Documente Academic

Documente Profesional

Documente Cultură

Advanced Project Desktop Clock

Încărcat de

Gabriel LeonDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Advanced Project Desktop Clock

Încărcat de

Gabriel LeonDrepturi de autor:

Formate disponibile

WOODWORKS: ADVANCED PROJECT

DESKTOP CLOCK

This clock holds a secret chamber under the lid, and its construction involves a few secrets as well. The case is made from 1/2"-thick cherry

plywood, which isnt available at most lumberyards. You can simply make your own by gluing together two pieces of 1/4" cherry plywood. Another

secret to building this clock is to glue the moldings to the plywood case material first and then miter the parts on the table saw as a single piece. It

simplifies the building and sure beats mitering all the moldings individually.

Advanced woodworkers will be challenged to execute this project neatly and precisely. Youll be doing a lot of router work to make the moldings

and some precision rabbetting, dadoing and mitering to put all the pieces together. After its assembled, youll learn more about applying and using

stains and finishes to protect the wood and keep it looking beautiful.

CONTINUED - WOODWORKS: ADVANCED PROJECT DESKTOP CLOCK

TOOLS REQUIRED

Hand Tools

Backsaw

Miter box

Spring clamps

Toggle clamps

Power Tools

Table saw

Planer

Router in a router table;

a classic router bit and a

1/8" round-over bit

Drill press with an

adjustable circle cutter

SHOPPING LIST

Miscellaneous

Pencil

Safety glasses

Carpenters glue

Masking tape

120-, 150- and 220-grit

sandpaper

Clean, lint-free cloths

Respirator

Gloves for finishing

Mineral spirits (for oilbased stains and finishes)

Water-filled metal container

with tight-fitting lid (for oilbased stains and finishes)

Minwax Wood Finish

Stain Brush or other good

quality, natural bristle brush

(for oil-based stains and

finishes)

Minwax Polycrylic

Brush or other good quality,

synthetic bristle brush

(for water-based stains

and finishes)

Item

1/4" cherry-veneer plywood

Quantity

16" x 32" sheet; grain should

run across the short dimension.

3/4" cherry

3" wide by 32" long, 1 pc.

3/4" x 6" x 48", 1 pc.

Battery-powered clock mechanism (see Source, page 5)

WOOD FINISHING PRODUCTS

Recommended Finish

Prep:

Prep: Minwax Pre-Stain Wood Conditioner

Stain:

Minwax Wood Finish English Chestnut

(or your choice of 24 Minwax Wood Finish

Stain colors)

Finish: Minwax Fast-Drying Polyurethane Semi-Gloss

Alternate Finish

Prep:

Minwax Water Based Pre-Stain Wood Conditioner

Stain:

Minwax Water Based Wood Stain Spice,

(or a Minwax Water Based Wood Stain of your

choice, available in 50 custom-mixed colors

and a White Wash Pickling Stain.)

Finish:

Minwax Polycrylic Protective Finish Semi-Gloss

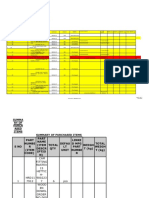

CUTTING LIST

Overall Dimensions: 8" x 6-3/8" x 5-3/8"

Key Part

Pcs. Material

A Front, back

2

cherry

Dimensions

1/2" x 4-3/4" x 7-1/2"

B

C

D

E

F

G

H

J

K

L

Sides

Upper flat trim (front/back)

Upper flat trim (sides)

Lower flat trim (front/back)

Lower flat trim (sides)

Top classic molding (front/back)

Top classic molding (sides)

Bottom classic molding (front/back)

Bottom classic molding (sides)

Half-bead trim (front and back)

2

2

2

2

2

2

2

2

2

4

cherry plywood

cherry

cherry

cherry

cherry

cherry

cherry

cherry

cherry

cherry

3-3/4" x 7-1/2"

1/8" x 3/8" x 5"

1/8" x 3/8" x 4"

1/8" x 3/4" x 5"

1/8" x 3/4" x 4"

5/8" x 3/4" x 6-1/4"

5/8" x 3/4" x 5-1/4"

3/4" x 3/4" x 6-1/4"

