Documente Academic

Documente Profesional

Documente Cultură

Excess Flow Valves Bleed Valves and Purge Valves

Încărcat de

Nilesh MistryDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Excess Flow Valves Bleed Valves and Purge Valves

Încărcat de

Nilesh MistryDrepturi de autor:

Formate disponibile

Excess Flow Valves, Bleed

Valves and Purge Valves

EV Series, RB Series, RP Series

FITOK Group

FITOK GmbH (Headquarter)

Sprendlinger Landstr. 115, 63069 Offenbach am Main, Germany

Tel.: +49 69 8900 4498

Fax: +49 69 8900 4495

FITOK, Inc.

13843 North Promenade Blvd., Suite 750, Stafford, Texas 77477, USA

Tel.: +1 281 888 0077

Fax: +1 281 310 8687

FITOK Incorporated

1-4F, Block C, Zone E, Yingtailong lndustrial Park, Dalang Street,

Longhua District, Shenzhen, 518109, China

Tel.: +86 755 2803 2500

Fax: +86 755 2803 2619

FITOK Middle East Oil Equipment Trading LLC

208-209, Makateb Tower, Airport Road, P.O.Box 185412, Deira, Dubai, UAE

Tel.: +971 4 2959 853

Fax: +971 4 2959 854

info@fitokgroup.com

www.fitokgroup.com

FK-IC-GV-08-EN-140819

www.fitokgroup.com

Excess Flow Valves, Bleed Valves and Purge Valves 1

Contents

Excess Flow Valves

EV Series

Excess Flow Valves

EV Series

Introduction

01

Bleed Valves

RB Series

If downstream line ruptures, the excess flow valve can stop uncontrolled release of system media. When the system is

functioning normally, the working element remains in the open position. If the excess flow occurs downstream, the working

element quickly moves to the tripped position to stop bleeding. When system pressure reaches balance through the bleed vent,

the spring resets the working element to the open position automatically. The flow which goes through the bleed vent should

be lower than one percent of the flow rate in the trip range.

05

Features

Purge Valves

RP Series

07

Compact design for convenient installation

Working pressure up to: 6000 psig (414 bar)

Working temperature: -10F to 400F (-23C to 204C)

Variety of end connections

Stainless steel construction

Leak-tight performance testing for every valve with

nitrogen at the maximum working pressure

End Connection:

tube fitting, thread or

face sealed

Easy installation

Improved system reliability

Spring Drive to Brake

All Metal Seat

Working Element

Bleed Vent

Enhanced durability

No maintenance needed

Improved capability and reliability

High flow capability

Nuisance tripping eliminated

Eliminate complicated

by-pass mechanism

Spring resets the element

automatically

Easy operation

Enabled to work in any

direction and improve

the safety of system

Temperature Ranges for Different Seal Materials

O-ring Material

Temperature Ranges oF (oC)

Buna N

-40 to 250 (-40 to 121)

Ethylene Propylene

-50 to 300 (-45 to 148)

Fluorocarbon FKM

-10 to 400 (-23 to 204)

Kalrez

-10 to 527 (-23 to 275)

Neoprene

-40 to 250 (-40 to 121)

2 Excess Flow Valves, Bleed Valves and Purge Valves

o

Excess Flow Valves, Bleed Valves and Purge Valves 3

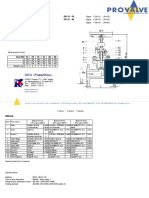

Dimensions

Flow Data at 70 F (20 C)

Orifice Size: 0.19 in. (4.8 mm)

Air Flow (std L/min)

6000

8000 10000

3000

400

300

100

80

60

Trip

Range

1000

800

600

40

30

400

300

20

Tripped

lnlet Pressure (psig)

200

Open

2000

10

8

100

60

80

100

200

6000 8000 10000

300

20000

200

Open

2000

1000

800

600

100

80

60

Trip

Range

400

300

40

30

20

Tripped

200

200

40

4000

400

300

4000

3000

lnlet Pressure (bar)

4000

3000

lnlet Pressure (psig)

3000 4000

Air Flow (std L/min)

10

8

100

80

400

100

200

300

400

Orifice Size: 0.39 in. (10 mm)

Air Flow (std L/min)

3000

20000

Water Flow

30000

400

300

1000

800

600

100

80

60

40

30

Trip

Range

400

300

Tripped

200

20

Orifice

in. (mm)

0.19 (4.8)

0.33 (8.4)

0.39 (10)

10

8

100

100

200

Basic

Ordering

Number

Connections Type and Size

Inlet

Outlet

300

400

600

Trip Range

Std ft3 /min (L/min)

0.52 to 0.77 (14.7 to 21.9)

1.09 to 1.34 (31.0 to 37.8)

1.50 to 2.00 (42.3 to 56.3)

