Documente Academic

Documente Profesional

Documente Cultură

MAG 5000, 6000 Operation Manual

Încărcat de

lauraDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

MAG 5000, 6000 Operation Manual

Încărcat de

lauraDrepturi de autor:

Formate disponibile

s

Operating Manual

SITRANS F M MAGFLO

Electromagnetic flowmeters

Transmitter types MAG 5000, MAG 6000

Order no.: FDK:521H0739

SFIDK.PS.027.Z5.02 - A5E00253213

*083R9141*

SITRANS F M MAGFLO

1. Technical data

1.1 Transmitter type MAG 5000 & MAG 6000

MAG 5000 accuracy 0.5%

MAG 6000 accuracy 0.25%

Current output

Current

Load

Time constant

Digital output

Frequency

Time constant

Active

Passive

Relay

Time constant

Load

Digital input

Activation time

Current

Functions

Galvanic isolation

Cut-off

Low flow

Empty pipe

Totalizer

Display

Time constant

Zero point adjustment

Electrode input impedance

Excitation frequency

Ambient temperature

Custody transfer approval

0-20 mA, 4-20 mA or 4-20 mA + alarm

< 800 ohm

0.1-30 s adjustable

0-10 kHz, 50% duty cycle

0.1-30 s adjustable

24 V DC, 30 mA, 1 K Rload 10 K, short-circuit-protected

3-30 V DC, max. 110 mA, 200 Rload 10 K

Changeover relay, time constant same as current time constant

42 V AC/2 A, 24 V DC/1A

11-30 V DC, Ri = 4.4 K

50 ms

I11 V DC = 2.5 mA, I30 V DC = 7 mA

Flow rate, 2 totalizers, low flow cut-off, empty pipe cut-off, flow direction, error system, operating time,

uni/bidirectional flow, limit switches, pulse output, control for cleaning unit and batch2)

All inputs and outputs are galvanically isolated

0-9.9% of maximum flow

Detection of empty pipe1)

Two eight-digit counters for forward, net or reverse flow

Background illumination with alphanumerical text, 3 20 characters to indicate flow rate, totalized

values, settings and faults

Reverse flow indicated by negative sign

Time constant as current output time constant

Automatic

> 1 x 1014

Sensor size depending pulsating DC current (125 mA)

Display version during operation: 20 to +50C

Blind version during operation: 20 to +60C

During storage: 40 to +70C (RH max. 95%)

PTB

DANAK OIML R75 2)

DANAK OIML R117 2)

(cold water)

(hot water)

(cold water/milk, beer etc.)

6.221

99.19

Communication

Standard

Optional

Compact

Enclosure material

Enclosure rating

Mechanicalload

19" insert

Enclosure material

Enclosure rating

Mechanical load

EMC performance

Supply voltage

Power consumption

1)

Prepared for client mounted add-on modules2)

HART, Profibus PA & DP, Modbus RTU, CANopen, DeviceNet as add-on module2), HART (MAG 5000)

Fibre glass-reinforced polyamide

IP 67 to EN 60529 and DIN 40050 (1 m w.g. for 30 minutes)

18-1000 Hz random, 3.17 G rms in all directions to EN 60068-2-36

Standard 19" insert of aluminium/steel (DIN 41494)

Width: 21 TE

Height: 3 HE

IP 20 to EN 60529 and DIN 40050

Version: 1 G, 1-800 Hz sinusoidal in all directions to EN 60068-2-36

Emission: EN 50081-1 (Light industry)

Immunity: EN 50082-2 (Industry)

115-230 V AC +10% to 15%, 50-60 Hz

11-30 V DC or 11-24 V AC

230 V AC: 9 VA

24 V DC: 9 W, IN = 380 mA, IST = 8A (30 ms)

12 V DC: 11 W, IN = 920 mA, I ST = 4A (250 ms)

2)

Special cable required in separate mounted installation

MAG 6000 only

SFIDK.PS.027.Z5.02

SITRANS F M MAGFLO

1.2

Output characteristics MAG 5000 &

MAG 6000

1. Technical data

Output characteristics

0-20 mA

Bidirectional mode

Unidirectional mode

4-20 mA

Frequency

Pulse output

Relay

Power down

Active

Error relay

No error

Error

Limit switch or

direction switch

1 set point

2 set points

Low flow

(Reverse flow)

Intermediate flow

High flow

(Forward flow)

High flow/

Low flow

Hold

Batch

Batch on digital

output

(MAG 6000 only)

Batch on relay

(MAG 6000 only)

1.3.1 Sensor cables and

conductivity of

medium

Conductivity of

medium

Compact installation: Liquids with an electrical conductivity 5 S/cm.

