Documente Academic

Documente Profesional

Documente Cultură

Patent US7501725 - Method of Converting Piston Driven Engines To Operate On Electricity - Google Patents

Încărcat de

MahendraMeenaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Patent US7501725 - Method of Converting Piston Driven Engines To Operate On Electricity - Google Patents

Încărcat de

MahendraMeenaDrepturi de autor:

Formate disponibile

4/21/2015

PatentUS7501725MethodofconvertingpistondrivenenginestooperateonelectricityGooglePatents

Signin

Patents

Application

Grant

Findpriorart

Discussthispatent

ViewPDF

DownloadPDF

Methodofconvertingpistondrivenenginesto

operateonelectricity

Publicationnumber

Publicationtype

Applicationnumber

Publicationdate

Filingdate

Prioritydate

Feestatus

US7501725B2

Grant

US11/507,318

Mar10,2009

Aug21,2006

Aug21,2006

Paid

Alsopublishedas

US20080042497

Inventors

StephenPatrickParker

SolenoidTube(13)orDLST(13)isfittedwithflangesapproximatelyoneachend

OriginalAssignee

SteveParker

andinthemiddle,andiswoundwithsuitablewireinlayersfromendflangesto

ExportCitation

BiBTeX,EndNote,RefMan

middlemakingtwoseparatemagneticcoilsontheDLST(13)abar,whichcan

betemporarilymagnetized,foridentificationpurposesiscalledthepower

PatentCitations(19),Referencedby(7),Classifications(9),

LegalEvents(1)

magnet,PM(16)isattachedtoarod,whichcannotbemagnetized,for

ExternalLinks:USPTO,USPTOAssignment,Espacenet

US7501725B2

ABSTRACT

Amethodofconvertingpistondrivenenginestooperateonelectricity.Thehead

isremovedfromtheengine.Asolenoidtube,approximatelytwiceaslongasthe

strokeoftheenginepiston,foridentificationpurposes,calledaDoubleLength

identificationpurposes,calledthePowerRod,PR(21)isfastenedtothetopof

theenginepiston(31).Whentheenginepiston(31)approachesTopDead

Center,TDC,thePM(16)isinthetophalfoftheDLST(13)approximatelyatthispositionthebottommagneticcoil(85)isenergizedpullingthePM(16)andthePR

(21)downpushingtheenginepiston(31)downturningthecrankshaft(34)from0degreeto180degrees.Whentheenginepiston(31)isatBottomDeadCenter,

BDC,thePM(16)isasclosetothecenterofthecrankshaft(34)asitcanbe.Thetopcoilisenergized,magneticallypullingthePM(16)thePR(21)andtheengine

piston(31)upturningthecrankshaftfrom180degreesto360degrees,completingthecycle.Therefore,byusingadoublelengthsolenoidtubewithtwocoils,a

solenoidmagnetbar16pushesdownonthedownstrokeandpullsupontheupstroketotheenginepistondeliveringpowertothecrankshaftoneverystroke.Included

inspecificationsisanelectricalswitchingsystem,twocoolingsystemsandalubricationsystem.Thismethodcanbeappliedtoanypistondrivenengine.

IMAGES (7)

DESCRIPTION

CLAIMS (1)

CROSSREFERENCETORELATEDAPPLICATIONS

1.Amethodofconvertingpistondrivenenginestooperateonelectricity,

Notapplicable

FEDERALLYSPONSOREDRESEARCH

Notapplicable

comprising:

(a)providingadoublelengthsolenoidtubehavingapproximatelytwiceas

longasalengthofastrokeofanenginepiston,andbeingfittedwithflanges

coveringtheenginecylinder,thedoublelengthsolenoidtubeisfastened

withflangeswhereinamiddleofthedoublelengthsolenoidtubeatleastone

SEQUENCELISTINGORPROGRAM

Notapplicable

FIELDOFTHEINVENTION

Theinventionrelatestoconvertingpistondrivenenginestooperateonelectricity.

flangehasholesdrilledtoalignandfastenoveranenginecylindertoan

engineblock

(b)providingwirewoundinlayersaroundthedoublelengthsolenoidtubeto

formtwoseparatemagnetictopandbottomcoils,whereinthetopcoilis

farthestawayfromatopoftheengineblock,thebottomcoilisclosetothe

topoftheengineblock,

BACKGROUNDOFTHEINVENTION

(c)providingamagnetizablebarhavingapproximatelysamelengthasthe

Thegrowingenergycrisishascausedmanypeopletotrytoconvertgasoline

lengthofthestrokeoftheenginepiston,andpredeterminedsizeandweight

enginestorunbatteries.Idiscoveredamethodtoconvertagardentractorengine

sothatsaidmagnetizablebarabletoturnthecrankshaft,assaid

tooperateonacarbattery.ThenIhadapatentsearchmade.Ihadnotbeen

magnetizablebarslidesbackandforth,fromsaidtopcoiltosaidbottomcoil

influencedbyotherinventions.Severalpatentsregardingelectrifyingengines

http://www.google.com/patents/US7501725

1/8

4/21/2015

PatentUS7501725MethodofconvertingpistondrivenenginestooperateonelectricityGooglePatents

havebeengranted.MyinventiondiffersfromallIsawinseveralways.Ifound

inthedoublelengthsolenoidtube,whereinsaidmagnetizablebar,hasat

nopatentusingadoublelengthsolenoidtubehavingtwoseparatecoilsto

leastonering,aroundoutsideend,slidingagainstaninsidesurfaceofthe

producepoweronthedownstrokeandtheupstroke.Ifoundnopatentsusing

doublelengthsolenoidtube

theflywheelorcrankshaftpulleytohostdevicesusedinelectricalswitching

systemstohavethemagnetspullingoneverystroke.Ifoundnopatentsthat

claimedtohaveaworkingmodel.Myconversionmethoddoesalloftheabove

listed,andtheconversioncanbemadewithpartseasilyobtainable.

SUMMARYOFTHEINVENTION

(d)providinganonmagneticrodhaving,approximatelysamelengthaslength

ofstrokeoftheenginepiston,whereinoneendofthenonmagneticrodis

fastenedtoanendofthemagnetizablebarandtheotherendofthe

nonmagneticrodisfastenedtothetopoftheenginepiston

(e)providingasetoftwoflywheelswitchesforeachcoilorpluralityofcoils,

Amethodofconvertingpistondrivenenginestooperateonelectricity.This

saidflywheelswitchesarefastenedtotheflywheelorcrankshaftpulley,

methodcanbeusedonalternatingcurrent,AC,ordirectcurrent,DC,onengines

approximately180degreesapartacrossadiameteroftheflywheelor

withanynumberofpistons.Themeansofprovidingthisconversionisbymaking

crankshaftpulley,

asolenoidtubeapproximatelytwicethelengthofthestrokeoftheenginepiston.