Standard Materials of Construction

Component

Material Grade/ASTM Specification

Inlet Body

316 SS/A479

Mark Ring

6061 Al/B491

Working Element

316 SS/A479

Spring

302 SS/A313

O-ring

Fluorocarbon FKM

Seal Ring

PTFE/D1710

Outlet Body

316 SS/A479

Dimension, in. (mm)

A

11/16

(17.46)

11/16

(17.46)

1

(25.4)

1

(25.4)

11/16

(17.46)

11/16

(17.46)

1

(25.4)

1

(25.4)

11/16

(17.46)

11/16

(17.46)

1/4" FITOK

1/4" FITOK

0.19

(4.8)

2.43

(61.7)

EV-FL6-6

3/8" FITOK

3/8" FITOK

0.33

(8.4)

2.75

(69.9)

2.97

(75.4)

2.43

(61.7)

EV-FL8-8

1/2'' FITOK

1/2'' FITOK

0.39

(10.0)

EV-ML6-4

6 mm FITOK

6 mm FITOK

0.19

(4.8)

EV-ML8-6

8 mm FITOK

8 mm FITOK

EV-ML10-6

10 mm FITOK

10 mm FITOK

EV-ML12-8

12 mm FITOK

12 mm FITOK

EV-FNS2-4

1/8 Female NPT

1/8 Female NPT

EV-FNS4-4

1/4 Female NPT

1/4 Female NPT

EV-FNS6-6

3/8 Female NPT

3/8 Female NPT

0.33

(8.4)

2.55

(64.8)

1

(25.4)

1

(25.4)

EV-FNS8-8

1/2 Female NPT

1/2 Female NPT

0.39

(10.0)

3.03

(77.0)

1 1/16

(26.99)

1 1/16

(26.99)

EV-NS2-4

1/8 Male NPT

1/8 Male NPT

11/16

(17.46)

11/16

(17.46)

EV-NS4-4

1/4 Male NPT

1/4 Male NPT

EV-NS6-6

3/8 Male NPT

3/8 Male NPT

0.33

(8.4)

2.36

(59.9)

2.73

(69.3)

1

(25.4)

1

(25.4)

11/16

(17.46)

11/16

(17.46)

1

(25.4)

1

(25.4)

0.33

(8.4)

0.39

(10.0)

0.19

(4.8)

800 10001200

Air Flow (std ft 3/min)

Orifice

in. (mm)

EV-FL4-4

200

Open

2000

lnlet Pressure (bar)

4000

3000

lnlet Pressure (psig)

4000 6000 8000 10000

600 800

Air Flow (std ft 3/min)

Air Flow (std ft 3/min)

lnlet Pressure (bar)

2000

Orifice Size: 0.33 in. (8.4mm)

0.19

(4.8)

2.70

(68.6)

2.80

(71.1)

2.96

(75.2)

1.87

(47.5)

2.12

(53.8)

1.79

(45.5)

2.17

(55.1)

EV-NS8-8

1/2 Male NPT

1/2 Male NPT

0.39

(10.0)

EV-NS4-FL4-4

1/4 Male NPT

1/4" FITOK

0.19

(4.8)

2.30

(58.4)

EV-NS6-FL6-6

3/8 Male NPT

3/8" FITOK

0.33

(8.4)

2.56

(65.0)

EV-NS8-FL8-8

1/2 Male NPT

1/2" FITOK

0.39

(10.0)

2.85

(72.4)

EV-NS4-FNS4-4

1/4 Male NPT

1/4 Female NPT

0.19

(4.8)

2.13

(54.1)

11/16

(17.46)

11/16

(17.46)

EV-NS6-FNS6-6

3/8 Male NPT

3/8 Female NPT

0.33

(8.4)

2.46

(62.5)

1

(25.4)

1

(25.4)

EV-NS8-FNS8-8

1/2 Male NPT

1/2 Female NPT

0.39

(10.0)

3.03

(77.0)

1 1/16

(26.99)

1 1/16

(26.99)

1. FITOK means FITOK double ferrule tube fittings.

2. Sizes and types listed are standard. Other sizes and types are available upon request.

3. Dimensions are shown with FITOK nuts finger-tightened. All dimensions are for reference only and are subject to change.

For dimensions not shown above, please contact the authorized representative or FITOK Group.