For a conductivity between 5 and 10 S/cm, the repeatability may degrade to

0.5% of actual flow.

Remote

Standard cable

Special cable

installation:

Note For detection of empty sensor the min. conductivity must always be 20 S/cm and the max.

length of electrode cable when remote mounted is 50 metres. Special cable must be used.

For remote mounting in Ex applications special cable cannot be used, empty sensor cannot

be detected and the electrically conductivity must be 30 S/cm.

For remote mounted CT installations the max. cable length is 200 metres.

1.3.2 Minimum accept

data for cable

Basic data

Max. cable loop

resistance

SFIDK.PS.027.Z5.02

No. of conductors

Min. sqr. area

Screen

Max. capacitance

Media temperature:

< 100C

< 200C

Coil cable

2

0.5 mm2

Yes

N.A.

40

6

Electrode cable

3

0.2 mm2

Yes

350 pF/m

N.A.

N.A.

SITRANS F M MAGFLO

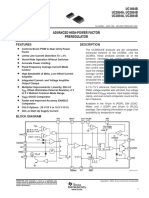

2. Electrical connection

2.1 Transmitter MAG

5000 & MAG 6000

connection diagram

Note

Special cable with individual

wire shields (shown as dotted

lines) are only requried when

using empty pipe function or

long cables.

(See Technical data)

Potential Hazards

Grounding

The mains protective earth wire must be connected to the PE terminal in accordance with the

diagram (class 1 power supply).

Mechanical counters

When mounting a mechanical counter to terminals 57 and 58 (active output), a 1000 F capacitor

must be connected to the terminals 56 and 58.

Capacitor + is connected to terminal 56 and capacitor to terminal 58.

Output cables

If long cables in noise environment, we recommend to use screened cable.

Electrodes cables

Dotted connections only to be when using special electrode cable.

4

SFIDK.PS.027.Z5.02 - this page has been updated 2004.06

SITRANS F M MAGFLO

3.1 Compact installation

MAG 5000 & MAG 6000

- Compact polyamide

3. Installation of transmitter

Step 1

Remove and discard the terminal box lid of the

sensor.

Fit the PG 13.5 cable glands for the supply and

output cables.

Step 2

Remove the two black plug assemblies for coil

and electrode cables in the terminal box and

connect them to their corresponding terminal

numbers on the connection board.

Step 3

Connect an earth wire between PE on connection board and bottom of terminal box.

Connect the 2 pin connector and 3 pin connector

as shown.

Note

System will not register flow

if black plugs are not

connected to connection

board

Note

In earlier version the 3 pin connector was a 5

pin connector.

Step 4

Mount the connection plate in the terminal box.

The SENSORPROM unit connections will be

established automatically when the connection

plate is mounted in the terminal box.

Note

Check that your connection board lines up with

the SENSORPROM unit, if not, move the

SENSORPROM unit to the other side of the

terminal box.

Caution

Exposing the transmitter to

direct sunlight may increase

the operating temperature

above its specified limit, and

decrease display visibilty

Step 5

Fit the supply and output cables respectively

and tighten the cable glands to obtain optimum

sealing.

Please refer to the wiring diagram Electrical

connections.

Mount the transmitter on the terminal box.

SFIDK.PS.027.Z5.02 - this page has been updated 2004.06

SITRANS F M MAGFLO

3. Installation of transmitter

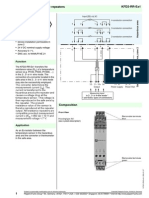

3.2.1 Remote installation At the sensor

Remove the SENSORPROM unit from the

sensor and mount it on the connection plate in

the transmitter.

Fit and connect the electrode and coil cables

as shown in Electrical connections.

