Documente Academic

Documente Profesional

Documente Cultură

Jan-1, 1935 - R. G. de La Mater Er Al 1,985,889

Încărcat de

lfilippiniTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Jan-1, 1935 - R. G. de La Mater Er Al 1,985,889

Încărcat de

lfilippiniDrepturi de autor:

Formate disponibile

Jan- 1, 1935-

. R. G. DE LA MATER; Er AL

1,985,889

METHOD AND APPARATUS FOR CONTROLLING RESISTANCE OF HYDRODYNAMIC BRAKES

- Filed larch 22. 1932

V/6I

ll/./

2 Sheets-Shae} 1

9.

ap///,/7/

/,, 44.

.0I.

.

gb

\\\\

\\\\\\

Jan. 1, 1935.

R. s. DE LA MATER El AL

11,935,339

METHOD AND APPARATUS FOR CONTROLLING RESISTANCE OF HYDRODYNAMIC BRAKES

Filed larch 22, 1952

2 Sheets-Sheet 2

9?.MW

IC\

HWI .H

l

.\31um

. . -

|Il._,UHIA|.I

2.-iH,.-i

TORS

1% ATTORNEYS

Patented Jan. 1, 1935

' 1.985.889

UNITED STATES

PATENT OFFICE 1'

1,985,839

METHOD AND APPARATUS FOR CONTROLLING RESISTANCE OF 7 HYDRODYNAMIO

BRAKES

'

'

'

Robert Grii?n De La Mater and William Schwcni

' lein, Parkersburg, W. Va., aseignors to The

Parkersburg Rig & Reel Company, a corpora

tion of West Virginia

Application March 22. 19st. Seriai No. 600,478

- zscisim.

(01. 188-90)

This invention relates to a method of and rate of discharge of liquid from a brake oper

means for regualting and controlling the braking ating full of liquid, it will be apparent that the

eilort developed by the so-called hydro-dynamic range of speed regulation will be rather limited.

brakes of the type in which energy is absorbed

An object or this invention is the provision of

by ?uid friction.

.

means for controlling the braking effort devel

Heretofore hydro-dynamic brakes have been oped ' by' hydro-dynamic brakes whereby such~

designed to operate full of liquid or water which braking eiIort may be regulated from practically

is introduced to the brake under pressure. Such zero value to the maximum value that may be

brakes unless provided with su?icient liquid to obtained with a brake full of liquid with no dis

10 maintain them full at all times, or unless a sup

ply pump, or a source of liquid under pressure

charge therefrom.

10

Another object of the invention is the provision ~

was provided to introduce liquid to the brakes" of a method and means of obtaining primary

at thesarne rate as it was discharged therefrom, regulation of the braking e?ort independent of

would not function properly. In accordance with the' rate of discharge of liquid and secondary

this invention it is proposed to provide an hydro- ' regulation by controllingv the rate of liquid dis

dynamic brake which may be operated either full charge from the brake.

of liquid or water, or only partially full.

A still further object of the invention is the

A brake constructed in accordance with this in provision of a brake which will function in its

vention may be operated full of liquid or water, intended manner although only partially ?lled

or partially full, with or without discharge of with liquid.

liquid therefrom. The brake will develop maxi - It is also an object of the invention to provide

15

mum braking e?ort when operated full of liquid means whereby the volume of liquid in the brake

with no discharge therefrom.~ Howevenif no may be predetermined and maintained constant

discharge takes place, and no liquid is circulated

at such volume.

'

through the brake, the temperature of the liquid

It is also an object of the invention to provide

may be raised to the point where steam pockets a fluid friction brake system wherein the heat

may form therein, thereby either impairing or absorbed in the liquid in the brake may be uti

destroying the braking action thereof. It is lized .to automatically increase the braking ac~

therefore proposed to discharge liquid from the

tion.

>

30 brake, whether operated full or partially full of

Other objects of the invention will, in part, be

liquid and to circulate cool liquid through the apparent and will, in part, be obvious from the

brake so that the temperature of the liquid there following description taken in conjunction with

in will be below the point where steam may the accompanying drawings in which:

develop.

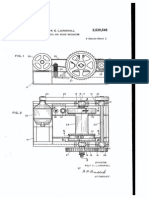

Figure 1 is a view of a hoist to which an hydro

If no discharge of liquid from the brake is per

dynamic brake is applied, the brake being shown

mitted, there is no leakage between the stator and partially in section;

I rotor, hence the back pressure and brake re

Fig. 2 is a more or less diagrammatic illustra

sistance are a maximum. If liquid is discharged tion of apparatus for obtaining primary and

from the brake, leakage between rotor and stator secondary regulation of the braking effort de

40 .takes place, causing the back pressure and brake veloped by the hydro-dynamic brake shown in7

resistance to be reduced. Therefore, by regu Fig. 1;

- ,

.

lating the rate of discharge, the back pressure

Fig. 3 is a'fragmentary sectional view of the

and the braking effort or resistance may be regu lnrdro-dynamlc brake taken on line III-III of

lated within predetermined limits.

'

_ Fig. 1 showing one form of nozzle or inlet tubevfor

v

regulate or control the speed of descent of a loaded ' Fig. 4 is a similar fragmentary sectional view

Where hydro-dynamic. brakes are utilized to introducing liquid to the brake, and-

hoist, the speedat which the load descends will

be substantially constant for a given rate of dis-_

charge of liquid from the brake. In hoist appli

cations, it is therefore apparent that the pri

mary function of means for obtaining regulation

is that of governing the descent of the load and

~ providing for variations in speed over a prede-'

termined range.

55

showing another form of nozzle or inlet tube for

introducing liquid to the brake;

,

Fig. 5 is a view of a tank, such as shown in Fig.

2, provided with a modi?ed form of apparatus for

regulating the level of the liquid therein and the

' braking action of the brake. .

Throughout the drawings andthe speci?cation

similar and like parts are designated by the some

If such regulation is dependent entirely on the reference characters.