4 Excess Flow Valves, Bleed Valves and Purge Valves

Excess Flow Valves, Bleed Valves and Purge Valves 5

Bleed Valves

Part Number Description

EVSS - FL6 - ML8 - 6Z - SF2

RB Series

Introduction

Series Body Material

SS

S4

S1

6L

4L

904L

316 SS

304 SS

321 SS

316L SS

304L SS

904L SS

Inlet Size

Outlet

Size

Orifice

Size

Seal

Material

Cleaning and

Special

Application Packaging

Fluorocarbon

NO

Female NPT

2 1/8"

Same as Inlet 4 0.19"

FC-01

FKM

(4.8 mm)

Male NPT

4 1/4"

NACE

S

F2

FC-02

Buna

N

B

0.33

"

MR0175

Specified in the 6

Female BSPT

6 3/8" or 6 mm

(8.4 mm) N Neoprene

same way as

8 1/2" or 8 mm

Male BSPT

the inlet type

Ethylene

8 0.39 "

Female Metric

and size

10 10 mm

(10 mm) E propylene

FMS Thread

Z Kalrez

12 3/4" or 12 mm

(for RP-M)

Male Metric

MS Thread

(for RG-M)

FRP Female BSPP

(for RP)

Note: "Part Number Description" is used for composition rules of FITOK product model,

BP Male BSPP

(for RG)

Not suitable for specific product part number selection, not random combinations.

Fractional Tube

If in doubt, please contact FITOK group or authorized agent.

FL Fitting

FNS

NS

FRT

RT

Metric Tube

ML Fitting

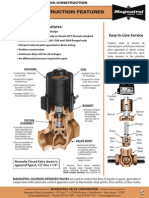

Bleed valves can be used on instrument devices such as multi-valve manifolds

or gauge valves to vent signal line pressure to atmosphere before removal of an

instrument or to assist in calibration.

Features

Compact design for easy installation

Chrome-plated stem and tip to extend cycle life

Working pressure up to: 10000 psig (690 bar)

Working temperature: -65F to 850F (-54C to 454C)

Variety of end connections

Stainless steel, carbon steel and alloy 400 available

Leak-tight performance testing for every valve with

nitrogen at 6000 psig

Pressure vs. Temperature

Temperature (C)

-54

10500

37

93

148

204

260

315

371

426

482

724

Steel Body

Alloy 400 Body

9000

621

316 SS Body

7500

517

6000

4500

-65

414

Pressure (bar)

1. Standard thread pitch for metric threads are as follows:

M10 and below: 1 mm

M12 to M24: 1.5 mm

M27 and above: 2 mm

Standard thread pitch should be ignored in the ordering number, others

should be specified.

2. Cleaning and Packaging:

FC-01: Standard cleaning and packaging for general industrial procedures.

FC-02: Special cleaning and packaging for wetted system components to

ensure compliance with product cleanliness requirement as stated in ASTM

G93 Level C.

Pressure (psig)

EV

Inlet Type

Outlet

Type

310

100

200

300

400

500

600

700

800

900

Temperature (F)

Contact the authorized representative or FITOK Group for curve graph of other materials.

Standard Materials of Construction

1

1

Valve Body Material Grade/ASTM Specification

2

3

Component

316 SS

Carbon Steel

Alloy 400

Stem

Chrome-plated

316 SS/A276

Chrome-plated

316 SS/A276

Alloy 400/B164

Body

316 SS/A479

1018/A108

Alloy 400/B164

Vent tube

316 SS/A276

316 SS/A276

Alloy 400/B164

1. Lubricant is nickel antiseize, hydrocarbon carrier.

2. Contact the authorized representative or FITOK Group for other materials.

Type 1

Type 2

6 Excess Flow Valves, Bleed Valves and Purge Valves

Excess Flow Valves, Bleed Valves and Purge Valves 7

Dimensions

Type

Basic

Ordering

Number

A (Close)

RB -NS4

1/4 Male NPT

1.31

(33.4)

5/8

(15.9)

RB -NS6

3/8 Male NPT

1.46

(37.1)

7/8

(22.2)

RB -NS8

1/2 Male NPT

RB -RT4

1/4 Male BSPT

1.31

(33.4)

5/8

(15.9)

RB -RT6

3/8 Male BSPT

1.46

(37.1)

7/8

(22.2)

RB -RT8

1/2 Male BSPT

1.57

(40.0)

5/8

(15.9)

1.74

(44.2)

7/8

(22.2)

C Hex

B Hex

Type 1

Type 1

Dimension, in. (mm)

Inlet Type and

Size

RB -NS4-L

1/4 Male NPT

RB -NS6-L

3/8 Male NPT

RB -NS8-L

1/2 Male NPT

RB -RT4-L

1/4 Male BSPT

RB -RT6-L

3/8 Male BSPT

RP Series

Introduction

Purge valves are manual bleed, vent or drain valves. The cap is used to release system pressure. One-quarter turn with a wrench

from finger-tight obtains leaktight closure during initial installation. Tightening with a wrench ensures closure to the rated

pressure with subsequent installations.

