (inch)*

1.000 1.230

1.375 1.410

1.750 2.250

2.625 2.812

3.500 4.625

5.500 5.750

F/N OD (inch)

0.875

1.187

1.375

1.750

2.312

2.312

Thread Connection Pin (in. TPI)

5/8-11 UNC

15/16-10 UN

15/16-10 UN

1-1/16-10 UN

1-9/16-10 UN

1-9/16-10 UN

Slickline Services

DATA DHT-01.00

Wireline Magnet

The Skirted Magnet is designed to retrieve ferrous

debris from the top of tools in the well. The Skirted

Magnet consists of a top sub body complete with

fishing neck and pin connection, magnet and skirt.

Applications

The skirted and bar fishing magnets are used to

retrieve any ferrous debris that may be obstructing

complete entry into the wellbore, or hindering the

retrieval of a sub-surface device

Features

Skirt is manufactured from nonmagnetic material

Prevents debris being dislodged during retrieval

Prevent hindrance during running and pulling by

keeping the magnet of the tubing wall

Benefits

Retrieves debris from the top of the tools in the

well

Size OD (inch)

1.50

1.75

2.25

2.65

3.65

Wireline Fishing Magnet

F/N OD (inch)

Thread Connection Pin (in. TPI)

1.375

1.375

1.375

1.375

1.750

15/16-10 UN

15/16-10 UN

15/16-10 UN

15/16-10 UN

1-1/16-10 UN

To pull (lbs.)

11 14

15 20

25 50

50 75

150 250

Slickline Services

DATA DHT-01.00

Fluted Centralizer

The Fluted Centralizer is designed to centralize

wireline tool strings inside the tubing, during

operations in deviated wells.

Applications

The Fluted Centralizer is used to centralize the tool

string when in the wellbore.

As it is fluted, a full bore centralizer can be run as

fluid bypass is achieved by the flutes.

Can be used as a drift if required

Features

Centralizes the wireline tool strings inside the

tubing

Available in various diameters and supplied with

industry standard connections complete with fishing

neck

Benefits

Full bore Centralizers can be run in fluid as bypass

is achieved by the flutes

Size(inch)

1-1/2

2-1/2

3-1/2

6

Max. OD (inch)

1.50

2.50

3.50

6.00

Fluted Centralizers

F/N OD (inch)

Thread Connection Pin X Box (in. TPI)

1.187

15/16-10 UN

1-1/16-10

UN

1.750

1-1/16-10

UN

2.312

1-9/16-10 UN

2.312

Slickline Services

DATA DHT-01.00

GR Adapter

The Shear Up Adapter GS Pulling Tools are used to

unlock and pull various down hole equipment

with Internal Fishing Necks. These tools are

designed to shear with Jar Down action. With

addition of GU Adapter, complete assembly is

changed to GR Shear Up Tool.

Applications

The Shear Up Adaptor is used to convert a

standard GS pulling tool from a jar down to release

toll, into a jar up to release tool.

The Shear pin in the GS must be removed once

the GU Adaptor is installed

Features

Fitted with industry standard connections and

fishing necks

Internal Sucker Rod connection to allow

installation on to a GS Pulling tool

Benefits

Available to suit as GS Pulling Tools

Size

1-1/2

2

2-1/2

3, 3-1/2, 4

Shear Up Adapter GU

Actual OD (inch)

F/N OD (inch)

1.470

1.812

2.250

2.718

1.187

1.375

1.750

2.312

Thread Connection

15/16-10

15/16-10

15/16-10

1-1/16-10

Slickline Services

DATA DHT-01.00

GS Pulling Tool

The Pulling Tool Type GS Pulling Tools are used to

unlock and pull various down hole equipment

with Internal Fishing Necks. These tools are

designed to shear with Jar Down action. With

addition of GU Adapter, complete assembly is

changed to GR Shear Up Tool.

Applications

The GS Pulling tool is used to engage and pull sub

surface flow control devices that are fitted with an

Internal Fishing Neck

Features

Fitted with industry standard connections and fish

necks

Jar down to release functionality

Can be converted to a jar up to release tool by

installing a GU Shear Up Adaptor

Benefits

Larger sizes GS are fitted with a pinning ring for

ease of pinning

Size

1-1/2 1-3/4

2

2-1/2

3

3-1/2

4

5

7

Prong

1/2-13

1/2-13

5/8-11

5/8-11

1-3/8-12

2-1/8-12

2-1/2-10

3-5/8-10

F/N ID

1.060

1.380

1.810

2.310

2.620

3.120

4.000

5.250

GS Pulling Tools

GS

1.470

1.750

2.160

2.720

3.110

3.620

4.500

5.880

F/N OD

1.187

1.375

1.750

2.312

2.312

2.312

3.125

3.125

Top

15/16-10

15/16-10

15/16-10

1-1/16-10

1-1/16-10

1-1/16-10

1-1/16-10

1-1/16-10

Reach

1.62

1.62

1.62

1.62

1.62

1.62

1.82

1.86

Slickline Services

DATA DHT-01.00

JU Running/Pulling Tool

The JU Series Pulling Tool is designed to engage

external fishing necks on Sub-surface devices

within the well-bore

The Pulling Tool Type JU (Jar Up) Pulling Tools are

used to shear and release tools and are available

with C, S Core options. The cores of JU & JD are

same.