55

1,985,889

' 2

In the drawings, with particular reference to threaded into tapped holes formed in the stator

Fig. 1, av hoist rig is shown that comprises a shaft walls separating the stator pockets from the

1 on which a drum or reel 2 is mounted. _A cable chambers. In one form, the nozzles may extend

3 wound on the drum, operates over a pulley 4 at right angles to the rotor as shown in Fig. 4.

and carries a load W. A motor 5 coupled to the In another form, nozzles 25 inclined at an angle

shaft by means of a clutch .6, for example a jaw as shown in Fig. 3, may be provided. When

clutch, is utilized to turn the shaft, whereby the mounted as shown in Fig. 3, liquid is discharged

' cable is wound on the drum when it is desired to from the nozzles in the general direction of ro

raise the load. When the load is to be lowered, tation of the rotor when functioning as a brake.

10 the clutch is shifted to disengage the motor from,

the shaft, permitting the load to fall under the

action of gravity, thereby turning the drum and

unwinding the cable.

In order that the speed at which the load falls

15 or descends may be regulated and limited to some

desired safe speed, an hydro-dynamic brake '7 is

provided, the load being stopped and/or held in

the desired position by means of a mechanical or

solid friction brake 8 of standard or known con

20 struction mounted on the reel shaft. When the

load is being raised'by the motor, brake 7 offers

negligible resistance to rotation of the. reel shaft.

The particular form of brake shown and de

10

scribed'above is shown and described in the co

pending application of Robert G. De La Mater,

Serial No. 601,337, ?led March 26, 1932. In such

a brake, the braking action is not dependent upon

the amount of liquid in the brake, except as'it 15

affects the degree of braking effort or resisting

torque developed thereby, nor is it necessary to

introduce liquid into the brake under pressure.

However, the braking action may be varied from

a minimum, or practically zero value, to a maxi 20

mum value by controlling the amount of liquid

con?ned in the brake. Thus the braking action

As shown, brake '7 is mounted on a portion of is a minimum when the brake is empty, and a

shaft 1 that overhangs its hearing so that the maximum when full with the discharge port

25

,

.

brake may be easily removed. The brake may closed.

In

accordance

with

this

invention

it

is

pro

preferably be mounted on an overhanging shaft

requiring the braking qualities or functions there posed to vary the quantity of liquid in the brake

by regulating the liquid level therein in order to

pedites assembly or disassembly. However, they obtain primary regulation of the braking action, [30

brake may be mounted in any position on the and to obtain secondary regulation by adjusting

of. The mounting on an overhanging shaft ex

shaft, or mounted on an auxiliary shaft driven

from the shaft, the braking of which is required.

The hydro-dynamic brake 7 comprises a stator

9' having a rotor 10 therein which is journalled in

bushings 11 mounted in the stator. The journal

of the rotor is hollow to accommodate the reel

shaft 1, and is provided with a keyway to accom

a valve 26 in the discharge line.

In order to obtain such regulation, a closed tank

or container 27 is provided having a stand pipe

or riser 28 which is vented at its top to the atmos

phere. The lower end of the pipe or riser ex 85

tends downwardly into the tank to a depth below

.the lowest point whichthe level of the'liquid in

modate a key 12 so that the rotor may be held the tank may reach in operation. Thus, a con

' fast on the shaft. The stator "may be bolted to a ?ned space is provided in the top of the tank which

40

40 foundation as indicated at 13 and 13' (see Fig. 2) is sealed from'the atmosphere because the lower

end of the pipe or riser 28 is always submerged

The top of the tank is preferably at

the

level

of

the inlet to the brake and the top of

stator prevented from rotating by tying it to the

thestand pipe at a level slightly higher than the.

foundation or any stationary support.

.

.

The stator is provided with a series of radially discharge outlet from the top of the brake.

45

The inlet to the brake is connected by a pipe

disposed pockets or recesses 14 on one side there

to prevent its turning when the brake is in op

eration, or it may be mounted on the shaft and the in liquid.

of and a similar series of radially disposed pockets 30 to the bottom of the tank, a valve 31 being pro-.

or recesses 15 on the opposite side. Each series vided so that the brake may be shut 03 from the

of pockets, or recesses are formed concentrically tank. The outlet from the brake is connected by

a pipe 32 to the stand pipe at a point preferably

the broken line circles A and B of Fig. 2, repre above the level of the top of the brake so that

50 to the axis of rotation of the rotor as indicated by

'

.55

senting, respectively, the outer and inner ends of liquid dischargingtherefrom may be returned to

The pockets of each series or group the tank. To control the amount of liquid dis

the recesses.

are separated by vanes ' or partitions, 16 which ' charging from the brake, valve 26 is appropriately

slope in a direction rearward to that in which the

rotor rotates while functioning as a brake.

The braking effort developed by the brake for

Each side of the rotor is provided with a series a given rotor speed depends primarily upon the

' of pockets or recesses 1'1 and 18 of substantially amount of liquid con?ned in the brake and sec

the same shape and size as the pockets in the ondarily upon the amount of liquid discharging 60

60 stator and occupy substantially the same posi-. therefrom. . Since the amount of liquid in the

tion relativev thereto, The pockets in the rotor brake is dependent upon the level of the liquid in

are separated by slopingv vanes or partitions 19. the stand pipe it follows that primary regulation ~

> As shown the rotor partitions or vanes slope in a of the braking action may be obtained by con

forward direction with respect to the direction trolling the level of the liquid in the pipe.

In order to control the liquid level in the pipe,

in which the rotor rotates when functioning as a

means are provided for auperposing an artificial

In order that liquid may be introduced to the head or pressure on the liquid in the tank. The

brake to replace the water which is permitted to liquid level may be conveniently adjusted by in

discharge therefrom at the top of the stator, the troducing air, under pressure, to thetank. A

stator is provided with circular chambers 20 convenient way of providing such air pressure is

and 21 having inlets .22 and 23, respectively, at to utilize an air pump 34, preferably a manual

the bottom of the stator. .These inlets are con ly operated plunger pump. By operating the

nected by a pipeto a source of supply of liquid. pump and forcing air into the tank through a pipe

The liquid is introduced into the pockets. of the 35, the liquid level will rise in the stand pipe and

rotor through nozzles or tubes 24 which are in the brake to equal levels. By varying the air

brake.

to

,3

1,986,889

pressure, the levels may be adjusted from a point

where the brake is empty to the point where the

brake is full. By 'placing a gauge glass 36 on

the stand pipe, the level of the liquid in the brake

may be determined by observation.