Features

7/16

(11.1)

C Hex

B Hex

Purge Valves

Compact design for easy installation

Bonnet crimped to valve body to prevent accidental disassembly

Working pressure up to: 4000 psig (276 bar)

Working temperature: -65F to 600F (-54C to 315C)

316 stainless steel, brass and carbon steel materials available

Leak-tight performance testing for every valve with nitrogen at

the maximum working pressure

Type L

Type 2

Type 2

RB -RT8-L

1.57

(40.0)

5/8

(15.9)

1.74

(44.2)

7/8

(22.2)

Type TL

Type TA

1/2 Male BSPT

Part Number Description

Temperature (C)

-54

4500

4000

3000

2000

1000

RBSS - NS4 - L - SH - SF2

Pressure vs. Temperature

0

-65

10

37

65

93

121 148 176 204 232 260 287 315

310

276

316 SS

Body

241

Steel Body

207

172

Br

as

138

sB

103

od

y

69

34

0

50 100 150 200 250 300 350 400 450 500 550 600

Pressure (bar)

Sizes and types listed are standard. Other sizes and types are available upon

request. All dimensions are for reference only and are subject to change.

For dimensions not shown above, please contact the authorized representative

or FITOK Group.

Pressure (psig)

These bleed valves don't have a cap thread seal,

so open the valve slowly and direct the vent hole

away from the operator. These valves contain no

packing, so some fluid leakage will occur when

the valves are opened.

Temperature (F)

Contact the authorized representative or FITOK Group for curve graph of other materials.

RB

Body

Material

SS 316 SS

6L

Caution

Series

Type C

316L SS

Inlet Type

NS

RT

Inlet Size

Male NPT

2 1/8"

Male BSPT

4 1/4"

S4 304 SS

6 3/8"

4L

8 1/2"

304L SS

S1 321 SS

B

Brass

Alloy R-405

CS Carbon Steel

Outlet

Type 1

L Type 2

Handle

Special

Application

NO

NO

Stainless

Steel

SH Handle

(Only For

Type 2)

NACE

MR 0175

Cleaning and

Packaging

Standard Materials of Construction

FC-01

F2 FC-02

Note: "Part Number Description" is used for composition rules of FITOK product model,

Not suitable for specific product part number selection, not random combinations.

If in doubt, please contact FITOK group or authorized agent.

Cleaning and Packaging:

FC-01: Standard cleaning and packaging for general industrial procedures.

FC-02: Special cleaning and packaging for wetted system components to ensure

compliance with product cleanliness requirement as stated in ASTM G93 Level C.

Component

Valve Body Material Grade/ASTM Specification

316 SS

Brass

Steel

Body

316 SS/A182

316 SS/A479

Brass C36000/B16

Brass C37700/B283

12L4/A108

Chromium-plated

Cap

316 SS/A276

Brass C36000/B16

12L4/A108

Chromium-plated

Poppet (Ball)

316 SS/A276

316 SS/A276

316 SS/A276

Spring

302 SS/A313

1. Lubricant: molybdenum disulfide-based and silicone-based.

2. Contact the authorized representative or FITOK Group for other materials.

-FL6

3/8" FITOK

-FL8

1/2" FITOK

-ML6

6 mm FITOK

-ML8

8 mm FITOK

-ML10

10 mm FITOK

-ML12

12 mm FITOK

-FNS4

1/4 Female NPT

-FNS6

3/8 Female NPT

Caution:

-FNS8

1/2 Female NPT

These purge valves don't have a cap

thread seal, so open the valve slowly

and direct the vent hole away from

the operator. These valves contain no

packing, so some fluid leakage will

occur when the valves are opened.

-NS4

1/4 Male NPT

-NS6

3/8 Male NPT

-NS8

1/2 Male NPT

A

B

Type C

Valve End

D Hex

C Hex

2

RP -TL

RP -TA

RP -C

3

B

1. FITOK means FITOK double ferrule tube fittings.

2. Dimensions are shown with FITOK nuts finger - tightened. All dimensions are

for reference only and are subject to change.

3. Sizes and types listed are standard. Other sizes and types are available upon

request, refer to the ordering information.

1. Standard thread pitch for metric threads are as follows:

M10 and below: 1 mm

M12 to M24: 1.5 mm

M27 and above: 2 mm

Standard thread pitch should be ignored in the ordering number, others should be specified.

2. Cleaning and Packaging:

FC-01: Standard cleaning and packaging for general industrial procedures.

FC-02: Special cleaning and packaging for wetted system components to ensure compliance with

product cleanliness requirement as stated in ASTM G93 Level C.

1/4" FITOK

Note: "Part Number Description" is used for composition rules of FITOK product model,

Not suitable for specific product part number selection, not random combinations.

If in doubt, please contact FITOK group or authorized agent.

