Documente Academic

Documente Profesional

Documente Cultură

0101e - Guide For Applicant Cos

Încărcat de

99demonTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

0101e - Guide For Applicant Cos

Încărcat de

99demonDrepturi de autor:

Formate disponibile

CWB Form 101E/2011-1

CERTIFICATION GUIDE

FOR APPLICANT COMPANIES TO

CSA STANDARDS W47.1, W47.2 & W186

Purpose

The purpose of this guide is to assist applicant companies in meeting the requirements of

certification specified in CSA Standards W47.1, W47.2 and W186. Additional information can be

obtained by contacting any of the following CWB Offices.

Canadian Welding Bureau Offices

HEAD OFFICE:

8260 ParkHill Drive,

Milton, Ontario L9T 5V7

Tel: 1-800-844-6790

Fax: (905) 542-1318

Email: info@cwbgroup.org

web site: www.cwbgroup.org

OFFICES ACROSS CANADA

Page 1 of 14

CWB Form 101E/2011-1

Western Operations:

Suite 206, 2528 Ellwood Drive

Edmonton, Alberta T6X 0A9

Ontario Operations:

8260 Park Hill Drive

Milton, Ontario L9T 5V7

Quebec Operations:

4321 Autoroute des Laurentides

Laval, Quebec H7L 5W5

Atlantic Operations:

Suite 304, 73 Tacoma Drive

Dartmouth, Nova Scotia B2W 3Y6

Page 2 of 14

CWB Form 101E/2011-1

Obtaining Certification to CSA Standards W47.1, W47.2 and W186

Certification to CSA Standards W47.1, W47.2 and W186 is obtained upon completion of the

following 6 elements.

1. Provide Company Documentation

Each new company receives a "Certification Binder" which contains all of the necessary

materials to complete the certification process. Included in this package are several forms that

must be completed and returned to the Bureau. The forms are used to designate and list

personnel and to document the welding related experience of the welding supervisors and

engineers. Also included in the binder are the applicable CSA Welding Standards, study guides

and other relevant documents.

2. Qualify Welding Supervisor(s)

Each company must employ an adequate number of Welding Supervisors to control its welding

operations. Each Welding Supervisor must have welding related experience and complete

written examinations on welding symbols, weld faults, quality control and inspection methods

and the following standard(s), as applicable:

For certification to CSA Standard W47.1

- CSA Standard W47.1, Certification of Companies for Fusion Welding of Steel

- CSA Standard W59, Welded Steel Construction (Metal Arc Welding)

For certification to CSA Standard W47.2

- CSA Standard W47.2, Certification of Companies for Fusion Welding of Aluminum

- CSA Standard W59.2, Welded Aluminum Construction

For certification to CSA Standard W186

- CSA Standard W186, Welding of Reinforcing Bars in Reinforced Concrete Construction

In addition each Welding Supervisor is given a brief verbal examination on the following

subjects:

- welding equipment

- drawings

- welding procedures

Additional examination details are provided on Page 7.

The qualification examinations on welding symbols, weld faults and quality control and

inspection methods may be waived if the Welding Supervisor holds a diploma from a recognized

course in welding fundamentals or weld quality control and inspection. Examinations are

normally held in each of the CWB's regional offices. Seminars are provided occasionally on

each of the subjects required for qualification. To help Welding Supervisors prepare for the

exams, a copy of the applicable CSA Standards plus a number of study guides are provided to

each applicant company.

Page 3 of 14

CWB Form 101E/2011-1

The Canadian Welding Bureau also provides an optional program for Welding Supervisors

under CSA Standard W47.1. Welding Supervisors may qualify as a Welding Inspector and

Welding Supervisor, by writing the qualifying examinations of CSA Standard W178.2 only. The

W178.2 examinations are similar in content to the current Welding Supervisor qualification

examinations. The W178.2 certification is the personal certification of the individual. Certified

Welding Inspectors who leave the employ of a company certified to CSA Standard W47.1 will

still maintain their Welding Inspectors certification as long as they continue to meet the

requirements of CSA Standard W178.2. Welding Supervisor qualifications remain in effect with

the certified company even if the certification as a Welding Inspector has expired.