If the level in the stand pipe is high and it is

desired to lower the same, air maybe exhausted

fromthe tank. To' provide for exhausting or re

ducing the air pressure in the tank, a two-way

10 cock 37 is provided in line 35'between the pump

and the tank. By turning the valve to one posi

tion, air ?ows from the tank to the atmosphere,

and to another position, air may be forced by the

pump into the tank.

15

'

If the liquid level in'the brake and the stand

pipe is at X for example (the brake being only

charged from the brake and returned to the tank

.via the discharge line 32. Such discharge of

liquid tends-to create a partial vacuum in the

brake, causing liquid to flow from the tank into

the brake to replace the quantity of liquid dis

charged. Thus the quantity of liquid and the

volume of air in the brake are maintained at a

constant value regardless of how wide open or how

nearly closed the discharged valve may be.

If thedischarge valve is opened wide, the flow v10

of liquid out of the brake permits, considerable

leakage between the outside circumference of the

rotor and stator, thus reducing the quantity of the

liquid thrown from the rotor pockets ~to stator

and reducing the braking resistance.

If the discharge valve is completelyv closed, the

partially full) and the rotor is driven in the liquid around the outside of the rotor would form

direction of arrow 38 by the descending load W,

the braking effort developed will be of a prede

20 termined value when the rotor speed is at a pre

determined value. That is, for a given amount

of liquid in the brake, whether full or only par?

tially full, the load will increase in speed until

the power absorbed by the brake is equalto the

25 kinetic energy of the load. When the kinetic

a solid wall and prevent .any leakagebetween the

outside circumference of rotor and the stator.

The liquid will thenbe thrown from rotor to

stator with-maximum velocity and the maximum

resistance obtained.

'

By varying the air pressure in the tank, the

quantity of liquid con?ned in the brake may be

varied over a widerange whereby a wide' range

' energy is equal to the power absorbed by the of braking effort may be obtained. "A wide range

brake,the speed of the load will remain constant.

The braking action is caused by the rotor pock

ets collecting slugs or small bodies of liquid

30 and throwing these bodies, under the action of

centrifugal force, to the outer ends of the rotor

pockets which are shaped to direct them across

the spaces between the sides of the-rotor and

"

50

55

60

of braking effort also permits of a wide range in

the speed-at which the load W may be dropped.

The maximum braking effort is obtained when the

brake is full of liquid andgvoid of air, the dis

charge valve being completely clpsed. However,

where a considerable amount of power is ab

sorbed by the liquid, the discharge valve should

the stator in the form of high velocity jets. , When .be open to permit 'su?icient circulation through

' these high velocity Jets strike the stator pockets the brake to prevent the temperature of the liquid

they are de?ected to the inner ends thereof and from rising beyond a certain value, say 180 to 190

thence back to the rotor pockets. The direction degrees F. If steam should be generated in the

in which these slugs move is indicated by vectors brake, the braking action may be impaired, but

in Fig. 1. The acceleration of these slugs of liquid no damage would result to {the brake because the

in the rotor, the cutting of the high velocity jets pressure thus developed would merely cause the 40

by the stator vanes as they sweep across the stator liquid and steam to v?ow back into the tank

vanes, the deceleration thereof in the stator, and through the inlet pipe 30.

the friction between the liquid and the surfaces of _ If load W falls a great distance, say 5,000 feet

the rotor and stator pockets, produces the brak or-more, and the brake is absorbing considerable

ingaction required to hold the speed of the load power, the temperature of the liquid passing

in check. This absorption of power causes the through the brake will be raised. Since the heated

liquid to be heated. If the heat developed in the liquid is discharged from the brake and returned

liquid is too great, the discharge valve is opened to the tank _via stand pipe 28, the temperature of

to permit a certain amount of .the liquid to be the liquid in the tank will rise.- The rise in tem

circulated and recirculated from the tank through perature of the liquid causes the air and liquid in 50

the brake, thereby dissipatingthe heat in the the tank to expand, whereby the pressure of the

liquid and maintaining the temperature of the air is increased. Since the air and the liquid in

liquid delivered to the brake within operating _ the tank expand, the liquid level in the stand pipe

and in the brake is raised, thereby automatically

limits.

The larger the slugs or bodies of water which increasing the braking effort developed by the

are thrown from the rotor pockets to the stator brake.

'

pockets, the greater will be the braking action.

Such automatic increase in braking action may It therefore follows that the greater the quantity be particularly useful in some applications where

of liquid in the brake, the greater will be the the cable spooled fromv the reel materially in

braking action for a given rotor speed.

creases the load tending to drive the shaft on 60

The operation of the brake may be described as which the brake is mounted.

For example, if the brake is applied to the

follows: If the brake has been filled withliquid

tothe desired level, the remainder of the brake. draw works of rotary-drill rigs, the total weight

if not full of liquid, will be filled with air, the which the brake'must hold in check increases

discharge valve being either iully open or partly rapidly as thev load is lowered, thereby increasing 65

open. When the'rotor starts to rotate in the di the energy absorbed by the'brake and the tem

rection of arrow 38, the liquid in the brake is perature of the liquid discharged therefrom. vThe:

caused to circulate between the rotor and statorj heat of the discharged liquid, as stated above,

pockets as described above. Partl'of the liquidis varying with the increase in load,- automatically

thrown out to the rim of the stator where itlseals increasesthe quantity of liquid in the brake, and

oi! the discharge port so that the air near the consequently automatically increases the braking

center of the brake cannot escape. Therefore

Thus- by controlling the vair pressure in the sup

the original volume of air will remain in the

action.-

75

brake.

iv

As the rotor co tinues to rotate, liquid is dis

ply tank, the level of the liquid in the brake may ,

be adjusted to that value which will give the brak

4.

