Documente Academic

Documente Profesional

Documente Cultură

Spe 36878

Încărcat de

tomk2220Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Spe 36878

Încărcat de

tomk2220Drepturi de autor:

Formate disponibile

6ilaii

,,.

Societyd PetroleumEngineers ~

SPE 36878

Long-Term

Hydraulic

Fracture Conductivities

Under Extreme Conditions

Marin Cikes, SPE, lNA-Naftaplin

CcpyrIght 1996 Soctety of Petroleum Engineers, Inc

Thm paper was prepared for presentatmn at the 1996 SPE European Petroleum Conference

held m M!Ian, italy, 2224 October 19%

Introduction

Hydraulic fracturing treatments are required to ensure

economic production rates from wells completed in low- to

moderate-permeability

formations for a long period of time.

The relationship between the productivity improvement factor,

by hydraulic

fracture

stimulation

and the

obtained

dimensionless fracture conductivity, C,,), of the propped

fracture, has been published first by Prats. A series of

important contributions in the understanding of the behavior

of hydraulically fractured wells was provided by Cinco et af.2

and Cinco and Samaniego. ] Since then, Cinco and his COworkers have produced a number of additional works.4-6 It

follows from all that works that the productivity improvement

to the dimensionless

fracture

factor is proportional

conductivity, C,,), which is defined as:

This paper was selected for presenlatmn by an SPE Program Committee follow!ng rewew of

!nformataon ccntamed m an abstract subm!tled by the author(s) Conlenls of lhe paper, as

presented, have not been rew%wed by the Society of Petroleum Engineers and are subject 10

correchon by the author(s) The materml, as presented, dws not necessarily reflecl any

POSIIIWIof the SocIoty of Pelroleum Engineers, tts offIc8rs. or metm%rs Papers presented at

SPE meehngs are subject 10 pubkatlon rewew by Ed[forlal Commttees of the Soc!ety of

Petroleum Engineers Perm!swon 10 copy IS restricted to an abstract of not more than 300

words

Illustrabons may not be cnpmd Ttw abstract should ccmtaln Cnnsphwous

acknowkdgmenl of where and by whom the paper was presented Write Ltbrarmn, SPE, P O

Box t133W13 Richardson, TX 7S083-3836 U S A fax 01.214.952.9435

Abstract

Proppants for hydraulic fracturing are subjected to very severe

conditions of stress, temperature and chemical environment

while they are expected to maintain their structural integrity

for a period of many years. The performance of these

proppants over time at simulated in-situ conditions has been a

topic of laboratory investigation for several years, but in many

cases the real conditions exceed the capabilities of the

laboratory apparatus. In order to determine the proppant

behavior under real reservoir conditions, production history

and numerous pressure buildup tests of eight fractured wells

have been analyzed. The reservoir conditions of these wells

are so severe, that it was almost impossible to simulate them in

laboratory. The formation temperature is 179-195 C (354-383

F), while the reservoir pressure varies between 44.5 and 50.0

MPa (6453-7250 psi). The producing fluid is large gravity

(0.825 to 1.047 to air) sour gas (up to 22 Y. C02 and up to

0.02 A H2S), while the producing water is practically

deionized. The proppants are high strength zirconium oxide

and sintered bauxite, while the amount of injected proppant

varies between 100 and 628 tons (2.2E+05 to 1.38E+06 Ibm).

The net closure stress is in the range of 30 to 50 MPa (43507250 psi). The production time of these hydraulically

fractured wells varies between five and ten years. Emphasis in

this paper is given to the results of production history and

pressure buildup tests analysis, as well as to the relationships

of calculated fracture conductivity and reservoir conditions

over time.

Cfl, = k,wf/kxf

. ................................................... (I)

AS it can be seen, for given fracture length, x,, and

k,

the dimensionless

fracture

reservoir

permeability,

to

proppant-pack

conductivity,

C,,), is proportional

permeability, k,, and fracture width, w,, or simple to fracture

conductivity, k,w,. The fracture conductivity may be increased

by enlarging the propped fracture width, which means by

application of high proppant concentration, or by improving

proppant-pack

permeability.

Many factors influence the

M%

effective proppant-pack permeability, kf, e.g. proppzfnt

grain size, effective closure stress acting on the proppant pack

and formation face, formation temperature and chemical

environment, non-Darcy flow effects in the fracture, damage

from fracturing-fluid residue remaining atler fracture cleanup,

multiphase flow effects, well production history, etc.

Although the permeability of a lightly stressed proppant

pack can be found theoretically as a function of the porosity of

the pack, $, and the mean diameter of the proppant grains, d50,

that is:

kf ccd;o$s ,

..

. . . . . ...... ........... . . (2)

the fracture conductivity dependence on effective closure

stress, formation temperature, chemical environment, etc., can

not be assessed theoretically, Empirical relations based on

61

MARIN CIKES

extensive proppant conductivity measurements over a wide

range of conditions are required. The majority of these

measurements have been carried out in ideal laboratory

conditions, with low liquid flow rate (negligible non-Darcy

flow effects) at low temperature and short measurement

times.s However, continuing advances in transient pressure

analysis on hydraulically fractured wells have allowed a postfrac estimation of the effective fracture conductivity. z-b