Applications

The JU Series Pulling tool is used to latch and pull

any subsurface device that is fitted with an external

fishing neck

Jar up to release functionality

Features

Available with 3 different core lengths:

C being a long core with a short reach

S being an intermediate core with a medium

reach

L being a short core with a long reach

Supplied with industry standard connections and

fishing necks

Benefits

Different core lengths give the operator flexibility

to use one tool for various different applications

JU Pulling Tools, Type JUC

Size

(inch)

Max.

OD(inch)

F/N OD

(inch)

Pulls Neck Connecting Thread Pin Prong Connecting

OD (inch)

Thread Box

Reach (inch)

1-1/4

1.250

1.187

1.937

15/16-10

1/4-20

1.937

1-1/2

1.422

1.187

1.187

15/16-10

1/2-13

1.093

1.437

1.859

1.375

1.375

15/16-10

1/2-13

2-1/2

2.250

1.375

1.750

15/16-10

1/2-13

1.312

2.812

1.750

2.312

15/16-10

5/8-11

1.437

3.750

2.312

3.125

1-1/6-10

1-1/4-12

3.375

Slickline Services

DATA DHT-01.00

JD Running/Pulling tool

The JD Series Pulling Tool is designed to engage

external fishing necks on sub-surface devices within

the well-bore.

Pulling Tool Type JD (Jar down) Pulling Tools are

used to shear and release tools and are available

with C, S Core options. The cores of JU & JD are

same.

Applications

The JD Series Pulling tool is used to latch and pull

any subsurface device that is fitted with an external

fishing neck

Jar down to release functionality

Features

Available with 3 different core lengths:

C being a long core with a short reach

S being an intermediate core with a medium

reach

L being a short core with a long reach

Supplied with industry standard connections and

fishing necks

Benefits

Different core lengths give the operator flexibility

to use one tool for various different applications

JD Pulling Tools, Type JDC

Size

(inch)

Max. OD

(inch)

F/N OD

(inch)

Pulls Neck

OD (inch)

1-1/4

1-3/8

1-1/2

2

2-1/2

3

3

4

1.291

1.375

1.422

1.859

2.250

2.796

2.796

3.750

1.187

1.187

1.187

1.375

1.375

1.750

1.750

2.312

0.875

1.000

1.187

1.375

1.750

2.312

2.312

3.125

Connecting

Thread Pin

15/16-10

15/16-10

15/16-10

15/16-10

15/16-10

15/16-10

15/16-10

1-1/6-10

Prong Connecting

Thread Box

Reach

(inch)

1/4-20

N/A

1/2-13

1/2-13

1/2-13

1/2-13 and 5/8-11

5/8-11

1-1/4-12

1.937

1.875

1.093

1.437

1.312

1.437

0.687

2.312

Slickline Services

DATA DHT-01.00

R Running/ Pulling Tool

The R Pulling Tool is designed to engage external

fishing necks on Sub-surface devices within the wellbore. R pulling tools are available with four different

core lengths, sized to acJD Running/Pulling tool rJD

Running/Pulling tooly standard fishing necks.

R pulling tools are categorized for easy reference;

the first letter designates the direct of shear release,

R being jar up to release. The second letter

designates the effective reach, which depends upon

the core length

Applications

The R Series Pulling tool is used to latch and pull

any subsurface device that is fitted with an external

fishing neck

Jar up to release functionality

Features

Available with 3 different core lengths:

B being a long core with a short reach

S being an intermediate core with a medium

reach

J being a short core with a long reach

Supplied with industry standard connections and

fishing necks

Benefits

Different core lengths give the operator flexibility

to use one tool for various different applications

R Pulling Tools, Type

Size (inch)

1-1/4

1-1/2

1-3/4

2

2-1/2

3

3-1/2

4

Max. OD (inch)

Pulls Neck OD(inch)

Top Thread

Reach (inch)

1.220

1.430

1.484

1.770

2.180

2.740

3.110

F/N OD (inch)

1.000

1.188

1.188

1.375

1.375

2.312

2.312

1.000

1.188

1.188

1.375

1.750

2.312

2.750

5/8-11

15/16-10

15/16-10

15/16-10

15/16-10

1-1/16-10

1-1/16-10

1.219

1.264

1.050

1.219

1.203

1.297

1.350

3.670

2.312

3.125

1-1/16-10

1.490

Slickline Services

DATA DHT-01.00

S Running/ Pulling Tool

The S Pulling Tool is designed to engage external

fishing necks on Sub-surface devices within the wellbore.