1,985,889

ing action desired. The regulation of the braking

action, as aifected by the air- pressure in the tank,

provides the primary form of control, adjustment

of the discharge valve 26 gives a secondary form of

control, and the increasing temperature of the.

liquid discharging from the brake gives automatic

increase in resistance through the primary- con

braking resistance may be regulated by draining

the tank until the liquid level is reduced to the

desired point, or by adding-liquid until the leve '

is raised to the proper height.

'

i If it were desired to run the brake full of liquid

but to have the discharge valve open so as to per

mit circulation, the resistance of the brake may

be further increased by increasing the pressure

. '

'

It may also be desirable to provide means on the liquid at the brake inlet. This may be

trol, if this is desired.

10 whereby the braking e?ort developed by the brake

may be suddenly increased, in case it should be

necessary to decelerate the load quickly. A means

for accomplishing this result is illustrated as

comprising a storage tank T, having air or com

15 pressible ?uid therein under pressure, for ex

ample, a pressure of 25 or 30 pounds per square

inch, connected to tank 27. A valve V is utilized

320

accomplished by having the stand pipe 28 and 10

the discharge pipe 32 extend as high as required

in order to securethe head desired. The pres

sure may be regulated within the range made pos

sible by the height of the stand pipe by varying

the liquid level in the stand pipe in the manner 16

previously described.

While various modi?cations and changes may

be-made in the method for controlling the liquid

level in the brake andin the apparatus for car

rying out such method, without departing from 20

the spirit or the scope of the invention, it is to be.

understood that only such limitations shall be

to normally shut off tank T from tank 2'7. When

it is desired to rapidly increase thebraking ac

tion, valve V is opened thereby increasing the

pressure in tank 27, and raising the level of the

liquid in the brake quickly. The quantity of liq

uid being increased rapidly the braking action'is placed on the invention as are imposed by the

.

increased correspondingly whereby the load is de prior art and the appended claims.

Whatwe claim as new and desire to secure by 25

celerated at a high rate. In practice, it has been

'

found thatby suddenly 9.11pm air, under pres Letters Patent is:

1. The method of controlling the braking action

sure, to tank 27 that the load may be decelerat- _

in hydro-dynamic brakes that consists in provid

ed quickly almost to the point of stopping.

ing

a source of supply or liquid, connecting said

From the above description, it will be appre

30 ciated that we have provided an hydro-dynamic supply to the brake, superposing on said source a 30

brake which will function as a brake when either supply of compressible ?uid under pressure, and

partially full or completely full of liquid and adjusting said pressure until the head of liquid

that we have also provided means whereby the in the brake is of the desired value.

2. The method of controlling the braking action

volume of the liquid in the brake may be accu

rately adjulted to give the desired control of in hydro-dynamic brakes that consists in provid 35

the speed at which the load W is permitted to fall. ing a source of supply of liquid, connecting said

The means illustrated insures that a predeter supply to the brake, superposing on said source a

mined quantity of liquid may be introduced to the supply of compressible ?uid under pressure, ad

brake and that this quantity will be maintained justing the level of the liquid in the brake by

-40 constant even though the discharge control valve adjusting the pressure of the ?uid acting on the 40

supply source, and discharging liquid from the

is wide open or nearly completely closed.

In the system shown, the pipe leading from brake to supply source in accordance with the

the brake to the tank and the tank itself serve braking action desired.

3. The method of controlling the braking action

as a cooling system for the dischargedliquid which

45 maintains the liquid at a temperature well below in hydro-dynamic brakes that consists in provid

the critical value above which the braking action ing a source of supply of liquid, connecting said

supply to the brake, superposing on said source

would ordinarily be impaired.

a supply of compressible ?uid under pressure, ad

justing the level of the liquid in the brake by

adjusting the pressure of the ?uid acting on the 50

supply source, discharging liquid from the brake

ducinga weight into the tank, thus displacing to supply source in accordance with the braking

the ?uid to the required level. In Fig. 5 such an action desired, and varying the rate of discharge

arrangement is shown. It a weight is used to of liquid from the brake to the supply source.

4. In combination, an hydro-dynamic brake 55

55 variably displace liquid in tank 27, pump 34 and

the connections therefor, and pressure tank T and comprisinga stator having a rotor therein, a

valve Vmay be omitted, and a weight 40 substi closed container having a supply of liquid there

in, means placing the interior of the containerin

tuted in lieu thereof.

_

Weight 40 may be disposed in a pipe or cylinder communication with the interior of the brake,

41 that extends through and opens into the'top'of and means for introducing'a compressible ?uid

the tank, and be suspended from av cable forming _' pressure to said container of such value that a

part of a windlass 42 mounted on top or the pipe. predetermined quantity of liquid is delivered to

Thus, by operating the windlass, weight 40 may said brake.

,

In the system shown the level of the liquid in

the stand pipe is controlled by air pressure: This

'50 could be accomplished in a number of other ways.

For example, the level could be varied by intro

be lowered or raised, displacing more or less liq

to

5. In combination, an hydro-dynamic brake ~

uid in the tank, thereby raising or lowering the comprising a stator having a rotor therein, a

level of theliquidand correspondingly regulat closed tank having a supply of liquid therein,

means placing the interior or the tank in com

ing the amount of active liquid in the brake.

In cases where the load on the brake remains munication with the interior of the brake, means

practically constant, it may not be necessary to for introducing a compressible ?uid under pres

pump air into the tank. Instead, the tank may sure to said tank of such value that a predeter~

be ?lled with liquid until the level rises in the mined quantity of liquid is delivered to said brake,

stand pipe to the point where the brake contains and'means to indicate the level of the liquid in

su?icient liquid to produce the braking action re the brake.

-_ quired. If operated in this manner, tank 27 and

6. In combination, an hydro-dynamic ?uid

75 stand pipe 281cm, in elIect, an open tank. The friction brake comprising astator having a rotor 75

5.

1,985,889

therein adapted to be driven by an over-hauling in response'toincreasing loads being imposed on

load, a closed container having a supply of liquid

therein, a stand pipe extending into said con-

the

brake.