Typically, a post-frac analysis calculated a value significantly

lower than was predicted by laboratory fracture conductivity

measurements on the same proppant,9- The post-frac values

usually differ by a factor of 0.1 to 0.5 times the laboratory

data. Occasionally the factor is closer to 1.0, but factors of

0.02 have also been calculated. The importance of the

fracture conductivity for the successful fracture stimulation

was stressed in the state-of-the-art paper published at that

time.2 Those were some of the reasons why, in the past ten

years, much progress has been made toward developing more

realistic methods for determining fracture conductivity,

One of the first long-term tests on fracture conductivity at

simulated reservoir conditions reported some decline in

proppant permeability with time at elevated temperature.~ The

test variable covered in the next investigation were (l) closure

stress versus time, (2) test temperature (24- 135 C [75-275

F]), (3) combined effect of closure stress and elevated

temperature versus time, (4) oxygen content of test fluid, and

(5) presaturation of test fluid with silica.4 Later investigation

has extended temperature range up to 149 C (300 F), with

the use of equipment capable to simulate the whole process of

hydraulic

fracturing

including

cleanup

phase.5 The

importance of obtaining realistic fracture conductivity data for

treatment design is also reported. b Recently published works

cover the other effects on fracture conductivity such as nonDarcy flow effects, effect of repeated production cycles,8

and effect of proppant failure and fines migration.9 To the

best of my knowledge, no data on fracture conductivity at

formation temperature higher than 149 C (300 F) in

presence of sour gas and deionized water have been reported.

However, hydraulic fracture treatments in such conditions

have been perforrned.20 In preparing these treatments, an

attempt to perform the long-term test on fracture conductivity

at 200 C (392 F) was unsuccessful because it exceeded the

capabilities of the laboratory apparatus. Due to that reason the

best commercially available proppants, zirconium oxide and

sintered bauxite, were selected. Today, nearly ten years later,

there are many data on production parameters and pressure

buildup tests in producing wells, so it can be tried to determine

the proppant behavior under real reservoir conditions in the

very long period of time. This paper presents transient

pressure analysis results of producing fractured wells, with

emphasis on the calculated effective fracture conductivity as a

function of producing time.

SPE 36878

Reservoirs Physical Properties

The hydraulically fractured wells are producing from specific

formations of three different reservoirs in north Croatia:

Molve, Kalinovac and Stari Gradac. Geological and physical

properties of these reservoirs are described in Refs. 20-22, and

will not be repeated here. Reservoir data for all three fields

are summarized in Table 1. The reservoirs are more or less

naturally fissured, overpressurized,

with extremely high

temperature gradients.

Physical properties

of reservoir

fluids and their

composition are summarized in Table 2. The reservoir fluid of

Molve field is a wet sour gas with GOR of 14,300 m3/m3

[79,300 scf/STB] and GWR of 20,000 m3/m3 [111,000

scf/STB]. The Kalinovac and Stari Gradac fields are gascondensate reservoirs with high dewpoint pressure (Table 1).

GOR and G WR for Kalinovac field are 1,110 m3/m3 [6,160

scf/STB] and 33,330 m3/m3 [ 184,800 scf/STB] respectively,

while Stari Gradac has GOR of 910 m3/m3 [5,050 scf/STB]

and GWR of 12,500 m3/m3 [69,400 scf/STB]. Producing water

in all three fields represents mainly water-vapor condensate

from gas, with very low mineral content (TDS=900

mg/dm3).22

Fracture Treatments Characteristics

Fracture treatment designs and executions are described in

Ref. 20. Only few crucial parameters should be mentioned

here for the wells which are selected for detailed analysis,

These selected wells and related parameters are given in Table

3. Relatively low values for fracture conductivities follow

from pessimistic approach that, as rule of thumb, uses onl

2/

10% of proppant permeability obtained in laboratory testing.

Post-Frac Pressure Transient Analysis

Four out of eight producing wells, with the longest producing

history and with the best pressure buildup data, are selected

for the post-frac pressure transient analysis, The analysis is

performed by matching the buildup response with the type

curves generated by numerical simulator, as well as by using

analytical

solutions or specialized

plots.24 For these

heterogeneous, naturally fissured reservoirs, double-porosity

reservoir model is indicated,2325 but in many cases a good

match is obtained with homogeneous reservoir model, so they

are used interchangeably. As we are dealing with two gascondensate wells, a compositional model should be used,26 but

the one-phase model is applied for all wells. Due to that, the

analysis results should be taken with caution, when the

bottom-hole flowing pressure (BHFP) drops below the

dewpoint.

One of the pressure buildup tests performed in the well

Molve-25 is used as an example of this analysis. Postfracture

production rates and wellhead flowing pressure of this well is

shown in Fig. 1. The pressure buildup test data are given in

62

SPE 36078

LONG-TERM HYDRAULIC FRACTURE CONDUCTIVITIES

Table 4, while the reservoir fluid properties can be find in

Table2. Reservoir data for Molvefield are given in Table 1,

but specifically for this well they are as follows:

perforated interval: 3362 -3412 m[ll,031 - ll,195ft];

. net thickness: 100 m [328 ft];

porosity: 100/0.

The well was tested during 1988th year. From several prefrac pressure buildup tests the reservoir permeability of

O.15x10-3 pm2 [0.15 md] was extracted, while the extrapolated

reservoir pressure was about 45 MPa [6,525 psi]. The fracture

treatment was performed in June 1989 that was followed by

cleanup procedure. After measuring postfracture production,

the well was closed for first post-frac pressure buildup test.

The last flow rates for gas, condensate and water, as well as

bottom-hole flowing pressure (BHFP), can be found in Table

5 together with main results of pressure transient analysis.

Complete results of this analysis are given in Figs. 2-5.