-FL4

5/8

(15.9)

Fractional Tube

Fitting

Metric Tube

ML Fitting

1/2 Male NPT

Valve end

FL

-NS8

Male BSPP

(for RG)

3/8 Male NPT

BP

-NS6

FRP Female BSPP

(for RP)

1/4 Male NPT

C Hex

D Hex

Male Metric

MS Thread

(for RG-M)

-NS4

Specified in the same way as

the end connection 1 type

and size

1/2 Female NPT

Specified in the same way as

the end connection 1 type

and size

-FNS8

NO

NACE

S MR0175

3/8 Female NPT

Same as connection 1

-FNS6

Type TA

Same as connection 1

1/4 Female NPT

2

4

6

8

10

12

-FNS4

Female NPT

Male NPT

Female BSPT

Male BSPT

Female Metric

FMS Thread

(for RP-M)

12 mm FITOK

FNS

NS

FRT

RT

-ML12

Straight

In-line Tee

Angle Tee

Cross

10 mm FITOK

R P -L

L

TL

TA

C

-ML10

C Hex

316 SS

316L SS

304 SS

304L SS

321 SS

Brass

Carbon

CS Steel

904L 904L SS

8 mm FITOK

SS

6L

S4

4L

S1

B

-ML8

D Hex

End

Connection

3 Size

6 mm FITOK

Valve End

End

Connection

3 Type

-ML6

Type TL

End

Connection

2 Size

1/2" FITOK

End

Connection

2 Type

-FL8

1/2

(12.7)

5/8

(15.9)

13/16

(20.6)

0.55

(14.0)

0.59

(15.0)

0.71

(18.0)

0.87

(22.0)

3/4

(19.1)

7/8

(22.2)

1 1/16

(26.9)

9/16

(14.3)

11/16

(17.5)

7/8

(22.2)

1/2

(12.7)

5/8

(15.9)

13/16

(20.6)

1/2

(12.7)

5/8

(15.9)

11/16

(17.5)

13/16

(20.6)

11/16

(17.5)

13/16

(20.6)

1

(25.4)

1/2

(12.7)

11/16

(17.5)

13/16

(20.6)

End Connection

1 Size

3/8" FITOK

0.69

(17.5)

0.75

(19.1)

0.88

(22.4)

0.69

(17.5)

0.73

(18.6)

0.77

(19.6)

0.87

(22.0)

0.72

(18.3)

0.78

(19.8)

0.97

(24.6)

0.56

(14.2)

0.56

(14.2)

0.75

(19.1)

1.06

(26.9)

1.20

(30.5)

1.42

(36.1)

1.06

(27.0)

14.95

(29.9)

1.24

(31.6)

1.41

(36.0)

1.17

(29.7)

1.42

(36.1)

1.56

(39.6)

1.05

(26.7)

1.17

(29.7)

1.45

(36.8)

End Connection

1 Type

-FL6

1.96

(49.8)

2.05

(52.1)

2.20

(56.0)

1.96

(49.8)

2.02

(51.3)

2.10

(53.4)

2.20

(55.9)

1.76

(44.7)

1.83

(46.5)

2.02

(51.3)

1.84

(46.8)

1.89

(48.0)

2.11

(53.6)

1.41

(35.8)

1.49

(37.8)

1.61

(40.9)

1.41

(35.8)

1.48

(37.7)

1.52

(38.6)

1.60

(40.6)

1.66

(42.2)

1.75

(44.4)

1.75

(44.4)

1.54

(39.2)

1.68

(42.6)

1.75

(44.4)

Type

1/4" FITOK

-FL4

Amax

Body

Material

C Hex

Dimension, in. (mm)

Series

Connection

Type and Size

RPSS - C - FL8 - ML10 - FL8 - SF2

D Hex

Part Number Description

Basic

Ordering

Number

Valve End

RP

Type L

1/8"

1/4"

3/8" or 6 mm

1/ 2" or 8 mm

10 mm

3/4" or 12 mm

14 mm or

14

M14 x 1.5

16 1" or 16 mm

Special

Cleaning and

Application Packaging

Models and Dimensions

F2 FC-02

Excess Flow Valves, Bleed Valves and Purge Valves 9

FC-01

8 Excess Flow Valves, Bleed Valves and Purge Valves

S-ar putea să vă placă și

- Hydrotechnik Full CatalogueDocument128 paginiHydrotechnik Full CatalogueEysakaylovasÎncă nu există evaluări

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsEvaluare: 4.5 din 5 stele4.5/5 (10)

- Supplier Quality Assurance ManualDocument29 paginiSupplier Quality Assurance ManualNilesh Mistry0% (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1De la EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Evaluare: 3.5 din 5 stele3.5/5 (3)

- Nippon Steel Seamless CasingDocument18 paginiNippon Steel Seamless Casingjohndo3Încă nu există evaluări

- Api Plan 11Document6 paginiApi Plan 11johnsaballaÎncă nu există evaluări

- Design of Composite Haunch Beams and Connections For Long Span Applications PDFDocument176 paginiDesign of Composite Haunch Beams and Connections For Long Span Applications PDFVance kang100% (1)

- Science 8 Unit 3 Light and Optics Final Review BookletDocument44 paginiScience 8 Unit 3 Light and Optics Final Review BookletShayne NicoleiÎncă nu există evaluări