'

'

'

12. A ?uid friction brake, a source of supply

tainer, said pipe having its lower end submerged .for said ?uid, connecting means between the

in the liquid therein and its upper end vented to brake and ?uid supply, means for varying the level a

the atmosphere, a connection from said container of the liquid in the brake to thereby regulate the

to the inlet of said brake, a connection from'the resistanceof the brake, and meansfor discharg

outlet of the brake to the upper portion of the ing liquid from the brake into the ?uid supply.

stand pipe for returning liquid discharged from 13. The method of controlling the braking ac-.

the brake to the container, and means for intro- I tion in hydrodynamic brakes of the liquid fric 10

ducing a charge of compressible ?uid to said . tion type that consists in providing a source of

container, in the space between the top thereof supply of liquid, connecting said supply to the

and the liquid.

brake, returning the liquid discharged from the

'

7. In combination, an hydro-dynamic ?uid brake to the source of supply and regulating the

15 friction brake comprising a stator having a rotor level of the liquid at the'source to increase or 15

therein adapted to be driven by' an over-hauling decrease the quantity of active liquid in the brake.

load, a closed container having a supply of liquid

14. A liquid friction brake, a tank containing ,

therein, a stand pipe, extending into saidtank, the supply of liquid for said brake, means for

said pipe having its lower end submerged in the connecting the tank to brake and circulating .

20 liquid therein and its upper end vented to the liquid therethrough, and means for varying the 20

atmosphere, a connection from said container liquid level in the- tank for varying the level of

to the inlet of said brake, a connection from the the liquid in the brake.

outlet of-the brake to the upper portion of the 15. The method of controlling the braking ac

stand pipe for returning liquid discharged from tion in hydro-dynamic brakes that consists in

the brake to the container, and means for intro

ducing ?uid to said container under variable pres

sure to vary the liquid level in the brake in ac

cordance with the braking action desired.

so

providing a source of supply of liquid, connect 25

ing said supply to the brake, superposing' a vari

ablepressure onthe source, and adjusting said

pressure until the level of the liquid in the brake

8. In combination, an hydro-dynamic ?uid is of the desired value. , '_

"

friction brake comprising a stator having a rotor

16. The method of controlling the braking ac 30

therein adapted to be driven by an over-hauling tion in liquid friction brakes that consists in pro

load, a closed tank having a supply of liquid there viding a source of supply of liquid, connecting

.in, a stand pipe entending into said tank, 'said ' said simply to the brake, superposing a variable

pipe having its lower end submerged in the liquid

therein and its upper end vented to the'atmos

phere, a connection from said tank to the inlet

of said brake, a connection from the outlet of

the brake to the upper portion of the "stand pipe

pressure on the source, and adjusting-said pres- -

sure until the level of the liquid in the brake is of 35

the desired value.

1'7. In combination, aliquid friction brake com

prising a stator having a rotor therein, a closed

for. returning liquid discharged from the brake container having a supply of liquid therein, means

(0 to the tank, means for introducing a charge of placing the interiorof the container in communi

compressible ?uid to said tank in the space be cation 'with the interior of the brake, and means

tween the top'thereof and the liquid, and means for introducing a compressible ?uid, to said con

to regulate the rate at which liquid is discharged tainer, under pressure of such value that a pre

from the brake.

determined quantity of liquid is delivered to said

45

9. In combination, an hydro-dynamic. brake .brake.

having an inlet and an outlet through which liquid I '18. In combination, a liquid friction brake hav

may discharge, a closed tank having liquid and ing an inlet and an outlet through which liquid

a charge of compressible ?uid therein under pres may discharge, a closed tank having liquid and

sure, and connections from said tank to the inlet , a charge of compressible ?uid therein under pres

of the brake and from the outlet of the brake to sure, a connection from said tank to the inlet of 50

the tank, the heat developed in the liquid passing

through the brake heating the compressible ?uid

in the tank to expand thesame, therebyraising

the liquid level in the brake and increasing the

braking action thereof.

10. In combination, an hydro-dynamicbrake

comprising a stator and a rotor, said stator hav

ing an inlet for liquid and outlet through which

liquid may be discharged, 9. source of supply liquid

connected to the ihlet to the stator and means

responsive to the heat ' absorbed by the liquid

passing through the brake' for automatically in

creasing the quantity of liquid introducedto the

brake and thereby automatically increasing the

- braking effort developed thereby.

'

'

the brake, and means for utilizing the heat de- I

veloped in the liquid in the brake and imparted

to said ?uid forvvarying the liquid level in the

tank. and brake to thereby vary the braking action

of the brake in response to changes in- temper

55

ature of said compressible ?uid.

19. A liquid friction brake, a tank having there

in a supply of liquid for the brake, means for con

necting the tank to the brake and circulating

liquid therethrough, and means coacting with the

liquid in the tank for regulating the active quan

tity of liquid in the brake.

20. A liquid friction brake having an inlet,

through which liquid may enter the brake, an out

let from which liquid may discharge, a source of 65

supply of liquid connected to the inlet, means for

11. In combination, [an hydro-dynamic ?uid

the quantity of active liquid in the

friction brake comprising a'stator and a rotor, controlling

brake independently of the rate at which liquid

said stator having an inlet and outlet for, re

being discharged therefrom, and means for

70 spectively, introducing liquid to the brake and is

regulating the rate of discharge.

discharging liquid therefrom, a source of supply

21. In combination, a liquid friction brake,

~ of liquid connected to the inlet, and means adqot having an inlet and outlet for liquid, a tank hav

7o.

ed to automatically increase the quantity of fric ing a connection with the inlet of the brake, there

tion absorbing liquid in the brake and thereby being a' discharge pipe connected to the outlet of >

15 increase the braking effort developed by-the broke the

brake arranged to return liquid to the tank .,75

1,986,889

at a point above the liquid level therein and a . ing an inlet and outlet for liquid, a tank having

substantiallyconstant volume of liquid in the a connection with the inlet 0! the brake, there

tank, brake and connections therebetween, and being a discharge pipe connected to the outlet of

means for adjustably displacing liquid in the tank the brake arranged to return" liquid to the tank

to vary the active quantity of liquid in the brake. at a point above the liquid level therein and a

22. In combination, a liquid friction brake, a substantially constant volume of liquid in the

tank having a supply of liquid therein, means for tank, brake and connections therebetween, and

' connecting the tank to the brake and circulating means for varying the level of the liquid in the

liquid therethrough, and means for varying the tank to adjust the braking eiIort developed by the

10

.

level of the liquid'in the, tank to adjust the brak brake.