3. Qualify Professional Engineer(s)

Each company applying for certification in Division 1 or 2 (See Divisions of Certification on Page

6) of CSA Standard W47.1 and W47.2 must designate and qualify a Welding Engineer who is

responsible for welding related activities as specified by the company. The engineer(s) must

meet the minimum educational and experience requirements of the applicable standard and

complete the written examinations on the following standards:

For certification to CSA Standard W47.1

- CSA Standard W47.1, "Certification of Companies for Fusion Welding of Steel"

- CSA Standard W59, "Welded Steel Construction (Metal Arc Welding)"

For certification to CSA Standard W47.2

- CSA Standard W47.2, "Certification of Companies for Fusion Welding of Aluminum"

- CSA Standard W59.2, "Welded Aluminum Construction"

For certification to CSA Standard W186

- CSA Standard W186, "Welding of Reinforcing Bars in Reinforced Concrete Construction"

If the educational requirements of the applicable standard have not been met, additional courses

may be required. Each designated engineer's educational and experience qualification

information must be submitted to the Canadian Welding Bureau for review. An interview will be

conducted to review the material submitted and discuss the engineer's experience and

educational background.

4. Submit for Approval the Company's Welding Procedures

Each company must prepare and submit to the Canadian Welding Bureau for acceptance, a

detailed set of welding procedures consisting of:

- Welding Procedure Specifications (WPS) for each welding process used.

- Welding Procedure Data Sheets (WPDS) for each welding process used, joint configuration,

electrode type, etc.

In certain circumstances, based on the welding procedure submission, procedure qualification

tests may be required to verify the acceptance of the welding procedure data sheets. See

additional information on Page 10.

Page 4 of 14

CWB Form 101E/2011-1

5. Qualify Welders

All welders, welding operators and tack welders employed by the company must be tested for

the processes and positions of welding which they use in production.

6. Review and Recommendation for Certification

From time to time, a CWB Representative will visit each company to complete an audit report

and provide assistance. Once all of the above are completed and all other items such as

electrode storage facilities (shop and field), general appearance of welding, etc. are acceptable,

then the company is recommended for certification. At this time the Chief Executive Officer or

his/her designate of the company applying for certification must review and sign the CWB

Service Agreement, which is included in the Certification Binder.

Upon satisfactory completion of the final review procedure, the company is issued a Letter of

Certification, Letter of Validation and a Document of Certification. Permission is also granted to

use the Canadian Welding Bureau's registered trademark on the company's letterhead and

promotional material.

Page 5 of 14

CWB Form 101E/2011-1

Divisions of Certification

CSA Standards W47.1 and W47.2

CSA Standards W47.1 and W47.2 contain provisions for the certification of a company in one of

three Divisions. The Division chosen will depend on the type of work being performed, and the

authority to which the company is responsible (i.e. municipality, owner, contractor, etc.).

Division 1

To be certified in Division 1, the company must employ on a full-time basis a registered professional

engineer(s) responsible for welding related activities specified by the company.

Division 2

To be certified in Division 2, the company must retain on a part-time basis a registered professional

engineer(s) responsible for welding related activities specified by the company.

Division 3

The company is not required to have a registered professional engineer, either employed or

retained.

CSA Standard W186

CSA Standard W186 does not have Divisions however, it requires that the company either employs

on a full time basis or retains on a part time basis a registered professional engineer(s) responsible

to the company for welding design and welding procedures and practice.

Page 6 of 14

CWB Form 101E/2011-1

Welding Supervisor Examinations for CSA Standards W47.1, W47.2 and W186

Written Examinations

Examination

Format

Time Limit

(Minutes)

Study Materials

Comments

CSA W47.1

open book

40 multiple choice

questions

75

CSA Standard W47.1

and study guide CWB

Publication 110.

Bring the latest edition of CSA Standard W47.1

only

CSA W59

open book

40 multiple choice

questions

75

CSA Standard W59

and study guide CWB

Publication 111.