Thedoublelengthsolenoidtubeiswoundwithsuitablewiretwoseparate

magneticcoilsarewoundfromapproximatelyoppositeendstothemiddle.Abar,

whichcanbetemporallymagnetizedandisapproximatelythelengthofthe

strokeoftheenginepiston,isconnectedatoneendtoarod,whichcannotbe

magnetizedtheotherendoftherod,isconnectedtothetopoftheengine

piston.Thelengthoftherodisapproximatelythelengthofthestrokeofthe

enginepiston.Thedoublelengthsolenoidtubeisfastenedoveracylinderifa

pluralityofcylindersareused,eachshouldhaveitsownapproximatelydouble

lengthsolenoidtube.Whenthebarisinthetoppartofthetube,thebottomcoil

isenergizedpullingthebarintothebottompartofthedoublelengthsolenoid

tube,pushingtheenginepistondown,turningthecrankshaft180degrees,when

thebaranditspistonconnectionsareinthebottompartofthedoublelength

(f)placingadjustablepickupsneartheflywheelforprovidingameansto

energizevoltageamplifierssothatsaidvoltageamplifiersenergizethe

magnetictopandbottomcoils,whereintheflywheelswitchesdetermine

whichcoilsareturnedontoenergizeandpullthemagnetizablebar,forcing

theenginepistondownorup,turningoneofacrankshaft,theflywheeland

crankshaftpulley,forprovidingameanstoturnelectricalimpulsefromthe

flywheelswitches,astheflywheelorcrankshaftpulleyturnandincreaseor

decreaseinspeed,whereinpositionofsaidadjustablepickupscanbe

changedbyoneofamechanicalmeans,usingacomputerand

microprocessortomonitoraspeedoftheengineandanelectricalflowand

otherfactors,anddetermineeitheradvanceorretardpositionofthe

adjustablepickups,

solenoidtube,thetopcoilisenergized,pullingthebaranditspistonconnections

(g)providingameansfortakingkineticenergy,causedbytheweightofthe

up,turningthecrankshaftcompletelythe360degreecycle.Theenginepistonor

magnetizablebarandthenonmagneticrodinmotionattheendofeach

pistonsandthecrankshaftareunderworkingpressurefromeachpiston,almost

strokebydeenergizing,turningoffelectricitytooneworkingcoilofsaidtop

allthetime.

andbottomcoilsthatmagnetizingthemagnetizablebar,beforethebar

BRIEFDESCRIPTIONOFTHEDRAWINGS

FIG.1,thepreferredembodiment,showsahalfsectionviewoftheblockofa

fourcylinderenginewithadoublelengthsolenoidtubeaboveeachcylinder,with

twoseparatecoilswoundaboutthetubes,asmallcoolingtubemarkedwith

verticallines,iswoundwithcoils:thebasicelectricalsystemisalsoshown.

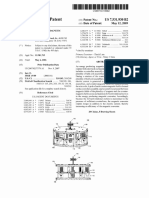

FIG.2showsahalfsectionviewoftheblockofafourcylinderenginewitha

doublelengthsolenoidtubeaboveeachcylinderwithtwoseparatelywoundcoils,

woundaroundthetube,aircoolingtubesareplacedaroundthecoilstocool

them,thebasicelectricalsystemisalsoshown.

reachestopdeadcenter,thatpointinrotationalcycle,

wherethemagnetizablebarbeingfarawayfromthecenterlineandbeing

energizing,turningonelectricitytothebottomcoil,beforethemagnetizable

bar,slidinginthedoublelengthsolenoidtube,reachestopdeadcenter,the

kineticenergycanbeminimizedfromthemagnetizablebar,the

nonmagneticrod,thepistonandconnectingrodthereofwhilehavefullpower

approximatelengthofadownstroke

likewise,whenthemagnetizablebarapproachesbottomdeadcenter,the

workingcoilisdeenergizedandthetopcoilisenergizedbeforebottomdead

center,thekineticenergycanbeminimizedfromthemagnetizablebar,the

FIG.3aperspectiveviewwithcutaways,showingonedoublelengthsolenoid

nonmagneticrod,thepistonconnectingrodthereofwhilehavefullpower

withitsparts,oneenginecylinderwithitsparts,andtheconnectiontothe

approximatelengthofaupstroke

crankshaft.

(h)providingameansforcooling,bywindingsmallflexiblecoolingtubes

FIG.4anexplodedviewshowingthedoublelengthsolenoidtube,thecoilsthe

withsaidwireorbywindinginbetweenthelayersofsaidwiresaidsmall

powermagnet,thepowerrod,theenginepistonandconnectingrodalsoshown

flexiblecoolingtubecanbefastenedtoenginecoolingsystemprovidinga

(notclaimed)isasystemIusedtoaligntheflangestothetubepriortosoldering.

meanstocoolthetopandbottomcoils,orarefrigerantcanbepumped

FIG.5anelectricalsystemshowingaflywheelwithswitchingdevicesattached,

depictingbydotswhatcircuitsareenergizedduringthefirst180degreesturning

oftheflywheel.

throughthesaidflexiblecoolingtubeprovidinganalternatemeanstocool

thetopandbottomcoils

(i)providingaircoolingforaircooledengines,thecoolingtubeshavingsame

FIG.6anelectricalsystemshowingaflywheelanddepictingbydotswhat

circuitsareenergizedduringthe2nd,180degreeturningtothe360degreeturning

oftheflywheel.

asthelengthofthedoublelengthsolenoidtubeareplacedaroundthe

outsideofthetopandbottomcoils,throughthesolenoidflanges,said

coolingtubeshaveonewayvalvesfixedintoabottomthereof,

approximatelyhalfofthesaidcoolingtubeshaveonewayairintakevalves

andhalfofthesaidcoolingtubeshaveonewayexhaustvalveshaveholes

DRAWINGSReference

alongonesideofsaidcoolingtubes,saidholesfacethesaidtopandbottom

numerals

coilssothatcoolingaircanbeblownontothesaidtopandbottomcoils

7onewayoil/air/intakevalve

8onewayoil/airexhaustvalve

http://www.google.com/patents/US7501725

whereinthesaidcoolingtubeswithsaidonewayintakevalvescanhave

holesalongonesideorwiththetopthereofopentofacilitatepassageofair

intosaidcoolingintaketubes

2/8

4/21/2015

PatentUS7501725MethodofconvertingpistondrivenenginestooperateonelectricityGooglePatents