Fig. 2 is log-log plot of real gas pseudopressure differences

and their derivative,

matched with model of finiteconductivity fracture in homogeneous, infinite reservoir. From

the match points, calculated values for fracture half-length,

dimensionless fracture conductivity and reservoir permeability

are 54 m [ 177 ft], 0.778 and 0.586x 10-3 pm2 [0.586 md]

respectively. According to Eq. 1, fracture conductivity of

25x10-] pm2m [25 md.m] is calculated. Comparing with the

designed values, the effective fracture length and conductivity

seems unrealistic, while the apparent increase in post-frac

reservoir permeability over the pre-frac permeability of

O.15x10-3 pmz [0.15 md] suggests fracture height growth

and/or intersection of natural fractures resulting in an increase

in permeability-thickness

product. An attempt, to get match

pre-frac

permeability,

resulted

in

using the constant

unrealistically long fracture of 1987 m [6,520 ft]. Due to that

reason, the model of double-porosity reservoir with pseudosteady state of flow is applied, instead of homogeneous

reservoir. 2324Keeping the reservoir permeability constant at

value of O.15x10- pmz [0.15 red], good match is obtained, but

error amounts to 10OO/.for each variable (Fig. 3). Although the

calculated fracture half-length is closer to the designed value,

the effective fracture conductivity is nearly the same as in case

of homogeneous reservoir. Comparing with the pre-frac

analysis using same model, the storativity ratio, u, is too high

and interporosity flow parameter, 1, is too low.

Because of unreliable results, obtained by type-curve

matching procedure, for further analysis the specialized plots

are utilized. Fig. 4 is a specialized plot for bilinear flow, that is

linear plot of real gas pseudopressure vs. quarter root of time.~

From the bilinear-flow straight Iifle slope, mhfi using equation

= &~,h(k,w,)2(@+y4

and fracture length previously found by type-curve matching

using homogeneous reservoir model, dimensionless fracture

conductivity of 1.634 is calculated, from which follows

effective fracture conductivity of 5 1.7x10-3 ~mzm [5 1.7

mdm]. However, using the pre-frac permeability of O.15x 10-3

pm2 [0.15 red], the value of effective fracture conductivity

should be I02x10-3 ~mzm [102 mdm].

Fig, 5 is a specialized plot for pseudolinear flow, that is

linear plot of real gas pseudopressure vs. square root of time.6

From the pseudolinear-flow straight line slope, m,fi using

equation

fiPt)qT

UNDER EXTREME CONDITIONS

PM

f

= h~)xf (nk$~c,

~t2

.......... ...... ........... ........... (4)

the product of square root of reservoir permeability and

fracture length can be calculated. As in case of bilinear flow,

for permeability and fracture length found by type-curve

matching, effective fracture length of 71.86 m [236 ft] is

calculated, while, using the pre-frac permeability of O.15x 103

pm2 [0.15 red], the value of effective fracture length should be

142 m [466 ft]. Assuming that the pre-frac permeability

represents real value, the calculation in specialized plots

analysis utilizing that value is accepted as correct.

The same procedure is applied to the wells Molve- 15,

Kalinovac-3 and Stari Gradac- 1. The results of all analyses,

accompanying with the last flow rates for gas, condensate and

water, as well as with bottom-hole flowing pressure are

summarized in Table 5.

Discussion of Results

As it is shown in detailed analysis of one test in the well

Molve-25, type-curve matching technique does not give the

unique results concerning the effective fracture half-length

and fracture conductivity. Similar conclusion can be done for

the rest of eighteen analyses of the four wells (Table 5).

Generally, for all the wells the post-frac permeability is

higher than pre-frac value. For Molve- 15, Kalinovac-3 and

Stari Gradac- 1, the pre-frac permeabilities have values of

O.lx 103pm2 [0.1 red], 0.2x10-3 ~m2 [0.2 red], and 0.05x 103

pm2 [0.05 md] respectively, while the post-frac permeabilities

are few times higher (Table 5), With the time the

permeabilities usually decrease accompanying with decrease

in fracture conductivity and changing fracture length. After

some period of time (8 years for Kalinovac-3 and 5 years for

Stari Gradac- 1), some wells even stopped to behave as

fractured wells, although they had some negative skin factor.

Any other conclusion from these results could be doubtful.

The results of specialized plots analysis could be a base for

some concrete conclusions (Table 5). Generally, these results

suggest that effective fracture half-length does not differ

significantly from designed value, while the effective fracture

conductivity differs significantly, not only from laboratory

(3)

the product of square root of reservoir permeability and

fracture conductivity can be calculated. For the permeability

63

MARIN CIKES

SPE 36678

lower than designed value, which used only 10% of proppant

permeability obtained in laboratory testing.

3. l%e initial fracture conductivity fiu-ther decreases with

producing time, what could be correlative with increase in

effective fracture closure stress, but also with the time which

the proppant spent under extreme reservoir conditions.

4. Further investigation is necessary to resolve discrepancy

between post-frac calculated

fracture conductivity

and

laboratory measured data.

measured data, but also from designed value, which used only

10% of proppant permeability obtained in laboratory testing.

For the Molve- 15, the effective

fracture

half-length

is

significantly lower than designed and what would be expected

after pumping 628 Mg [1,383,260 Ibm] of proppants. As the

effective fracture conductivity is significantly lower than

designed value, and also lower than in other three cases, the

explanation for short and low conductive fracture could be in

low crush resistance of the proppant, utilized in this well

(Zirconium

Oxide). Even low initial fracture conductivity

further decreased with time as effective fracture closure stress

increased. The last value (after 8 years) should not be taken in

account due to high water cut.