- Butterfly ValveDocument20 paginiButterfly Valvenazar750Încă nu există evaluări

- Cebu City Department of ChemistryDocument7 paginiCebu City Department of ChemistryGeorgette RepunteÎncă nu există evaluări

- L&T Gate Globe Check Valves API 602Document12 paginiL&T Gate Globe Check Valves API 602Nilesh MistryÎncă nu există evaluări

- Instrument Hookup DWGDocument26 paginiInstrument Hookup DWGkassimhos83% (6)

- Quick Quiz: Exploring Science Edition © Pearson Education Limited 2008Document2 paginiQuick Quiz: Exploring Science Edition © Pearson Education Limited 2008Victor Barber Sanchis50% (2)

- Swagelok Hose MS 01 167Document28 paginiSwagelok Hose MS 01 167ashok_04meÎncă nu există evaluări

- Parker 3349112014 PGP511 Series, Pgp511a0140ab1h2vf5f3b1b1Document21 paginiParker 3349112014 PGP511 Series, Pgp511a0140ab1h2vf5f3b1b1Anonymous srN69mFE100% (1)

- Regulador American Meter PDFDocument6 paginiRegulador American Meter PDFjmcg1974Încă nu există evaluări

- 200 Series Check ValvesDocument2 pagini200 Series Check ValvesMoanquileÎncă nu există evaluări

- 60 Series Tube Fittings and TubingDocument5 pagini60 Series Tube Fittings and TubingNilesh MistryÎncă nu există evaluări

- MPVN BrochureDocument32 paginiMPVN Brochurefernando_naciamentÎncă nu există evaluări

- T101 Drilling MachineDocument4 paginiT101 Drilling MachineFranklin Avendaño ArapaÎncă nu există evaluări

- T101 Drilling Machine BrochureDocument4 paginiT101 Drilling Machine BrochureRicardo OrtegaÎncă nu există evaluări

- Ss 01059 eDocument8 paginiSs 01059 eDavid LapacaÎncă nu există evaluări

- FCG300 Grooved Swing Check Valve: UL Listed Sizes 2 1/2" To 6" / FM Approved Sizes 2" To 8"Document2 paginiFCG300 Grooved Swing Check Valve: UL Listed Sizes 2 1/2" To 6" / FM Approved Sizes 2" To 8"mefaisal75Încă nu există evaluări

- High Pressure Pipe FittingsDocument16 paginiHigh Pressure Pipe Fittingsalejandro rojasÎncă nu există evaluări

- 6 Series Weld FittingsDocument10 pagini6 Series Weld FittingsNilesh MistryÎncă nu există evaluări

- High Pressure Ball ValvesDocument5 paginiHigh Pressure Ball ValvesNilesh MistryÎncă nu există evaluări

- FITOK Adapters and CouplingsDocument19 paginiFITOK Adapters and CouplingsNilesh MistryÎncă nu există evaluări

- Norgren - MufflersDocument14 paginiNorgren - Mufflerssh4kzyÎncă nu există evaluări

- NOVA Servo CatalogueDocument7 paginiNOVA Servo CatalogueDip Narayan BiswasÎncă nu există evaluări

- Automatic Valve Gemue DB - 512 - GBDocument6 paginiAutomatic Valve Gemue DB - 512 - GBTaher Yusuf100% (1)

- Robotmount: Specified Internationally For The New Arc Welding Robot ARC Mate 100icDocument8 paginiRobotmount: Specified Internationally For The New Arc Welding Robot ARC Mate 100icAsrul Arashi IrdianaÎncă nu există evaluări

- Qualitek 381F No Clean Flux: Technical Specifications Technical Data SheetDocument4 paginiQualitek 381F No Clean Flux: Technical Specifications Technical Data SheetteknoartistÎncă nu există evaluări

- TYCO Keystone F14.Lined - Butterfly.valve enDocument4 paginiTYCO Keystone F14.Lined - Butterfly.valve enIrina CretuÎncă nu există evaluări

- Min1244a12 - Tag 130-Pu-029Document7 paginiMin1244a12 - Tag 130-Pu-029Monty MathewsÎncă nu există evaluări

- 1guia para Válvulas de ControlDocument25 pagini1guia para Válvulas de ControlLindsey PatrickÎncă nu există evaluări

- Grundfos MTS Screw Spindle PumpDocument68 paginiGrundfos MTS Screw Spindle PumpAnonymous lswzqlo100% (1)

- Brochure 3Document12 paginiBrochure 3Gohilakrishnan ThiagarajanÎncă nu există evaluări

- Sanitary TurbinaDocument4 paginiSanitary TurbinaCindy MateusÎncă nu există evaluări

- Rotork 300 Quarter TurnDocument4 paginiRotork 300 Quarter TurngullenariÎncă nu există evaluări

- High Speed High Performance Drilling & Tapping CenterDocument8 paginiHigh Speed High Performance Drilling & Tapping CenterAlexandra PanaiteÎncă nu există evaluări