3/4" x 3/4" x 5-1/4"

1/8" x 5/16" x 5-1/8"

M

N

P

Q

R

S

Half-bead trim (sides)

Lid

Half-bead trim for lid (front/back)

Half-bead trim for lid (sides)

Bottom

Feet

4

1

2

2

1

4

cherry

cherry

cherry

cherry

cherry

cherry

1/8" x 5/16" x 4-1/8"

3/4" x 4-5/8" x 5-5/8"

1/8" x 5/16" x 6"

1/8" x 5/16" x 5"

1/2" x 3-1/4" x 4-1/4"

5/16" x 1" x 1"

Recommended Wood - Cherry

Alternate Wood - Mahogany

Notes

Cut to final widths after

attaching moldings C through K.

Rough-cut parts C through K to 32"

long. They will be cut to final length

after they are attached to the 1/2"

plywood that makes up parts A and B.

CONTINUED - WOODWORKS: ADVANCED PROJECT DESKTOP CLOCK

BEFORE YOU BEGIN

6. Drill the opening for the clock insert into the front panel. The clock

insert is centered vertically on the front between the two half-bead trim

pieces (L). Set the drill press to its slowest speed and hold the part with

two toggle clamps. Secure a backer board to the drill table with a couple of clamps. The backer board will ensure that the cutter makes a

clean cut on the backside.

Good craftsmanship begins and ends with good work habits, so make

the following steps part of your routine workshop practice. If you have

any doubts or questions about how to proceed with a project, always

discuss them with your instructor.

Carefully and fully review plans and instructions before putting

a tool to the project lumber.

Work sensibly and safely. Wear safety goggles and the appropriate

respirator whenever making sawdust or working with thinners

or other solvents.

At the end of every work session, clean up your shop area and

put away all portable tools.

7. Apply glue to two sides first and hold them together with masking

tape. Add the other two sides one at a time. Grasp the tape firmly and

pull the parts tightly together. Then glue in the bottom and add the four

feet (S) 1/8" in from the edges of the molding. Next make the lid (N).

Cut the rabbets on the bottom of the lid (Fig. 4). Check that the lid fits

easily into the rabbet in the top of the clock case.

CUTTING AND ASSEMBLY

PROCEDURE

8. Using a small backsaw and a miter box, miter the half-bead trim

that goes around the lid (P, Q) and attach it to the underside of the

lid (Fig. 6). Youll need some small spring clamps to hold these trim

pieces in place while the glue dries. Remove one of the plastic jaw

covers from the spring clamp to provide more pressure on the small

trim. Leave the other jaw cover on to protect the top from

getting dented.

1. Cut two 32" x 8" pieces of 1/4" cherry plywood so that the grain

runs across the short dimension. Glue them together to form the 1/2"

plywood needed for the clock case. Use a few bricks as clamps and a

piece of cardboard to protect the plywood from getting scratched. After

the glue has dried, rip the plywood to 7-1/2" wide. Take about 1/4" off

each edge so they are both straight and parallel. Next, cut two 1/8"

dadoes in the face of the plywood (Fig. 1). Use a push block for safety

and to maintain even pressure while cutting.

STAINING AND FINISHING

Woodworkers Tip: Though you may be tempted to cut short

your sanding, preparation and application time, dont do it.

These tasks are very important steps in obtaining a high-quality

finish. Remember, it is the finish, just as much as the fit and

smoothness of the parts that will have great bearing on how

people judge your craftsmanship. To ensure an excellent result,

follow the steps listed in this section and also the instructions

the finish manufacturer puts on its products.

2. Make the upper and lower flat trim pieces (C, D, E and F). Insert

temporary spacer strips (use no glue) in the small dadoes in the panel

to provide a stop for the flat trim to push up against, and glue the flat

trim to the plywood panel (Fig. 2). Remove the spacer sticks before

the glue dries to prevent them from getting stuck.

3. Cut a strip of cherry for the top and bottom moldings (G, H, J and K).

Use feather boards to hold the molding against the fence and table for

the smoothest cut. Shape these pieces with a classic router bit. Note

that the top moldings are 1/8" thinner than the bottom moldings and

they are attached to the plywood so they mirror each other (Fig. 1).