Nomenclature

q= total compressibility, Pa- [psi-]

Cj[, = dimensionless

fracture conductivity

dj(, = mean diameter ofproppant grains, m [ft]

h= reservoir thickness, m [tl]

k= formation permeability, m2 [red]

k,= fracture permeability, m2 [red]

m(p) = real gas pseudopressure, PaJs

mbf= slope of strai$ht line for bilinear flow, Pak54

[psiz/cp/hr4]

roll= slope of strai ht line for pseudolinear flow, Pa/s32

&

[psi2/cp/hr ]

P,>= st&dard pressure, Pa [psi]

q. flow rate, m3/s [Mscf/D]

For the well Molve-25, the effective fracture half-length is

close to designed value and practically did not change with the

time, The effective fracture conductivity is slightly lower than

designed value but more or less stable in time, except the last

value (after 6 years).

Except for the

first value (after cleanup), which is

unreliable, the effective fracture half-length and fracture

conductivity for the well Kalinovac-3 are significantly lower

than designed values. Similar as for well Molve- 15, fracture

length and fracture conductivity

decreased

with time as

effective fracture closure stress increased, but this correlation

is not exact. Again, the last value (after 8 years) should not be

T= absolute temperature, K [R]

T,,= standard temperature, K [R]

~, = fracure width, m [ft]

~, = fracture half-length, m [ft]

p= viscosity, Pas [cp]

~= porosity, fraction

taken into account due to high water cut.

In case of Stari Gradac- I well, the effective fracture halfIength is higher than designed, but the effective fracture

conductivity is slightly lower than designed value. An

important notice is that the well was closed after cleanup for

more than one year, which means that production started atler

second pressure buildup test. Nevertheless, both the effective

fracture

between

half-length

and fracture conductivity

decreased in

these two tests. The question is what the cause was

References

1. Prats, M: Effect of Vertical Fractures on Reservoir Behavior --

for these changes: the lower bottom-hole flowing pressure

and, consequently, the higher effective fracture closure stress

at the second test, or the time which the proppant spent under

extreme reservoir conditions had the main role. Next two tests

indicate severe decrease in fracture conductivity, but it has to

be taken with caution, because the bottom-hole flowing

pressure was fare bellow dewpoint pressure causing two-phase

flow.

2.

3.

4.

5.

Conclusions

1. Pressure transient analysis performed by matching the

buildup response with the type curves does not give the unique

results concerning effective fracture half-length and fracture

conductivity. The analytical solutions or specialized plots

analysis should be used instead, but that requires knowing of

reservoir permeability from pre-frac test.

2. The effective fracture half-length, obtained by the

specialized plots analysis, does not differ significantly from

designed value, while the effective fracture conductivity is

6.

7.

8.

64

Incompressible Fluid Case, SPE.J (June 1961) 105; Trans.,

AIME (1961) 222.

Cinco-Ley, H., Samaniego-V., F. and Dominguez-A., N.:

Trarsient Pressure Behavior for a Well with a FiniteConductivity Vertical Fracture, SPEJ (August 1978) 253.

Cinco-Ley, H. and Samaniego-V., F.: Transient Pressure

Analysis for Fractured Wells, JPT (September 1981) 1749.

Guppy, K. H., Cinco-Ley, H. and Ramey, H.J. Jr.: Effect of

Non-Darcy Flow on the Constant-Pressure Production of

Fractured Wells, SPEJ (June 1981) 390.

Guppy, K. H., Kumar, S. and Kagawan, V.D.: Pressure

Transient Analysis for Fractured Wells Producing at Constant

Pressure, SPEFE (March 1988) 169.

Cinco-Ley, H., Samarriego-V., F. and Rodriguez, F.:

Application of the Pseudolinear-Flow Model to the PressureTransient Analysis of Fractured Well, SPEFE (Sept. 1989)

438.

Cutler, R.A. et al : Fracture Conductivity Comparison of

Ceramic Proppants, SPfiJ (April 1985) 157.

Gidley, J.L. et al.: Recent Advances in Hydraulic Fracturing,

Monograph Volume 12, Henry L Doherty Series, SPE of

SPE 36878

LONG-TERM HYDRAULIC FRACTURE CONDUCTIVITIES

AIME, New York, Dallas ( 1989) 109.

9

Secombe,

J.C. and Anderson,

26.

G. E.: Selection

of a Fracture

Proppant in a Tight Gas Field, Bauxite vs. Sand, Wamsutter

Are& Wyoming,

paper SPE 10827 presented at the 1982

SPEIDOE

Unconventional

Gas

Recovery

Symposium,

10

Pittsburgh, May 16-18.

Soliman, MY.,

Venditto,

12

C.T.

and Steanson,

The Key to Successful

1985) 2163.

13

14

Selection:

JPT (December

Fracture Stimulation,

International

Meeting

on Petroleum

Engineering,

Beijing,

China, March 17-20.

McDaniel, B. W.: Conductivity

Testing of Proppants at High

Temperature and Stress, paper SPE 15067 presented at the

Regional

April 2-4, 1986.

Penny, G. S.. An

Conditions

and

Meet!ng

Evaluation

Fracturing

Depth, m

Net thickness, m

Porosity, fraction

Permeability, 103 ~m2

Initial pressure, MPa

Temperature, C

Minimal horizontal

stress, MPa

Dewpoint pressure at

reservoir temperature,

MPa

of the SPE, C3akland, CA,

of the Effect

Fluids

Technical Conference and Exhibition

September 27-30, 1987.

of Environmental

Upon

the

Lcmg-Term

Gidley, J.L.: A Method for Correcting

18

Conductivity

for Non-Darcy Flow Effects, SPEPE (November

1991)391.

IIolditch,

S.A. and f31akeley, D. M.: FIow Characteristics of

Dimensionless

SPEF&F (February 1995) 21.