Bring the latest edition of CSA Standard W59

only

CSA W47.2

open book

40 multiple choice

questions

75

CSA Standard W47.2

Bring the latest edition of CSA Standard W47.2

only

CSA W59.2

open book

40 multiple choice

questions

75

CSA Standard W59.2

Bring the latest edition of CSA Standard W59.2

only

CSA W186

open book

40 multiple choice

questions

75

CSA Standard W186

Bring the latest edition of CSA Standard W186

only

Welding

Symbols

closed book

20 multiple choice

questions

40

CWB Publication 112

No reference material allowed during the exam

CWB Publication 113

No reference material allowed during the

exam

Know the causes and corrections of various

weld faults

Know the terminology used to describe the

parts of a fillet weld and fillet weld defects

CWB Publication 113

No reference material allowed during the

exam

Know the principles of visual inspection

(before, during and after welding)

Be familiar with the applications and

limitations of various non-destructive

inspection methods

Weld Faults

Quality

Control

&

Inspection

Methods

closed book

25 multiple choice

questions

closed book

25 multiple choice

questions

45

45

Verbal Examinations

Welding

Equipment

Verbal

Not

Applicable

Not Applicable

Know the operating characteristics, use

maintenance and limitations of the companys

welding equipment

Drawings

Verbal

Not

Applicable

Not Applicable

Be prepared to explain what is required when

presented with drawings of the companys

welded products

Welding

Procedures

Verbal

Not

Applicable

Companys Welding

Procedures

Be prepared to demonstrate the use welding

procedure specifications and data sheets

Page 7 of 14

CWB Form 101E/2011-1

Obligations of a Certified Company

It is the responsibility of each company to maintain compliance with the standard on a continual

basis. Listed below are the minimum requirements that must be met:

Personnel

1.

Employ an adequate number of qualified Welding Supervisors to supervise all shop and field

welding activities.

2.

Ensure that the Welding Supervisor is qualified and has the authority and time to control

welding operations in the shop and/or field.

3.

Employ or retain the services of engineers qualified in accordance with the appropriate

standard (this requirement is not applicable to Division 3 companies in CSA Standards W47.1

and W47.2).

4.

Ensure that all welders are qualified for the positions and processes that they are expected to

use.

5.

Inform the CWB immediately of any changes in designated engineering, supervisory or quality

control personnel, the relocation of plant and changes in telephone numbers, etc.

Procedures

1.

Ensure that the companys welding procedures cover all joints, processes and positions used

in fabrication/erection, and are up to date and approved by the Bureau.

2.

Ensure that the companys welding procedures are available to all those personnel requiring

them and are followed in the design office, shop and field.

Equipment

1.

Ensure that all welding equipment and auxiliary equipment are maintained in good repair.

2.

Ensure that all welding equipment is adequate to produce the required weldments.

Workmanship

1.

Ensure that welding performed by the company and its subcontractors is continuously done in

accordance with the requirements of the certification standard and the approved welding

procedures.

2.

Maintain weld quality and workmanship at the levels specified by the design or product

standard.

3.

Ensure that all welding is completed using certified consumables that are stored and

reconditioned in accordance with the applicable standard.

Page 8 of 14

CWB Form 101E/2011-1

Maintain Records and Reports

1.

Maintain an up-to-date file containing copies of the necessary reports and forms, etc.

2.

Ensure that copies of the companys welding procedures, welder and welding operator and

tack welder employment and qualification reports (CWB Form 108 or an equivalent) and

engineers reports (CWB Form 107 or an equivalent) are up to date and available to the

Bureaus representative.

Proper Use of the CWB Trademark

1.

Companies that obtain certification to CSA Standards W47.1, W47.2 and W186 are granted

permission to use the CWBs trademark in their advertising, promotional material and other

literature only to indicate their certification.

2.

The trademark may not be altered or used in any way that could be interpreted as meaning the

certification of the companys products or services.

3.

The trademark must not be used in conjunction with any modifying terms or phrases and must

not be misleading as to the extent of certification.

4.

Use of the CWBs trademark must be discontinued upon the termination of certification.

Page 9 of 14

CWB Form 101E/2011-1

Preparation of Company Welding Procedures

For companies applying for certification to CSA Standards W47.1, W47.2 and W186 their welding

procedures will consist of the following separate documents:

- Welding Procedure Specification(s) (WPS)

- Welding Procedure Data Sheets (WPDS)

Sample documents are available upon request from the Bureau's representatives or Region Offices.