The unscreened cable ends must be kept as

short as possible.

The electrode cable and the coil cable must be

kept separate to prevent interference.

Tighten the cable glands well to obtain optimum sealing.

Mount the terminal box lid before power

up.

Mount wall bracket on a wall or on a pipe using

ordinary hose clips or duct straps.

3.2.2 Remote installation Wall mounting

transmitter

Take the SENSORPROM memory unit from

the sensor. Mount the SENSORPROM unit in

the wall mounting unit as shown. The text on

the SENSORPROM unit must face towards

the wall bracket.

Mount an earth wire between PE on connection

board and bottom of terminal box.

SFIDK.PS.027.Z5.02

SITRANS F M MAGFLO

3. Installation of transmitter

3.2.2 Remote installation Wall mounting

transmitter

(continued)

Mount the connection plate in the terminal box.

Fix the connection plate with the two diagonal

opposite screws.

Fit the coil, electrode, supply and output cables

respectively and tighten the cable glands to

obtain optimum sealing. Please see the wiring

diagram in Electrical connections.

Mount the transmitter on the terminal box.

Attention

When remote mounted, power supply PE wire

must be connected to PE terminal.

Coil cable shield must be connected to SHIELD

terminal.

Use the supplied insulating tube to insulate the

core shield.

Caution

Exposing the transmitter to

direct sunlight may increase

the operating temperature

above its specified limit, and

decrease display visibilty

3.2.3 Remote installation Transmitter in 19"

insert

1. Fit the SENSORPROM memory unit on the connection board supplied with the transmitter.

The SENSORPROM unit is supplied with the sensor in the terminal box.

2. Mount the guide rails into the rack system as shown. Distance between guide rails is 20 TE.

Guide rails are supplied with the rack system and not with the transmitter.

3. Mount the connection board as shown.

4. Connect the cables as shown under "Electrical connection".

5. Insert the transmitter into the rack system.

SFIDK.PS.027.Z5.02 - this page has been updated 2004.06

SITRANS F M MAGFLO

4.1

4. Commissioning

MAG 5000 & MAG 6000

SFIDK.PS.027.Z5.02

SITRANS F M MAGFLO

4.1

4. Commissioning

MAG 5000 & MAG 6000 (continued)

SFIDK.PS.027.Z5.02

SITRANS F M MAGFLO

4. Commissioning

4.2 Keypad and display

layout

Keypad

Display

The keypad is used to set the flowmeter. The function of the keys is as follows:

TOP UP KEY

This key (hold 2 sec.) is used to switch between operator menu

and setup menu. In the transmitter setup menu, a short press will

cause a return to the previous menu.

FORWARD KEY

This key is used to step forward through the menus. It is the only

key normally used by the operator.

BACKWARD KEY

This key is used to step backward through the menus.

CHANGE KEY

This key changes the settings or numerical values.

SELECT KEY

This key selects the figures to be changed.

LOCK/UNLOCK KEY

This key allows the operator to change settings and gives access

to submenus.

The display is alphanumerical and indicates flow values, flowmeter settings and error messages.

The upper line is for primary flow readings and will always show either flow rate, totalizer 1 or totalizer

2. The line is divided into 3 fields.

S: Sign field

P: Primary field for numerical value

U: Unit field

The centre line is the title line (T) with individual information according to the selected operator

or setup menu.

The lowest line is the subtitle line (ST) which either will add information to the title line or keep

individual information independent of the title line.

F: The alarm field.

Two flashing triangles will appear by a fault condition.

M: The mode field. The symbols indicate the following.

L:

10

Communication mode

Basic settings

Operator active

Service mode

Output

Operator inactive

Operator menu

External input

Product identity

Sensor characteristics

Language mode

Reset mode

The lock field. Indicates the function of the lock key.

Ready for change

Access to submenu

Value locked

RESET MODE: Zero setting of

totalizers and initialization of setting

SFIDK.PS.027.Z5.02

SITRANS F M MAGFLO

4. Commissioning

4.3.1 Basic settings

Main frequency

To select the main power supply frequency corresponding

to the country in which the flowmeter is installed.

(US = 60 Hz)

Flow direction

Select the correct flow direction in the pipe.

Qmax.