Glue and clamp them to the plywood (Fig. 3). The edge of the molding

and the plywood should be flush. If theyre not, wait until the glue has

dried and trim the parts flush on your table saw. Complete the plywood

panel by cutting a rabbet at the top and bottom on the backside (Fig. 1).

FINISHING TIPS

Test the stains and finishes you are planning to use on scraps of

wood. On the back of the scrap, mark the stain/finish combination

and the type of wood. Allow all samples to dry thoroughly before

making your final finish selection. Save your samples for quick

reference on future projects.

All stains and finishes must be allowed to dry thoroughly between

coats. Remember that drying times can vary due to humidity and

other climatic conditions.

If you have some leftover stain or finish, wipe the can rim so that

stain or finish in the rim wont dry out and prevent the lid from

forming a tight seal.

Brushes used for water-based products, such as Minwax WaterBased Wood Stains or Minwax Polycrylic Protective Finish,

should be cleaned with soap and water; oil-based finishes must be

cleaned with mineral spirits.

4. Make the half-bead trim (L, M, P, Q) that goes around the case and

the lid. This trim is very small, but is easy to make using the step-bystep cutting sequence shown in Fig. 5. Apply a thin bead of glue to the

pieces that wrap around the case (L, M) and clamp them into the 1/8"

x 1/8" dadoes previously occupied by the spacer sticks. If any glue

squeezes out, wipe it away immediately with a damp sponge or towel.

5. Set your table saw blade to 45 degrees and use a table saw sled to

miter the clocks four sides. Start by cutting the sides about 1/4"

oversize. Then miter the sides to their final width. Hold each piece in

place with a toggle clamp to ensure a straight cut and to keep your

hands out of harms way.

9. Sand all pieces with 120-grit paper, then move up to 220-grit to

complete the pre-finish smoothing. Use an orbital sander and with-thegrain sanding strokes to remove any marks or scratches. Wipe the

piece carefully with a clean, lint-free cloth lightly dampened with

mineral spirits.

Woodworkers Tip: Cut slowly to avoid chip-out on the moldings.

If you do get a chip, save it and glue it back on. Use a toothpick to

apply the glue and masking tape to hold the chip in place.

CONTINUED - WOODWORKS: ADVANCED PROJECT DESKTOP CLOCK

Recommended Finish

10. Apply the Minwax Wood Finish youve chosen to the interior

surfaces using a natural bristle brush and a clean, lint-free cloth following the directions on the can. The brush will help you get the stain into

the many inside corners and other tight spots. Allow the Wood Finish

to set for about 5 to 15 minutes, then wipe off any excess. To achieve a

deeper color, you may apply a second coat after 4-6 hours, repeating

the application directions for the first coat. Allow the stain to dry for

24 hours before applying the protective clear finish.

15. After allowing the assembled piece to dry overnight, apply

Minwax Polycrylic Protective Finish following the directions on the

can. Stir the can contents thoroughly before starting and periodically

repeat the stirring during your work session.

16. Working a small area at a time to maintain a wet edge, apply the

first coat. Work quickly and make the final strokes in each newly

finished section using with-the-grain brushstrokes.

17. Allow the finish to dry a minimum of 2 hours. Then sand lightly

with 220-grit or finer sandpaper wrapped around a soft backup block.

Thoroughly wipe all surfaces with a cloth lightly dampened with water.

Woodworkers Tip: When wiping off stain, make certain that

your last wipe with the cloth goes with the grain of the wood. This

way, any stain you might miss during wipe-off will be visually

minimized by the wood grain.

18. Repeat steps 15 and 16 to apply the second and final coat. Allow

the piece to cure for a few days before installing the clock mechanism.

Its simply a pressure fit and requires no fasteners.

11. Apply Minwax Fast-Drying Polyurethane following the directions

on the can. Use a good quality, natural bristle brush. Allow the first coat

to dry overnight.