S pulling tools are available with three different core

lengths, sized to accommodate the different reach

lengths on industry standard fishing necks.

S pulling tools are categorized for easy reference; the

first letter designates the direct of shear release, S

being jar down to release. The second letter

designates the effective reach, which depends upon

the core length

Applications

The S Series Pulling tool is used to latch and pull

any subsurface device that is fitted with an external

fishing neck

Jar down to release functionality

Features

Available with 3 different core lengths:

B being a long core with a short reach

S being an intermediate core with a medium

reach

M is designed for use in Gas-Lift operations

Fitted with industry standard connections and

fishing necks

Benefits

Different core lengths give the operator flexibility

to use one tool for various different applications

Size (inch)

1-1/4

2-1/2

2-1/2

2

2-1/2

3

3

3-1/2

4

Max. OD (inch)

1.220

1.437

1.437

1.766

2.188

2.734

2.844

3.115

3.670

S Pulling Tools, Type SB

F/N OD (inch)

Pulls Neck OD (inch)

1.000

1.188

1.188

1.375

1.375

2.312

2.312

2.312

2.312

1.000

1.188

1.188

1.375

1.750

2.312

2.312

2.750

2.750

Top Thread

Reach (inch)

5/8-11

15/16-10

15/16-10

15/16-10

15/16-10

1-1/16-10

1-1/16-10

1-1/16-10

1-1/16-10

1.280

0.688

1.297

1.219

1.281

1.380

1.500

1.690

1.500

Slickline Services

DATA DHT-01.00

X Running Tool

The X Running Tool is designed to deploy and set sub

surface flow control devices equipped with X and XN

lock mandrels, landing in corresponding selective or

no-go landing nipples.

Applications

Used to run and set Otis X and XN Lock Mandrels

Features

The tool can be run in either Selective or NonSelective position

Benefits

Fishing neck fitted with industry standard

connections

X Running Tools

Actual OD (inch)

1.720

2.171

2.687

2.843

3.250

3.750

4.500

To suit Nipple Bore

1.875

2.313

2.750

2.875

3.313

3.813

4.562

F/N OD (inch)

1.375

1.750

2.313

2.313

2.313

2.313

3.125

Thread Connection

15/16-10 UN

15/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

Slickline Services

DATA DHT-01.00

B Shifting Tool

The B Positioning (Shifting) Tool is designed to move

the inner sleeve to their open or closed position in the

type XA, RA, XO and XD Sliding Side-Door circulating

sleeve.

Applications

The B Shifting Tools are designed to shift the XA,

RA, XO and XD Sliding side door sleeves

Features

Designed to release itself only after the sleeve has

reached the full extent of its travel

Supplied with industry standard connections and

fishing necks

Fitted with a shear pin to allow the keys to collapse

should the tool not engage the profile

Benefits

Self release design

Conforms to industry standards

B Shifting Tools

SSD ID (inch)

OD (Keys Retracted) (inch)

F/N OD (inch)

1.875

2.125

2.188

2.313

2.562

2.750

2.813

3.125

3.313

3.437

3.688

1.84

1.97

2.17

2.16

2.53

2.73

2.72

3.06

3.25

3.38

3.66

1.375

1.375

1.750

1.750

1.750

2.313

2.313

1.750

2.313

2.313

3.125

Thread Connection Pin X Box (in.

TPI) UN

15/16-10

15/16-10 UN

15/16-10 UN

15/16-10 UN

15/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

15/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

Slickline Services

DATA DHT-01.00

Sand Pump Bailer

The Sand Pump Bailer is designed to remove sand

and other debris, which may have settled on top of

any sub-surface control within the well, preventing

retrieval of the control by regular wireline operations.

Applications

The Pump Bailer is used to remove sand and other

deposits which may be impeding access for retrieval

of a downhole device

Working on the same principle of the bicycle pump,

the pump bailer is manipulated by the operator,

sucking debris into the bailer chamber

The debris is retained within the body by means of

either a flapper or a ball

Features

Various shoe sizes and types are available

Supplied with industry standard pin connection

complete with fishing neck

Benefits

Removes sand and other debris which may have

settled on top of any sub surface control within the

well

Sand Pump Bailer

Size

F/N OD (inch)

Thread Connection Pin

Guide Shoe OD (inch)*

1-1/4

1-1/2

1-3/4

2

2-1/2

3

1.187

1.375

1.375

1.375

2.313

2.313

15/16-10 UN

15/16-10 UN

15/16-10 UN

15/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

1.250

1.50

1.75

2

2.5

3

Slickline Services

DATA DHT-01.00

Sample Bailer

The Sample / Drive Down Bailer is designed to

acquire samples of debris causing an obstruction in

the well.