Sets the measuring range, the analog outputs and the

frequency output. Value, decimal point, unit and time can

be set individually (setting is dimension dependent).

Qmax.2

Sets the measuring range, the analog outputs and the

frequency output. Value, decimal point, unit and time can

be set individually (setting is dimension dependent).

Only visible when it has been choosen as external digital

input.

Totalizers

To set unit and decimal point.

Low flow cutt off

To set a % of selected Qmax.. To filter noise in the

installation. Influences display and all outputs.

Error level

To select which error level, the flowmeter will detects an

error.

Empty pipe cut off

Set on - the alarm will indicate when sensor is running

empty. All readings, display and outputs will indicate zero.

Comma for flow rate, totalizer 1 and totalizer 2 can be individually positioned.

open the respective window.

ensure that the cursor is positioned below the comma. Use the SELECT KEY

move the comma to the requested position. Use the CHANGE KEY

.

Units are changed by means of the CHANGE KEY

with the cursor placed below the unit

selected. Select units (cursor moved) by means of the SELECT KEY

.

Totalizer 2 is not visible when batch is selected as digital output.

Qmax. 2 - is only visible when it has been choosen as external input.

SFIDK.PS.027.Z5.02

11

SITRANS F M MAGFLO

4. Commissioning

4.3.2 Outputs

Current output

Proportional to flowrate

(Terminal 31 and 32)

4 - 20 mA + alarm:

Current output gives the following mA, depending on what is selected as error level in basic settings.

Fatal: 1 mA, permanent: 2 mA, warning: 3 mA

The current output must be set off when not used.

Digital output

Pulse/volume

(Terminal 56, 57, 58)

Digital output

Frequency

Proportional to flowrate

(Terminal 56, 57, 58)

4.3.3 External input

Batch control is available on MAG 6000 only.

12

SFIDK.PS.027.Z5.02

SITRANS F M MAGFLO

4. Commissioning

4.3.4 Sensor characteristics

If SENSORPROM not

installed is shown, refer to

chapter 6 in the handbook

(depending on type of

mounting configuration).

4.3.5 Language mode

SFIDK.PS.027.Z5.02

13

SITRANS F M MAGFLO

4. Commissioning

4.3.6 Service mode

1) Standard

2) If digital output is set to

frequency

All previous settings are reinitialised when service mode is exited using the top up key.

The error system

The error system is divided into an error pending list and a status log list. Time is gained as days,

minutes and hours since the error has occurred.

The first 9 standing errors are stored in error pending. When an error is removed it is removed

from error pending.

The latest 9 errors are stored in the status log. When an error is removed it is still kept in status

log. Errors in status log is stored for 180 days.

Error pending and status log are accessible when enabled in the operator menu.

14

SFIDK.PS.027.Z5.02

SITRANS F M MAGFLO

5. Service

5.

Often problems with unstable/wrong measurements occur due to insufficient/wrong earthing or

potential equalization. Please check this connection. If OK, the SITRANS F M MAGFLO transmitter can be checked as described under 9.1 and sensor under 9.3 in the handbook.

Service

5.1 Transmitter check list

When checking SITRANS F M MAGFLO installations for malfunction the easiest method to

check the transmitter is to replace it with another MAG 5000/6000 transmitter with a similar power

supply.

A replacement can easily be done as all settings are stored in and downloaded from the

SENSORPROM unit - no extra settings need to be made.

If no spare transmitter is available - then check transmitter according to check table.

Power on transmitter,

display light on

YES

YES

Error triangles flashing

NO

Check cables/connections YES

Check connection board

Check pins in transmitter

multiplug - OK

NO

Correct fault

Check error table

NO

Output

readings OK

YES

Display defect

Change display

Output and display

readings OK ?

NO

Transmitter

defective

YES

NO

Check cables/connections YES

Check connection board

Check pins in transmitter

multiplug - OK

Transmitter OK Check settings/application

Check installation/sensor/

earthing connection etc.