Welding Procedure Specifications (WPS)

A company must have a Welding Procedure Specification outlining the general welding procedure

to be followed in the construction of weldments built in accordance with any governing design or

manufacturing standard, or both.

A separate WPS is required for each welding process (e.g. SMAW, FCAW, etc.) and is usually

required to define the welding of special applications (e.g. stainless steels, Q & T steels, welding

with controlled heat inputs, etc.).

All pertinent essential variables should be defined numerically. A special effort should be made to

convey information on the actual process and welding technique practised in the shop. It is

suggested also that ranges of operating parameters for the various sizes of electrodes used be

shown in the WPS.

Each WPS must be signed and/or sealed by the designated engineer, or the Welding Supervisor,

for Division 3 companies.

Welding Procedure Data Sheets (WPDS)

A WPDS lists specific information required for the actual welding of each joint. The WPDS defines

the joint geometry, layer and pass sequence, the welding symbol, material, welding and other

parameters. Each WPDS must be signed and/or sealed by the designated engineer, or the Welding

Supervisor, for Division 3 companies.

Companies applying for certification to CSA Standard W47.1 may submit a WPS in lieu of individual

data sheets for each prequalified joint. See Clause 11.1.1 of CSA Standard W47.1 and/or Clause

10.1.2 of CSA Standard W47.2 for details.

Page 10 of 14

CWB Form 101E/2011-1

General Comments Regarding WPS AND WPDS

All WPSs, and WPDSs must be submitted to the Bureau for approval.

The companys welding procedures must be made available for use by the shop and field Welding

Supervisors, as well as by the engineering and detailing staff, and other authorized personnel,

including the Bureaus representative.

The companys welding procedures must be updated upon subsequent issues of pertinent CSA

Standards and extended to include the use of any additional welding processes, or new joint

geometry, or joints welded in positions other than allowed by existing WPSs and WPDSs.

To reduce the costs of qualification testing and thus certification, all welding electrodes used by a

company must be certified by the CWB to the appropriate electrode standard. Companies applying

for certification may qualify an uncertified electrode for their own use by completing the electrode

and procedure qualification tests specified in clause 11.8.2 of CSA Standard W47.1- and/or Clause

10.2.2.2 of CSA Standard W47.2. There are no provisions for the use of uncertified electrodes in

CSA Standard W186M.

Page 11 of 14

CWB Form 101E/2011-1

Prequalified Joints

Certain joint configurations that conform to the provisions of Clause 10 of CSA Standard W59 are

deemed prequalified. Such joints may be approved for use without performing procedure

qualification tests. Welding procedures must also conform to Clauses 4, 5 and 10 of CSA Standard

W59 in order for the joint to be considered prequalified. Prequalified joints exist for the shielded

metal arc, submerged arc, gas metal arc, flux and metal-cored arc welding processes. There are no

prequalified joints in CSA Standards W59.2 and W186M.

Joint details may depart from those prescribed in Clause 10 of CSA Standard W59. However, in

such cases the proposed welding procedure may require qualification testing to be performed in

accordance with the requirements of Clause 11 of CSA Standard W47.1.

Page 12 of 14

CWB Form 101E/2011-1

Certification Timetable/Checklist

The following certification timetable/checklist is for use as an aid to provide you with a summary of

the required items that your company must complete throughout the certification process. This

timetable/checklist should be completed in the presence of your CWB Certification Services

Representative at his initial visit to your company.

It is recommended that the order shown on the certification timetable/checklist be followed to save

time and money.

Page 13 of 14

CWB Form 101E/2011-1

Certification Timetable/Checklist

Certification Bench Mark

(Recommended Order of Completion)

Check off

When

Complete

Task Completion Dates

Notes

1. Submit CWB Forms 151, 155, 159

For CSA Standards W186 also submit CWB

Forms 152 and 153.

2. Welding Supervisors to complete exams by:

(i)

(ii)

(iii)

3. Engineers to complete exams by:

(i)

(ii)

4. Engineers to complete educational

requirements by:

(i)

(ii)

5. Initial submission of welding procedures

6. Procedure qualification testing completed by:

7. Revised welding procedures submitted by:

8. Submission of alternate welder qualification

test data sheets (Form 161)

9. Welder qualification tests completed by:

10.