- EurotrodDocument76 paginiEurotrodPedro SilvaÎncă nu există evaluări

- Transformer Fan DetailsDocument38 paginiTransformer Fan DetailsNeha GuptaÎncă nu există evaluări

- Actuador NeumaticoDocument12 paginiActuador NeumaticoJose Alfredo Rojas UribeÎncă nu există evaluări

- 6 Series Pipe FittingsDocument18 pagini6 Series Pipe FittingsNilesh MistryÎncă nu există evaluări

- Manuales Bombas PLUS SV-SL-SLXDocument16 paginiManuales Bombas PLUS SV-SL-SLXLeo XavierÎncă nu există evaluări

- Block and Bleed Valve-SystemsDocument4 paginiBlock and Bleed Valve-Systemsvmr456Încă nu există evaluări

- KSB Valvula Diafragma SISTO10Document4 paginiKSB Valvula Diafragma SISTO10Sarah PerezÎncă nu există evaluări

- Pump Out Plug Technical DatasheetDocument3 paginiPump Out Plug Technical DatasheetEvolution Oil ToolsÎncă nu există evaluări

- Catalogo HAKKO 2014Document66 paginiCatalogo HAKKO 2014Diego Hermosilla MotaÎncă nu există evaluări

- Rociadores STD TycoDocument86 paginiRociadores STD TycoIvAldreteÎncă nu există evaluări

- Wps 08-04-2015 - 3Document6 paginiWps 08-04-2015 - 3Nector MoyanoÎncă nu există evaluări

- Dezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bDocument24 paginiDezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bjasonlaiymÎncă nu există evaluări

- 5 Globe Valves-DINDocument20 pagini5 Globe Valves-DINkemo10Încă nu există evaluări

- Order Information Sheet (OIS) : Insertion Air/Gas Mass Flow MeterDocument3 paginiOrder Information Sheet (OIS) : Insertion Air/Gas Mass Flow MeterjakkyjeryÎncă nu există evaluări

- C 800Document8 paginiC 800rodonietoÎncă nu există evaluări

- AE AccessoriesDocument16 paginiAE AccessoriesmisaelzaÎncă nu există evaluări

- Valvula Check 6000 Lbsv3xDocument6 paginiValvula Check 6000 Lbsv3xMaik AmayaÎncă nu există evaluări

- Pin Through Shaft Concentric Butterfly Valve Series: Weather Seal Mounting FlangeDocument4 paginiPin Through Shaft Concentric Butterfly Valve Series: Weather Seal Mounting Flangeshashikanth79Încă nu există evaluări

- Documents - PARKER WORLD PRESSURE FILTERS PDFDocument5 paginiDocuments - PARKER WORLD PRESSURE FILTERS PDFBilly ZununÎncă nu există evaluări

- Pulse Valves - Turbocontrols - It PDFDocument40 paginiPulse Valves - Turbocontrols - It PDFRicardo Ferrari TrevisanÎncă nu există evaluări

- High Pressure Needle ValvesDocument11 paginiHigh Pressure Needle ValvesNilesh MistryÎncă nu există evaluări

- How to prepare Welding Procedures for Oil & Gas PipelinesDe la EverandHow to prepare Welding Procedures for Oil & Gas PipelinesEvaluare: 5 din 5 stele5/5 (1)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDe la EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryÎncă nu există evaluări

- 2015 Q1 - Intertek - MalaysiaDocument1 pagină2015 Q1 - Intertek - MalaysiaNilesh MistryÎncă nu există evaluări

- Cat Acvbr9000Document16 paginiCat Acvbr9000Nilesh MistryÎncă nu există evaluări

- Resources Industrial Thomson ValveLineCard OnlineversionDocument4 paginiResources Industrial Thomson ValveLineCard OnlineversionNilesh MistryÎncă nu există evaluări

- Valve Con STR FeaturesDocument1 paginăValve Con STR FeaturesNilesh MistryÎncă nu există evaluări

- WWW - Ventile.cz 7. Instrument Manifold Amp Gauge ValvesDocument10 paginiWWW - Ventile.cz 7. Instrument Manifold Amp Gauge ValvesNilesh MistryÎncă nu există evaluări

- Instrumentation Tube: Tube and Tube AccessoriesDocument4 paginiInstrumentation Tube: Tube and Tube AccessoriesNilesh MistryÎncă nu există evaluări

- Tech Ascend CNC Student ManualDocument42 paginiTech Ascend CNC Student ManualabyzenÎncă nu există evaluări

- VS3 VS6 Instrumentation ValvesDocument2 paginiVS3 VS6 Instrumentation ValvesNilesh MistryÎncă nu există evaluări

- L&T Globe Control ValvesDocument4 paginiL&T Globe Control ValvesNilesh MistryÎncă nu există evaluări

