Documente Academic

Documente Profesional

Documente Cultură

Al Omran

Încărcat de

shahbazdgTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Al Omran

Încărcat de

shahbazdgDrepturi de autor:

Formate disponibile

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

LEGEND :

GENERAL NOTES

1 ) All Dimensions are in millimeters (mm) unless otherwise mentioned:

2 ) Bay sizes for Scaffolding not to exceed ________ , Unless otherwise mentioned:

3 ) Portions /Areas not covered by Scaffolding should be supported by the

Contractor as per site condition.

4) Bracing & Tying :

The Customer is responsible for ensuring that all structures are adequately braced

and/or tied to carry the load and ensure stability as indicated on the drawing. No braces

or ties are to be removed with Manar concern

5) TEMPORARY WORKING PLATFORMS :

Temporary working platforms for erection or Dismantling purpose will be designed,

Supplied and fitted by customer. Customer is responsible to ensure that working

platform or means of access necessary for safe access are provided whether shown

on this drawing or not

6) SCAFFOLDING GENERAL NOTES

A) ERECTION :

PANEL 20 x 240

PANEL 30 x 240

PANEL 60 x 240

PANEL 90 x 240

PANEL 120 x 240

a . Erection of Scaffolding should be as per the Drawing .

b . Max distance ( Spacing ) Between Ledger to Ledger is 1.5m .

c . Manar does not supply labours or technical supervision . The responsibility of

Customer includes the method ,control and suitability of all sequencing, the time

checking, loading , striking, movement , lifting and Stripping of the temporary work and the

design , supply and erection of any temporary working platform for erection & dismantling.

B) RE - SHORING :

a . Back propping may be required . Back propping is the responsibility of the

Customer. .

7) CONCRETE GENERAL NOTES

A) GENERAL NOTE :

a . Loads on forms and falsework have been analyzed in accordance with the Guide for Formwork

and BS 5975 & 5973 , Code of practice for False Work :

b . Loads are assumed as Uniformly Distributed.

c . Dead Load of structure has been considered in designing of Scaffolding, excluding of Finishing

Push Pull Props

Integler 5 x 240

Outer Angle 10x10x240

Inner Angle 30x30x240

loads.

d . For Removing (dismantling /unfixing) of Scaffolding, the contractor must check for cube

strength. This is the responsibility of contractor.

e .This drawing is prepared based on the information Provided to us by the customer.

However, it is the responsibility of client to verify and check the requirements of loading

PLAN

PLAN

assumptions,details, dimensions, erection sequences etc. as as required.

PLAN

B) DESIGN LOADS :

1. For Slabs & Beams

Density Of Concrete

Area by client

Weight of Formwork

Tie Rod with

water stopper

25.00 KN/m^3

0.48 KN/m^2

Live Load ( BS 5975 )

_____ KN/m^2

Total Load

_____ KN/m^2

2. For Walls & Columns

Max Allow Load For Walls

_____ KN/m^2

Max Allow Load For Columns _____ KN/m^2

Max Design Wind Pressure

_____KN/m^2

8) SPECIFICATIONS

A) MATERIAL PROPERTIES :

Raw-material properties used for fabrication of our Falsework are ,

I . Plywood

Thickness of plywood : 18 mm

Allowable Stresses :

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

Fc =1.200,000 PSI or 8273.76 N/mm2,

L/ 360 ( As per ACI )

II . Manar Alluminium Beam

Allowable Bending Moment 8.75 N/Sqm

Allowable Shear Force

45.11 N/Sqm

9 ) NOTE :

Quality,Satisfaction, Economy and safety are our main objectives. Therefore, if any

inconvenient with our offered design , our highly qualified and experienced design team

will work with you to reach your target and goal .

This drawing is the property of MANAR AL OMRAN. Any unauthorized use of this

drawing is considered illegal and subject to legal action by MANAR. This drawing is

NOT VALID UNLESS SIGNED AND STAMPED BY MANAR DESIGN DEPT.

SECTION X-X

REV.

DESCRIPTION

DATE DESIGNED CHKD

Wailing Splice

DRAWING STATUS

Tie Rod with Counter Plate and

Wingnut

FOR APPROVAL

This Drawing is for

This Drawing has been

Technical Discussion ,

issued for construction

Pricing and Approval

Push Pull Props

X1 & X4(on concrete base or concrete block)

with acceptance of

by the Client. Unless

client with respect to

issued and signed in

Construction Status,

design.

this drawing forms

By______________

no part of Agreement.