Cikes, M. and Economies,

Naturally

M. J.:

Economies,

22

23

Fracturing

Fissured, Gas-Condensate

M. J., Cikes, M. ef al: The Stimulation

Gas-Condensate Well,

Prooeriies

24

25

of

Gas Gravity (to air)

Temperature, C

Pseudo-Critical P, MPa

Pseudo-Critical T, K

Gas Viscosity, cp

Total compressibility,

MPal

co m Dosition (mole O/iJ

H2S

Nz

Coz

CH4

C2H6

C3He

I-C4H10

n-CdHIO

i-C5Hq2

n-C~H12

CeH14

C7H15

CaH1a

CgH20

CIOHZZ.

lligh-

Reservoirs,

of a Tight,

SfEFE

Double-Porosity

(March

Behavior,

Ben Naceur, K. and Economies,

M. J.: Production

From

Naturally

Fissured

Reservoirs

Intercepted

by a Vertical

Iiydraulic Fracture, SPEFE (December 1989) 550.

Beier, R. A.. Pressure-Transient

Model

for a Vertically

Fractured Well in a Fractal Reservoir,

55-66

54-55

65-69

36.7

35.9

MQ!!fE

KalinovaG

Skad

GEt!dw

Cikes, M. et u/.: A Successful Treatment of Formation Damage

Caused by High-Density Brine, .SPEPE(May 1990) 175.

[[ouze, O. P., Home R.N. and Ramey, H.J. Jr.: PressureTransient

Response of an lntini[e-Conductivity

Vertical

Fracture in a Reservoir

With

SPEFE (September 1988) 5 If)

3325-3560

30-50

0.04-0.06

0.2-0,35

44.5-47,5

180

TABLE 2- RESERVOIR FLUIDS PROPERTIES AND

COMPOSITIONS

SPEPE (May 1992) 226.

Very-High-Temperature

1989) 63.

3307-3378

33-1oo

0,07-0.1

0.1-0.2

46.0-46.5

179

m

G@tdFsQ

3785-3690

41-55

0.04-005

0,05-0.2

47.5 -50.0

195

Fracture

1[ydraulic Fracture Proppants Subjected to Repeated Production

Cycles, SPEPE (February 1992) 15.

Gidley, J.L., Penny, G,S. and McDaniel,

RR.: Effect of

Proppant Failure on Conductivity

of Propped Fractures,

Tcmperature,

21

= kg

=m2

= Pa

of the SPE, Dallas, TX,

17

20

=0

TABLE 1- RESERVOIRS DATA

Kalinovac

N!.QL!e

Conductivity

of Proppants, paper SPE 16900 presented at the

62nd Annual Technical Conference and Exhibition of the SPE,

Dallas, TX, Sep[ember 27-30, 1987

16, Parker, M.A. and McDaniel,

B. W.: Fracturing

Treatment

Design Improved by Conductivity

measurement Under In-Situ

paper SPE 16901 presented at tbe 62nd Annual

Conditions,

19

= m3

= Pa

= Pas

=m

= m3

Cobb, S.L. and IFarell, J.J.: Evaluation of Long-Term Proppant

Stability,

paper SPE 14133 presented at the SPE 1986

56th California

15

R. E,: Proppant

Jones, JR. and Raghavan, R.: Interpretation

of Flowing Well

Response in Gas-Condensate Wells, SPEFE (September 1988)

S1 Metric Conversion Factore

bbl x 1.589873

E01

E+05

bar x 1.0

Cpxl.o

E03

ft X 3.048

E-01

ft3 x 2.831685

E-02

F (F-32)/l .8

Ibm x 4.535924

E-01

md x 9.869233

E16

psi x 6.894757

E+03

J.J. and SIusher, G. L.: Evaluating

Conference, Midland, TX, March 1984.

Reinicke, K.M. ef al.: Interpretation

of Buildup Data Obtained

From MHF Wells [n Northern Germany, ./P7 (December 1985)

2173.

Montgomery,

578.

Fractured Well Performance Using Type Curves, paper SPE

12598 presented at the 1984 Permian Basin Oil & Gas Recovery

11

UNDER EXTREME CONDITIONS

.YPEFE (June 1994) 122.

65

0.8253

179

4.95

209.8

0.024

0.9467

180

4.59

231.88

0.0279

1.047

195

4.48

239.75

003

0.0143

0.0125

00107

0.007

1.64

21.647

71.17

3,359

1.017

0.254

0.227

0.088

0.057

0.109

0.061

0.041

0.044

0.279

0,007

1.382

12,218

70.373

6.762

2.325

0.619

0.724

0.374

0.323

0.715

0.796

0.553

0.452

2.386

0.0174

0799

8.732

69.918

7.421

2,402

0.727

0.886

0.485

0.447

1.12

1.221

0.931

0.559

4.334

MARIN CIKES

SPE 36878

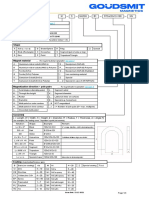

TABLE 3- DESIGNED FRACTURES PARAMETERS

Kalmovac-t

Molve-25

Mk!l

m

Mw.&15

TABLE 4- BUILDUP TEST DATA FOR WELL

MOLVE-25

Gda!21

Fracture

length, m

Fracture

Conductivityy,

103 pmzm

Proppant

Concentration

kglmz

Proppant

Pumped, Mg

Proppant

Type

Proppant

Size, mm

400

140

280

MQlM4J5

After Cleanup

After 2 years

After 3 years

After 4 years

After 8 years

MQ@25

After Cleanup

After 2 years

After 3 years

After 5 years

After 6 years

~

vac-~

After Cleanup

After 3 years

After 4 years

After 6 years

After 8 years

Stari Gradac -1

After Cleanup

After 1 year

After 5 years

After 7 years

160

127

122

174

137

8.4

6.9

12.3

8.5

628

Zirconium

Oxide

196

Sintered

Bauxite

321

Sintered

Bauxite

164

Sintered

Bauxite

0.42-0.84

0.42-0.84

0.42-0.84

0.42-0.64

TABLE 5- PRODUCTION

Wel I Name and

Time of

Analvsis

Shut-in Time

Pressur?