ROBERT

GRIFFIN

DE

LA

MATER.

ing e?ort developed by the brake.

WILLIAM SCHWEMLEIN.

23. In combination, a liquid friction brake, hav

S-ar putea să vă placă și

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SDe la EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SÎncă nu există evaluări

- Hydraulic DynamometerDocument26 paginiHydraulic DynamometerhelderlpÎncă nu există evaluări

- Tesla Patent 1,061,142Document4 paginiTesla Patent 1,061,142jmunjaÎncă nu există evaluări

- Stepless Variable Capacity ControlDocument7 paginiStepless Variable Capacity Controlswapneel_kulkarniÎncă nu există evaluări

- Jan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1Document5 paginiJan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1luiscremaschiÎncă nu există evaluări

- Hydraulic Bumo StopDocument61 paginiHydraulic Bumo StopRaja Sekaran SajjaÎncă nu există evaluări

- Hydrodynamic Braking SystemDocument5 paginiHydrodynamic Braking SystemRajeev VarmaÎncă nu există evaluări

- May 12, 1942-, 'J. D Spaldlng 2,282,615: Brake For DrawworksDocument10 paginiMay 12, 1942-, 'J. D Spaldlng 2,282,615: Brake For DrawworkslfilippiniÎncă nu există evaluări

- H. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Document4 paginiH. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Josh FullerÎncă nu există evaluări

- JP2020180696A Proportional Solenoid VV in Hyd CKT PDFDocument12 paginiJP2020180696A Proportional Solenoid VV in Hyd CKT PDFRajesh CÎncă nu există evaluări

- Anti Dive Device For Telescopic Forks of MotorcyclesDocument4 paginiAnti Dive Device For Telescopic Forks of MotorcyclesRonnie RohmÎncă nu există evaluări

- Hyper Valve PatentDocument15 paginiHyper Valve PatenttonytayicÎncă nu există evaluări

- Linear Hydraulic CircuitsDocument11 paginiLinear Hydraulic CircuitsBetileno QuadAlexÎncă nu există evaluări

- OpenDocument9 paginiOpenchristian1777Încă nu există evaluări

- PUMPDocument38 paginiPUMPMurugavel VenkatÎncă nu există evaluări

- European Patent Specification: F03B 3/12 F03B 11/04 F03B 11/00Document15 paginiEuropean Patent Specification: F03B 3/12 F03B 11/04 F03B 11/00romeoresigaÎncă nu există evaluări

- Patent 01061206Document5 paginiPatent 01061206Milan ĐurićÎncă nu există evaluări

- Pages From Centrifugal Pumps HandbookDocument4 paginiPages From Centrifugal Pumps HandbooksalamrefighÎncă nu există evaluări

- GT LL: NN W///, WM)Document5 paginiGT LL: NN W///, WM)lfilippiniÎncă nu există evaluări

- 3.7 Reciprocating Inertia (Joggle) PumpsDocument27 pagini3.7 Reciprocating Inertia (Joggle) PumpsNourTarekHassenÎncă nu există evaluări

- CHAPTER 13 - Flow Controls and Flow DividersDocument8 paginiCHAPTER 13 - Flow Controls and Flow DividersVideonÎncă nu există evaluări

- Water Lifting Devices PDFDocument41 paginiWater Lifting Devices PDFSrinathRaghavan0% (1)

- Sept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LDocument4 paginiSept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LRakeshÎncă nu există evaluări

- Pelton Lab UseDocument11 paginiPelton Lab UseackimÎncă nu există evaluări

- Unit 6 PumpsDocument7 paginiUnit 6 PumpsAlex CarlyÎncă nu există evaluări

- United States Patent (191: Swearingen (11) 4,287,758Document7 paginiUnited States Patent (191: Swearingen (11) 4,287,758NicandroGonzalesÎncă nu există evaluări

- May 13, 1969 M. R. Jones: So, 1966 L Of4 Filed DecDocument16 paginiMay 13, 1969 M. R. Jones: So, 1966 L Of4 Filed DecluiscremaschiÎncă nu există evaluări

- 5.CHAPTER 13 - Flow Controls and Flow DividersDocument12 pagini5.CHAPTER 13 - Flow Controls and Flow DividersVinod YbÎncă nu există evaluări

- 20080012322-Vortex Flow ControlDocument10 pagini20080012322-Vortex Flow Controlozland9Încă nu există evaluări

- Flowing Well PerformanceDocument57 paginiFlowing Well PerformancemkwendeÎncă nu există evaluări

- Flowing Well PerformanceDocument57 paginiFlowing Well PerformanceTogoumas Djide100% (4)

- 3.7 Reciprocating Inertia (Joggle) Pumps: 3.7.1 Flap Valve PumpDocument48 pagini3.7 Reciprocating Inertia (Joggle) Pumps: 3.7.1 Flap Valve PumprexÎncă nu există evaluări

- 3.7 Reciprocating Inertia (Joggle) Pumps: 3.7.1 Flap Valve PumpDocument44 pagini3.7 Reciprocating Inertia (Joggle) Pumps: 3.7.1 Flap Valve PumprexÎncă nu există evaluări

- Centrifugal Pump Test RigDocument4 paginiCentrifugal Pump Test RigVaidish Sumaria100% (1)

- Lab 3 - Pelton TurbineDocument4 paginiLab 3 - Pelton TurbineLuqman HakimÎncă nu există evaluări

- Controlling Ejector Performance: BY C. G. Blatchley Schutte & KoertingDocument9 paginiControlling Ejector Performance: BY C. G. Blatchley Schutte & KoertingCan YıldırımÎncă nu există evaluări