11.

12.

13. All requirements completed by:

Page 14 of 14

S-ar putea să vă placă și

- Calibration Certificates and Maintenance ReportDocument4 paginiCalibration Certificates and Maintenance ReportSuresh Rathod100% (1)

- Calibration Certificates and Maintenance ReportDocument4 paginiCalibration Certificates and Maintenance ReportSuresh Rathod100% (1)

- Calibration Certificates and Maintenance ReportDocument4 paginiCalibration Certificates and Maintenance ReportSuresh Rathod100% (1)

- Asme b31.1 - ErrataDocument3 paginiAsme b31.1 - ErrataCarlos JesusÎncă nu există evaluări

- AWS CWI Training Program PDFDocument22 paginiAWS CWI Training Program PDFDjamelÎncă nu există evaluări

- CSWIP 3.1 - Question With Answer and Explanation - Part 7 - AMARINEDocument5 paginiCSWIP 3.1 - Question With Answer and Explanation - Part 7 - AMARINEGoranÎncă nu există evaluări

- Astm A 53 PDFDocument22 paginiAstm A 53 PDFminhyÎncă nu există evaluări

- Macro Inspection Part IIDocument16 paginiMacro Inspection Part IImohammed dallyÎncă nu există evaluări

- General 2Document4 paginiGeneral 2Sobia KalsoomÎncă nu există evaluări

- Day 1answersDocument31 paginiDay 1answersMahmoud Elsayed MohamedÎncă nu există evaluări

- PVP2014-28958 Writing and Reviewing FEA Reports Under ASME Div 1 and 2 Design PDFDocument5 paginiPVP2014-28958 Writing and Reviewing FEA Reports Under ASME Div 1 and 2 Design PDFmatteo_1234Încă nu există evaluări

- Calibration BookletDocument12 paginiCalibration BookletGeorge Manuel50% (2)

- Calibration BookletDocument12 paginiCalibration BookletGeorge Manuel50% (2)

- Safe Practices For Welding Inspectors: 8/16/2018 AWS-CWI Seminar 1Document30 paginiSafe Practices For Welding Inspectors: 8/16/2018 AWS-CWI Seminar 1Ahmed Shaban KotbÎncă nu există evaluări

- Weld Joint Design and Symbols PresentationDocument110 paginiWeld Joint Design and Symbols PresentationEric WoodsÎncă nu există evaluări

- CSWIP WIS 5 General Quiz: TWI Training & Examination ServicesDocument62 paginiCSWIP WIS 5 General Quiz: TWI Training & Examination Serviceshaoues23Încă nu există evaluări

- CWB Certification ServicesDocument7 paginiCWB Certification ServicesSaid Alauddeen FaiszÎncă nu există evaluări

- CWBDocument2 paginiCWBShyam ParsanaÎncă nu există evaluări

- AWS C5.7 (2000) - 2006r - Recommended Practices For Electrogas WeldingDocument65 paginiAWS C5.7 (2000) - 2006r - Recommended Practices For Electrogas WeldingPubcrawlÎncă nu există evaluări

- 03-Symbols Mock ExamDocument5 pagini03-Symbols Mock ExamCRISTIAN SILVIU IANUC100% (1)

- Sampleq Practice Exam d11 2002Document22 paginiSampleq Practice Exam d11 2002Michael J Chandik0% (1)

- Competitive Solutions For Joining TechnologyDocument19 paginiCompetitive Solutions For Joining Technologyjy12bhuÎncă nu există evaluări

- Norma CWB Cambios en W47.1-2009Document6 paginiNorma CWB Cambios en W47.1-2009Jose ManuelÎncă nu există evaluări

- 471 Dif 0Document2 pagini471 Dif 0Shyam ParsanaÎncă nu există evaluări

- Welding Inspection: Multi-Choice Questions Paper 1 Please Return This Paper UnmarkedDocument16 paginiWelding Inspection: Multi-Choice Questions Paper 1 Please Return This Paper UnmarkedRobert MichaelrajÎncă nu există evaluări