- Quick Release Coupling: CouplingsDocument3 paginiQuick Release Coupling: CouplingsNilesh MistryÎncă nu există evaluări

- ValvesDocument13 paginiValvesNilesh MistryÎncă nu există evaluări

- 04 Two Three Way Ball Valves For CNG ApplicationsDocument4 pagini04 Two Three Way Ball Valves For CNG ApplicationsNilesh MistryÎncă nu există evaluări

- 11 Why Sealexcel Tube FittingsDocument20 pagini11 Why Sealexcel Tube FittingsNilesh MistryÎncă nu există evaluări

- 08 Push in Fittings For PneumaticDocument20 pagini08 Push in Fittings For PneumaticNilesh MistryÎncă nu există evaluări

- 02 Precision Pipe FittingsDocument28 pagini02 Precision Pipe FittingsNilesh MistryÎncă nu există evaluări

- Good PDFDocument3 paginiGood PDFDarshna SoniÎncă nu există evaluări

- Class 8 Cbse Science Sample Paper Term 2 Model 2Document5 paginiClass 8 Cbse Science Sample Paper Term 2 Model 2Sunaina RawatÎncă nu există evaluări

- Cytotoxic Screening of Tropical Plants Using Brine Shrimp Lethality TestDocument20 paginiCytotoxic Screening of Tropical Plants Using Brine Shrimp Lethality TestPrograma BRICÎncă nu există evaluări

- Hydrcolloids 2Document24 paginiHydrcolloids 2nakshatra1714Încă nu există evaluări

- SL No 2Document3 paginiSL No 2Chakravarthi NagaÎncă nu există evaluări

- Corrosometer ER Probe Selection GuideDocument4 paginiCorrosometer ER Probe Selection GuideHenny CasanovaÎncă nu există evaluări

- Standard For Food Grade Salt PDFDocument5 paginiStandard For Food Grade Salt PDFMercyÎncă nu există evaluări

- Calcium Control of Neurotransmitter Release PDFDocument15 paginiCalcium Control of Neurotransmitter Release PDFNisa Yulianti SuprahmanÎncă nu există evaluări

- C17H PDFDocument40 paginiC17H PDFramau619Încă nu există evaluări

- Hyundai Welding Co., LTDDocument4 paginiHyundai Welding Co., LTDGerry Dan ChanliongcoÎncă nu există evaluări

- Spectrophotometric Determination of The Total Phenolic ContentDocument4 paginiSpectrophotometric Determination of The Total Phenolic ContentevitajulieÎncă nu există evaluări

- Part 2 Microscopic World (I) LQ AnswersDocument17 paginiPart 2 Microscopic World (I) LQ AnswersWing LamÎncă nu există evaluări

- Supplemental Space Shuttle Tire Lessons: Grades K-12Document22 paginiSupplemental Space Shuttle Tire Lessons: Grades K-12Emannuel FernandesÎncă nu există evaluări

- KitosanDocument24 paginiKitosanFarras MuhammadÎncă nu există evaluări

- Geography Assignment Presentation ListDocument8 paginiGeography Assignment Presentation ListDEEPALI KUMARIÎncă nu există evaluări

- X X X A T: MECH 364 Assignment 2Document9 paginiX X X A T: MECH 364 Assignment 2Chandra SekarÎncă nu există evaluări

- Transcription FactorsDocument25 paginiTranscription FactorsPriya.RÎncă nu există evaluări

- VukcevicEtAl GhostFluidMethodInPolyhedralFV AnnotatedDocument19 paginiVukcevicEtAl GhostFluidMethodInPolyhedralFV AnnotatedputhenkulamÎncă nu există evaluări

- Tucker Wright 1990 Carbonate SedimentologyDocument252 paginiTucker Wright 1990 Carbonate SedimentologyGrace Ester Parsaulian SiahaanÎncă nu există evaluări

- Galvafroid Data SheetDocument13 paginiGalvafroid Data SheetAdam HughesÎncă nu există evaluări

- Keragaan Nilai DO, BOD Dan COD Di Danau Bekas Tambang Batu BaraDocument8 paginiKeragaan Nilai DO, BOD Dan COD Di Danau Bekas Tambang Batu Baranurul_595600924Încă nu există evaluări

- Westergaard Stress Solution Method PDFDocument2 paginiWestergaard Stress Solution Method PDFEmilia Elena MilutinoviciÎncă nu există evaluări

- Backup of PB Lead Stab 01Document16 paginiBackup of PB Lead Stab 01chemagrabgÎncă nu există evaluări

- Addition of Ref#2080, #2081, #2082, #2083 and #2084. D D: EB-455Wi/465i/450W/450Wi/460/460iDocument15 paginiAddition of Ref#2080, #2081, #2082, #2083 and #2084. D D: EB-455Wi/465i/450W/450Wi/460/460ifefotroncitoÎncă nu există evaluări