DATE ____________

By ______________

DATE ____________

SECTION Y-Y

Y

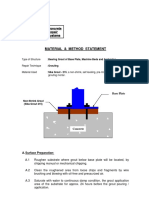

FORMWORKS & SCAFFOLDING

CLIENT:

Al Omran Contracting

PROJECT TITLE:

Water Tank

DRAWING TITLE:

DRAWN

FORMWORK FOR TANK

DESIGNED

ENG.NASEER

DATE

11/02/15

SCALE TECHNICAL

MANAGER

AS SHOWN

ENG.SHAHID

REV. A

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

Fb=1200 PSI= 8.27 N/mm2 , Fv= 53 PSI= 0.365 N/mm2

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

S-ar putea să vă placă și

- Scaffolding DetailsDocument8 paginiScaffolding DetailsGopal Sudhir100% (1)

- Sample Structure ReportDocument38 paginiSample Structure ReportBe Seang SeÎncă nu există evaluări

- Civil Engineering Design ServicesDocument1 paginăCivil Engineering Design ServicesSitche ZisoÎncă nu există evaluări

- BrochureDocument4 paginiBrochureJulius Ceasar SanorjoÎncă nu există evaluări

- Middle East Scaffolding Calculation SheetDocument8 paginiMiddle East Scaffolding Calculation SheetissaÎncă nu există evaluări

- Design of Single Storey Municipal BuildingDocument88 paginiDesign of Single Storey Municipal BuildingrfgtkoÎncă nu există evaluări

- Contract Sum AnalysisDocument1 paginăContract Sum AnalysisMuhammadIqbalMughalÎncă nu există evaluări

- DIV-13 Labor (Special Construction)Document7 paginiDIV-13 Labor (Special Construction)Ajaya KumarÎncă nu există evaluări

- Summary Sheet (Annexure F1 & F2)Document5 paginiSummary Sheet (Annexure F1 & F2)Ajay Malik100% (1)

- Task No. Task Description Precedes DurationDocument3 paginiTask No. Task Description Precedes DurationANDREA MARTINA BAYÎncă nu există evaluări

- Foundation Plan and DetailsDocument1 paginăFoundation Plan and DetailsbalramtcsÎncă nu există evaluări

- Construction Systems ComparisonDocument2 paginiConstruction Systems Comparisongetvicky247Încă nu există evaluări

- BoQ For A 3-Classroom Block 2021-22Document78 paginiBoQ For A 3-Classroom Block 2021-22mukiibiÎncă nu există evaluări

- Quantity Surveying Documents Notes Books HandbookDocument6 paginiQuantity Surveying Documents Notes Books HandbookGAURAVÎncă nu există evaluări

- Column Base Design:: Input DataDocument3 paginiColumn Base Design:: Input DataEng HatemÎncă nu există evaluări

- DOKA FormworkDocument7 paginiDOKA Formworkhenok hailemichaelÎncă nu există evaluări

- Structural analysis of multi-storey steel frames exposed to travelling fires and traditional design firesDocument17 paginiStructural analysis of multi-storey steel frames exposed to travelling fires and traditional design firesAlem LoajnerÎncă nu există evaluări

- Strap Footing TheoryDocument4 paginiStrap Footing TheorySwopnilOjhaÎncă nu există evaluări

- Structural CalculationsDocument112 paginiStructural Calculationsmechpandian100% (1)

- Piles DesignDocument12 paginiPiles Designn_sasanÎncă nu există evaluări

- Muro Wall FormworkDocument10 paginiMuro Wall FormworkDaliform GroupÎncă nu există evaluări

- Firm's References for Pier Construction Supervision ProjectDocument18 paginiFirm's References for Pier Construction Supervision ProjectMwesigwa DaniÎncă nu există evaluări

- 8M-Digest VOL 6 PDFDocument52 pagini8M-Digest VOL 6 PDFSamuel AcidriÎncă nu există evaluări

- Formwork, Scaffolding and Shoring Definition and ProductivityDocument12 paginiFormwork, Scaffolding and Shoring Definition and ProductivityMuhammad Iqbal100% (1)