- BDM 2021Document547 paginiBDM 2021Messy CoolÎncă nu există evaluări

- BTC Pile DesignDocument19 paginiBTC Pile DesignSrutha KeerthiÎncă nu există evaluări

- Question Excerpt From CSWIP 3Document4 paginiQuestion Excerpt From CSWIP 3Ekor JohnÎncă nu există evaluări

- CWB 2 Module 22 Questions Flashcards - Quizlet - PDF (CWB 2)Document8 paginiCWB 2 Module 22 Questions Flashcards - Quizlet - PDF (CWB 2)HusnainAhmedÎncă nu există evaluări

- Module 1 Welding Inspection and CertificationDocument16 paginiModule 1 Welding Inspection and CertificationMiki JaksicÎncă nu există evaluări

- Cswip 3.1 QU MSR WI 3 05Document8 paginiCswip 3.1 QU MSR WI 3 05Luan Nguyen100% (1)

- Moduel 01Document4 paginiModuel 01Prabhakar KattulaÎncă nu există evaluări

- MK Marine ServicesDocument16 paginiMK Marine ServicesAndy MagerÎncă nu există evaluări

- Welding GaugeDocument11 paginiWelding GaugeDevesh ChauhanÎncă nu există evaluări

- Exam Sample QuestionsDocument9 paginiExam Sample QuestionsYousab JacobÎncă nu există evaluări

- BS709 1983Document17 paginiBS709 1983Sang SekÎncă nu există evaluări

- CWB Level 2 Study Modules 4-5-6-7-8!9!12!17!18-19-22 Flashcards - Quizlet - PDF (CWB 2)Document129 paginiCWB Level 2 Study Modules 4-5-6-7-8!9!12!17!18-19-22 Flashcards - Quizlet - PDF (CWB 2)HusnainAhmedÎncă nu există evaluări

- Industrial radiography A Complete Guide - 2019 EditionDe la EverandIndustrial radiography A Complete Guide - 2019 EditionÎncă nu există evaluări

- Salary Survey 2019 Europe PDFDocument197 paginiSalary Survey 2019 Europe PDFFilippo MeucciÎncă nu există evaluări

- Obróbka Powierzchni DobrzańskiDocument483 paginiObróbka Powierzchni DobrzańskiKamil RomanowskiÎncă nu există evaluări

- CWB - Welding Requirements Csa-S6 Canadian Highway Bridge Design Code Welding RequirementsDocument2 paginiCWB - Welding Requirements Csa-S6 Canadian Highway Bridge Design Code Welding RequirementsStephen TilleyÎncă nu există evaluări

- Are You Really Ready To Take A CWI SeminarDocument3 paginiAre You Really Ready To Take A CWI SeminarJerryÎncă nu există evaluări

- MODULE 9 - Weld and Base Metal Discontinuities Discontinuity: Discontinuity IsDocument7 paginiMODULE 9 - Weld and Base Metal Discontinuities Discontinuity: Discontinuity IsNsidibe Michael EtimÎncă nu există evaluări

- AISE Anchor Bolt Details PDFDocument1 paginăAISE Anchor Bolt Details PDFYash PaulÎncă nu există evaluări

- AA0850126 Rev 02Document10 paginiAA0850126 Rev 02Manish KumarÎncă nu există evaluări

- CWB Weld Specialist Branding GuideDocument5 paginiCWB Weld Specialist Branding GuideBala SingamÎncă nu există evaluări

- 2017 Welding School CatalogDocument34 pagini2017 Welding School CatalogDiego AlonsoÎncă nu există evaluări

- Question 1 of 25Document7 paginiQuestion 1 of 25antonio larotta100% (1)

- Catalog 2017 Winter Spring PDFDocument52 paginiCatalog 2017 Winter Spring PDFLhagva DalaibatÎncă nu există evaluări

- Welding Inspection and CertificationDocument30 paginiWelding Inspection and Certificationmahmoud_allam3Încă nu există evaluări

- BS en 287Document7 paginiBS en 287Chris Thomas0% (1)