PRODUCT SAFETY

For your safety and the safety of those you work with, always read the

safety warnings, which manufacturers print on their labels, and follow

them to the letter. Typical safety advice and instructions will contain

information such as the following:

12. The next day, sand all surfaces lightly with 220-grit or finer

sandpaper using with-the-grain strokes. Wipe all surfaces with a

cloth lightly dampened with mineral spirits. Apply a second coat

of polyurethane and set the piece aside to cure overnight.

WARNING! Removal of old paint by sanding, scraping or other means

may generate dust or fumes that contain lead. Exposure to lead dust

or fumes may cause brain damage or other adverse health effects,

especially in children or pregnant women. Controlling exposure to lead

or other hazardous substances requires the use of proper protective

equipment, such as properly fitted respirator (NIOSH approved) and

proper containment and cleanup. For more information, call the

National Lead Informations Center at 1-800-424-LEAD (in US) or

contact your local health authority.

13. The following day, sand all surfaces lightly with 220-grit paper.

Wipe the piece with a cloth lightly dampened with mineral spirits and

apply the third and final coat of polyurethane. When the polyurethane is

dry, apply a thin bead of glue to the trim pieces (L, M) and clamp them

to the clock case. If any glue squeezes out, wipe it away immediately

with a damp sponge or paper towel. Allow the piece to cure for a few

days before installing the clock mechanism. Its simply a pressure fit

and requires no fasteners.

When using oil-based wood finishing products:

CAUTIONS: CONTAINS ALIPHATIC HYDROCARBONS. Contents

are COMBUSTIBLE. Keep away from heat and open flame. VAPOR

HARMFUL. Use only with adequate ventilation. To avoid overexposure,

open windows and doors or use other means to ensure fresh air entry

during application and drying. If you experience eye watering,

headaches, or dizziness, increase fresh air, or wear respiratory protection (NIOSH approved) or leave the area. Avoid contact with eyes and

skin. Wash hands after using. Keep container closed when not in use.

Do not transfer contents to other containers for storage.

Alternate Finish

Before applying Minwax Water-Based Wood Stain to a hardwood or

softwood, apply Minwax Pre-Stain Water-Based Wood Conditioner

following the directions on the can. After 1 to 5 minutes, wipe off all

excess conditioner using a clean, lint-free cloth. Wait 15 to 30 minutes

then use fine-grade sandpaper to sand off any whiskers raised by the

conditioner. Proceed to the staining within 2 hours.

14. Apply the Minwax Water-Based Wood Stain youve chosen using

either a nylon/polyester brush or soft cloth. Allow stain to penetrate no

longer than 3 minutes. While stain is still wet, wipe off all excess with a

clean cloth thats been lightly dampened with stain. Allow the piece to

dry for 2 hours before applying a second coat, if desired. Allow the

pieces to dry overnight before assembling and applying the protective

clear finish.

FIRST AID: In case of eye contact, flush thoroughly with large amounts

of water for 15 minutes and get medical attention. For skin contact,

wash thoroughly with soap and water. In case of respiratory difficulty,

provide fresh air and call physician. If swallowed, call Poison Control

Center, hospital emergency room, or physician immediately.

NOTICE: Reports have associated repeated and prolonged occupational exposure to solvents with permanent brain and nervous system

damage. Intentional misuse by deliberately concentrating and inhaling

contents may be harmful or fatal.

WARNING: This product contains a chemical known to the

State of California to cause cancer and birth defects or other

reproductive harm.

DO NOT TAKE INTERNALLY. KEEP OUT OF REACH

OF CHILDREN.

Woodworkers Tip: Minwax Water-Based Wood Stain is

available in 50 custom-mixed colors and a White Wash Pickling

Stain. So, you can actually pick and apply a color to

complement the dcor of the room in which the clock will be

placed. For this reason, make sure you look over all of the

Minwax color charts or go to minwax.com before making

your final selection.

CONTINUED - WOODWORKS: ADVANCED PROJECT DESKTOP CLOCK

When using water-based wood finishing products:

CAUTIONS: Use Only With Adequate Ventilation. To avoid overexposure, open windows and doors or use other means to ensure fresh air

entry during application and drying. If you experience eye watering,

headaches, or dizziness, increase fresh air, or wear respiratory protection (NIOSH approved), or leave the area. Avoid contact with eyes and

skin. Wash hands after using. Keep container closed when not in use.