Unlike standard pump bailers, the Sample Bailer is

also very effective in retrieving heavy substances

Applications

The Sample Bailer is used when it is require to

retrieve a sample of downhole material such as scale

or sand that is causing an obstruction within the well

bore

Features

To acquire samples of debris causing obstruction in

the well

The ball or flapper opens when the bailer enters the

debris and closes as it exists, effectively trapping the

debris inside

Benefits

Unlike the standard pump bailer, it is very effective

in retrieving heavy substances

Size (inch)

1.5

1.75

2

2.5

3

4

Sample Bailer

F/N OD (inch)

Thread Connection Box (in. TPI)

1.375

15/16-10 UN

1.375

15/16-10 UN

1.750

1-1/16-10 UN

2.312

1-1/16-10 UN

2.312

1-1/16-10 UN

2.312

1-1/16-10 UN

Slickline Services

DATA DHT-01.00

Hydrostatic Bailer

The Piston Hydrostatic Bailer is designed to remove

debris which has settled on top or around a

subsurface control within the well, preventing

retrieval by regular wireline operations.

A hydrostatic bailer is used when debris cannot be

removed with a normal pump bailer assembly.

Applications

Hydrostatic Bailers have an atmospheric chamber

which is sealed at surface and then run into the

wellbore. Once on depth, downwards jarring shears

the pin on the piston. This creates a draw in effect,

which draws in the sand, scale etc. onto the bailer

chamber

The debris is contained within the bailer by means

of a ball

Features

Consists of a chamber sealed at surface

atmospheric pressure, complete with a relief plug at

the top and shear piston on the bottom

Supplied with industry standard connections and

fishing necks

Benefits

Can remove debris when over pump bailer assembly

cannot

Hydrostatic Bailer

Size (inch)

1.5

1.75

2

2.5

3

4

F/N OD (inch)

1.375

1.375

1.750

2.312

2.312

2.312

Thread Connection Box (in. TPI)

15/16-10 UN

15/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

Slickline Services

DATA DHT-01.00

Wireline Cutter

The Wireline Cutter is required when a slickline or

stranded wireline must be cut in the well.

The Wireline Cutter is run down under its own weight

guided by the line and when it strikes the stuck tool,

it cuts the wire and wedges it into its body.

Subsequently the cutter will be retrieved along with

the cut wire

Applications

The Rotary Wireline Cutter is used when Slickline or

Braided Wire is required to be cut downhole

The cutter is run under its own weight on the wire

until it strikes the stuck tool where it cuts the wire

and wedges itself onto the wire thus being completely

retrievable

Features

Fitted with industry standard connections and

fishing necks

Available for both Slickline and Braided line

Available in standard and interface versions

Benefits

No risk of accidental cutting at interface

Will not cut against the tubing

Wire cutting and retrieval are carried out in one

operation

Wireline Cutters

Size OD (inch)

1.500

1.875

F/N OD (inch)

1.375

1.375

Slickline Services

DATA DHT-01.00

GO Devil

The Go Devil is designed to cut and retrieve wireline

from a stuck tool string.

It is manufactured from a solid length of bar and has

an integral wireline socket head with a milled slot and

guide to accommodate and retain the wire.

Applications

The Go Devil is used in Fishing operations when the

wire is required to be cut. With a slot manufactured

into the whole length of the body, the wire slots into

it and is retained by screws. This allows the Go Devil

to slide down the wire, effecting a cut at the rope

socket leaving a clean fishing neck

Features

Cut and retrieve wireline from a stuck tool string

Manufactured from a solid length of bar and has an

integral wireline socket head with a milled slot and

guide to accommodate and retain the wire

Provide two Go-Devils to suit different situations

when the rope socket is clean and when the rope

socket is fouled by debris

Benefits

Flexible depending on the environment

Go Devil

Size (inch)

Max. OD (inch)

F/N OD (inch)

1-1/2

1-7/8

1.500

1.875

1.375

1.750

Slickline Services

DATA DHT-01.00

Solid Wire Finder

The Solid Wire Finder is designed to locate and ball

the upper end of the broken wireline in the wellbore

during fishing operations.

The wire can then be engaged by a wireline grab and

retrieved

Applications

The Solid Wire Finder is used to locate and ball up

the broken end of Wire, during fishing operations, in

preparation for retrieval

Features

One piece design

Supplied with industry standard connections and

Fishing Necks

Available in various sizes

Benefits

The wire can then be engaged by a wireline grab

and retrieved

Size (inch)

1.500

2.000

2.500

3.000

4.000

Wireline Wirefinder

F/N OD (inch)

Thread Connection Pin (in. TPI)

1.375

15/16-10 UN

1.375

15/16-10 UN

1.375

15/16-10 UN

1.750

1-1/16-10 UN

1.750

1-1/16-10 UN

Slickline Services

DATA DHT-01.00

Wire Grab

The Wire Grab is designed to retrieve a broken

wireline during fishing operations, after a split skirt

wirefinder has been deployed to locate and ball the

upper end of the wire in the well bore.