9onewayairintakevalve

whenthesaidenginepistongoesdown,airispulledintosaidcoolingtubes,

10onewayairexhaustvalve

throughthesaidonewayintakevalvesintosaidenginecylinder,

11heatswitch

whenthesaidenginepistongoesup,saidonewayintakevalvesclose,air

12oilairtubeflange

ispushedupthroughthesaidonewayexhaustvalvesintosaidexhaust

13doublelengthsolenoidtube

coolingtubesthroughthesaidholesontothesaidtopandbottomcoils

14suitablecoilwire

15groundedwire

providingcoolingmeanstocoolthetopandbottomcoilsof,especially

whereanaircooledengineisconverted,

16powermagnet

(j)providingameansforlubricationandcoolinginsideofthetopofthe

17powermagnet

doublelengthsolenoidtube,saidtopisfarthestawayfromthecenterlineof

18powermagnet

19powermagnet

20oilairring

21powerrodmadeofnonmagneticmaterial

22threadednut

thecrankshaft,wherebysaidmagnetizablebarhassaidatleastonering

aroundthetopendbeingfarthestfromthecenterlineofthecrankshaft,said

atleastoneringhelpscentersaidbarinsaiddoublelengthsolenoidtube,

andsealsaidinnertoppartofsaiddoublelengthsolenoidtube,

whereinthedoublelengthsolenoidtubehasanoilairflangeputonthetop

endthereof,saidoilairflangehastwoormoresmallertubesfastenedto

23connectingrodbetweenenginepistonand

saidflange,anexhausttube,onewayexhaustvalve,fixedinsidesaid

crankshaft

smallertubesandroutedtoventintothecrankcase,atleastoneintaketube

24crankshaftlobe

isfastenedtooilairflange,saidatleastoneintaketubehasaoneway

25allthreadrod

intakevalveisfixedinsidethereto,saidatleastoneintaketubeisventedto

26enginecylinder

27oilairmistadjustingscrew

ambientairandplacedadjacenttoanoilsupplytubewithadevice

therebetweentocausetheoiltomixwiththeaircausinganoilairmist,

28smallliquidcoolingtube

whensaidmagnetizablebar,withsaidatleastoneringisinthetoppartof

29airintakecoolingtube

thedoublelengthsolenoidtube,saidbottomcoilisenergizedpullingdown

30airexhaustcoolingtube

31enginepiston

themagnetizablebar,withsaidatleastoneringsaidmagnetizablebarpulls

ambientairintotheoilairintaketube,pastsaiddevice,pullingdropletsofoil

fromanoilsupplysource,theoilandairformanoilairmist,beingpulled

32wristpin

intoupperpartofthedoublelengthsolenoidtubelubricatingandcoolingthe

33solenoidflange

toppartofsaiddoublelengthsolenoidtube,

34crankshaft

whensaidmagnetizablebartravelstobottomdeadcenter,inthedouble

35crankcase

lengthsolenoidtubeandstartsbackupinsaiddoublelengthsolenoidtube,

36crankshaftpulley

saidmagnetizablebarsaidatleastonering,pushtheoilairmistoutthe

37enginepistoncompressionring

onewayexhaustvalve,throughthesaidexhaustpipes,intothecrankcase,

38enginepistonoilring

completingthecycle,

39flywheelcover

(k)placingthemagnetizablebarinthetopofthedoublelengthsolenoid

40flywheel

tube,andenergizingthebottomcoilthatpullsthemagnetizablebartothe

41fuse

bottompartofthedoublelengthsolenoidtube,pushingtheenginepiston

42voltageamperageamplifierwiredtoadjustable

pickup46

43voltageamperageamplifierwiredtoadjustable

pickup47

down,turningthecrankshaft180degrees,whenthemagnetizablebarand

saidenginepistonareallthewaydown,thetopcoilisenergized,pullingthe

barandenginepistonup,turningthecrankshaftfrom180degreesto360

degreescompletingthecycle.

44voltageamperageamplifierwiredtoadjustable

pickup48

45voltageamperageamplifierwiredtoadjustable

pickup49

46adjustablepickupoppositeflywheelswitch52

and72

47adjustablepickupoppositeflywheelswitch53

and73

48adjustablepickupoppositeflywheelswitch54

and74

49adjustablepickupoppositeflywheelswitch55

and75

50oilairintaketube

51oilairexhausttube

52Nflywheelswitchon

http://www.google.com/patents/US7501725

3/8

4/21/2015

PatentUS7501725MethodofconvertingpistondrivenenginestooperateonelectricityGooglePatents

53Nflywheelswitchon

54Fflywheelswitchoff

55Fflywheelswitchoff

60battery

61ignitionswitchapparatus

62pedalvoltageamperagecontroller

63mainelectricalsourcesupplywire

64computer

65engineblock

66enginefan

67airshroud

68airfilter

70oilsupplytube

71valveseat

72Fflywheelswitchoff

73Fflywheelswitchoff

74Nflywheelswitchon

75Nflywheelswitchon

77supplywire

78startermotorhole

80topmagneticcoil

81topmagneticcoil

82topmagneticcoil

83topmagneticcoil

85bottommagneticcoil

86bottommagneticcoil

87bottommagneticcoil

88bottommagneticcoil

DETAILEDDESCRIPTIONOFTHEINVENTION

TurningnowtoFIG.1,adetaileddescriptionconcerningbasiccomponentsofaconventionalinternalcombustionengineas

wellasthecomponentsformodifyingtheinternalcombustionenginetofacilitateconversionintoanelectricaldrivenengine

willnowbeprovided.AscanbeseeninFIG.1theinternalcombustionenginecomprisesanengineblock65,whichhasa

desirednumberofcylinderbores26,formedtherein,e.g.inthisFIG.1therearefourcylinderbores.Eachcylinderbore26,

hasaninwardlyfacingsurface,whichissizedtohaveacloseslidingfitwithamatingoutwardlyfacingsurfaceofmating

piston31.Eachpiston31,typicallyhastwospringbiasedloweroilrings38,andtwospringbiasedcompressionrings37,

whicharepositionedbetweentheoutwardlyfacingsurfaceoftheenginepistons31andtheinwardlyfacingsurfaceofthe

cylinderbore26.Theoilrings38slideagainsttheinwardlyfacingsurfacesofthecylinderbores26,asthepistons31,move

backandforthwithinthecylinderbores26,duringtheoperationoftheengineandseparatetheoilintheenginefromthetop

ofthecylinderbores26.

Alowerportionofeachpiston31ispivotallyconnectedtoacentralcrankshaft34,byaconnectingrod23,atthecrankshaft

lobe24,inaconventionalmanner,asiswellknownintheart.Thecentralcrankshaft34suppliesoutputdrivingpowerfor

theenginetodriveashaft(notshown).Inaconventionalmannereachoneofthefourpistons31issimilarlyconnectedwith

thecrankshaft34(partiallyshown),atadesiredspacingalongthecrankshaft34,byanassociatedconnectingrod23.

Thecrankshaft34iscoupledtoaflywheel40,andthecrankshaftpulley36inaconventionalmanner.Theconventional

internalcombustionengine65isalsoprovidedwithaninternaloilpump(notshown),whichprovideslubricatingoil,located

inthebottomportionoftheoilpan(notshown).Theoilpumpsuppliesoiltothemovingcomponentsoftheinternal

combustionenginetokeepthosecomponentssufficientlylubricatedduringtheoperationoftheengine,asisconventially

doneintheart.Assuchteachingiswellknownintheart,afurtherdetaileddiscussionconcerningthesameisnotprovided.

Nowthatthebasiccomponentsoftheinternalcombustionenginehavebeenbrieflydescribed,adetaileddescription

concerningmodificationoftheengine65accordingtotheteachingforthepresentinvention,willnowbeprovided.

ToconvertapistondrivenenginetooperateonelectricitywemustfirstfindtheLengthofStroke,LOS,oftheenginepiston.

http://www.google.com/patents/US7501725

4/8

4/21/2015

PatentUS7501725MethodofconvertingpistondrivenenginestooperateonelectricityGooglePatents

Removetheheadoftheengine.MeasuretheLOSoftheenginepiston31,thatisthedistancetheenginepiston31,travels

intheenginecylinder26,fromTopDeadCenter,TDC,wherethetopoftheenginepiston31,isnearthetopoftheengine

cylinder26,andisasfarawayfromthecenterlineoftheenginecrankshaft34asitcanbe,untilittravelsdowntheengine

cylinder26,toBottomDeadCenter,BDC,wherethetopoftheenginepiston31,isasclosetothecenterlineoftheengine

crankshaft34asitcanbe.Thentheenginepiston31isidentifiedasbeingatBDC.TheLOSdeterminesthelengthofthree

ofthemaincomponentsoftheconversionofthepistonengine31tooperateonelectricity.TheLOSwillbethesameforall

pistons31,inthesameengine65.ThelengthofthesolenoidtubeisapproximatelytheLOSmultipliedby2.ADouble

LengthSolenoidTube,DLST13hasflanges33,fastenedapproximatelyateachendandinthemiddleoftheDLST13,

theseflanges33arelargeenoughtocovertheenginecylinder26withatleastoneflange33,havingholesdrilledinitto

alignandfastenitovertheenginecylinder26,totheengineblock65,headboltholes.