Do not transfer contents to other containers for storage.

Source

Clock insert, #23995, $10.59

Rockler Companies, Inc.

(800) 279-4441

www.rockler.com

FIRST AID: In case of eye contact, flush thoroughly with large amounts

of water. Get medical attention if irritation persists. If swallowed, get

medical attention immediately.

WARNING: Contains Alkyl propanols, ethylene glycol, n-methyl pyrrolidone. VAPOR HARMFUL. Use only with adequate ventilation. To avoid

overexposure, open windows and doors or use other means to ensure

fresh air entry during application and drying. If you experience eye

watering, headaches, or dizziness, increase fresh air, or wear respiratory protection (NIOSH approved) or leave the area. Avoid contact with

eyes and skin. Wash hands after using. Keep container closed when not

in use. Do not transfer contents to other containers for storage.

DO NOT TAKE INTERNALLY.

FIRST AID: In case of eye contact, flush thoroughly with large amounts

of water for 15 minutes and get medical attention. For skin contact,

wash thoroughly with soap and water. In case of respiratory difficulty,

provide fresh air and call physician. If swallowed, call Poison Control

Center, hospital emergency room, or physician immediately.

DELAYED EFFECTS FROM LONG-TERM OVEREXPOSURE.

Contains solvents which can cause permanent brain and nervous

system damage. Intentional misuse by deliberately concentrating

and inhaling contents may be harmful or fatal.

WARNING: This product contains a chemical known to the

State of California to cause cancer and birth defects or other

reproductive harm.

KEEP OUT OF REACH OF CHILDREN.

SAFE DISPOSAL OF RAGS AND WASTE.

DANGER: Rags, steel wool, other waste soaked with this product, and

sanding residue may spontaneously catch fire if improperly discarded.

Immediately place rags, steel wool, other waste soaked with this product, and sanding residue in a sealed, water-filled, metal container.

Dispose of in accordance with local fire regulations.

This project was adapted with permission from American

Woodworker magazine, Home Services Publications, Inc., an

affiliate of Readers Digest Association, Inc., Suite 700, 2915

Commers Drive, Eagan, MN 55121. Copyright 2004. All rights

reserved. For subscriptions call toll-free: 1-800-666-3111.

CONTINUED - WOODWORKS: ADVANCED PROJECT DESKTOP CLOCK

FIG 1. CLOCK DETAIL

/4" x /2" Rabbet

1"

/8" x /8"

Dado

H

A

3" Dia.

7-1/2"

D

M

B

L

2-3/8"

1-1/2"

/8"

CONTINUED - WOODWORKS: ADVANCED PROJECT DESKTOP CLOCK

FIG 2. GLUE AND CLAMP THE FLAT TRIM

Spacer Strip

Flat Trim

FIG 3. GLUE AND CLAMP THE MOLDING

Spacer

Strip

Flat

Trim

Flush

CONTINUED - WOODWORKS: ADVANCED PROJECT DESKTOP CLOCK

FIG 4. BOTTOM LID DETAIL

/8"

/8"

Lid

/16"

/2"

FIG 5. CUTTING SEQUENCE FOR

THE HALF-BEAD TRIM

/8"

Rip

Fence

DETAIL 1

Dimensions for the rabbets on

the bottom of the lid.

3

1

FIG 6. GLUE THE HALF-BEAD TRIM

Clamp Jaw Cover

Table Saw

1. Rout the corners with a 1/8" round-over bit.

2. Saw a 1/4"-deep slot down the middle of the edge.

3. Rip the trim off. Position your rip fence as shown so

the trim falls away from the blade at the end of the cut.