- Project: Interior Design of Residence Date: 28 May, 2018 Client: Mr. Pratik AdhikaryDocument1 paginăProject: Interior Design of Residence Date: 28 May, 2018 Client: Mr. Pratik AdhikaryRaju ShresthaÎncă nu există evaluări

- Formwork 11Document77 paginiFormwork 11Anish OhriÎncă nu există evaluări

- HORDY Design Example ContinuedDocument6 paginiHORDY Design Example Continuedabdul kareeÎncă nu există evaluări

- Repair and painting works of Swastik Alps CHSDocument25 paginiRepair and painting works of Swastik Alps CHSSandeep MauryaÎncă nu există evaluări

- Sample Civil Enginer CVDocument3 paginiSample Civil Enginer CVsamratkadamÎncă nu există evaluări

- Topic 2 RoofDocument20 paginiTopic 2 RoofChee HernÎncă nu există evaluări

- Design Quotation SignedDocument2 paginiDesign Quotation SignedBernardÎncă nu există evaluări

- Material ListDocument3 paginiMaterial ListxyzhynÎncă nu există evaluări

- Details of Demolition QuantityDocument92 paginiDetails of Demolition QuantityK. Mehedi HasanÎncă nu există evaluări

- Roof BOQDocument9 paginiRoof BOQOscarKonzultÎncă nu există evaluări

- Calculating Scaffold LoadsDocument39 paginiCalculating Scaffold LoadsSotara RenÎncă nu există evaluări

- Material & Method Statement: Concrete Repair SystemsDocument3 paginiMaterial & Method Statement: Concrete Repair SystemsJuris DixonÎncă nu există evaluări

- 07 Building Up Rates For The BoQ UIPE ApprovedDocument24 pagini07 Building Up Rates For The BoQ UIPE Approvedjoz lapÎncă nu există evaluări

- BoqDocument106 paginiBoqpowerpanelÎncă nu există evaluări

- BOQ For Construction of Boundary Wall in QTR No. III-31 in Colony Sector at MANIT PDFDocument2 paginiBOQ For Construction of Boundary Wall in QTR No. III-31 in Colony Sector at MANIT PDFVeena NageshÎncă nu există evaluări

- 2.0mH Footing 1st 20200715Document10 pagini2.0mH Footing 1st 20200715Chung Him Joe ChanÎncă nu există evaluări

- Salam Studio Stores, Salam Plaza Extention at Gate Mall: Bill of QuantitiesDocument4 paginiSalam Studio Stores, Salam Plaza Extention at Gate Mall: Bill of QuantitiesAko AkotoÎncă nu există evaluări

- Formwork (Shuttering) For Different Structural Members - Beams, Slabs EtcDocument6 paginiFormwork (Shuttering) For Different Structural Members - Beams, Slabs EtcAravindanÎncă nu există evaluări

- Structural 02 - Retaining Wall DetailDocument1 paginăStructural 02 - Retaining Wall DetailJoseph Cloyd LamberteÎncă nu există evaluări

- Masonry Cavity Wall Insulation IllustrationsDocument0 paginiMasonry Cavity Wall Insulation IllustrationsGonzalo Luque GarcíaÎncă nu există evaluări

- Scope of Work - Townhouse MandaluyongDocument14 paginiScope of Work - Townhouse MandaluyongMark Nathan Sta. MonicaÎncă nu există evaluări

- The Interfacial Transition Zone (ITZ) Between Cement Paste and Aggregate in ConcreteDocument11 paginiThe Interfacial Transition Zone (ITZ) Between Cement Paste and Aggregate in ConcreteJudy TanÎncă nu există evaluări

- Profile - Enginering Design ServicesDocument3 paginiProfile - Enginering Design ServicesBilal ShahÎncă nu există evaluări

- WIND ANALYSIS OPEN SCAFFOLDDocument2 paginiWIND ANALYSIS OPEN SCAFFOLDAbdul HameedÎncă nu există evaluări

- Managing Hangar Construction From Start To FinishDocument17 paginiManaging Hangar Construction From Start To FinishArvindSinghÎncă nu există evaluări

- RFQ - Tremix and FM 2 Floor (45827) - BuildconDocument3 paginiRFQ - Tremix and FM 2 Floor (45827) - BuildconhemantrulzÎncă nu există evaluări

- Composite Slab Report For GIS AreaDocument7 paginiComposite Slab Report For GIS AreaMINÎncă nu există evaluări