- Previews AWS CM-2000-ALL PreDocument16 paginiPreviews AWS CM-2000-ALL PreWanderley Fonseca50% (2)

- Module 4 Weld Geometry and Welding Symbols-1Document87 paginiModule 4 Weld Geometry and Welding Symbols-1Miki Jaksic100% (1)

- Cswip 3.1Document8 paginiCswip 3.1AnandÎncă nu există evaluări

- CWI TEST Flashcards PDFDocument30 paginiCWI TEST Flashcards PDFGary Oporto cabasÎncă nu există evaluări

- Catalog Fabricante TechnipDocument9 paginiCatalog Fabricante Technipjimy GutiérrezÎncă nu există evaluări

- Workbook Module 01Document3 paginiWorkbook Module 01kyeong cheol leeÎncă nu există evaluări

- CWB Group Exams: Welding Inspector (Levels 1 / 2 / 3) ExaminationsDocument2 paginiCWB Group Exams: Welding Inspector (Levels 1 / 2 / 3) ExaminationsHoangÎncă nu există evaluări

- Ans. Cswip555 Q&ADocument8 paginiAns. Cswip555 Q&AMyak OkuokuÎncă nu există evaluări

- Test No 5Document3 paginiTest No 5Muhammad AsimÎncă nu există evaluări

- WIS5 Paper 1 Rev 3Document4 paginiWIS5 Paper 1 Rev 3ghcalotaÎncă nu există evaluări

- Rail WeldingDocument4 paginiRail WeldingOlga Sandoval RomeroÎncă nu există evaluări

- Microstructure Materials SelectionDocument49 paginiMicrostructure Materials SelectionSaptarshi SenguptaÎncă nu există evaluări

- Multiple Choice 7 Mechanical TestingDocument5 paginiMultiple Choice 7 Mechanical TestingChandra MohanÎncă nu există evaluări

- Name: . Date: .. Each Question Has Only One Correct Answer! Please Enter Your Answers On The Answer SheetDocument9 paginiName: . Date: .. Each Question Has Only One Correct Answer! Please Enter Your Answers On The Answer SheetKarthikeyan GanesanÎncă nu există evaluări

- Study+guide 16-19Document39 paginiStudy+guide 16-19bakerbjÎncă nu există evaluări

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceDe la EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceÎncă nu există evaluări

- 101e - 2023-1 - Guide For Applicant CompaniesDocument12 pagini101e - 2023-1 - Guide For Applicant CompaniesgopinathbkpÎncă nu există evaluări

- Welding Requirements Csa b3541 Portable Elevating PlatformsDocument2 paginiWelding Requirements Csa b3541 Portable Elevating Platformscobraz420Încă nu există evaluări

- 0450e - Application For Certification As A Welding InspectorDocument6 pagini0450e - Application For Certification As A Welding InspectorGagandeep KaurÎncă nu există evaluări

- Welding Requirements Csa b3542 Self Propelled Elevating Work Platforms PDFDocument2 paginiWelding Requirements Csa b3542 Self Propelled Elevating Work Platforms PDFcobraz420Încă nu există evaluări

- Saw Storage HandlingDocument1 paginăSaw Storage HandlingDave MulvihillÎncă nu există evaluări

- Evio de Documentacion AISCDocument2 paginiEvio de Documentacion AISC99demonÎncă nu există evaluări

- 2801 Words FrequencyDocument15 pagini2801 Words Frequency99demonÎncă nu există evaluări

- Ficha Tecnica de SoldaduraDocument2 paginiFicha Tecnica de Soldadura99demonÎncă nu există evaluări

- Saw Storage HandlingDocument1 paginăSaw Storage HandlingDave MulvihillÎncă nu există evaluări

- 2012 Products CatalogDocument18 pagini2012 Products Catalog99demonÎncă nu există evaluări

- 2012 Products CatalogDocument18 pagini2012 Products Catalog99demonÎncă nu există evaluări

- 2012 Products CatalogDocument18 pagini2012 Products Catalog99demonÎncă nu există evaluări

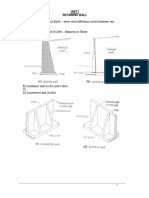

- Csa w471 Vs Aws d11 Similarities and DifferencesDocument2 paginiCsa w471 Vs Aws d11 Similarities and Differences99demonÎncă nu există evaluări