NO

Correct fault

SFIDK.PS.027.Z5.02

15

SITRANS F M MAGFLO

5.2 Trouble shooting MAG

transmitter

5. Service

Symptom

Empty display

Output

signals

Minimum

No flow signal

Minimum

Error

code

F70

W31

Undefined

F60

P42

P41

Indicates flow

with no flow

in pipe

Unstable

flow signal

Measuring error

Undefined

Undefined

F61

F62

F63

F71

W30

W21

Measuring

approx. 50%

OK

OK

1. No power supply

Power supply

Check MAG 5000/6000 for

bended pins on the connector

Replace MAG 5000/6000

Turn on current output

Turn on digital output

Change direction

Check cables/connections

Ensure that the measuring

pipe is full

Replace MAG 5000/6000

Check cables/connections

Replace MAG 5000/6000

Switch off MAG 5000/6000,

wait 5 s and switch on again

Select empty pipe cut-off

Ensure that the measuring

pipe is full

Ensure that electrode cable

is connected and sufficiently

screened

Increase time constant

Use special electrode cable

2. MAG 5000/6000 defective

1. Current output disabled

2. Digital output disabled

3. Reverse flow direction

Incorrect or no coil current

Measuring pipe empty

Internal error

1. No load on current output

2. MAG 5000/6000 defective

Initializing error

Electrode connection missing/

electrode cable is insufficiently

screened

1. Pulsating flow

2. Conductivity of medium

too low

3. Electrical noise potential

between medium and

sensor

4. Air bubbles in medium

P40

P44

Loss of totalizer

data

#####

Signs in display

Remedy

Measuring pipe empty

Empty pipe cut-off is OFF

Unstable

Maximum

Cause

W20

5. High concentration of particles or fibres

Incorrect installation

No SENSORPROM unit

CT SENSORPROM unit

Deficient SENSORPROM unit

Wrong type of SENSORPROM

unit

Deficient SENSORPROM unit

Loss of internal data

Flow exceeds 100% of Qmax.

Pulse overflow

Volume/pulse too small

Pulse width too large

Missing one electrode

connection

Initializing error

Totalizer roll over

Ensure sufficient potential

equalization

Ensure medium does not

contain air bubbles

Increase time constant

Check installation

Install SENSORPROM unit

Replace SENSORPROM unit

or reset SENSORPROM unit

with MAG CT transmitter

Replace SENSORPROM unit

Replace SENSORPROM unit

Replace SENSORPROM unit

Replace MAG 5000/6000

Check Qmax. (Basic Settings)

Change volume/pulse

Change pulse width

Check cables

Reset totalizer manually

Reset totalizer or increase

totalizer unit

We have checked the contents of this manual for agreement with the hardware and

software described. Since deviations cannot be precluded entirely, we cannot guarantee

full agreement. However, the data in this manual are reviewed regularly and any

necessary corrections included in subsequent editions. Suggestions for improvement

are always welcomed.

The reproduction, transmission or use of this document or its contents is not permitted without

express written authority.

Offenders will be liable for damages. All rights, including rights created by patent grant or

registration of a utility model or design, are reserved.

Technical data subject to change without prior notice.

Copyright Siemens AG 03.2004 All Rights Reserved

Siemens Flow Instruments A/S

Nordborgvej 81

DK-6430 Nordborg

Order no.: FDK:521H0739-02

Printed in: Denmark

16

SFIDK.PS.027.Z5.02

S-ar putea să vă placă și

- Agile: Operating Instructions Frequency Inverter 230V / 400V 0.25 KW ... 11 KWDocument20 paginiAgile: Operating Instructions Frequency Inverter 230V / 400V 0.25 KW ... 11 KWrollinga2013Încă nu există evaluări

- Op MFM384 MFM384-C Op347-V05Document4 paginiOp MFM384 MFM384-C Op347-V05Lyle ThompsonÎncă nu există evaluări

- St420 Users Manual Rev DDocument4 paginiSt420 Users Manual Rev DSherif M. DabourÎncă nu există evaluări

- Programmable In-Head Universal Temperature Transmitter ConfigurationDocument5 paginiProgrammable In-Head Universal Temperature Transmitter ConfigurationjhuskanovicÎncă nu există evaluări

- DVP Slim Digital I/O Extension Instruction SheetDocument2 paginiDVP Slim Digital I/O Extension Instruction SheetBustamante PerroneÎncă nu există evaluări