Lid

Half-Bead

Trim

S-ar putea să vă placă și

- A Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.De la EverandA Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.Încă nu există evaluări

- Modular Planter Bench: Woodworks: Intermediate ProjectDocument7 paginiModular Planter Bench: Woodworks: Intermediate ProjectEucap MdzÎncă nu există evaluări

- Sliding Bookrack: Woodworks: Intermediate ProjectDocument8 paginiSliding Bookrack: Woodworks: Intermediate ProjectEucap Mdz100% (1)

- Folding Stool: I Can Do ThatDocument3 paginiFolding Stool: I Can Do ThatSergio PazÎncă nu există evaluări

- EZPine Wall ShelfDocument3 paginiEZPine Wall ShelfBSulliÎncă nu există evaluări

- 44-Shoulder Planes-3-BDocument7 pagini44-Shoulder Planes-3-BleeroyhaspoonÎncă nu există evaluări

- Projeto para Encaixe Rabo de AndorinhaDocument8 paginiProjeto para Encaixe Rabo de AndorinhaVInixsoad100% (2)

- Wall Hung Magazine and Book Rack: Project 14211EZDocument3 paginiWall Hung Magazine and Book Rack: Project 14211EZBSulliÎncă nu există evaluări

- Z3083 CurlymapledesktoporganizerDocument0 paginiZ3083 Curlymapledesktoporganizerroose1Încă nu există evaluări

- Wall-Hung Telephone Cabinet: Project 11257EZDocument6 paginiWall-Hung Telephone Cabinet: Project 11257EZBSulli100% (1)

- Showcase Cabinets: The Delicate Interplay of Glass and WoodDocument7 paginiShowcase Cabinets: The Delicate Interplay of Glass and WoodAdrian Cocis100% (1)

- Deluxe Router TableDocument27 paginiDeluxe Router Tableiacob_gilberto6473100% (1)

- Bowl Basics 1Document5 paginiBowl Basics 1api-522254901Încă nu există evaluări

- HowWoodWords PDFDocument4 paginiHowWoodWords PDFJavier D100% (1)

- PicnicTable PDFDocument2 paginiPicnicTable PDFAvi KarmonÎncă nu există evaluări

- 111 - Router Table PlanDocument18 pagini111 - Router Table PlanFrans SadieÎncă nu există evaluări

- 2 - Woodworking Plans - OakplateDocument6 pagini2 - Woodworking Plans - OakplatemacpatorÎncă nu există evaluări

- Pine Desk Organizer: Project 13782EZDocument6 paginiPine Desk Organizer: Project 13782EZBSulli100% (1)

- Deluxe Router TableDocument27 paginiDeluxe Router TableNebojša JovanovÎncă nu există evaluări

- 94 Shooting-BoardDocument6 pagini94 Shooting-Boardbjørn vidar andersenÎncă nu există evaluări

- Porch Swing: Project 16258EZDocument5 paginiPorch Swing: Project 16258EZBSulli100% (1)

- Record and Tape Cabinet: Project 11185EZDocument8 paginiRecord and Tape Cabinet: Project 11185EZBSulliÎncă nu există evaluări

- Drill Press ForDocument52 paginiDrill Press FortumadrepuesÎncă nu există evaluări

- Sea ChestDocument2 paginiSea ChestAnninha Sud AlvesÎncă nu există evaluări

- How To Make A Jack Plane: Overcoming PrejudiceDocument10 paginiHow To Make A Jack Plane: Overcoming Prejudicebollería PebeÎncă nu există evaluări

- Box Joint Jig PlanDocument8 paginiBox Joint Jig PlanLarry MullinsÎncă nu există evaluări

- Threading OptionsDocument3 paginiThreading Optionsapi-522254901Încă nu există evaluări

- Hollows and RoundsDocument3 paginiHollows and RoundsMitch ArchÎncă nu există evaluări

- Wooden Scrub Plane From ScrapDocument9 paginiWooden Scrub Plane From ScrapRod HyattÎncă nu există evaluări

- Book Case (Mission Style)Document8 paginiBook Case (Mission Style)khunchaiyai100% (3)

- How To Make A Meat SafeDocument5 paginiHow To Make A Meat SafeChristian Theriault100% (1)

- Spindle Turning: Fine Points For The BeginnerDocument6 paginiSpindle Turning: Fine Points For The Beginnerapi-25885411Încă nu există evaluări

- Sash PlanesDocument5 paginiSash PlanesBlakdawg15100% (1)

- Lynns Box Joint JigDocument21 paginiLynns Box Joint Jigstacktranzer100% (1)