Applications

The Wireline Grab is normally run after a Wire

Finder

The Wireline Grab is used to grab the ball of wire

that is left in the hole

The Barbs tangle into the wire. The more the grab

is pulled up, the tighter the wire grips the barbs

Features

The wire grab consists of a top complete with

fishing neck and pin connection and a body with two

or three bendable prongs

Each prong has several pointed barbs welded on

the inner side to form hooks

The flexible design allows the operator to bend the

grab prong ends to suit the inside diameter of the

tubing

Benefits

The flexible design helps to prevent the wire grab

from bypassing the broken line

Wireline Grabs

Size(inch)

1-1/2

2 2-1/2

3

4 5-1/2

Max. OD(inch)

1.437

1.843

2.718

2.875

F/N OD (inch)

1.187

1.375

2.312

2.312

Thread Conn. Pin X Box (in. TPI)

15/16-10 UN

15/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

No. of prong

2

2

3

3

Slickline Services

DATA DHT-01.00

Shock Absorber

The Shock Absorber is designed to dampen impact

shock loads that can occur during wireline

deployment and so prevent damage to sensitive

instrumentation being run on the tool string

Applications

The Wireline Shock Absorber is used to reduce the

shock to sub surface instruments such as pressure /

temperature gauges, caused due to the impacts of

jarring

Features

Consists of a main body, top sub, bottom sub, inner

mandrel and absorber strings

The lower spring is heavier than the upper one to

sustain the tool weight

Floating action of the mandrel against the spring

dampens the shock loads

Supplied in stainless steel

Benefits

Dampen impact shock loads during deployment

Prevent damage to instrumentation being run in the

tool string

Wireline Shock Absorber

Size

F/N OD (inch)

Top Connection Pin

Bottom Connection Box

1.50

1.75

1.375

1.375

15/16-10 UN

15/16-10 UN

- 16 UNF

- 16 UNF

Slickline Services

DATA DHT-01.00

Spring Centralizer

The Adjustable Spring Centralizer is designed to

centralize tool strings and gauges during slickline

operations, in the production tubing and exiting into

the casing.

Applications

The Adjustable Spring Centralizer is designed to

centralize sub surface tools in various tubingShock

AbsorberDs

EspecShock Absorbere when running tools out of

the Production string and into the casing strings

Features

Flexible design

Comes with industry standard pin by pin box

connections complete with fishing necks

Benefits

One centralizer can be used for multiple Internal

Diameters of pipe

Bow Spring Centralizer

OD range (inch)

F/N OD (inch)

Top Connection (in. TPI)

27

1.755

15/16-10 UN

Slickline Services

DATA DHT-01.00

Scratcher/Brush

The Wireline Scratcher / Brush is designed to loosen

and remove paraffin wax and scale deposits from

inside the wall of the completion bore.

This operation is usually carried out with the well

flowing through a reduced choke, to remove the

loose wax or solids

Applications

The Wireline Scratchers and Brushes are used to

clean any deposits that may have accumulated on the

tubing walls. They are also particularly effective at

cleaning lSpring Centralizert may hSpring Centralizer

with debris, hindering the setting of sub surface

devices

Features

Wire installation can be

done in two ways to suit

operation

Wire locked in place

with grub screws

Available in various

diameters and supplied

with industry standard

connections complete with

fishing neck

Benefits

Loosens and removes paraffin wax, scale deposits

from inside the wall of the completion bore

Can be carried out while the well is flowing which

does not hinder operations

Flexible wire installation to suit the type of

operation

Scratchers

Thread Connection Pin (inch TPI)

5/16-10 UN

15/16-10 UN

1-1/16-10 UN

1-1/16-10 UN

F/N OD (inch)

1.187

1.375

1.750

1.750

Size (inch)

1-1/2 2-1/16

2 2-1/2

2 2-1/2

3-1/2

Slickline Services

DATA DHT-01.00

S-ar putea să vă placă și

- Slickline-Tools Catalog en WebDocument57 paginiSlickline-Tools Catalog en Webneoamn100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!De la EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Evaluare: 5 din 5 stele5/5 (2)

- Standard Slickline Tools 6Document7 paginiStandard Slickline Tools 6eng200720070% (1)

- Thru Tubing Electronic CatalogDocument77 paginiThru Tubing Electronic CatalogEduardo Oyarzun100% (2)

- Slickline TallybookDocument29 paginiSlickline Tallybookpitia100% (3)

- E-Line and Braided LineDocument40 paginiE-Line and Braided LineLherrera07Încă nu există evaluări

- Coiled Tubing PDFDocument230 paginiCoiled Tubing PDFNguyễnTrườngÎncă nu există evaluări

- Slickline I X & R EquipmentDocument47 paginiSlickline I X & R EquipmentRadhat Simon100% (1)

- STC1 S2 Slickline I v.2Document165 paginiSTC1 S2 Slickline I v.2Siew Qian100% (1)

- PARVEEN Measuring Line Stuffing Boxes and Lubricator RisersDocument46 paginiPARVEEN Measuring Line Stuffing Boxes and Lubricator RisersKedai KopiÎncă nu există evaluări