ThelengthofanyoftheDLST13isapproximatelytheLOSmultipliedby2,eachDLST13has2separatecoilsofsuitable

wire14,woundfromoppositeendflanges33,tothemiddleflange33inlayers.Thetopmagneticcoils80,81,82,83are

farthestawayfromthetopoftheengineblock65astheycanbe.Thebottommagneticcoils85,86,87,88areascloseto

thetopoftheengineblock65astheycanbe.

Themainsourceofelectricitycanbealternatingcurrent,AC,ordirectcurrent,DC,inthisexample,abattery60,which

provideselectricalflowthroughtheignitionswitchapparatus61,throughthepedalvoltageamperagecontroller62,through

themainelectricalsourcesupplywire63,throughthevoltageamplifiers42,43,44,45,herethevoltagecanbeincreasedas

itisdistributedtothesupplywires.Thevoltageamplifiers,electronicdevices,whichcanalsoworkinconjunctionwitha

computer64ormicroprocessor64sothatthespeedoftheengine,RevolutionsPerMinute,RPM,andtheamperagedraw

(electricalflow),andotherfactors,canbeusedtodeterminetheadvancementorretardationofthetimingpositionofthe

adjustablepickups46,47,48,49.Theadjustablepickupscanbepositionedthroughtheemptystartermotorhole78,

providingaccesstotheflywheel40,sincethereisnoneedforthestartermotorinthisconversion.Avacuumcanbetaken

fromtheoilairintaketube50tooperateamechanicaladvancesimilartothatusedonthedistributorofsomeconventional

engines.FIG.3depictsaperspectiveviewwhichportraystheapproximateplacementoftheadjustablepickups46,47,48,

49throughthestartermotorhole78.FIG.4depictsanexplodedviewofthemainpartsofaconversionunit.Thethreaded

nuts22androd21,usestandardthreads.Therearemanyfasteningsystemsthatcanbeused.Thethreadedsystemhere

bynomeansexcludesothersystems.Thelongallthreadrods25andnuts22,areameans,notclaimed,Iusedtoinsure

accuracyofplacementwhilesolderingorwelding.

FIG.5andFIG.6depicttheswitchingpartsoftheelectricalsystem.FIG.5depictsaflywheel40,withteeth,withflywheel

switches75N,74N,73N,73F,and72Ffastenedononesideandflywheelswitches52N,53N,54F,and55Ffastenedon

thesidewheretheyaredepictedinFIG.5,directlyoppositetheadjustablePickups46,47,48,49.Whentheflywheelturns

pasttheadjustablepickups,theflywheelswitchessendanappropriateelectricalimpulsetotheadjustablepickups46,47,

48,49whichinturnsendanappropriateelectricalimpulsetothevoltageamplifiers42,43,44,45whichcontrolthevoltage

andamperagefromthemainelectricalsource.

Abar,whichcanbetemporarilymagnetized,isapproximatelytheLOSandfitslooselyintotheDSLT13,thetopendof

eachbarisfittedtoaccommodateanoilairring20orrings20,theotherendofthebar,thebottomendisfittedto

accommodatearodwhichisconnectedattheotherendtothetopoftheenginepiston31,thebar,whichforidentification

purposesisnamedaPowerMagnet,PM,orPM16,PM17,PM18,PM19.EachPMisconnectedtoanenginepiston31,

byarod,whichcannotbemagnetized,andforidentificationpurposesisnamedaPowerRod,PR21,isapproximatelythe

LOSoftheenginepiston31,andisasstrongastheenginepistonconnectingrod23.

FIG.1,FIG.2,andFIG.3depictalubricationsystemfortheupperhalfoftheDLST13andthering20orrings20onthe

PMS'.Thesystemcomprisesaonewayoilairexhaustvalve8,anoilairexhausttube51,whichisconnectedtothe

crankcase35,aonewayoilairintakevalve7,anoilairintaketube50placednearanoilsupplytube70,whichis

connectedtoconventionalengineoilsystem,anoilairmistadjustingscrew27andits'seat71,asameanstoletdropsof

oilintotheoilairintaketube50,tomixwithairtocreateanoilairmistwhichcanbepulledintothetoppartoftheDLST13.

EachPMhasanoilairring20orrings20,whichsealthetopofthePM'stoprovideameanstocreateacompressionor

vacuuminthetophalfoftheDLST13,whenthePM'sslidebackandforthintheDLST13,asameanstopullinanoilair

mistmixtureforlubricationtothetopoftheDLST13.

Coolingthemagneticcoils80,81,82,83,85,86,87,88inFIG.1smallflexibletubes28,incoilsmarkedwithverticalslash

marks,arewoundwithsuitablewire14,orinlayerswitheachofthemagneticcoils80,81,82,83,85,86,87,88these

tubesareconnectedtotheradiatorsystemoftheengineblock65.Anyenginecoolantcanbepumpedthruthesmallflexible

tubes28,tocoolthemagneticcoils80,81,82,83,85,86,87,88,orarefrigerantcanbepumpedthruthetubingtoprovide

coolingforthemagneticcoils.

FIG.2depictstubes,withholes,inthesides,areplacedaroundtheoutsideofthemagneticcoils,thetubesarethesame

lengthastheDLST's13andconnectedtotheinterioroftheenginecylinders26byintakeonewayintakevalves9,andone

wayexhaustvalves10.Whentheenginepiston31movesdowntheenginecylinder26,airispulledintothecylinder26,the

onewayintakevalve9isopen,andtheonewayexhaustvalve10isclosed.Whentheenginepiston31movesupinthe

http://www.google.com/patents/US7501725

5/8

4/21/2015

PatentUS7501725MethodofconvertingpistondrivenenginestooperateonelectricityGooglePatents

cylinder26,theonewayintakevalve9,isclosedandtheonewayexhaustvalve10isopen,theairinthecylinder26is

pushedthroughtheexhaustvalve10,throughtheholesoftheexhaustcoolingtubes30,ontothemagneticcoils,tocool

them.

DESCRIPTIONANDFUNCTION

Themainpartofthismethodofconvertingapistondrivenengineisinmakingthesolenoidtubeapproximatelytwicethe

lengthofthestrokeoftheenginepiston,makingaDoublelengthSolenoidTube,DLST.EachDLSTiswoundwithsuitable

wiretomaketwoseparatemagneticcoils,withamainelectricalsource,inthisexample,abattery60whichprovides

electricalflowthroughtheignitionswitchapparatus61,throughthepedalvoltageamperagecontroller62,throughthemain

electricalsourcesupplywire63,throughthevoltageamplifiers42,43,44,45,herethevoltagecanbeconjunctionwitha

computer64ormicroprocessor64sothatthespeedoftheengine,RevolutionsPerMinute,RPM,andtheamperagedraw

(electricalflow),andotherfactors,canbeusedtodeterminetheadvancementorretardationofthetimingpositionofthe

adjustablepickups46,47,48,49.

