Documente Academic

Documente Profesional

Documente Cultură

Evaluation of Camel Meat in Processing Burger Products Under Sudanese Conditions

Încărcat de

IOSRjournalTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Evaluation of Camel Meat in Processing Burger Products Under Sudanese Conditions

Încărcat de

IOSRjournalDrepturi de autor:

Formate disponibile

IOSR Journal of Agriculture and Veterinary Science (IOSR-JAVS)

e-ISSN: 2319-2380, p-ISSN: 2319-2372. Volume 8, Issue 4 Ver. II (Apr. 2015), PP 18-21

www.iosrjournals.org

Evaluation of Camel Meat in Processing Burger Products under

Sudanese Conditions

Adam, Y.S.I.1 and H.A. Abugroun2

1

Department of Food Technology, Faculty of Agriculture Technology and Fish science,

University of Al-Neelain, Khartoum, Sudan

2

Department of Food Science Technology, Faculty of Agriculture,

Alzaiem Alazhari University, Khartoum, Sudan

Abstract: The study was carried out to evaluate the burger products processed from camel meat. Burger

products were processed from various amount of meat (camel and beef) as mixing and divided into four groups.

A (100% camel meat). B (75% camel meat, 25% beef). C (50% camel meat 50% beef).and D (100% beef meat)

as a control group. Samples were prepared for analysis after processing. Chemically crud protein content (%)

were not significantly different (p>0.05) among burger treatments, ash, fat and moisture content (%) also were

not significantly differences. Determined the pH value for burger treatments, cooking loss and were not

significantly differences among burger products. There were no differences in microbial growth assessed by

total microbial count between camel and beef meat were used in processing burger. The sensory attributes

conducted, flavor, color, juiciness, tenderness and overall acceptability were not differences.

Keyword: camel meat, Beef, Burger, processing, Quality attributes.

I.

Introduction

The world population of camels is estimated to be 17 million (Elgasim & Alkanhal, 1992). Compared

to other livestock, the camel is unique in having an exceptional ability to survive and thrive under adverse

climatic conditions such as high ambient temperatures, low rainfall, and feed scarcity. Therefore, it offers an

ideal option for animal production in arid and semi-arid regions of the world. Camel is a unique animal having

the ability to survive and produce with low cost of feeding under harsh conditions compared to other livestock.

It is a good source of meat in areas where the climate adversely affects other animal's production efficiency

(Kadim et al., 2006). Traditionally, camel meat comes mostly from old males and females that are primarily

kept for milk, racing, and transportation rather than for meat production. General consumers' view is that camel

meat is unacceptably tough, but in fact meat from young camels has been reported to be comparable in taste and

texture to beef (Kurtu, 2004). Carcass characteristics of camels were equal to those of other red meat animal

species (Elgasim & Alkanhal, 1992). Chemically camel muscles had been found to have low fat content, high

water holding capacity recommending camel meat as a healthy food with good processing properties (Babiker &

Yousif, 1990). However, there is evidence of a great demand for fresh camel meat and for camel meat in

blended meat products even in societies not herding camels (Morton, 1984; Prez et al., 2000).

II.

Materials & Mathods

2.1 processing products: Camel meat from around cuts and Beef top side cuts were purchased from west

Omdurman and divided to four groups for used in processing burger products which consists from various

amount of lean meat as mixing according to percentage of camel meat A (100%camel meat) B (75%camel

meat 25% Beef meat) C (50%camel meat 50% Beef) and control D (100% Beef meat). Burger samples were

processed using the formulation in table (1).

Table (1):- burger ingredients per g/kg

DOI: 10.9790/2380-08421821

www.iosrjournals.org

18 | Page

Evaluation of Camel Meat in Processing Burger Products under Sudanese Conditions

Chemical evaluation: Approximately 150 g of products from each treatment were blended for 15s in laboratory

blender and were used in all chemical analysis. Each products samples was homogenized and analyzed in

triplicate, to determine moisture (drying for 6 h at 105c), fat (as extractable component in Soxhlet apparatus)

protein (Kjeldahl nitrogen) using standard methods (AOAC, 1980). The ultimate pH of products samples

determined by sing pH meter. The pH meter was calibrated with buffers 4 and 7.

Meat quality attributes: burger products were prepared for colour sensing and covered by polythene sheets.