- Wire LineDocument54 paginiWire LineAbid Ali88% (8)

- Slickline Basics.1 10Document10 paginiSlickline Basics.1 10Rio de Mario100% (1)

- Wire Line Pressure Control EquipmentDocument39 paginiWire Line Pressure Control EquipmentStan Andrei100% (1)

- Running A Bridge Plug and Cement Retainers 4531366 01Document32 paginiRunning A Bridge Plug and Cement Retainers 4531366 01Mohamed HashemÎncă nu există evaluări

- Coiled Tubing OverviewDocument120 paginiCoiled Tubing Overviewyazid100% (3)

- SCSSVDocument8 paginiSCSSVSaqxank100% (4)

- PCE Wireline Technology CatalogueDocument120 paginiPCE Wireline Technology CatalogueWaled FekryÎncă nu există evaluări

- TTC Slickline ManualDocument2 paginiTTC Slickline Manualibidabo60% (5)

- Baker Flow Control Devices PDFDocument32 paginiBaker Flow Control Devices PDFfelipe67% (3)

- Wireline ManualDocument307 paginiWireline ManualJorge Rodriguez100% (14)

- 02 DownholeDocument84 pagini02 Downholerajibsingha100% (1)

- Cerberus WirelineDocument6 paginiCerberus Wirelinejavier100% (2)

- Coiled Tubing Cleanout, Diagnosis, and Remediation of Sand Control FailuresDocument43 paginiCoiled Tubing Cleanout, Diagnosis, and Remediation of Sand Control FailuresDavide Boreaneze100% (1)

- Bowen Fishing Tools CatalogDocument49 paginiBowen Fishing Tools CatalogJ harper100% (1)

- Slick LineDocument10 paginiSlick LineChoochart Thongnark100% (1)

- Completions Packer CatalogDocument56 paginiCompletions Packer Catalogknn52unnÎncă nu există evaluări

- Slickline Guide: Everything You Need to KnowDocument40 paginiSlickline Guide: Everything You Need to Knowwilliam MadingÎncă nu există evaluări

- Workover ProceduresDocument9 paginiWorkover ProceduresAnonymous eGlNdZÎncă nu există evaluări

- Coil TubingDocument14 paginiCoil TubingMAKTAR5422100% (3)

- Slickline TenderDocument10 paginiSlickline Tender李四江Încă nu există evaluări

- Otis ToolsDocument11 paginiOtis ToolsSammyTapiaBaldoceda0% (1)

- CT Problem ProceduresDocument29 paginiCT Problem ProceduresMuhammad ShahrukhÎncă nu există evaluări

- Slickline DownholeToolsDocument238 paginiSlickline DownholeToolsTg Tarro100% (2)

- Slickline Care 3Document22 paginiSlickline Care 3Slim.B100% (3)

- AberdeeenDS-Well Intervention PC PDFDocument316 paginiAberdeeenDS-Well Intervention PC PDFHernán Ricardo Castillo Alarcón100% (2)

- Coiled Tubing Surface EquipmentDocument75 paginiCoiled Tubing Surface EquipmentMIRCEA1305100% (2)

- Storm Choke K Safety ValveDocument2 paginiStorm Choke K Safety ValveHIPAP100% (5)

- 59 PSL Wireline Basic Manual Rev2Document128 pagini59 PSL Wireline Basic Manual Rev2Tebengz ShakespearÎncă nu există evaluări

- Coiled Tubing & SnubbingDocument4 paginiCoiled Tubing & SnubbingMichael LunaÎncă nu există evaluări

- Nov Asep Elmar Ict WL Tools Poster v3Document95 paginiNov Asep Elmar Ict WL Tools Poster v3Victor Martinez100% (1)

- Coiled Tubing Operation PDFDocument51 paginiCoiled Tubing Operation PDFMaleja Perpiñan Barrios89% (19)

- Wireline Slickline Training ProgramDocument1 paginăWireline Slickline Training ProgramPurwanto Pur100% (4)

- Well Completion Equipment OverviewDocument91 paginiWell Completion Equipment OverviewRanim Hisham100% (1)

- Wireline (Cabling) - WikipediaDocument9 paginiWireline (Cabling) - Wikipediaharshpatel18100% (2)

- Thru-Tubing Retriveable PackerDocument9 paginiThru-Tubing Retriveable PackerilkerkozturkÎncă nu există evaluări

- Rotary Cutters PDFDocument3 paginiRotary Cutters PDFAlleyson AkinÎncă nu există evaluări

- Subsurface Safety EquipmentDocument36 paginiSubsurface Safety Equipmentgus_tavo161100% (1)

- WPS Chapter 7Document34 paginiWPS Chapter 7richemengÎncă nu există evaluări

- Elmar Wireline Tools CatalogDocument147 paginiElmar Wireline Tools CatalogDragonÎncă nu există evaluări

- NORSOK Standard Wireline Equipment RequirementsDocument14 paginiNORSOK Standard Wireline Equipment RequirementsRio de Mario100% (2)