- Column & Shearwall Formwork CalculationDocument6 paginiColumn & Shearwall Formwork CalculationPrakash Singh RawalÎncă nu există evaluări

- 8.19.3 Laying: 8.20 Curtain W T T ALL W W With Aluminium Composite Panels (Acp) Cladding P P 8.20.1 GeneralDocument5 pagini8.19.3 Laying: 8.20 Curtain W T T ALL W W With Aluminium Composite Panels (Acp) Cladding P P 8.20.1 GeneralAnshuman RathÎncă nu există evaluări

- Technical Manual PDFDocument39 paginiTechnical Manual PDFMatumbi NaitoÎncă nu există evaluări

- Trakhees Mandatory InspectionsDocument2 paginiTrakhees Mandatory InspectionsGhayas JawedÎncă nu există evaluări

- Building Visual Handover Inspection ReportDocument12 paginiBuilding Visual Handover Inspection ReportRajprabu sÎncă nu există evaluări

- Steel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiDocument6 paginiSteel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- Duffer Inc a Construction Business Start Up AdventureDe la EverandDuffer Inc a Construction Business Start Up AdventureEvaluare: 5 din 5 stele5/5 (1)

- Piled Embankment Construction ProceduresDocument9 paginiPiled Embankment Construction Procedureschandar70Încă nu există evaluări

- Clash Detection in BIM ModelingDocument2 paginiClash Detection in BIM ModelingshahbazdgÎncă nu există evaluări

- Gre Exam Model PaperDocument27 paginiGre Exam Model PaperJee VaniÎncă nu există evaluări

- Business Value of Bim in Middle EastDocument52 paginiBusiness Value of Bim in Middle EastshahbazdgÎncă nu există evaluări

- Airline CateringDocument3 paginiAirline CateringshahbazdgÎncă nu există evaluări

- SHM Assignment BagchiDocument1 paginăSHM Assignment BagchishahbazdgÎncă nu există evaluări

- Produced by An Autodesk Educational ProductDocument1 paginăProduced by An Autodesk Educational ProductshahbazdgÎncă nu există evaluări

- Basic TPS HandbookDocument33 paginiBasic TPS HandbookSumith KobewattaÎncă nu există evaluări

- How To Write A Cover Letter For Research JobsDocument7 paginiHow To Write A Cover Letter For Research JobsDinesh RamooÎncă nu există evaluări

- Design Plate PDFDocument20 paginiDesign Plate PDFshahbazdgÎncă nu există evaluări

- Manar Al Omran Co: Olgana TowerDocument6 paginiManar Al Omran Co: Olgana TowershahbazdgÎncă nu există evaluări

- Formwork design for tie beam approval - Amana Buildings DM Port projectDocument1 paginăFormwork design for tie beam approval - Amana Buildings DM Port projectshahbazdgÎncă nu există evaluări

- New Block ModelDocument1 paginăNew Block ModelshahbazdgÎncă nu există evaluări

- AUS CodebookDocument54 paginiAUS CodebookshahbazdgÎncă nu există evaluări

- Scaffold Design Drawing Load Calculations Scaffolding Code2009Document59 paginiScaffold Design Drawing Load Calculations Scaffolding Code2009fcgvcxbgv100% (1)

- AUS CodebookDocument54 paginiAUS CodebookshahbazdgÎncă nu există evaluări

- PART3-BS 1139 ScaffoldingDocument23 paginiPART3-BS 1139 Scaffoldingshahbazdg100% (10)

- Scaffolding For One SlabDocument1 paginăScaffolding For One SlabshahbazdgÎncă nu există evaluări

- Early Striking and Improved BackproppingDocument4 paginiEarly Striking and Improved Backproppingrami1964100% (1)

- Project Planning For CivilDocument3 paginiProject Planning For CivilshahbazdgÎncă nu există evaluări

- Basement ModelScaffoldingDocument1 paginăBasement ModelScaffoldingshahbazdgÎncă nu există evaluări

- 3m Dbi Sala Confined Space CatalogDocument31 pagini3m Dbi Sala Confined Space Catalogefrain bulaÎncă nu există evaluări

- History of PC VirusDocument4 paginiHistory of PC VirusKhanjanÎncă nu există evaluări

- Lec No.6 Solvent ExtractionDocument13 paginiLec No.6 Solvent Extractionrejie magnayeÎncă nu există evaluări