The colour was determined using a Hunter-Lab Tristimulus colorimeter (Model D25 M.Z, Hunter Associated

Lab. Inc., Virginia, USA). Hunter (L) lightness, (a) redness and (b) yellowness were recorded before and after

storage. Duplicate samples, each of approximately 0.5 gm of two products, were placed on a humidified filter

paper (Whatman No. 4 in adesiccator over saturated KCl solution) and pressed between two plexiglass for 1 min

at 25 Kg/cm2. Meat and moisture areas were measured using a compensating planometer. The result was

expressed as ratio (Grau and Hamm, 1953). Water Holding Capacity (WHC) =[Loose water area-meat film area]

meat film area. Cooking loss determined as Babiker (1981) by using thermostatically controlled water bath

90c for 90 min, samples were weighed before and after cooking

The storage loss % was determined by taking the initial weight of the products (sausage or burger) after

processing immediately and then after the storage period (five weeks). The frozen samples were left overnight in

a refrigerator at 4oC for thawing and then weighed.

Microbial analysis: One gram of products burger was homogenized in nine ml of sterile distilled water for 1-5

min. ten fold dilutions of homogenate were prepared in normal saline.

Enumeration of total aerobic mesophilic bacteria: Plating was performed into plate count agar (PCA,

OXOID CM 325) from the prepared dilutions by spread plate method. Colonies formed after 48 h incubation at

30c under aerobic conditions were counted (Swanson et al., 1992).

Sensory attributes: The sensory evaluation was conducted in the sensory evaluation facilities of the Meat

laboratory, Samples were separately cooked from each group of treatment, 11 semi trained panelists were used

to evaluate the burger samples. The evaluation included, colour, tenderness, flavour and juiciness using an 8point scale score (hedonic scale) card as described by Cross and Overby (1988).

Statistical analysis: The data obtained were analyzed statistically and the means were tested for significance

using Duncan Multiple range test as described by SPSS. v.16 (2008).

III.

Results And Discussion

Table (2): Means and standard error of chemical composition of burger treatment.

Burger were processed from camel meat and others the mixed with beef were not significantly different in

protein content % among all groups present in table (2) with a higher mean value for group D which processed

from beef and that refer for beef meat protein content %, agreement with the overall average 17.2 % for camel

meat protein content in different season by Abdelhadi et al., (2012) Babiker and Yousif (1990) . Burger

processing additives as a constant percentage for all groups from water and other ingredients, chemically there

were no different (p>0.05) in moisture, fat, and ash %, among burger products with means value 65.3-63%, 5.34.7%, and 0.9-0.8% respectively. Observe that the higher one in moisture content for camel meat and a lower

one for beef. In general, camel meat is high in moisture content, moderate in protein and ash, but low in fat,

which clearly confirms the fact that camel meat is healthier due to its low intramuscular fat content compared to

other species (for review, see Hocquette et al., 2010) like cattle (Delgado et al., 2005; Sasaki, Mitsumoto, &

Kawabata, 2001), sheep (Farid, 1991; Sen, Santra, & Kadim, 2004) and goats (Mahgoub, Kadim, Al-Saqry, &

Al-Busaidi, 2004; Sen et al., 2004).

DOI: 10.9790/2380-08421821

www.iosrjournals.org

19 | Page

Evaluation of Camel Meat in Processing Burger Products under Sudanese Conditions

Table (3): Means and standard error of ultimate pH and coking loss and color and W.H.C of burger treatments.

Meat quality attributes of burger treatments were determined by pH value, cooking loss, W.H.C, and

colour measurement, present in table (3). The ultimate pH of burger were processed from camel meat had a

higher value with average 5.8 and a lower for beef burger (5.3). The mean value pHu was 5.8 which falls within

the pHu range value of 5.46.0 reported by Abdelhadi et al., 2012, Kadim and Mahgoub (2006), Shariatmadari

and Kadivar (2006), Kadim et al. (2006, 2008) and Kadim, Mahgoub, et al. (2009). However, the pHu were

decreased in this study for burger products which mixed camel and beef meat clearly in group B and C and that

refer for beef.

Water holding capacity and cooking loss is important issue in meat quality and it depend on pH value

were its clear shown in table (3) and there were no significantly different (p>0.05) with increase in cooking

loss% for beef burger and less in group C which consist 50% from camel and beef meat and improved quality of

burger (Parang Nikmaram et al. 2011) reported the Cooking loss of camel and veal were obtained 42.46 and

41.20% for microwave cooking. Adam and Abugroun (2010) mentioned, the results of ultimate pH for

processed meat sausage and burger groups were not significantly different in water holding capacity (p>0.05).