FIG.1andFIG.2depictafourcylinderpistondrivenenginewithconversionunitsovereachcylinder,theDoubleLength

SolenoidTubes,DLST13,areshownwithseparaterepresentativecoilsofwirewoundoneachDLST13,aPowerMagnet,

PM16,PM17,PM18,PM19,islocatedinsideeachDLST13,andaPowerRod,PR21,connectseachPMtoanengine

piston31,thereare2separatecoilswoundaroundeachDLST13,sincetheyareenergizedatdifferenttimestheyare

numberedseparatelyforidentificationandfunction,theyare80topmagneticcoil,81topmagneticcoil,82topmagneticcoil,

83topmagneticcoil,85bottommagneticcoil,86bottommagneticcoil,87bottommagneticcoil,88bottommagneticcoil.

Thetopmagneticcoils80,81,82,83,pulltheirrespectivePM'sup.Thebottommagneticcoils,85,86,87,88,when

energized,pulltheirrespectivePM'sdown.Energizingofthecoilsinthisexample,butnotlimitedto,occurswhenthe

flywheelwithits2sets,of4eachflywheelswitches72F,73F,74N,75Nand52N,53N,54F,55F,fastenedtoitturnspast

theadjustablepickups46,47,48,49,sendinganelectricalimpulsesthroughthemtotheircorrespondingvoltageamplifiers

42,43,44,45.FIG.5depictsflywheel40,withteeth,withflywheelswitches52N,53N,54F,and55F,oppositeadjustable

pickups46,47,48,49.TheFlywheelSwitches,FS,withtheNidentifier,alwaysturnthedesignatedcoilson,theflywheel

switcheswithFidentifier,alwaysturntheirdesignatedcoilsoff.InFIG.5theFlywheelSwitch,FS52N,sendsanon

electricalimpulsetotheadjustablepickup46,whichinturnsendsanelectricalimpulsetovoltageamplifier42,anelectronic

devicewhichcanincreasethevoltageanddecreasetheamperagetoenergizecoils87and85,pullingdownonPM16and

18,sincethispairisinthesamemode.OneFS52N,oneadjustablepickup46,andonevoltageamplifier42,canoperate

twocoils.InFIG.5,theFS53Nsendsanelectricalimpulsetotheadjustablepickup47,whichinturnsendsanonelectrical

impulsetothevoltageamplifier43,anelectronicdevice,whichcanincreasethesourcevoltagetoahigherelectrical

voltage,andlowertheamperage,throughthesupplywire77,throughthefuse41,tocoil83,andcoil81,pullingthePM17

andPM19up.AtthesametimeFS55FandFS54Fhaveturnedofftheelectricalsupplytoadjustablepickup48and49,

turningofftheelectricitytovoltageamplifier44,turningoffcoils80and82,turningoffcoils86and88,andallfourpistons

areturningthecrankshaftthefirst180degrees.InFIG.6,aftertheflywheel40,makesahalfturn,theflywheelswitches

72F,73F,74Nand75Nareoppositetheadjustablepickups46,47,48and49.Theflywheelswitch72Fturnsoffthe

electricalimpulsetoadjustablepickup46,turningoffthevoltageamplifier42,turningoffcoils85and87,thenflywheel

switch73F,turnsoffadjustableamplifier47,turningoffcoils81and83,theFS74Nturnsontheelectricalimpulseto

adjustablepickup48,turningonthevoltagetovoltageamplifier44,anelectronicdevice,whichcanincreasethevoltageand

decreasetheamperage,andsendstheincreasedvoltagetoits'supplywire77,throughthefuse41,andenergizescoil82

andcoil80,pullingthepairofPM's16and18up.Sincethecoils82and86areapair,theoneFS74canturnonbothcoils.

TheFS75Nsendsanelectricalimpulsetoadjustablepickup49,turningonvoltageamplifier45,anelectricaldevice,which

canincreasethevoltageanddecreasetheamperagefromthevoltagesource60,sendingtheincreasedvoltagetoavoltage

supplywire77,throughthefuse41andenergizingcoils88and86pullingthepairofPM's17and19down.Sincethecoils

88and86areapairinthesamemode,theoneFS75Ncanenergizebothcoils.Allfourenginepistons31areturningthe

crankshaft34,from180degreesto360degrees,completingthecycle.

FIG.1.FIG.2,FIG.3,andFIG.4depictanoilairtubeflange12,whichisconnectedtothetopoftheDLST13.Theoilair

tubeflange12,isthebaseforanoilairexhausttube51,andanoilairintaketube50.FIG.1,andFIG.2,depictsaoneway

oilairintakevalve7,andaonewayoilairexhaustvalve8.WhenthePM'smovedowntheDLST13theypullcleanairby

virtueoftheencasementoftheairshroud67,theairfilters68,andtheblowingoftheflywheel66,throughtheoilairintake

tube50,pasttheregulatedvalveseat71,intheoilsupplytube70,theseatisregulatedbytheoilairadjustingscrew27.

Theslightvacuumatthisseatcausesoildropletstoentertheoilairintaketube50,makinganoilairmist,whichpasses

throughtheonewayoilairintakevalve7intotheDLST13,coatingthetoppartoftheDLST13,andthering20orrings20

withoilandcoolingair.WhenthePM'sreachBDCandstartbackup,theonewayoilairintakevalves7,closeandtheone

wayoilairexhaustvalves8open,thesealedPM'spushtheremainingoilairmistouttheoilairexhausttubes51,andback

intothecrankcase35.Lubricatingthering20orrings20andthetopoftheinterioroftheDLST13.

Coolingthemagneticcoils80,81,82,83,85,86,87,88inFIG.1smallflexibletubes28,incoilsmarkedwithverticalslash

marks,arewoundwithsuitablewire14,orinlayerswitheachofthemagneticcoils80,81,82,83,85,86,87,88these

tubesareconnectedtotheradiatorsystemoftheengineblock65.Anyenginecoolantcanbepumpedthruthesmallflexible

http://www.google.com/patents/US7501725

6/8

4/21/2015

PatentUS7501725MethodofconvertingpistondrivenenginestooperateonelectricityGooglePatents

tubes28,tocoolthemagneticcoils80,81,82,83,85,86,87,88,orarefrigerantcanbepumpedthruthetubingtoprovide

coolingforthemagneticcoils.

FIG.2depictstubes,withholes,inthesides,areplacedaroundtheoutsideofthemagneticcoils,thetubesarethesame

lengthastheDLST's13andconnectedtotheinterioroftheenginecylinders26byintakeonewayintakevalves9,andone

wayexhaustvalves10.Whentheenginepiston31movesdowntheenginecylinder26,airispulledintothecylinder26,the

onewayintakevalve9isopen,andtheonewayexhaustvalve10isclosed.Whentheenginepiston31movesupinthe

cylinder26,theonewayintakevalve9,isclosedandtheonewayexhaustvalve10isopen,theairinthecylinder26is

pushedthroughtheexhaustvalve10,throughtheholesoftheexhaustcoolingtubes30,ontothemagneticcoils,tocool

them.Providingameanstocoolthecoilsonanaircooledengine.