- UVTron Driver Hamamatsu C10423Document6 paginiUVTron Driver Hamamatsu C10423Agam ArlandoÎncă nu există evaluări

- Felcom15 InstalDocument50 paginiFelcom15 Instaltoumassis_pÎncă nu există evaluări

- IL410, IL4108 Optocoupler DatasheetDocument9 paginiIL410, IL4108 Optocoupler DatasheetDinesh KumarÎncă nu există evaluări

- Encoder PSCDocument2 paginiEncoder PSCMarco AbrilÎncă nu există evaluări

- Instalation ManualDocument9 paginiInstalation Manualjoseluisrosglz1678Încă nu există evaluări

- OnkyoC701A JP SMDocument21 paginiOnkyoC701A JP SMHelder MartinsÎncă nu există evaluări

- 3A Low Dropout Voltage Regulator DatasheetDocument9 pagini3A Low Dropout Voltage Regulator DatasheetRobertoJavierAÎncă nu există evaluări

- SMD ManualDocument8 paginiSMD ManualJose K ManadanÎncă nu există evaluări

- GP1U77R Sreies: Remote Control IR Detecting Unit ForDocument4 paginiGP1U77R Sreies: Remote Control IR Detecting Unit Forjulius999Încă nu există evaluări

- RX 4m50rr30sfDocument4 paginiRX 4m50rr30sfGina HarringtonÎncă nu există evaluări

- High Accuracy, Low I, Anycap Adjustable Low Dropout RegulatorDocument12 paginiHigh Accuracy, Low I, Anycap Adjustable Low Dropout Regulatortrillion5Încă nu există evaluări

- Features Description: D D D D D D D D D D D DDocument16 paginiFeatures Description: D D D D D D D D D D D D1eugen1Încă nu există evaluări

- TDA2008Document10 paginiTDA2008miusayÎncă nu există evaluări

- MTL7000 SeriesDocument13 paginiMTL7000 SeriesquocvttÎncă nu există evaluări

- IR Receiver Modules GuideDocument7 paginiIR Receiver Modules Guidestari692002Încă nu există evaluări

- E550 Seri 2Document10 paginiE550 Seri 2waterrock123Încă nu există evaluări

- Advanced Monolithic Systems: Features ApplicationsDocument8 paginiAdvanced Monolithic Systems: Features ApplicationsAndres AlegriaÎncă nu există evaluări

- Features Description: LT3085 Adjustable 500ma Single Resistor Low Dropout RegulatorDocument28 paginiFeatures Description: LT3085 Adjustable 500ma Single Resistor Low Dropout Regulatoram1liÎncă nu există evaluări

- 177232D1Document6 pagini177232D1Muhammad Usman SindhuÎncă nu există evaluări

- Moc 3052Document11 paginiMoc 3052Haidu Ionut SebastianÎncă nu există evaluări

- Receptor IR TSOP4836Document7 paginiReceptor IR TSOP4836damijoseÎncă nu există evaluări

- 1 Performance DataDocument9 pagini1 Performance DataYusep KurniaÎncă nu există evaluări

- SIM-Q, Installation Instructions 4189330016 UKDocument9 paginiSIM-Q, Installation Instructions 4189330016 UKAndrei KrivdaÎncă nu există evaluări

- ADP3338 Data SheetsDocument16 paginiADP3338 Data SheetstarpinoÎncă nu există evaluări

- N219 Distances between the Receiver and the TransmitterDocument8 paginiN219 Distances between the Receiver and the Transmitterdumitrescu viorelÎncă nu există evaluări

- Op To CouplerDocument10 paginiOp To CouplerDiogoVasconcelosÎncă nu există evaluări

- KFD2 VR4 EX1.26 196355 EngDocument4 paginiKFD2 VR4 EX1.26 196355 EngDurgaram JayavananÎncă nu există evaluări

- Transformerless Inverters Powador 10.0 TL3 to 14.0 TL3Document3 paginiTransformerless Inverters Powador 10.0 TL3 to 14.0 TL3Nikolai MravovÎncă nu există evaluări