- 1!!! Microalgae and Wastewater Treatment PDFDocument19 pagini1!!! Microalgae and Wastewater Treatment PDFAhmadÎncă nu există evaluări

- Fastening Wood: Unit 10 Pages 119-127Document22 paginiFastening Wood: Unit 10 Pages 119-127Jerard BalalaÎncă nu există evaluări

- Datasheet SBRY577950 enDocument2 paginiDatasheet SBRY577950 enKiss JózsefÎncă nu există evaluări

- DICOM Conformance StatementDocument7 paginiDICOM Conformance StatementHugo MoralesÎncă nu există evaluări

- 30m3 Standart Drawing Penawaran 01.03.22Document1 pagină30m3 Standart Drawing Penawaran 01.03.22medtsl.cppÎncă nu există evaluări

- Three Phase AC Flame Proof Motors Regional Offices and Branch DetailsDocument8 paginiThree Phase AC Flame Proof Motors Regional Offices and Branch DetailsvipulpanchotiyaÎncă nu există evaluări

- Job Application LetterDocument4 paginiJob Application Letterfamily photoÎncă nu există evaluări

- Console Cherokee Sport 97 XJ Over ConsoleDocument8 paginiConsole Cherokee Sport 97 XJ Over ConsoleFrancisco KappsÎncă nu există evaluări

- Surefire l2 ManualDocument6 paginiSurefire l2 ManualspcsysÎncă nu există evaluări

- Make An AnemometerDocument2 paginiMake An AnemometerMark CuaÎncă nu există evaluări

- Operating System Version (Windows)Document2 paginiOperating System Version (Windows)BlueÎncă nu există evaluări

- Input: Design of Ties As Per BS 8110 Rw014 - Stone GroveDocument6 paginiInput: Design of Ties As Per BS 8110 Rw014 - Stone Grovethanigai veluÎncă nu există evaluări

- Desain Kolam Retensi Berbantu Komputer Di Cibuluh Kota BogorDocument10 paginiDesain Kolam Retensi Berbantu Komputer Di Cibuluh Kota BogorfitriÎncă nu există evaluări

- En 112 122 Compact TCBB TCFB Fid5904Document11 paginiEn 112 122 Compact TCBB TCFB Fid5904r364n_c1v36Încă nu există evaluări

- Contoh Bagian Application LetterDocument3 paginiContoh Bagian Application LetterZitaAmeliaMÎncă nu există evaluări

- Golismero Cheat SheetDocument9 paginiGolismero Cheat SheetJavier RuizÎncă nu există evaluări

- Barch Sem9 PDFDocument15 paginiBarch Sem9 PDFVaishali VasanÎncă nu există evaluări

- Western Railway Recruitment 2020Document24 paginiWestern Railway Recruitment 2020Sana Zaidi100% (4)

- IOT Based Smart Light Management Using Arduino: Presented by Under The Guidance ofDocument3 paginiIOT Based Smart Light Management Using Arduino: Presented by Under The Guidance ofgoutamÎncă nu există evaluări

- Certificate of Calibration: Customer InformationDocument2 paginiCertificate of Calibration: Customer InformationSazzath HossainÎncă nu există evaluări

- Gasification Technology Option - Ronald Schoff, EPRIDocument34 paginiGasification Technology Option - Ronald Schoff, EPRIAnonymous 4PuFzARÎncă nu există evaluări

- Intelligent Web ApplicationsDocument36 paginiIntelligent Web Applicationsrajashekarpula100% (1)

- Blast Vibration Analysis by Different Predictor Approaches A Comparison-A ParidaDocument9 paginiBlast Vibration Analysis by Different Predictor Approaches A Comparison-A Paridaaufal RiswanÎncă nu există evaluări

- Problem-Set HumidificationDocument1 paginăProblem-Set Humidificationari_blackroseÎncă nu există evaluări

- Dowex Marathon CDocument2 paginiDowex Marathon CMuhammad ImranÎncă nu există evaluări

- Determining The Electrical Resistivity of A Printed Conductive MaterialDocument3 paginiDetermining The Electrical Resistivity of A Printed Conductive Materialmasoud132Încă nu există evaluări

- Greek Etruscan Roman TemplesDocument1 paginăGreek Etruscan Roman Templesapi-596255492Încă nu există evaluări