PATENTCITATIONS

CitedPatent

Filingdate

Publicationdate

Applicant

Title

US1436245*

Nov19,1920

Nov21,1922

GeislerKurtM

Electricalengine

US1886040

Aug28,1930

Nov1,1932

WSHunt

Electricmotor

US4317058

Dec28,1979

Feb23,1982

TroyL.Cook

Electromagneticreciprocatingengine

US4473763

Sep30,1981

Sep25,1984

Mcfarland

DouglasF

Solenoidmotor

US4510420

Feb7,1984

Apr9,1985

Servo

Technology

Corp.

Multicylinderelectromagneticengine

US4523114

Mar9,1984

Jun11,1985

SmithRaymond

H

Magneticreciprocatingmotor

US4631455

Feb4,1985

Dec23,1986

TaishoffHoward

A

Methodandapparatusforconvertingaconventionalinternalcombustionengine

intoahighspeedelectricmotorandgenerator

US4749893

Jul14,1986

Jun7,1988

ReynoldsBillyD

Magneticallyactuatedengine

US5036930*

May17,1990

Aug6,1991

BiselCharleyW

Electromagneticallypoweredengineapparatusandmethod

US5276372*

Jun22,1992

Jan4,1994

Hammer

CharlesF

Reciprocatingelectricmotor

US5457349*

Jun30,1993

Oct10,1995

GiffordLeland

W.

Reciprocatingelectromagneticengine

US5469004

May13,1994

Nov21,1995

JachimFrank

M.

Electricvehiclesolenoidmotor

US5547349

Aug25,1995

Aug20,1996

AisinSeiki

Kabushiki

Kaisha

Oilpumpsystem

US5592036

Jul18,1994

Jan7,1997

PinoRaulM.

Engineconstruction

Electromagneticallypoweredengine

US5637936

May25,1995

Jun10,1997

Meador

AnthonyL.

US5757093

Mar13,1997

May26,1998

Susliaev

Konstantin

Electromagneticallypoweredengine

US6049146

Dec24,1996

Apr11,2000

TakaraMuneaki

Electromagneticpistonengine

US6278204

Jun18,1999

Aug21,2001

EugeneRoland

Frenette

Methodofconvertinginternalcombustionengineintoelectricallydrivenengine

US7105958*

Nov15,2004

Sep12,2006

ShimonElmaleh

Electromagneticengine

*Citedbyexaminer

REFERENCEDBY

CitingPatent

Filingdate

Publicationdate

Applicant

Title

US7913783*

May6,2008

Mar29,2011

ShimonElmaleh

Powergeneratingdeviceforelectromagneticoranyelectric

engine

US8188690

Feb8,2010

May29,2012

MagneticMiles,Llc

Magneticallypoweredreciprocatingengineandelectromagnet

controlsystem

US8324762*

Nov23,2009

Dec4,2012

ChristianHarveyKeller

Magneticallypropelledenginewithmagneticfieldreduction

US8446112

Apr24,2012

May21,2013

MagneticMiles,Llc

Magneticallypoweredreciprocatingengineandelectromagnet

controlsystem

US8601685*

Nov23,2010

Dec10,2013

TheInventionScience

FundI,Llc

Methodofretrofittinganengine

US20100066181*

Nov23,2009

Mar18,2010

Mr.ChristianHarveyKeller

MagneticallyPropelledEngineThatDoesNotRequireFuel

http://www.google.com/patents/US7501725

7/8

4/21/2015

PatentUS7501725MethodofconvertingpistondrivenenginestooperateonelectricityGooglePatents

US20110067216*

Nov23,2010

TheInventionScience

FundI,Llc

Mar24,2011

Methodofretrofittinganengine

*Citedbyexaminer

CLASSIFICATIONS

U.S.Classification

310/24,310/34,310/35,180/65.1

InternationalClassification

H02K7/065,F15B11/00,H02K7/06

CooperativeClassification

H02K7/06

EuropeanClassification

H02K7/06

LEGALEVENTS

Date

Code

Event

Description

Jun15,2012

FPAY

Feepayment

Yearoffeepayment:4

GoogleHomeSitemapUSPTOBulkDownloadsPrivacyPolicyTermsofServiceAboutGooglePatentsSendFeedback

DataprovidedbyIFICLAIMSPatentServices

http://www.google.com/patents/US7501725

8/8

S-ar putea să vă placă și

- Marine Electrical Practice: Marine Engineering SeriesDe la EverandMarine Electrical Practice: Marine Engineering SeriesEvaluare: 4 din 5 stele4/5 (8)

- 1875 Patent On Earth BatteriesDocument22 pagini1875 Patent On Earth Batteriesjoetylor100% (1)

- Earth Batteries PDFDocument0 paginiEarth Batteries PDFMarìa Angélica Guerreiro0% (1)

- TorquesDocument108 paginiTorquesnaruxzÎncă nu există evaluări

- ABC COSTING With Answers PDFDocument13 paginiABC COSTING With Answers PDFShaira Rehj Rivera100% (1)

- Magnacoaster Patent WillisDocument22 paginiMagnacoaster Patent WillisMikolas*Încă nu există evaluări

- Premature Stator FailureDocument9 paginiPremature Stator FailurePugalenthi.SÎncă nu există evaluări

- Aspden - Power From Ice - Thermoelectrics Part 1 (1994)Document73 paginiAspden - Power From Ice - Thermoelectrics Part 1 (1994)izoldoÎncă nu există evaluări

- 7FH2 Gen Fund ConstructionDocument30 pagini7FH2 Gen Fund ConstructionRamon de Oliveira100% (2)

- Alak Description Pelton TurbineDocument12 paginiAlak Description Pelton Turbinepavankumar001Încă nu există evaluări

- Vibration Applications of Vibrating ScreensDocument15 paginiVibration Applications of Vibrating Screensamoli001100% (2)

- Power Transformer ENUDocument32 paginiPower Transformer ENUDaniel RizzoÎncă nu există evaluări

- Patent Application Publication (10) Pub. No.: US 2008/0156564 A1Document13 paginiPatent Application Publication (10) Pub. No.: US 2008/0156564 A1JasperGementizaÎncă nu există evaluări

- Patent US5469004 - Electric Vehicle Solenoid Motor - Google PatentstetDocument7 paginiPatent US5469004 - Electric Vehicle Solenoid Motor - Google PatentstetMahendraMeenaÎncă nu există evaluări

- Component, Vibratinga, Materal - 2011 - (12) Patent Application Publication (10) Pub. No. US 20110280723 A1Document9 paginiComponent, Vibratinga, Materal - 2011 - (12) Patent Application Publication (10) Pub. No. US 20110280723 A1Joana AntunesÎncă nu există evaluări

- Brevet Generator US20080246361A1Document14 paginiBrevet Generator US20080246361A1eubogdan2013Încă nu există evaluări

- TimelineDocument32 paginiTimelinegoogols7521Încă nu există evaluări

- US4503349Document6 paginiUS4503349Build ItÎncă nu există evaluări

- 1 - Ee8002 Dea Unit 5Document32 pagini1 - Ee8002 Dea Unit 5Ramesh BabuÎncă nu există evaluări

- 154b-j 156bJ /151b 151d: (19) United StatesDocument22 pagini154b-j 156bJ /151b 151d: (19) United Statestyrer567899Încă nu există evaluări

- United States Patent: ShkondinDocument16 paginiUnited States Patent: ShkondinAngel DiosdadoÎncă nu există evaluări