- SMP1320 Series: Low Resistance, Low Capacitance, Plastic Packaged PIN DiodesDocument11 paginiSMP1320 Series: Low Resistance, Low Capacitance, Plastic Packaged PIN DiodesAnonymous CGk2roÎncă nu există evaluări

- Two Colours System FDocument19 paginiTwo Colours System FRiccardo SuzziÎncă nu există evaluări

- Model Paxlsg - Pax Lite Strain Gage Meter / Millivolt Meter: C Us Listed Us ListedDocument8 paginiModel Paxlsg - Pax Lite Strain Gage Meter / Millivolt Meter: C Us Listed Us ListedJosé Tomas CisnerosÎncă nu există evaluări

- DVP-Slim Digitai IO Module Instruction SheetDocument2 paginiDVP-Slim Digitai IO Module Instruction SheetAgnimuthuÎncă nu există evaluări

- Dvpes2 ManualDocument10 paginiDvpes2 Manualmarie1320Încă nu există evaluări

- Circuito Integrado TA8207KDocument11 paginiCircuito Integrado TA8207KIberê CamposÎncă nu există evaluări

- MC-300 CD - Service ManualDocument28 paginiMC-300 CD - Service ManualMilorad Pajovic100% (1)

- Datasheet ET1100Document10 paginiDatasheet ET1100Manal FeghaliÎncă nu există evaluări

- DatasheetDocument10 paginiDatasheettenisonÎncă nu există evaluări

- Stefan Mayer Instruments: - February 2018Document10 paginiStefan Mayer Instruments: - February 2018SaadÎncă nu există evaluări

- KFD2-CD-Ex1.32 104204 EngDocument3 paginiKFD2-CD-Ex1.32 104204 EngnileshsbodkeÎncă nu există evaluări

- Inversor Abb 2 5kwDocument2 paginiInversor Abb 2 5kwapi-290643326Încă nu există evaluări

- TSOP382.., TSOP384.., TSOP392.., TSOP394..: Vishay SemiconductorsDocument7 paginiTSOP382.., TSOP384.., TSOP392.., TSOP394..: Vishay SemiconductorssickdogÎncă nu există evaluări

- Em6438 6436 Dual Quick Start GuideDocument10 paginiEm6438 6436 Dual Quick Start GuideReji KurianÎncă nu există evaluări

- Conzerv 6438Document10 paginiConzerv 6438Pur WantoÎncă nu există evaluări

- Midas Venice ManualDocument29 paginiMidas Venice Manualcb4pdfsÎncă nu există evaluări

- Datasheet DM12Document9 paginiDatasheet DM12dff1967dffÎncă nu există evaluări

- KFD2 RR Ex1Document4 paginiKFD2 RR Ex1goparsucoÎncă nu există evaluări

- STX882 Catalogue: High Power Low Cost ASK Transmitter ModuleDocument7 paginiSTX882 Catalogue: High Power Low Cost ASK Transmitter ModuleCsaba CsehÎncă nu există evaluări

- Time Control Technique: Timer MK 9906N, On Delayed MinitimerDocument4 paginiTime Control Technique: Timer MK 9906N, On Delayed MinitimerKim Hảo Hoàng NguyễnÎncă nu există evaluări

- PXT Series Pressure Transmitters Installation Instructions: WarningDocument2 paginiPXT Series Pressure Transmitters Installation Instructions: WarningFred JonesÎncă nu există evaluări

- Data Sheet: 2 X 6 W Stereo Car Radio Power AmplifierDocument10 paginiData Sheet: 2 X 6 W Stereo Car Radio Power Amplifierazzeddine_a7601Încă nu există evaluări

- Orion Tv5532si - Oecf010a, Stv2247c - TV SMDocument34 paginiOrion Tv5532si - Oecf010a, Stv2247c - TV SMGsmHelpÎncă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Evaluare: 2.5 din 5 stele2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Încă nu există evaluări

- QUALITY CONSCIOUSNESS PRINCIPLESDocument47 paginiQUALITY CONSCIOUSNESS PRINCIPLESJames Lao TapiaÎncă nu există evaluări

- DX LogDocument27 paginiDX LogCristian96TÎncă nu există evaluări

- Ch2 (3) Handouts 3e PDFDocument10 paginiCh2 (3) Handouts 3e PDFAnonymous eiYUGFJZ3iÎncă nu există evaluări