- Hands DovetailsDocument5 paginiHands Dovetailsquique1967.ecÎncă nu există evaluări

- American Woodworker - 135 (May 2008)Document92 paginiAmerican Woodworker - 135 (May 2008)Emilian BalutaÎncă nu există evaluări

- A Classic Case: A Project Plan For A Case With A Modern Take On An Arts and Crafts ClassicDocument7 paginiA Classic Case: A Project Plan For A Case With A Modern Take On An Arts and Crafts ClassicMushroom Love Stars CrUz100% (1)

- Cortar CirculosDocument7 paginiCortar CirculosarenasrubenÎncă nu există evaluări

- Cove CalculationsDocument1 paginăCove CalculationsflerziÎncă nu există evaluări

- Loose-Tenon Options: Spend A Little, Spend A Lot: Three Great Ways To Make Loose-Tenon JointsDocument6 paginiLoose-Tenon Options: Spend A Little, Spend A Lot: Three Great Ways To Make Loose-Tenon JointsFausto Martin Vicente MoralesÎncă nu există evaluări

- Trestle Coffee TableDocument7 paginiTrestle Coffee Table- yAy3e -Încă nu există evaluări

- Woodworking Plans - RabbetingDocument3 paginiWoodworking Plans - RabbetingBob Kowalski100% (2)

- Country Bench: Project 10307EZDocument8 paginiCountry Bench: Project 10307EZBSulliÎncă nu există evaluări

- Resources For Making Bandsawn BoxesDocument4 paginiResources For Making Bandsawn BoxesFelixPÎncă nu există evaluări

- Segmentation Basic 1Document26 paginiSegmentation Basic 1Anonymous p2cFoXbjDÎncă nu există evaluări

- Lumber Grading ChartDocument2 paginiLumber Grading ChartKeith BibelhausenÎncă nu există evaluări

- Beveled MitresDocument1 paginăBeveled MitresRandallBergerudÎncă nu există evaluări

- Folding Sun LoungerDocument14 paginiFolding Sun LoungerKrespov100% (1)

- Moxon Vise Instructions-BC0317Document12 paginiMoxon Vise Instructions-BC0317Cameron RiosÎncă nu există evaluări

- ArtofWoodworking WorkbenchDocument4 paginiArtofWoodworking Workbenchsalulai100% (1)

- Wooden Puzzle BoxDocument19 paginiWooden Puzzle BoxDuarte Raulh RaulÎncă nu există evaluări

- Shaker Nightstand PlanDocument18 paginiShaker Nightstand PlanJess HendriksmaÎncă nu există evaluări

- How To Make A Wooden Bar Clamp PDFDocument13 paginiHow To Make A Wooden Bar Clamp PDFAldrin DejumoÎncă nu există evaluări

- Types of Joints in Carpentry With DescriptionDocument5 paginiTypes of Joints in Carpentry With DescriptionYuuki ChanÎncă nu există evaluări

- Plans Triple Picture FrameDocument7 paginiPlans Triple Picture Framehmam_88100% (1)

- Principles & Practice of Ornamental or Complex TurningDe la EverandPrinciples & Practice of Ornamental or Complex TurningÎncă nu există evaluări

- How-To Book of Christmas Carving: 32 Projects to Whittle, Carve & PaintDe la EverandHow-To Book of Christmas Carving: 32 Projects to Whittle, Carve & PaintÎncă nu există evaluări

- Celdek VS AspenDocument2 paginiCeldek VS AspenVidysagar VvecÎncă nu există evaluări

- Fiber Stress For Wood PolesDocument42 paginiFiber Stress For Wood PolesbcbianÎncă nu există evaluări

- Garage Doors: Interior & Exterior Doors CatalogDocument88 paginiGarage Doors: Interior & Exterior Doors CatalogPower Euro DoorsÎncă nu există evaluări

- 0109-BS en 636-2012+a1-2015Document23 pagini0109-BS en 636-2012+a1-2015Borga ErdoganÎncă nu există evaluări

- ANSI 117-2020 Standard Specification For Structural Glued Laminated Timber of Softwood Species PDFDocument75 paginiANSI 117-2020 Standard Specification For Structural Glued Laminated Timber of Softwood Species PDFAbdurrahman CinarÎncă nu există evaluări