- Csa w471 Vs Aws d11 Similarities and DifferencesDocument2 paginiCsa w471 Vs Aws d11 Similarities and Differences99demonÎncă nu există evaluări

- Csa w471 Vs Aws d11 Similarities and DifferencesDocument2 paginiCsa w471 Vs Aws d11 Similarities and Differences99demonÎncă nu există evaluări

- Csa w471 Vs Aws d11 Similarities and DifferencesDocument2 paginiCsa w471 Vs Aws d11 Similarities and Differences99demonÎncă nu există evaluări

- Lab 2 - Muhd Haziq Sufi - F1128Document10 paginiLab 2 - Muhd Haziq Sufi - F1128Muhamad HaziqÎncă nu există evaluări

- Ultra Thin WhitetoppingDocument21 paginiUltra Thin WhitetoppingDHRUV KDMC ProjectsÎncă nu există evaluări

- Neuro Solution For Damage Detection and Categorisation of Earthquake-Affected BuildingsDocument6 paginiNeuro Solution For Damage Detection and Categorisation of Earthquake-Affected BuildingsVinay PuraniÎncă nu există evaluări

- Computer Applications in TextilesDocument2 paginiComputer Applications in Textilesnatarajan1234Încă nu există evaluări

- Ramesh ResumeDocument3 paginiRamesh ResumeKrishnaswamy GnanasekaranÎncă nu există evaluări

- Thermal Properties of ConcreteDocument8 paginiThermal Properties of ConcreteS Praveenkumar100% (1)

- Advertisement For Assistant ProfessorDocument5 paginiAdvertisement For Assistant ProfessorrajuvadlakondaÎncă nu există evaluări

- List of Selected PG Applicants For Entrance Examination/Presentation/Interview For Regular ProgramDocument52 paginiList of Selected PG Applicants For Entrance Examination/Presentation/Interview For Regular ProgramtkÎncă nu există evaluări

- Drcebm NotesDocument141 paginiDrcebm NotesvallirajaÎncă nu există evaluări

- Experimental Analysis of The Dynamic Stress Distribution at The Soil Foundation InterfaceDocument9 paginiExperimental Analysis of The Dynamic Stress Distribution at The Soil Foundation InterfaceNeeleshKumarÎncă nu există evaluări

- Joist Size ScheduleDocument1 paginăJoist Size Schedulecaliangel1Încă nu există evaluări

- Computer Science & Engineering: An International Journal (CSEIJ)Document2 paginiComputer Science & Engineering: An International Journal (CSEIJ)cseijÎncă nu există evaluări

- Mani Esti MationDocument49 paginiMani Esti MationAnonymous 3hPIuGABÎncă nu există evaluări

- Jurnal Teknologi: Challenges IN Design AND Construction OF Deep Excavation FOR KVMRT IN Kuala Lumpur Limestone FormationDocument11 paginiJurnal Teknologi: Challenges IN Design AND Construction OF Deep Excavation FOR KVMRT IN Kuala Lumpur Limestone FormationPraviin viInZ.Încă nu există evaluări

- Ss Cac Phuong An CTCDocument1 paginăSs Cac Phuong An CTCThanhÎncă nu există evaluări

- Flyer - International Construction - Practice and LawDocument2 paginiFlyer - International Construction - Practice and LawFilip KojicÎncă nu există evaluări

- 2173408Document3 pagini2173408Dipen RavalÎncă nu există evaluări

- Innovation in MEP: CPVC Sprinkler PipingDocument11 paginiInnovation in MEP: CPVC Sprinkler PipingJohn DiasÎncă nu există evaluări

- Steel Design Identification ReviewerDocument2 paginiSteel Design Identification ReviewerJeson FranciscoÎncă nu există evaluări

- APP129Document10 paginiAPP129Gary LoÎncă nu există evaluări

- FEKO Software For Automotive 2016Document2 paginiFEKO Software For Automotive 2016UdhamÎncă nu există evaluări

- Brick BallastDocument9 paginiBrick BallastFarrukhBaigÎncă nu există evaluări