- GoverningDocument15 paginiGoverningmanishtopsecrets100% (1)

- 1972.10.10 EN Patent DragPump EnergyThic US3697190 Truncated Conical Drag PumpDocument7 pagini1972.10.10 EN Patent DragPump EnergyThic US3697190 Truncated Conical Drag PumpRenier SnymanÎncă nu există evaluări

- Us 5236286Document8 paginiUs 5236286Herlan Setiawan SihombingÎncă nu există evaluări

- Chapter II The Centrifugal Fire PumpDocument21 paginiChapter II The Centrifugal Fire PumpmjsebasÎncă nu există evaluări

- Flow Control ValvesDocument6 paginiFlow Control ValvesMohamed RadwanÎncă nu există evaluări

- Wartsila CPP PaperDocument4 paginiWartsila CPP Papergatheringforgardner9550Încă nu există evaluări

- Spe-104202-Pa-P (1) - 2 MarzoDocument6 paginiSpe-104202-Pa-P (1) - 2 MarzodanonninoÎncă nu există evaluări

- 7 Hydraulic CKT 18P2Document17 pagini7 Hydraulic CKT 18P2M RazzaqueÎncă nu există evaluări

- Ducted Prop For STOL PaperDocument8 paginiDucted Prop For STOL PaperLEADAÎncă nu există evaluări

- Pump Card Analysis Simplified and ImprovedDocument14 paginiPump Card Analysis Simplified and ImprovedOsmund MwangupiliÎncă nu există evaluări

- United States Patent (191: Lown (45) Nov. 11, 1980Document4 paginiUnited States Patent (191: Lown (45) Nov. 11, 1980HamedJamshidiÎncă nu există evaluări

- United States: (12) Patent Application Publication (10) Pub. No.: US 2012/0227970 A1Document14 paginiUnited States: (12) Patent Application Publication (10) Pub. No.: US 2012/0227970 A1zbhdzpÎncă nu există evaluări

- Sept. 4 - , 1956 A. Cherkin 2,761,445: Filed May 3, 1952 2 Sheets-Sheet 1Document5 paginiSept. 4 - , 1956 A. Cherkin 2,761,445: Filed May 3, 1952 2 Sheets-Sheet 1cvkkkk1Încă nu există evaluări

- Rotary Screw ProcessDocument9 paginiRotary Screw ProcessEagle WingsÎncă nu există evaluări

- Fluid MachineryDocument16 paginiFluid MachineryprashantÎncă nu există evaluări

- Bombas de Glicol KimrayDocument14 paginiBombas de Glicol KimrayLuis Carlos Saavedra100% (1)

- Performance Test of Kaplan TurbineDocument3 paginiPerformance Test of Kaplan TurbineJhiGz Llausas de Guzman0% (1)

- Operation of The Teaching Flume at The Cee Hydraulics LaboratoryDocument13 paginiOperation of The Teaching Flume at The Cee Hydraulics LaboratoryNgo AcaiÎncă nu există evaluări

- Water Lifting DevicesDocument22 paginiWater Lifting Devicesbman0051401Încă nu există evaluări

- AU2020201626B2Document59 paginiAU2020201626B2jÎncă nu există evaluări

- Pump Slippage Equation To Design Pump ClearancesDocument15 paginiPump Slippage Equation To Design Pump ClearancesSalim Ben AmorÎncă nu există evaluări

- The Petrol Engine: A Text-book dealing with the Principles of Design and Construction, with a Special Chapter on the Two-stroke EngineDe la EverandThe Petrol Engine: A Text-book dealing with the Principles of Design and Construction, with a Special Chapter on the Two-stroke EngineÎncă nu există evaluări

- Us 5113943Document7 paginiUs 5113943lfilippiniÎncă nu există evaluări

- Us20040221985 PDFDocument13 paginiUs20040221985 PDFlfilippiniÎncă nu există evaluări

- United States Patent (19) (11) 4,298,078Document9 paginiUnited States Patent (19) (11) 4,298,078lfilippiniÎncă nu există evaluări

- Us4027816 PDFDocument8 paginiUs4027816 PDFlfilippiniÎncă nu există evaluări

- Us 5038863Document5 paginiUs 5038863lfilippiniÎncă nu există evaluări

- United States Patent: Ryan US 6,176,311 B1Document9 paginiUnited States Patent: Ryan US 6,176,311 B1lfilippiniÎncă nu există evaluări

- United States Patent (19) : B JornstadDocument4 paginiUnited States Patent (19) : B JornstadlfilippiniÎncă nu există evaluări

- United States Patent: Ryan US 6,176,311 B1Document9 paginiUnited States Patent: Ryan US 6,176,311 B1lfilippiniÎncă nu există evaluări

- United States Patent: (12) (10) Patent No.: US 7,188,675 B2Document13 paginiUnited States Patent: (12) (10) Patent No.: US 7,188,675 B2lfilippiniÎncă nu există evaluări

- Ulllted States Patent (10) Patent N0.: US 7,610,957 B2Document8 paginiUlllted States Patent (10) Patent N0.: US 7,610,957 B2lfilippiniÎncă nu există evaluări

- Us 6250387Document15 paginiUs 6250387lfilippiniÎncă nu există evaluări

- United States Patent US 6,276,452 B1: Davis Et Al. (45) Date of Patent: Aug. 21, 2001Document8 paginiUnited States Patent US 6,276,452 B1: Davis Et Al. (45) Date of Patent: Aug. 21, 2001lfilippiniÎncă nu există evaluări

- J. H. Wilson: Inventor.Document6 paginiJ. H. Wilson: Inventor.lfilippiniÎncă nu există evaluări

- United States: (12) Patent Application Publication (10) Pub. No.: US 2009/0126933 A1Document18 paginiUnited States: (12) Patent Application Publication (10) Pub. No.: US 2009/0126933 A1lfilippiniÎncă nu există evaluări

- GT LL: NN W///, WM)Document5 paginiGT LL: NN W///, WM)lfilippiniÎncă nu există evaluări