- US20080129254A1 S.M.Frayne-2008Document15 paginiUS20080129254A1 S.M.Frayne-2008olim owletÎncă nu există evaluări

- Unlted States Patent (10) Patent N0.2 US 8,314,522 B2Document4 paginiUnlted States Patent (10) Patent N0.2 US 8,314,522 B2avalosheÎncă nu există evaluări

- Single Phase RectifireDocument3 paginiSingle Phase RectifireNishith DhinoraÎncă nu există evaluări

- United States Patent (19) : Benway Et Al. (45) Date of PatentDocument9 paginiUnited States Patent (19) : Benway Et Al. (45) Date of PatentAngel GutierrezÎncă nu există evaluări

- Unit - Ii DC Machines DC Machines: 5/2/2010 V.Balaji, Ap/Eee, DceDocument133 paginiUnit - Ii DC Machines DC Machines: 5/2/2010 V.Balaji, Ap/Eee, DceMani KandanÎncă nu există evaluări

- Name/Title of The Drawing Drawing No Reamarks Sl. No. Send For App Date Approved DateDocument4 paginiName/Title of The Drawing Drawing No Reamarks Sl. No. Send For App Date Approved DateveeruduÎncă nu există evaluări

- Brevetto US20080246361 - Power Generation Device - Google BrevettiDocument7 paginiBrevetto US20080246361 - Power Generation Device - Google BrevettinikohakuÎncă nu există evaluări

- European Patent Specification: Power GeneratorDocument21 paginiEuropean Patent Specification: Power GeneratorMarlon MataÎncă nu există evaluări

- (Us 2005) 6864611 Synchronous Generator For Service in Wind Power Plants, As Well As A Wind PowerDocument14 pagini(Us 2005) 6864611 Synchronous Generator For Service in Wind Power Plants, As Well As A Wind PowerYesmaRofiaÎncă nu există evaluări

- Reactive Power Real PowerDocument9 paginiReactive Power Real Powersebastian.gonczarekÎncă nu există evaluări

- Pulse Pure Patent 01Document11 paginiPulse Pure Patent 01shahinÎncă nu există evaluări

- United States Patent: Nguyen-Dinh Sep. 18, 2001Document10 paginiUnited States Patent: Nguyen-Dinh Sep. 18, 2001KrozeÎncă nu există evaluări

- Us 20120090534Document28 paginiUs 20120090534Victor Von DoomÎncă nu există evaluări

- Replacement of Main Electrical Generator in NPP Krsko IRMC 2017Document6 paginiReplacement of Main Electrical Generator in NPP Krsko IRMC 2017NeopeakÎncă nu există evaluări

- AK-0-EE-IP-01-001 - Arrangement Plan of Excitation AC&DC Bus-Duct - FCDDocument57 paginiAK-0-EE-IP-01-001 - Arrangement Plan of Excitation AC&DC Bus-Duct - FCDrajbharath.pÎncă nu există evaluări

- United States Patent: Hanawa Et Al. Patent No.: Date of Patent: Feb. 26,2013Document21 paginiUnited States Patent: Hanawa Et Al. Patent No.: Date of Patent: Feb. 26,2013mohamedabbas_us3813Încă nu există evaluări

- Lecture 17 Power and Industrial ElectronicsDocument6 paginiLecture 17 Power and Industrial ElectronicsNirud PajanustanÎncă nu există evaluări

- Us 7973296Document33 paginiUs 7973296Anonymous Kti5jq5EJIÎncă nu există evaluări

- United States Patent: OliverDocument21 paginiUnited States Patent: OliverVictor Von DoomÎncă nu există evaluări

- A Foil Winding Pulse Transformer EP1929489B1Document15 paginiA Foil Winding Pulse Transformer EP1929489B1ourbobbyÎncă nu există evaluări

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0313948 A1Document28 paginiUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0313948 A1salvor00Încă nu există evaluări

- Reducing The Core-End Heating in Large Power GeneratorsDocument12 paginiReducing The Core-End Heating in Large Power GeneratorsMichal KowalczykÎncă nu există evaluări

- Free Energy 4Document5 paginiFree Energy 4Fadi BarakeÎncă nu există evaluări

- Rishabh Prasad (0068) Presentation - Mpia Lab-1Document34 paginiRishabh Prasad (0068) Presentation - Mpia Lab-1Pradyum ThakurÎncă nu există evaluări

- Wind Energy Turbine LayoutDocument15 paginiWind Energy Turbine LayoutjohnÎncă nu există evaluări

- Dual Rotor Wind Turbine PDFDocument9 paginiDual Rotor Wind Turbine PDFv7danielÎncă nu există evaluări

- Apc Spares Components ListDocument300 paginiApc Spares Components Listseufert100% (1)

- Automatic Side Stand For Two WheelerDocument84 paginiAutomatic Side Stand For Two Wheelercoolhari0825% (4)

- Ulllted States Patent (10) Patent N0.: US 7,701,083 B2Document19 paginiUlllted States Patent (10) Patent N0.: US 7,701,083 B2Umair KhalilÎncă nu există evaluări

- TSLA PatentDocument9 paginiTSLA PatentCharles GrossÎncă nu există evaluări

- United States Patent (19) : Hartman, Sr. Aug. 4, 1987Document4 paginiUnited States Patent (19) : Hartman, Sr. Aug. 4, 1987Mihai DanielÎncă nu există evaluări

- Multi-Winding Homopolar Electric MachineDocument12 paginiMulti-Winding Homopolar Electric Machinejegz booksÎncă nu există evaluări

- PMG Gen PDFDocument7 paginiPMG Gen PDFchecko_1258Încă nu există evaluări

- Noise Source Identification of Small Fan-BLDC Motor System For RefrigeratorsDocument8 paginiNoise Source Identification of Small Fan-BLDC Motor System For RefrigeratorsmitulÎncă nu există evaluări

- Ma CleanDocument91 paginiMa Cleanebene2Încă nu există evaluări

- Us 7531930 PatentDocument11 paginiUs 7531930 Patentsebastian.gonczarekÎncă nu există evaluări

- MWM Interface400VContainerTCG2016CDocument3 paginiMWM Interface400VContainerTCG2016Cgabinetedeiniciativa100% (1)

- Generation of Electricity Using Bladeless Wind TurbineDocument5 paginiGeneration of Electricity Using Bladeless Wind TurbineftahÎncă nu există evaluări

- US8055010Document9 paginiUS8055010Morena SlpÎncă nu există evaluări

- Device For Attaching An Electric Battery To The Chassis of A Motor VehicleDocument14 paginiDevice For Attaching An Electric Battery To The Chassis of A Motor VehicleTUNCAY GUMUSÎncă nu există evaluări

- United States Patent: (10) Patent No.: (45) Date of PatentDocument14 paginiUnited States Patent: (10) Patent No.: (45) Date of PatentAlecsandrÎncă nu există evaluări

- Electric Hub MotorDocument6 paginiElectric Hub Motorirctcsbt6bimblikipilÎncă nu există evaluări

- "Hy-Wire Car": Bachelor of Technology IN Mechanical EngineeringDocument7 pagini"Hy-Wire Car": Bachelor of Technology IN Mechanical EngineeringMahendraMeenaÎncă nu există evaluări