Shut-in Time

0.0

12

14

16

20

24

30

36

42

48

54

60

66

72

80

91

100

110

398.8

401.5

403.3

404.3

404.4

403.9

403.2

404.8

405.6

405.9

406.1

406.3

406,4

406,5

406.6

406,8

406.8

4069

4072

407.2

407.4

407,6

407.8

408.4

409

409.2

409,6

410.2

0.01

0,02

0,04

0,1

0.23

0.4

0.42

0.44

0,47

0.51

0.54

0.59

0.67

0.76

0,81

0.66

1

1.33

1.67

2

2,46

3

4

5

5.64

8

10

410.5

411

41f.4

411,9

412.2

412,7

413.4

414

414.4

4149

415.4

4~5.6

416

416,3

416.7

416.6

417.2

4~7.4

417.6

417.9

418.3

418.7

419.1

419,25

419.4

419.6

419.8

420.2

120

130

145

160

175

190

205

220

240

260

275

DATA AND PRESSURE TRANSIENT ANALYSIS RESULTS

Gas

Ion

Rate.

Co n densate

m~~

W-

!lKEPJ

m

&

L%;

xfJl

kf~r+

440,000

234,670

207,620

179,500

110,000

25

16.77

12,48

9.6

4.2

15

11.17

22,32

16.73

28.4

36.92

32.69

29.2

28.88

15.45

46.44

48.03

48.04

48.19

47.57

0.42

0.23

0,2

0.15

0,0007

19.8

26.6

25.6

34.8

164

253,200

254,400

234,600

227,400

274,000

9.4

22.56

21.28

16.9

19,97

10,2

9.12

10,56

10.19

14.66

39.88

33.52

32,16

27.07

23,05

42.29

38.59

35,88

34.17

29.63

0.59

03

0.67

0.25

0.72

132,300

97,000

104,200

93,100

28,000

120

75.1

88.7

86.0

21.0

7

5.5

4.7

5.16

39.0

43.31

40.87

36.94

30.3

21.74

46,31

45.22

43.31

38.96

38.32

81,890

134,800

42,200

23,000

77.55

137,56

50.1

27.0

14.1

13.78

4.0

4.0

44.75

37.36

23.31

14.22

50.18

53.04

46.62

40.72

Product

ihQJ!@

66

Cu

Mat

chtng

XLCO

y$3m2m

8,000

6,000

127

103

4.2

236

205

191

124

42

49

20

12

12

15

54

101

46.5

98.6

13,6

25

38

17

38

2.8

142

145

102

102

86

88

2.27

1.31

0.88

0.69

0,24

0,67

14.2

15

7.2

s=-2.6

0.056

0.009

0.093

0.067

183

266

S=-3.O

S=O.5

133

109

139

60

218

93

12

7.9

535 ?

183

166

96

46

429

100

60

191

92

132

85

116

97

11

22

99

73

16

18

SPE 36878

LONG-TERM HYDRAULIC FRACTURE CONDUCTIVITIES

UNDER EXTREME CONDITIONS

.....

r

35

~1

WHFP

#\

-CONDENSATE

-.

30

- WATER

l\

I

+ ,,

1-

1

/.

I

r-k ---

/\

,

C

\

4

I

I

/./.

\ /\\

\l

-.

I

I

---i

1000

500

1500

2000

2500

PRODUCING TIME (days)

Fig. 1- Post-frac production history for well Molve-25

f!aftuli

Cwaw

F,*Id

*11

L.a.-L09

P lot

M3L2WF1

lN,-WTIVLIM

T@st

MST

FRW

PKIVE

ht.

28,07

.!989.

W-25

1%.s.s

Na+twltn

Loq-Loq

cOmP,rN

PW,l

Field

*1

KCWICCU

Plot

mzwss

lW-WWTAFIIN

lest

PO?JTFRACP2W 1

KIW

ht.

2e.07.

P!fx-2s

1989.

e..

HECWWICA

Hatch

.a117E-s

Match

. 94bSE-6

106

.

.

1

.

.

..

-$

1./

A

-2

10-

10

Flcu

Po!-ind

ht.

Rat.

P

399.0

10

102

bt,h

)htch

. J692E-5

1862E-

1 *-1

Z@

F1..

IJ1.1

bar

c a

Sta-lw

Hal?

1M9th

W

cm

e

s

lg.

b,.

Fin.

tELL

*1*

Im-lgtll

c

x=

9CD

cm

skins

e.xw

ti.

k.h

*

3299

2s0.939

mob)litw

In...

-b41-2/,p

*ig.

PSS

Frac

<cd

6.DW

131.332

1.22293

0

a

15.07,0?

d..

e,

15W1

&,3214

k,mu

R

on...

L& mbda

-1?96

k-l

Idinit.

XIJwmv

StW.w

58.6292

n.

k,mu

83!

Z-Phi

ESEW21R

0.1

CI!596

0. 7?774

k.h

k

Inv..i

WI.

F...

bar

9wt.ar

54.

+< D

%1

R-ab, l,tw

cd

In+in Lt.

BmmruY

Prvswe

Wzdag

398.0

SEWIR

bar

11

@ WS/dav

-LU,-2T<P

Wav

422.725

e.

10

11

,1

%,-

W&

248

%oothllw

~,

Clwla

dt-e

10

111.246

e, 5349

2715E-4

SfiPHIR

VI .60

Fig. 3- Log-log plot of pressure response of the well Molve-25,

matched with the model of finite-conductivity fracture in doubleporosity, infinite reservoir with pseudo-steady stats of flow, and

match results.