- J. H. Wilson: Inventor.Document6 paginiJ. H. Wilson: Inventor.lfilippiniÎncă nu există evaluări

- L'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545Document12 paginiL'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545lfilippiniÎncă nu există evaluări

- Filed April 2, 1946Document4 paginiFiled April 2, 1946lfilippiniÎncă nu există evaluări

- Piper AlphaDocument3 paginiPiper AlphalfilippiniÎncă nu există evaluări

- Us 2464469Document8 paginiUs 2464469lfilippiniÎncă nu există evaluări

- May 12, 1942-, 'J. D Spaldlng 2,282,615: Brake For DrawworksDocument10 paginiMay 12, 1942-, 'J. D Spaldlng 2,282,615: Brake For DrawworkslfilippiniÎncă nu există evaluări

- Us 2109297Document6 paginiUs 2109297lfilippiniÎncă nu există evaluări

- 1KW Project in On GrideDocument5 pagini1KW Project in On GrideRAKESH PRADHANÎncă nu există evaluări

- Power System Statistics 41st Edition PDFDocument83 paginiPower System Statistics 41st Edition PDFYahya DarÎncă nu există evaluări

- Powechina Railway in The Philippines (Financing+financial) 20161224Document65 paginiPowechina Railway in The Philippines (Financing+financial) 20161224JINÎncă nu există evaluări

- Magnet Generator For Wind Power PDFDocument77 paginiMagnet Generator For Wind Power PDFXeltor100% (2)

- Calculating Solar Reflectance Index of Horizontal and Low-Sloped Opaque SurfacesDocument3 paginiCalculating Solar Reflectance Index of Horizontal and Low-Sloped Opaque SurfacesAbuAhmedQuazi100% (1)

- 01-Diesel Engine Basics (R1.2jb)Document29 pagini01-Diesel Engine Basics (R1.2jb)donsallus100% (1)

- FINAL Reiki Handbook1Document73 paginiFINAL Reiki Handbook1harmanpkÎncă nu există evaluări

- Wind Farms and Their Effect On Radio Navigation AidsDocument4 paginiWind Farms and Their Effect On Radio Navigation AidsicyregÎncă nu există evaluări

- 5000kVA UnindoDocument2 pagini5000kVA UnindoAndre ChandraÎncă nu există evaluări

- Fuse & MCCB For Capacitor Bank-MerlinDocument2 paginiFuse & MCCB For Capacitor Bank-MerlinUrsula JohnsonÎncă nu există evaluări

- Mae655 HW 1 2017 Updated Sept8Document2 paginiMae655 HW 1 2017 Updated Sept8JonÎncă nu există evaluări

- Smash Get Diva2 289469 FULLTEXT01Document116 paginiSmash Get Diva2 289469 FULLTEXT01Alysson DomingosÎncă nu există evaluări

- Solar Roadways: A Seminar Report OnDocument19 paginiSolar Roadways: A Seminar Report OnMetpalli AshwiniÎncă nu există evaluări

- EM6400 QSG V01.d18 (Web) PDFDocument4 paginiEM6400 QSG V01.d18 (Web) PDFGillala RamakanthÎncă nu există evaluări

- Improved Operation of Cables Connecting Offshore Wind Farms To The Power Grid H. J. Joergensen, J. Hjerrild, C. Jensen and J. Havsager Defu, Eltra and Elkraft System DenmarkDocument8 paginiImproved Operation of Cables Connecting Offshore Wind Farms To The Power Grid H. J. Joergensen, J. Hjerrild, C. Jensen and J. Havsager Defu, Eltra and Elkraft System DenmarkramsesiÎncă nu există evaluări

- Centrifugal Comp PDFDocument7 paginiCentrifugal Comp PDFmsaroladanÎncă nu există evaluări

- Account No: Total Amount Due:: Important InformationDocument2 paginiAccount No: Total Amount Due:: Important InformationWinnie LuongÎncă nu există evaluări

- Some Facts About Geothermal EnergyDocument9 paginiSome Facts About Geothermal EnergyPoochi DougÎncă nu există evaluări

- Biomass Resource Assessment-MWC - RBDG - Rev1Document88 paginiBiomass Resource Assessment-MWC - RBDG - Rev1Ryan JayÎncă nu există evaluări

- SIS Negros PH Solar Inc. 50 MW Solar Project PDFDocument116 paginiSIS Negros PH Solar Inc. 50 MW Solar Project PDFNegros Solar PH100% (2)

- Installation Instructions For Axial Fans For Bathroom, Toilets, Utility Rooms and KitchensDocument2 paginiInstallation Instructions For Axial Fans For Bathroom, Toilets, Utility Rooms and KitchenstylerdurdaneÎncă nu există evaluări

- JAC 4DA1 Series Diesel Engine PDFDocument12 paginiJAC 4DA1 Series Diesel Engine PDFFerran Alfonso80% (5)

- Hvac Install ChecklistDocument4 paginiHvac Install Checklistadnyat0% (1)

- Fundamentals of CarburetorDocument12 paginiFundamentals of Carburetorecasayang0% (1)

- Engineering Photovoltaic Systems 1 - 2010Document43 paginiEngineering Photovoltaic Systems 1 - 2010Joshua Pearce100% (9)

- VSEP Membrane Separation Ethanol Application NoteDocument12 paginiVSEP Membrane Separation Ethanol Application NoteHermawan Dwi AriyantoÎncă nu există evaluări

- Smart Coater Technical Specification SheetDocument4 paginiSmart Coater Technical Specification SheetAbhilash Narayanan100% (2)

- Req Equip Material Devlopment Power SectorDocument57 paginiReq Equip Material Devlopment Power Sectorayadav_196953Încă nu există evaluări

- Project Phase1 ReportDocument16 paginiProject Phase1 ReportNithinÎncă nu există evaluări

- Net Metering and Utility Interconnection: Bill Brooks Brooks EngineeringDocument55 paginiNet Metering and Utility Interconnection: Bill Brooks Brooks EngineeringGerardoAlainLoredoMoyedaÎncă nu există evaluări