- Draft: Marking Out and MeasuringDocument12 paginiDraft: Marking Out and MeasuringJose EvoraÎncă nu există evaluări

- AS 1604.1-2005 Specification For Preservative Treatment - Sawn and Round TimberDocument49 paginiAS 1604.1-2005 Specification For Preservative Treatment - Sawn and Round Timberskishark100% (1)

- Wood & Wood Products - KenyaDocument17 paginiWood & Wood Products - Kenyayrdgcgf5664Încă nu există evaluări

- Hom175652 - Prelam - Mply - Prelam - Mply - 100W Filler For 2400H Base UnitDocument3 paginiHom175652 - Prelam - Mply - Prelam - Mply - 100W Filler For 2400H Base UnitKushal PatilÎncă nu există evaluări

- LP CarpentryDocument4 paginiLP CarpentryNeil Roy MasangcayÎncă nu există evaluări

- American Woodworker - 101-2003-07Document62 paginiAmerican Woodworker - 101-2003-07api-19759721100% (2)

- AgroDocument6 paginiAgrolercutaÎncă nu există evaluări

- Basic TechDocument52 paginiBasic TechHASSAN MUH'D BELLOÎncă nu există evaluări

- ListofmillsDocument416 paginiListofmillsCompany Hoang Giang phuongÎncă nu există evaluări

- Framing Vocabulary Test 2009Document26 paginiFraming Vocabulary Test 2009Randy Stribley100% (1)

- Trees Botanical Name Common Name Uses Canopy Spread Height Root SpreadDocument5 paginiTrees Botanical Name Common Name Uses Canopy Spread Height Root Spreadritu habibÎncă nu există evaluări

- Furniture Cabinetmaking Issue 311 April 2023Document124 paginiFurniture Cabinetmaking Issue 311 April 2023KÎncă nu există evaluări

- Caesalpinia Sappan LDocument4 paginiCaesalpinia Sappan LSriArthiÎncă nu există evaluări

- Future Directions of Timber Eng RDocument10 paginiFuture Directions of Timber Eng RCsongor BiroÎncă nu există evaluări

- Alpine Theme: Town of SmithersDocument27 paginiAlpine Theme: Town of SmithersLeandro VangelÎncă nu există evaluări

- Hahn Plastics Hanit Ultra Fencing Specifications Specification GuideDocument9 paginiHahn Plastics Hanit Ultra Fencing Specifications Specification GuideMohammad AlizadehÎncă nu există evaluări

- Types of ReconstitutedDocument13 paginiTypes of ReconstitutedJishnu SamadderÎncă nu există evaluări

- Stall BarsDocument18 paginiStall BarsMathieu St-Onge100% (1)

- Secondary GrowthDocument33 paginiSecondary Growthgsr_sasiÎncă nu există evaluări

- Section 06 4023 - Interior Architectural WoodworkDocument32 paginiSection 06 4023 - Interior Architectural WoodworkMuhammad AbuBakarÎncă nu există evaluări

- Ehrhart-2020-European Beech (Fagus Sylvatica L.) - (Accepted Version)Document18 paginiEhrhart-2020-European Beech (Fagus Sylvatica L.) - (Accepted Version)kulin_banÎncă nu există evaluări

- Comparison Between Timber Concrete Composite Slab and Solid Slab For Residential BuildingsDocument12 paginiComparison Between Timber Concrete Composite Slab and Solid Slab For Residential BuildingsInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- ShopNotes Issue 42 PDFDocument32 paginiShopNotes Issue 42 PDFbenigno100% (1)

- Nonmetals: 3.1 Wood: Properties, Uses, and Production ProcessesDocument18 paginiNonmetals: 3.1 Wood: Properties, Uses, and Production ProcessesEmmanuel DelantarÎncă nu există evaluări

- Non Destructive Techniques For Wood Quality Assesment of Plantation Grown TeakDocument13 paginiNon Destructive Techniques For Wood Quality Assesment of Plantation Grown TeakMamet Edvant100% (1)