Fig. 2- Log-log plot of pressure rssponss of the well Molve-25,

matched &th

the model of finite-conductivity

fracture

in

homogeneous, infinite reservoir, and match results.

67

MARIN CIKES

Naft.Plin

Flwtble

cm.ny

Test

l!KVf

*11

Date

WY-25

m.?.

FQST

FRiX

N8?t.plm

ma-l

Plot

MI-* TwL]N

Fi,ld

SPE 36878

Flexible

CoI19arW

PBU/1

F,.ld

20.07.1999.

*11

MECWICI?J.

0.91E

[NwN13FTW

Plot

rw_2wF 1

IN

T.,t

POST FRfu PUJ,l

tWU2

D.t*

28.87.

MM-25

GWJW

lm.

ttECl!ANICIX

*07

12.9E+L27

0. C2EW2?

Y

;

0. EJ%.e?

:

0. ax.e7

0, E5E+07

. .

.

0, S5E+e?

T

-s

Flexible

LiIW

~ -18

-1

l/4r(

Flow Period #

Rat ,

Rat. Clung.

P * dt-B

1

&2)!

Flw

2

0 kWda

260 h~,dav

39S.8 bar

i

Intwc.pt

.&.

~

->

426.

U

Rat .

-13

KR

-12

-11

-10

-9

2

0

O!n3/da

2b8

R dt=O

-14

r(m),

Flm3.dw

398,8

bar

m(,

k.xF.

?99

0.3s63

x+-

54.0506

+<d

1.6S4S9

-)

Fig. 4- Linear plot of real gas pseudopressure

superposition tires for WWIIMolve-25.

$2074.95

t

xF

E,

96E+87

3i591

.29

lfk-O.5S.53d

-1W6

Sw(r(dt))

s 1.,,

Intcrc.,

.?2S2+S7

kf.

Period

Rat Chmg.

v, SuP(l/+(dt))

Sbv . 19if*

.(P)

-15

H>14

lm-.qth

Xi

71.%32

SW141R Vl, &@

vs. quarter root of

Fig. 5- Linear plot of real gas pseudopressure

superposition time for well Molve-25.

vs. square root of

S-ar putea să vă placă și

- Gravity Drainage Mechanism in Naturally Fractured Carbonate Reservoirs Review and ApplicationDocument26 paginiGravity Drainage Mechanism in Naturally Fractured Carbonate Reservoirs Review and ApplicationNassr Al BadriÎncă nu există evaluări

- Matrix Fractures Exchanges in Naturally Fractured Reservoirs Under EOR MechanismsDocument39 paginiMatrix Fractures Exchanges in Naturally Fractured Reservoirs Under EOR Mechanismstomk2220Încă nu există evaluări

- Application of Decline Analysis in Fractured ReservoirsDocument10 paginiApplication of Decline Analysis in Fractured Reservoirstomk2220Încă nu există evaluări

- Modeling and Simulation of Fluid Flow in Naturally and HydraulicallyDocument178 paginiModeling and Simulation of Fluid Flow in Naturally and Hydraulicallytomk2220Încă nu există evaluări

- Spe 93253Document10 paginiSpe 93253tomk2220Încă nu există evaluări

- Application of Decline Analysis in Fractured ReservoirsDocument10 paginiApplication of Decline Analysis in Fractured Reservoirstomk2220Încă nu există evaluări

- A Simulation Approach For Screening of EORDocument25 paginiA Simulation Approach For Screening of EORtomk2220Încă nu există evaluări

- Hydraulic Fracture Propagation and Analysis in HeterogeneousDocument17 paginiHydraulic Fracture Propagation and Analysis in Heterogeneoustomk2220Încă nu există evaluări

- A Novel Integrated Approach To Modelling of Depletion-InducedDocument12 paginiA Novel Integrated Approach To Modelling of Depletion-Inducedtomk2220Încă nu există evaluări

- Fluid Flow in Fractured and Fracturing Porous Media A Unified ViewDocument11 paginiFluid Flow in Fractured and Fracturing Porous Media A Unified Viewtomk2220Încă nu există evaluări

- Numerical Fluid Flow Modelling in MultipleDocument23 paginiNumerical Fluid Flow Modelling in Multipletomk2220Încă nu există evaluări

- Spe 79709 Pa P PDFDocument9 paginiSpe 79709 Pa P PDFtomk2220Încă nu există evaluări

- Spe 08952Document7 paginiSpe 08952tomk2220Încă nu există evaluări

- Spe 35742Document2 paginiSpe 35742tomk2220Încă nu există evaluări

- Spe 63030Document7 paginiSpe 63030tomk2220Încă nu există evaluări

- Spe 171019 MSDocument13 paginiSpe 171019 MStomk2220Încă nu există evaluări

- Spe 10791Document30 paginiSpe 10791tomk2220Încă nu există evaluări

- Spe 99Document2 paginiSpe 99tomk2220Încă nu există evaluări

- Stress Sensitivity of Saturation and End-Point Relative PermeabilitiesDocument12 paginiStress Sensitivity of Saturation and End-Point Relative Permeabilitiesari_si100% (1)

- Spe 08945Document12 paginiSpe 08945tomk2220Încă nu există evaluări

- Spe 57439Document8 paginiSpe 57439tomk2220Încă nu există evaluări

- Spe 07921Document10 paginiSpe 07921tomk2220Încă nu există evaluări

- Spe 06071Document8 paginiSpe 06071tomk2220Încă nu există evaluări

- Geo Mechanics Yn 3Document32 paginiGeo Mechanics Yn 3tomk2220Încă nu există evaluări