- Pass 300-115 Exam With The Help of Examcollection DumpsDocument12 paginiPass 300-115 Exam With The Help of Examcollection DumpsjackÎncă nu există evaluări

- Other Emerging Technologies: Chapter SevenDocument57 paginiOther Emerging Technologies: Chapter SevenGetachew HussenÎncă nu există evaluări

- Foot of The Mountains v8 PDFDocument53 paginiFoot of The Mountains v8 PDFReza Saputra40% (10)

- Microservices With Spring Boot and Spring Cloud - Build Resilient and Scalable MicroservicesDocument775 paginiMicroservices With Spring Boot and Spring Cloud - Build Resilient and Scalable MicroservicesGandikota SrinivasÎncă nu există evaluări

- Explore Usage of Basic Linux Commands and System Calls For File, Directory and Process ManagementDocument10 paginiExplore Usage of Basic Linux Commands and System Calls For File, Directory and Process ManagementAmruta PoojaryÎncă nu există evaluări

- Cs 7200Document21 paginiCs 7200Bio Eng Eslam TahaÎncă nu există evaluări

- DSP Unit 5Document34 paginiDSP Unit 5Maggi FelixÎncă nu există evaluări

- Underwriting Case Study: Tcs IlpDocument16 paginiUnderwriting Case Study: Tcs IlpsrujanaÎncă nu există evaluări

- CIS552 Indexing and Hashing 1Document56 paginiCIS552 Indexing and Hashing 1Vinay VarmaÎncă nu există evaluări

- Software Validation TemplateDocument8 paginiSoftware Validation TemplateHouser_BRÎncă nu există evaluări

- TLE 7 1st Quarter Exam SY 2022-2023Document3 paginiTLE 7 1st Quarter Exam SY 2022-2023dodongmakattigbasÎncă nu există evaluări

- Technical Application AND Programming GuideDocument44 paginiTechnical Application AND Programming GuideHasib KhanÎncă nu există evaluări

- 20BCS7358 CC Exp.5Document4 pagini20BCS7358 CC Exp.5Shudhashekhar DasÎncă nu există evaluări

- 3D Animator User GuideDocument85 pagini3D Animator User GuidecarlcoxÎncă nu există evaluări

- Polymorphism Interview Questions and AnswersDocument16 paginiPolymorphism Interview Questions and Answerssureshroopa2k15Încă nu există evaluări

- The Best Open Source Project Management Tool Zentao 2020Document4 paginiThe Best Open Source Project Management Tool Zentao 2020wajid hussainÎncă nu există evaluări

- MS Excel 2010 Level 3 1687164237Document32 paginiMS Excel 2010 Level 3 1687164237Jota PoyoÎncă nu există evaluări

- DMC Card 00180020430723Document2 paginiDMC Card 00180020430723jotu sheelaÎncă nu există evaluări

- Setting Up DB2 With TSMDocument5 paginiSetting Up DB2 With TSMprakash_6849Încă nu există evaluări

- MQ Managed File Transfer OverviewDocument72 paginiMQ Managed File Transfer OverviewfreddyandresÎncă nu există evaluări

- TreemacsDocument4 paginiTreemacsBaishampayan GhoseÎncă nu există evaluări

- Social Media Marketing Overview: Benefits and StrategyDocument3 paginiSocial Media Marketing Overview: Benefits and StrategyFarah TahirÎncă nu există evaluări

- A New Approach: Data Segregation ModelDocument3 paginiA New Approach: Data Segregation ModelEditor IJRITCCÎncă nu există evaluări

- SAP Workflow and Events - Control The Flow!Document35 paginiSAP Workflow and Events - Control The Flow!AMRÎncă nu există evaluări

- AirScale RNC Product DescriptionDocument46 paginiAirScale RNC Product Descriptionsamir YOUSIF100% (1)

- Image Processing CLO - Segmentation ThresholdingDocument2 paginiImage Processing CLO - Segmentation ThresholdingShridhar DoddamaniÎncă nu există evaluări

- Need of Cloud in DevOpsDocument17 paginiNeed of Cloud in DevOpsSuneetha BullaÎncă nu există evaluări