- Homework and Exercises - Help Making A Solenoid Engine - Physics Stack ExchangeDocument1 paginăHomework and Exercises - Help Making A Solenoid Engine - Physics Stack ExchangeMahendraMeenaÎncă nu există evaluări

- "Waterjet Cutting": Bachelor of Technology IN Mechanical EngineeringDocument7 pagini"Waterjet Cutting": Bachelor of Technology IN Mechanical EngineeringMahendraMeenaÎncă nu există evaluări

- "Solenoid Engine": Bachelor of Technology IN Mechanical EngineeringDocument7 pagini"Solenoid Engine": Bachelor of Technology IN Mechanical Engineeringtara chand kumawatÎncă nu există evaluări

- Application Details of Registration Id: ForDocument1 paginăApplication Details of Registration Id: ForMahendraMeenaÎncă nu există evaluări

- Application Details of Registration Id: ForDocument1 paginăApplication Details of Registration Id: ForMahendraMeenaÎncă nu există evaluări

- Mukesh Kumar Meena M 2405059822 ST 23/05/1991 2015165 16/06/2015Document2 paginiMukesh Kumar Meena M 2405059822 ST 23/05/1991 2015165 16/06/2015MahendraMeenaÎncă nu există evaluări

- "Aerodynamics of Vehicle": Bachelor of Technology IN Mechanical EngineeringDocument7 pagini"Aerodynamics of Vehicle": Bachelor of Technology IN Mechanical EngineeringMahendraMeenaÎncă nu există evaluări

- Shankar Lal Meena M 2405021679 ST 10/05/1996 2000526 25/05/2015Document2 paginiShankar Lal Meena M 2405021679 ST 10/05/1996 2000526 25/05/2015MahendraMeenaÎncă nu există evaluări

- "Anti-Lock Braking System": Bachelor of Technology IN Mechanical EngineeringDocument7 pagini"Anti-Lock Braking System": Bachelor of Technology IN Mechanical EngineeringMahendraMeenaÎncă nu există evaluări

- DKSVK Fo'Ofo - Ky ) DKSVK DKSVK Fo'Ofo - Ky ) DKSVK DKSVK Fo'Ofo - Ky ) DKSVK DKSVK Fo'Ofo - Ky ) DKSVKDocument2 paginiDKSVK Fo'Ofo - Ky ) DKSVK DKSVK Fo'Ofo - Ky ) DKSVK DKSVK Fo'Ofo - Ky ) DKSVK DKSVK Fo'Ofo - Ky ) DKSVKMahendraMeenaÎncă nu există evaluări

- 1418395957089Document3 pagini1418395957089MahendraMeenaÎncă nu există evaluări

- ISE551Document3 paginiISE551MahendraMeenaÎncă nu există evaluări

- "Casting Process": Bachelor of Technology IN Mechanical EngineeringDocument7 pagini"Casting Process": Bachelor of Technology IN Mechanical EngineeringMahendraMeenaÎncă nu există evaluări

- Meena Lashing. Feb-2015Document9 paginiMeena Lashing. Feb-2015MahendraMeenaÎncă nu există evaluări

- Lokendra 1Document7 paginiLokendra 1MahendraMeenaÎncă nu există evaluări

- "Casting Process": Bachelor of Technology IN Mechanical EngineeringDocument7 pagini"Casting Process": Bachelor of Technology IN Mechanical EngineeringMahendraMeenaÎncă nu există evaluări

- DSR Cabos SinteticosDocument28 paginiDSR Cabos SinteticosFabian Andres CelyÎncă nu există evaluări

- Emergency Access ManagementDocument5 paginiEmergency Access ManagementPabitraKumarÎncă nu există evaluări

- Seat Plan ChartsDocument10 paginiSeat Plan ChartsJayvee Montoya-PujanteÎncă nu există evaluări

- GT4 Strategy GuideDocument120 paginiGT4 Strategy GuideGiovanni BassiÎncă nu există evaluări

- Flange DimensionsDocument7 paginiFlange DimensionsDave DonohueÎncă nu există evaluări

- TumblrDocument1 paginăTumblrLumi EreÎncă nu există evaluări

- Printing, Laminating & Encoding Solutions: Fargo® Dtc5500LmxDocument6 paginiPrinting, Laminating & Encoding Solutions: Fargo® Dtc5500Lmxgroovey9040Încă nu există evaluări

- SAP BI BO Presentation TorrentDocument36 paginiSAP BI BO Presentation TorrentRajab Ali Jiwani100% (1)

- Engine Specifications: S.Nogami H.HaradaDocument10 paginiEngine Specifications: S.Nogami H.Haradaณัฐพันธ์ สุวรรณวิจิตรÎncă nu există evaluări

- Birla Institute of Technology & Science, Pilani Practice School Division Session 2018 PSI Assignment HandoutDocument3 paginiBirla Institute of Technology & Science, Pilani Practice School Division Session 2018 PSI Assignment Handouttarun chauhanÎncă nu există evaluări

- DM Automatic Irrigation System SpecsDocument56 paginiDM Automatic Irrigation System SpecsSarfraz AhmadÎncă nu există evaluări

- 7.3.2.3 Packet Tracer - Configuring RIPng InstructionsDocument3 pagini7.3.2.3 Packet Tracer - Configuring RIPng InstructionsCristian GarciaÎncă nu există evaluări

- SH5002-7J S EnuDocument304 paginiSH5002-7J S Enu19848096Încă nu există evaluări

- GSX ManualDocument69 paginiGSX ManualSalazar SantiagoÎncă nu există evaluări

- ASTM A395 - A 395M - 99 (Reapproved 2009)Document8 paginiASTM A395 - A 395M - 99 (Reapproved 2009)raulÎncă nu există evaluări

- AAFDS Service SpecificationDocument20 paginiAAFDS Service SpecificationLUIS GIRALDOÎncă nu există evaluări

- Power Xpert Power Quality Meters: Product FocusDocument20 paginiPower Xpert Power Quality Meters: Product FocusMike MendozaÎncă nu există evaluări

- Montage Kit 4x4 FGDocument30 paginiMontage Kit 4x4 FGsousou0033Încă nu există evaluări

- Weinig Rondamat 960 PDFDocument16 paginiWeinig Rondamat 960 PDFCimpean AlexandruÎncă nu există evaluări

- Dynamic (Vibration) Testing: Design-Certification of Aerospace SystemDocument16 paginiDynamic (Vibration) Testing: Design-Certification of Aerospace SystemCamelia MunteanuÎncă nu există evaluări

- Modelling Microstructures With OOF2: Andrew C.E. ReidDocument13 paginiModelling Microstructures With OOF2: Andrew C.E. ReidKaram JaradatÎncă nu există evaluări

- Magnetic Abrasive Finishing A Review IJERTV2IS3010Document9 paginiMagnetic Abrasive Finishing A Review IJERTV2IS3010Saketh ReddyÎncă nu există evaluări

- Resistivity LoggimnhDocument12 paginiResistivity LoggimnhMaqsood IqbalÎncă nu există evaluări

- Kool Calc GuideDocument24 paginiKool Calc GuideAlonso MejíaÎncă nu există evaluări

- Application of The EN 45545 Standard at SNCF: March 2016Document30 paginiApplication of The EN 45545 Standard at SNCF: March 2016pnagarajjÎncă nu există evaluări

- White Products CatalogDocument49 paginiWhite Products CatalogjesusÎncă nu există evaluări