Water holding capacity is affected by several factors such as pH, species, age and muscle type and function.

Price and Schweigert (1987) reported that the water holding capacity of meat could be increased by addition of

table salt. Addition of these salts to meat during curing or manufacture of emulsion thus increases the water

holding capacity. Water-holding capacity is especially critical in meat ingredients of meat products that are

subjected to combinations of heating, grinding and other processes. Weight losses during fabrication processes

are largely the results of water evaporation.

Table (4): Means and standard error of total viable bacterial count cfu/gm and storage loss of burger treatments.

The burger sample were stored at -18c as general attitude in market or customers, and they were not

significantly different (p>0.05) in storage loss. During freezing storage meat loses water by evaporation,

sublimation, and exudation, respectively, moisture is also lost during cooking. Moisture losses by evaporation

during freezing of non-packed carcasses or joints normally amount to between 0.5 and 1.2% of the total weight

(Genot 2000). The same author mentioned monthly losses of 0.15% to 0.7% were found in traditional stockinetwrapped meat at-30c and-10c, respectively. In other work, it has been reported that drip losses from fastfrozen and stored meat increase with storage time, reaching the same level as the drip losses observed from meat

frozen at slow rate not stored for any length of time (Ngapo et al, 1999b).

Acknowledgment

We are grateful to Mrs. Samia, Miss Amna of al-Kadro Institute for meat grading, Inspection and

Health and Mr. Mohammed Ibrahim and Mr. Mohammed Elamin for assistance during the experiments, thanks

to laboratory staff at Al-Neelain University College of Science.

Reference

[1].

[2].

[3].

[4].

[5].

[6].

[7].

Abdelhadi , O.M.A. Babiker , S.A. Picard , B. Jurie C., Jailler , R. Hocquette , J.F. Faye B. (2012) Effect of season on contractile

and metabolic properties of desert camel muscle (Camelus dromedarius) . Meat Science, 90 139-144.

Adam, Y. S. I. and Abugroun, H. A. (2010). Effect of Sudanese Marketing Condition on Quality Attributes of Meat Products. P. J.

of Nutrition 9 (12): 1149-1156, 2010

Babiker, S. A., & Yousif, O. Kh. (1990). Chemical composition and quality of camel meat. Meat Science, 27(4), 283287.

Delgado, E. J., Rubio, M. S., Iturbe, F. A., Mendez, R. D., Cassis, L., & Rosiles, R. (2005). Composition and quality of Mexi can

and imported retail beef in Mexico. Meat Science, 69, 465471

Elgasim, E. A., & Alkanhal, M. A. (1992). Proximate composition, amino acids and inorganic mineral content of Arabian camel

meat. Food Chemistry, 45, 14.

Farid, A. (1991). Carcass physical and chemical composition of three fat-tail breeds of sheep. Meat Science, 29, 109120.

Hocquette, J. F., Gondret, F., Baza, E., Mdale, F., Jurie, C., & Pethick, D. W. (2010). Intramuscular fat content in meat -producing

animals: development, genetic and nutritional control, identification of putative markers. Animal, 4, 303319.

DOI: 10.9790/2380-08421821

www.iosrjournals.org

20 | Page

Evaluation of Camel Meat in Processing Burger Products under Sudanese Conditions

[8].

[9].

[10].

[11].

[12].

[13].

[14].

[15].

[16].

[17].

[18].

[19].

[20].

Kadim, I. T., & Mahgoub, O. (2006). Meat quality and composition of longissimus thoracis from Arabian camel (Camelus

dromedarius and Omani beef): A comparative study. 1st conference of International Society of Camelid Research and

nDevelopment (ISOCARD), Al Ain Rotana Hotel, April 1517 (pp. 161).

Kadim, I. T., Mahgoub, O., Al-Marzooqi, W., Al-Maqbali, R. S., & Al-Lawati, S. M. (2008). The influence of seasonal

temperatures on meat quality characteristics of hotboned, m. psoas major and minor from goats and sheep. Meat Science, 80, 210

215.

Kadim, I. T., Mahgoub, O., Al-Marzooqi, W., Al-Zadjali, S., Annamalai, K., & Mansour,M. H. (2006). Effects of age on

composition and quality of muscle Longissimus thoracis of the Omani Arabian camel (Camelus dromedaries). Meat Science, 73(4),

619662.