- Basic Coiled Tubing Formulas and Conversions.Document2 paginiBasic Coiled Tubing Formulas and Conversions.Jeeten G.100% (6)

- JET - 36 - Coiled Tubing Downhole Tools UpdateDocument144 paginiJET - 36 - Coiled Tubing Downhole Tools UpdateMohamedIbrahim75% (4)

- The Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbDe la EverandThe Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbEvaluare: 4.5 din 5 stele4.5/5 (11)

- Well Control for Completions and InterventionsDe la EverandWell Control for Completions and InterventionsEvaluare: 4 din 5 stele4/5 (10)

- Measurement While Drilling: Signal Analysis, Optimization and DesignDe la EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignÎncă nu există evaluări

- Well Integrity for Workovers and RecompletionsDe la EverandWell Integrity for Workovers and RecompletionsEvaluare: 5 din 5 stele5/5 (3)

- TraducirDocument59 paginiTraducirKasuki KasamaÎncă nu există evaluări

- CompiladoDocument1 paginăCompiladoAdonis SaidlerÎncă nu există evaluări

- MonitoringDocument8 paginiMonitoringAdonis SaidlerÎncă nu există evaluări

- Product Data Sheet Downhole Wireless PT Sensor System Roxar en 81890Document2 paginiProduct Data Sheet Downhole Wireless PT Sensor System Roxar en 81890Adonis SaidlerÎncă nu există evaluări

- Maturity Model in Business ManagementDocument20 paginiMaturity Model in Business ManagementhendrigantingÎncă nu există evaluări

- Process Mapping Techniques To Investigate The Implementation of CustomerDocument8 paginiProcess Mapping Techniques To Investigate The Implementation of CustomerAdonis SaidlerÎncă nu există evaluări

- MonitoringDocument8 paginiMonitoringAdonis SaidlerÎncă nu există evaluări

- Timeline Powerpoint Template - Free PresentationDocument5 paginiTimeline Powerpoint Template - Free Presentationtania__starÎncă nu există evaluări

- 4 Common Process Mapping Mistakes PDFDocument5 pagini4 Common Process Mapping Mistakes PDFAdonis SaidlerÎncă nu există evaluări

- Cópia de SWOT Free Presentation TemplateDocument5 paginiCópia de SWOT Free Presentation TemplateAdonis SaidlerÎncă nu există evaluări

- Timeline Powerpoint Template - Free PresentationDocument5 paginiTimeline Powerpoint Template - Free Presentationtania__starÎncă nu există evaluări

- h17bm BK TasterDocument25 paginih17bm BK TasterMargaretaSianne0% (1)

- Process Based Management PDFDocument10 paginiProcess Based Management PDFAdonis SaidlerÎncă nu există evaluări

- Skrinjar, Stemberger, & Hernaus - The Impact of Business Process Orientation On Organizational PerformanceDocument15 paginiSkrinjar, Stemberger, & Hernaus - The Impact of Business Process Orientation On Organizational PerformanceAdonis SaidlerÎncă nu există evaluări

- Process Mapping Techniques To Investigate The Implementation of CustomerDocument8 paginiProcess Mapping Techniques To Investigate The Implementation of CustomerAdonis SaidlerÎncă nu există evaluări

- Skrinjar, Stemberger, & Hernaus - The Impact of Business Process Orientation On Organizational Performance PDFDocument15 paginiSkrinjar, Stemberger, & Hernaus - The Impact of Business Process Orientation On Organizational Performance PDFAdonis SaidlerÎncă nu există evaluări

- Petroleum Engineering ManualDocument181 paginiPetroleum Engineering ManualAdonis SaidlerÎncă nu există evaluări

- TQM Process Improvement ToolsDocument8 paginiTQM Process Improvement Toolsodang rizki0% (1)

- Kamthunzi EleanorDocument34 paginiKamthunzi EleanorAdonis SaidlerÎncă nu există evaluări

- PBM at Work in An OrganizationDocument10 paginiPBM at Work in An OrganizationAdonis SaidlerÎncă nu există evaluări

- Maturity Model in Business ManagementDocument20 paginiMaturity Model in Business ManagementhendrigantingÎncă nu există evaluări

- BaduraDocument16 paginiBaduraAdonis SaidlerÎncă nu există evaluări

- Common Process Mapping Mistakes and How to Avoid ThemDocument5 paginiCommon Process Mapping Mistakes and How to Avoid ThemAdonis SaidlerÎncă nu există evaluări

- TQM Process Improvement ToolsDocument8 paginiTQM Process Improvement Toolsodang rizki0% (1)

- VleflashDocument1 paginăVleflashAdonis SaidlerÎncă nu există evaluări

- Bwtasec 1Document56 paginiBwtasec 1jisaavÎncă nu există evaluări

- Ryerson EthicsDocument20 paginiRyerson EthicssinghbabaÎncă nu există evaluări

- Lecture 1: Newton Forward and Backward Interpolation: M R Mishra May 9, 2022Document10 paginiLecture 1: Newton Forward and Backward Interpolation: M R Mishra May 9, 2022MANAS RANJAN MISHRAÎncă nu există evaluări