- Spe 11182Document11 paginiSpe 11182tomk2220Încă nu există evaluări

- Spe 133452Document21 paginiSpe 133452tomk2220Încă nu există evaluări

- 1108Document184 pagini1108tomk2220Încă nu există evaluări

- Spe 84491 MSDocument9 paginiSpe 84491 MSZoha AhmedÎncă nu există evaluări

- Spe 84491 MSDocument9 paginiSpe 84491 MSZoha AhmedÎncă nu există evaluări

- Estimating Gas Desorption Parameters from Well Test DataDocument12 paginiEstimating Gas Desorption Parameters from Well Test Datatomk2220Încă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hylar 5000 PVDF Intro - EN v2.1 - 0Document3 paginiHylar 5000 PVDF Intro - EN v2.1 - 0Phạm TháiÎncă nu există evaluări

- Polymer Solar Cells PDFDocument19 paginiPolymer Solar Cells PDFJulio Andrés Casal RamosÎncă nu există evaluări

- Wavelength Tunable LED: Created in COMSOL Multiphysics 5.4Document6 paginiWavelength Tunable LED: Created in COMSOL Multiphysics 5.4David PinoÎncă nu există evaluări

- Modeling of Metamaterial Absorber Structures in Ansys HFSSDocument38 paginiModeling of Metamaterial Absorber Structures in Ansys HFSSyogesh pal singh50% (2)

- Cal Espes AutopipeDocument3 paginiCal Espes Autopipehernandez15Încă nu există evaluări

- Point Defects - Line Defects - Dislocations - Surface Defects - Grain Boundaries - Majority of This Chapter Is On Point DefectsDocument63 paginiPoint Defects - Line Defects - Dislocations - Surface Defects - Grain Boundaries - Majority of This Chapter Is On Point DefectsAmir Nazri KaibingÎncă nu există evaluări

- Mechanical Strength AgaroseDocument9 paginiMechanical Strength AgaroseHyunjung KimÎncă nu există evaluări

- CHE131 - Module6 Fluid Flow Phenomena (Part 2)Document43 paginiCHE131 - Module6 Fluid Flow Phenomena (Part 2)Jason PacilÎncă nu există evaluări

- SL Somos PerFORM Material Specifications PDFDocument2 paginiSL Somos PerFORM Material Specifications PDFTushar Prakash ChaudhariÎncă nu există evaluări

- 2020 UEC Physics Trial Paper 1Document5 pagini2020 UEC Physics Trial Paper 1Benson TanÎncă nu există evaluări

- Cao 2014Document8 paginiCao 2014Eki Saul HudsonÎncă nu există evaluări

- Product Key MX - Magnet PermanentDocument4 paginiProduct Key MX - Magnet PermanentFooÎncă nu există evaluări

- Final Programme of Frontiers of NanoEngineeringDocument11 paginiFinal Programme of Frontiers of NanoEngineeringCinthya ToroÎncă nu există evaluări

- Mechanical Properties of Shale Gas Reservoir RocksDocument12 paginiMechanical Properties of Shale Gas Reservoir RocksVictor Javier PerniaÎncă nu există evaluări

- Case Study on Sulfide Stress Corrosion Cracking of an A216-WCC Wellhead Flow Control Valve BodyDocument12 paginiCase Study on Sulfide Stress Corrosion Cracking of an A216-WCC Wellhead Flow Control Valve Bodypinkan25Încă nu există evaluări

- Engineering Physics 2 Unit-5Document98 paginiEngineering Physics 2 Unit-5Sriram J0% (1)

- Basics of Metallurgy & Material TestingDocument62 paginiBasics of Metallurgy & Material TestingMustafa Oğuzhan100% (2)

- Egg Yolk Lecithin: Set ADocument2 paginiEgg Yolk Lecithin: Set ABeni FelucciÎncă nu există evaluări

- Overall Heat Transfer CoefficientDocument8 paginiOverall Heat Transfer CoefficientSarthak DandareÎncă nu există evaluări

- Quick Start - FLOW-3D v11.1Document67 paginiQuick Start - FLOW-3D v11.1Xinwei LiÎncă nu există evaluări

- Arstruct Reviewer Compilation (GRP 7)Document9 paginiArstruct Reviewer Compilation (GRP 7)Nicole FrancisÎncă nu există evaluări

- Energy Dissipation Capacity of Flexure-Dominated Reinforced Concrete MembersDocument12 paginiEnergy Dissipation Capacity of Flexure-Dominated Reinforced Concrete Members01010Încă nu există evaluări

- 9508002v3 PDFDocument15 pagini9508002v3 PDFyoussef_pcÎncă nu există evaluări

- Customer: Project Number: Project Description: Constructor: Cozmuler Engineering Private Ltd. 721368 Ucontrol Controller For Atlas MRL KleemannDocument19 paginiCustomer: Project Number: Project Description: Constructor: Cozmuler Engineering Private Ltd. 721368 Ucontrol Controller For Atlas MRL KleemannZee BadshahÎncă nu există evaluări

- Huang 2019Document10 paginiHuang 2019Robertas ŽilinskasÎncă nu există evaluări

- Concrete Corbel Design SummaryDocument14 paginiConcrete Corbel Design Summarynavneet3bawaÎncă nu există evaluări

- Astm A983 A983m 01Document2 paginiAstm A983 A983m 01Salvador MazzaÎncă nu există evaluări

- Unit5 Power Press MachineDocument39 paginiUnit5 Power Press MachineApechRangerÎncă nu există evaluări

- Loading Process: Depok, November 2010Document16 paginiLoading Process: Depok, November 2010ilham ditamaÎncă nu există evaluări