Kadim, I. T., Mahgoub, O., Al-Marzooqi, W., Khalf, S. K., Mansour, M. H., Al-Sinani, S. S. H., et al. (2009). Effects of electrical

stimulation on histochemical muscle fibre staining, quality and composition of camel and cattle longissimus thoracis muscles.

Journal of Food Science, 74(1), S44S52.

Mahgoub, O., Kadim, I. T., Al-Saqry, N. M., & Al-Busaidi, R. M. (2004). Effects of body weight and sex on carcass tissue

distribution in goats. Meat Science, 67, 577585.

Parang Nikmaram1, Mohamad Said Yarmand, and Zahra Emamjomeh. (2011). Effect of cooking methods on chemical

composition, quality and cook loss of camel muscle (Longissimus dorsi) in comparison with veal .African Journal of Biotechnol ogy

Vol. 10(51), pp. 10478-10483, 7

Price, J.F. and B.S. Schweigert, 1987. The science of meat and meat products. 3rd Edn, Food and Nutrition Press, Inc. Westp ort,

Conn, USA.

Sasaki, K., Mitsumoto, M., & Kawabata, K. (2001). Relation between lipid peroxidation and fat content in Japanese Black beef

Longissimus muscle during storage. Meat Science, 59, 407410.

Sen, A. R., Santra, A., & Kadim, S. A. (2004). Carcass yield, composition and meat quality attribute of sheep and goat under

semiarid conditions. Meat Science, 66, 757763.

Sen, A. R., Santra, A., & Kadim, S. A. (2004). Carcass yield, composition and meat quality attribute of sheep and goat under

semiarid conditions. Meat Science, 66, 757763.

Shariatmadari, R., & Kadivar, M. (2006). Postmortem ageing and freezing of camel meat (a comparative study). 52nd Inter Cong

Meat Science (pp. 673674).

Ngapo, T.M.; Barbare, I.H.; Reynolds, J. and Mawson, R.F. (1999b). A preliminary investigation of the effects of frozen storage on

samples of pork. Meat Sci. 53: 169-177.

Genot, C. (2000). Congelation of qualite de la viande. Paris: 1NRA.

DOI: 10.9790/2380-08421821

www.iosrjournals.org

21 | Page

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- A Proposed Framework On Working With Parents of Children With Special Needs in SingaporeDocument7 paginiA Proposed Framework On Working With Parents of Children With Special Needs in SingaporeInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Socio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanDocument7 paginiSocio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Role of Extrovert and Introvert Personality in Second Language AcquisitionDocument6 paginiThe Role of Extrovert and Introvert Personality in Second Language AcquisitionInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Attitude and Perceptions of University Students in Zimbabwe Towards HomosexualityDocument5 paginiAttitude and Perceptions of University Students in Zimbabwe Towards HomosexualityInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- A Review of Rural Local Government System in Zimbabwe From 1980 To 2014Document15 paginiA Review of Rural Local Government System in Zimbabwe From 1980 To 2014International Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- "I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweDocument5 pagini"I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Relationship Between Social Support and Self-Esteem of Adolescent GirlsDocument5 paginiRelationship Between Social Support and Self-Esteem of Adolescent GirlsInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Investigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehDocument4 paginiInvestigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Impact of Technologies On Society: A ReviewDocument5 paginiThe Impact of Technologies On Society: A ReviewInternational Organization of Scientific Research (IOSR)100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- An Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyDocument14 paginiAn Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Comparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesDocument7 paginiComparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Motivational Factors Influencing Littering in Harare's Central Business District (CBD), ZimbabweDocument8 paginiMotivational Factors Influencing Littering in Harare's Central Business District (CBD), ZimbabweInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Assessment of The Implementation of Federal Character in Nigeria.Document5 paginiAssessment of The Implementation of Federal Character in Nigeria.International Organization of Scientific Research (IOSR)Încă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Edward Albee and His Mother Characters: An Analysis of Selected PlaysDocument5 paginiEdward Albee and His Mother Characters: An Analysis of Selected PlaysInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Transforming People's Livelihoods Through Land Reform in A1 Resettlement Areas in Goromonzi District in ZimbabweDocument9 paginiTransforming People's Livelihoods Through Land Reform in A1 Resettlement Areas in Goromonzi District in ZimbabweInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Topic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshDocument7 paginiTopic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Importance of Mass Media in Communicating Health Messages: An AnalysisDocument6 paginiImportance of Mass Media in Communicating Health Messages: An AnalysisInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Role of Madarsa Education in Empowerment of Muslims in IndiaDocument6 paginiRole of Madarsa Education in Empowerment of Muslims in IndiaInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Beowulf: A Folktale and History of Anglo-Saxon Life and CivilizationDocument3 paginiBeowulf: A Folktale and History of Anglo-Saxon Life and CivilizationInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Human Rights and Dalits: Different Strands in The DiscourseDocument5 paginiHuman Rights and Dalits: Different Strands in The DiscourseInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Women Empowerment Through Open and Distance Learning in ZimbabweDocument8 paginiWomen Empowerment Through Open and Distance Learning in ZimbabweInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Substance Use and Abuse Among Offenders Under Probation Supervision in Limuru Probation Station, KenyaDocument11 paginiSubstance Use and Abuse Among Offenders Under Probation Supervision in Limuru Probation Station, KenyaInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- An Exploration On The Relationship Among Learners' Autonomy, Language Learning Strategies and Big-Five Personality TraitsDocument6 paginiAn Exploration On The Relationship Among Learners' Autonomy, Language Learning Strategies and Big-Five Personality TraitsInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Lute Against Doping in SportDocument5 paginiThe Lute Against Doping in SportInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Classical Malay's Anthropomorphemic Metaphors in Essay of Hikajat AbdullahDocument9 paginiClassical Malay's Anthropomorphemic Metaphors in Essay of Hikajat AbdullahInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Kinesics, Haptics and Proxemics: Aspects of Non - Verbal CommunicationDocument6 paginiKinesics, Haptics and Proxemics: Aspects of Non - Verbal CommunicationInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Designing of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesDocument5 paginiDesigning of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesIOSRjournalÎncă nu există evaluări