- Health Education and Health PromotionDocument4 paginiHealth Education and Health PromotionRamela Mae SalvatierraÎncă nu există evaluări

- Statement of Compulsory Winding Up As On 30 SEPTEMBER, 2008Document4 paginiStatement of Compulsory Winding Up As On 30 SEPTEMBER, 2008abchavhan20Încă nu există evaluări

- Tender Notice and Invitation To TenderDocument1 paginăTender Notice and Invitation To TenderWina George MuyundaÎncă nu există evaluări

- Daftar PustakaDocument4 paginiDaftar PustakaRamli UsmanÎncă nu există evaluări

- Exor EPF-1032 DatasheetDocument2 paginiExor EPF-1032 DatasheetElectromateÎncă nu există evaluări

- Deluxe Force Gauge: Instruction ManualDocument12 paginiDeluxe Force Gauge: Instruction ManualThomas Ramirez CastilloÎncă nu există evaluări

- Um 0ah0a 006 EngDocument1 paginăUm 0ah0a 006 EngGaudencio LingamenÎncă nu există evaluări

- PW CDocument4 paginiPW CAnonymous DduElf20OÎncă nu există evaluări

- Colour Ring Labels for Wireless BTS IdentificationDocument3 paginiColour Ring Labels for Wireless BTS Identificationehab-engÎncă nu există evaluări

- THE PEOPLE OF FARSCAPEDocument29 paginiTHE PEOPLE OF FARSCAPEedemaitreÎncă nu există evaluări

- Emergency Room Delivery RecordDocument7 paginiEmergency Room Delivery RecordMariel VillamorÎncă nu există evaluări

- Modul-Document Control Training - Agus F - 12 Juli 2023 Rev1Document34 paginiModul-Document Control Training - Agus F - 12 Juli 2023 Rev1vanesaÎncă nu există evaluări

- Childrens Ideas Science0Document7 paginiChildrens Ideas Science0Kurtis HarperÎncă nu există evaluări

- Benjie Reyes SbarDocument6 paginiBenjie Reyes Sbarnoronisa talusobÎncă nu există evaluări

- Injection Timing (5L) : InspectionDocument2 paginiInjection Timing (5L) : InspectionaliÎncă nu există evaluări

- Give Five Examples Each of Nature Having Reflection Symmetry and Radial Symmetry Reflection Symmetry Radial Symmetry Butterfly StarfishDocument12 paginiGive Five Examples Each of Nature Having Reflection Symmetry and Radial Symmetry Reflection Symmetry Radial Symmetry Butterfly StarfishANNA MARY GINTOROÎncă nu există evaluări

- Overview of Quality Gurus Deming, Juran, Crosby, Imai, Feigenbaum & Their ContributionsDocument11 paginiOverview of Quality Gurus Deming, Juran, Crosby, Imai, Feigenbaum & Their ContributionsVenkatesh RadhakrishnanÎncă nu există evaluări

- Piping MaterialDocument45 paginiPiping MaterialLcm TnlÎncă nu există evaluări

- Practical Research 2: Self-Learning PackageDocument3 paginiPractical Research 2: Self-Learning PackagePrinces BaccayÎncă nu există evaluări

- 27 MARCH 2020: Assignment 5 Question PaperDocument4 pagini27 MARCH 2020: Assignment 5 Question PaperShadreck SandweÎncă nu există evaluări

- SQL Server 2008 Failover ClusteringDocument176 paginiSQL Server 2008 Failover ClusteringbiplobusaÎncă nu există evaluări

- How To Check PC Full Specs Windows 10 in 5 Ways (Minitool News)Document19 paginiHow To Check PC Full Specs Windows 10 in 5 Ways (Minitool News)hiwot kebedeÎncă nu există evaluări

- Understanding Oscilloscope BasicsDocument29 paginiUnderstanding Oscilloscope BasicsRidima AhmedÎncă nu există evaluări

- Supplier GPO Q TM 0001 02 SPDCR TemplateDocument6 paginiSupplier GPO Q TM 0001 02 SPDCR TemplateMahe RonaldoÎncă nu există evaluări

- Miami Police File The O'Nell Case - Clemen Gina D. BDocument30 paginiMiami Police File The O'Nell Case - Clemen Gina D. Barda15biceÎncă nu există evaluări

- Module 2Document42 paginiModule 2DhananjayaÎncă nu există evaluări

- Quiz-Travel - Beginner (A1)Document4 paginiQuiz-Travel - Beginner (A1)Carlos Alberto Rodriguez LazoÎncă nu există evaluări

- PREMIUM BINS, CARDS & STUFFDocument4 paginiPREMIUM BINS, CARDS & STUFFSubodh Ghule100% (1)