- Design Management, A Business Tools' Package of Corporate Organizations: Bangladesh ContextDocument6 paginiDesign Management, A Business Tools' Package of Corporate Organizations: Bangladesh ContextInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Micro Finance and Women - A Case Study of Villages Around Alibaug, District-Raigad, Maharashtra, IndiaDocument3 paginiMicro Finance and Women - A Case Study of Villages Around Alibaug, District-Raigad, Maharashtra, IndiaInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- A Study On The Television Programmes Popularity Among Chennai Urban WomenDocument7 paginiA Study On The Television Programmes Popularity Among Chennai Urban WomenInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Arbans Complete Conservatory Method For Trumpet Arbans Complete ConservatoryDocument33 paginiArbans Complete Conservatory Method For Trumpet Arbans Complete ConservatoryRicardo SoldadoÎncă nu există evaluări

- Loop Types and ExamplesDocument19 paginiLoop Types and ExamplesSurendran K SurendranÎncă nu există evaluări

- 32 Hyderabad HITEC City BisleriDocument23 pagini32 Hyderabad HITEC City BisleriSridhar ViswanathanÎncă nu există evaluări

- Ahmad Syihabudin: BiodataDocument2 paginiAhmad Syihabudin: BiodatabhjjqrgrwmÎncă nu există evaluări

- Project ProposalDocument4 paginiProject Proposaljiaclaire2998100% (1)

- A 138Document1 paginăA 138pooja g pÎncă nu există evaluări

- Enzymes IntroDocument33 paginiEnzymes IntropragyasimsÎncă nu există evaluări

- SurveyingDocument26 paginiSurveyingDenise Ann Cuenca25% (4)

- June 2017 (IAL) MS - Unit 1 Edexcel Physics A-LevelDocument16 paginiJune 2017 (IAL) MS - Unit 1 Edexcel Physics A-LevelNyraStardollÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Cosmopolitanism in Hard Times Edited by Vincenzo Cicchelli and Sylvie MesureDocument433 paginiCosmopolitanism in Hard Times Edited by Vincenzo Cicchelli and Sylvie MesureRev. Johana VangchhiaÎncă nu există evaluări

- A Semi-Detailed Lesson Plan in MAPEH 7 (PE)Document2 paginiA Semi-Detailed Lesson Plan in MAPEH 7 (PE)caloy bardzÎncă nu există evaluări

- Gujarat Urja Vikas Nigam LTD., Vadodara: Request For ProposalDocument18 paginiGujarat Urja Vikas Nigam LTD., Vadodara: Request For ProposalABCDÎncă nu există evaluări

- Homeopatija I KancerDocument1 paginăHomeopatija I KancermafkoÎncă nu există evaluări

- Benedict Anderson, Imagined CommunitiesDocument2 paginiBenedict Anderson, Imagined CommunitiesMonir Amine0% (1)

- PetrifiedDocument13 paginiPetrifiedMarta GortÎncă nu există evaluări

- A2Document4 paginiA2Akshay KumarÎncă nu există evaluări

- Daily Lesson Log Quarter 1 Week 1Document5 paginiDaily Lesson Log Quarter 1 Week 1John Patrick Famadulan100% (1)

- Action ResearchDocument2 paginiAction ResearchGeli BaringÎncă nu există evaluări

- DN102-R0-GPJ-Design of Substructure & Foundation 28m+28m Span, 19.6m Width, 22m Height PDFDocument64 paginiDN102-R0-GPJ-Design of Substructure & Foundation 28m+28m Span, 19.6m Width, 22m Height PDFravichandraÎncă nu există evaluări

- Guided-Discovery Learning Strategy and Senior School Students Performance in Mathematics in Ejigbo, NigeriaDocument9 paginiGuided-Discovery Learning Strategy and Senior School Students Performance in Mathematics in Ejigbo, NigeriaAlexander DeckerÎncă nu există evaluări

- Nutrition 2022 PIRDocument22 paginiNutrition 2022 PIRAlmira LacasaÎncă nu există evaluări

- Beyond Models and Metaphors Complexity Theory, Systems Thinking and - Bousquet & CurtisDocument21 paginiBeyond Models and Metaphors Complexity Theory, Systems Thinking and - Bousquet & CurtisEra B. LargisÎncă nu există evaluări

- Unit 2 - Industrial Engineering & Ergonomics - WWW - Rgpvnotes.inDocument15 paginiUnit 2 - Industrial Engineering & Ergonomics - WWW - Rgpvnotes.inSACHIN HANAGALÎncă nu există evaluări

- Neet Question Paper 2019 Code r3Document27 paginiNeet Question Paper 2019 Code r3Deev SoniÎncă nu există evaluări

- Aero Ebook - Choosing The Design of Your Aircraft - Chris Heintz PDFDocument6 paginiAero Ebook - Choosing The Design of Your Aircraft - Chris Heintz PDFGana tp100% (1)

- First - Second and Third Class Levers in The Body - Movement Analysis in Sport - Eduqas - Gcse Physical Education Revision - Eduqas - BBC BitesizeDocument2 paginiFirst - Second and Third Class Levers in The Body - Movement Analysis in Sport - Eduqas - Gcse Physical Education Revision - Eduqas - BBC BitesizeyoyoyoÎncă nu există evaluări

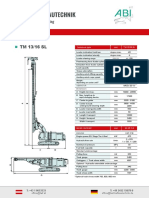

- ABI TM 13 16 SL - EngDocument1 paginăABI TM 13 16 SL - EngJuan Carlos Benitez MartinezÎncă nu există evaluări

- Drager Narkomed 6400 Field Service Procedure Software Version 4.02 EnhancementDocument24 paginiDrager Narkomed 6400 Field Service Procedure Software Version 4.02 EnhancementAmirÎncă nu există evaluări

- Duo Interpretation Class PresentationDocument31 paginiDuo Interpretation Class PresentationPlanetSparkÎncă nu există evaluări

- Bioinformatics Computing II: MotivationDocument7 paginiBioinformatics Computing II: MotivationTasmia SaleemÎncă nu există evaluări

- The Obesity Code: Unlocking the Secrets of Weight LossDe la EverandThe Obesity Code: Unlocking the Secrets of Weight LossEvaluare: 4 din 5 stele4/5 (5)

- Waiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterDe la EverandWaiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterEvaluare: 3.5 din 5 stele3.5/5 (487)

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldDe la EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldEvaluare: 3.5 din 5 stele3.5/5 (5)

- Chicano Eats: Recipes from My Mexican-American KitchenDe la EverandChicano Eats: Recipes from My Mexican-American KitchenÎncă nu există evaluări

- Pati's Mexican Table: The Secrets of Real Mexican Home CookingDe la EverandPati's Mexican Table: The Secrets of Real Mexican Home CookingEvaluare: 4 din 5 stele4/5 (9)

- Instant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookDe la EverandInstant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookEvaluare: 3.5 din 5 stele3.5/5 (2)

- Authentic Mexican: Regional Cooking from the Heart of MexicoDe la EverandAuthentic Mexican: Regional Cooking from the Heart of MexicoÎncă nu există evaluări