Documente Academic

Documente Profesional

Documente Cultură

Is 14458#3 Retaining Wall For Hill Area - Guidelines

Încărcat de

v2299Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Is 14458#3 Retaining Wall For Hill Area - Guidelines

Încărcat de

v2299Drepturi de autor:

Formate disponibile

IS 14458 (Part 3)

: 1998

Indian Standard

RETAINING WALL FOR HILL AREA GUIDELINES

PART

3 CONSTRUCTION

OF DRY STONE

WALLS

ICS 93.020

0 BIS 1998

BUREAU

MANAK

June

1998

OF

BHAVAN,

INDIAN

STANDARDS

9 BAHADUR

SHAH

NEW DELHI 110002

ZAFAR

MARG

Price

Group

Hill Area

Developmgnt

Engineering

Sectional

Committee,

CED 56

FOREWORD

This Indian Standard (Part 3) was adopted by the Bureau of Indian Standards, after the draft finalized by

the Hill Area Development

Engineering

Sectional Committee had been approved by the Civil Engineering

Division Council.

~_

Retaining wall is a structure used to retain backfill and maintain difference in the elevation

ground surfaces.

Retaining wall may be effectively utilized to tackle the problem of landslide

by stabilizing

the fill slopes and cut slopes.

of the two

in hill area

From the initial construction

cost consi&rations,

one methe of extra width in filling, requiring retaining

walls, costs much more than constructing

the same width by cutting inside the hill.

Similarly the cost

of a breast wall is several times more than a non-walled cut slope.

However, considering

maintenance

cost, progressive slope instability and environmental

degadation

from ,wprotected

heavy excavations,

the

use of retaining walls on hill roads and terraces becomes essential.

K&s standard (Part 3) is, therefore,

beine formulated to urovide necessary guidanace in construction

of dry stone retaining walls for stabihty

of hyll slopes, the o&er parts of the code being:

Part

Selection

of type of wall

,Part 2

Design

Part 4

Construction

of banded

dry stone walls

Part 5

Construction

of cement

stone walls

Part 6

Construction

of gabion

walls

Part 7

Construction

of RCC crib walls

Part 8

Construction

of timber

Part 9

Design

of RCC cantilever

Design

and construction

Part

10

of retaininwast

waIL,

crib walls

wall/buttressed

of reinforced

earth

walls/L-type

retaining

walls

walls

The present practice in various Government

departments is to construct retaining walls up to 4 m height

in random rubble dry stone masonry.

Retaining walls more than 4 m height are constructed either in lime

or cement mortar masonry or in dry stone masonry panels separated by 0.6 m wide mortarred masonry

sleepers laid 3 to 4 m apart both in horizontal and vertical directions;

The specified norms prescribed

by the respective departments usually do not give sufficient weightage to the nature and properties of the

soil or rock below the wall base and at the back of the wall, or the. weather conditions.

It is normally

assumed that the mortarred masonry or bands give sufficient strength to the wall for added stability and

confines local failure, if any. In actual practice it has however been observed that a number of dry as

well as banded or fully mortarred walls do collapse during rains without offering much resistance as such

these walls are used only as a temporary measure.

This part, therefti,

gives definite guidelines to the

field engineers

for construction

of dry stone retaining waHs.

..:

Dry stone masonry retaining walls

Good supervision is, therefme, the

supervision

is essential for longer

used in construction

of dry stone

The composition

Annex A.

_.

,.

,.

:

of technical

generally fail due to construction of.,#ossly inadequate section of walls.

key to better quality of construction. of dry stone masonry walls. Strict

life of these type of walls.

It shalb be ensured that skilled labour is

masonry walls.

:.

committee

responsible

for the formul$ion

of this standard is given at

;

IS 14458 (Part 3) : 1998

Indian Standard

RETAINING WALL FOR HILL AREA GUIDELINES

PART

3 CONSTRUCTION

a dry stone retaining

1 SCOPE

This standard (Part 3) deals with the construction

aspects of dry stone retaining walls.

2 REFERENCES

The Indian

Standard

IS 1123:1975

Method of

identification of natural building stones Cfirst revision)

contain provisions which through reference in this

text, constitute provision of this standard.

At the

time of publication, the edition indicated was valid.

All standards are subject to revision, and parties to

agreements

based on this standard are encouraged

to investigate

the possibility of applying the most

recent edition of the standard indicated above.

3 GENERAL

3.1 A hill road masonry retaining wall is a gravity

wall which shall be considered safe under the expected

conditions

of loading, if following conditions

are

satisfied:

it shall be safe against

shearing

strength

OF DRY STONE

overturning,

stress shall be less than shearing

available, and

the pressure at the toe shall remain less than

the safe bearing capacity of the foundation

material.

It may be, however, assumed that there is ,adequate

frictional bond between the stone layers from face

to back and from top to base so that the entire section

of the retaining wall acts as one unit. This may be

very easily achieved by using stones of rectangular

shape with sufficient overlap on each other enabling

proper interlocking.

The top width of the retaining

wall shall be taken as 600 mm.

3.2 The stability of the retaining wall mainly depends

upon the allow_rrble bearing pressure of the foundation,

particularly under the toe as compressive strength of

properly constructed

masonry

section is usually

adequate.

Sliding

at the base depends

on the

coefficient of friction between the wall base and the

foundation soil. The total earth pressure above any

level along the height of the retaining wall reduces

parabolically

from base upward, whereas the wall

thickness reduces linearly.

Therefore in most cases

the critical section in the wall is at the base.

3.3 It cannot be asserted with any degree of certainty

that fully mortarred

masonry wall or a panelled

masonry wall shall give a better performance than

WALLS

wall, on account of the following:

a>The

value of bonding material or mortar is

only from the point of view of making the

wall an integral unit. However it is not assured

in the case of hill roads and site development

in hills; due to lack of supervision,

nonavailability of skilled labour, improper mixing

of mortar, lack of post-construction,

curing,

etc and also sometimes paucity of water in

the area.

b) Since both types of wall are not supposed

to bear any tension, the strength of a dry

stone masonry wall having the same section

and similar soil conditions as a fully~mortarred

masonry

wall, shall be adequate.

The

compressive strength of properly packed dry

stone masonry is likely to be more than that

of foundation soil on the hill slope.

cl For sliding at the base, coefficient

of friction

between the wall base and the foundation soil

being same in both types, the mbehaviour shall

not be different.

Thus there is no particular

utility of bands or mortar and the strength

of a properly constructed dry stone masonry

retaining wall shall be quite sufficient.

On

account of its flexibility, a dry stone masonry

retaining wall may be expected to behave

better than a fully mortarred masonry wall

under seismic conditions.

4 Dry stone walls are easy to repair when it

fails.

3.4 The design bf dry stone masonry retaining wall

shall be in accordance with Part 2 of this standard.

A suitable computer program may be used for the

design.

4 MATERIAL

Stone, the main material required for the construction

of dry stone masonry retaining wall, is available in

large quantity in hills. To select and utilize them

for their satisfactory performance, it shall be necessary

to know the various

properties

which can be

determined according to relevant Indian Standards.

The strength

of rocks depends

on its mineral

constituents

which form the basis of classification

and identification

of rocks. Identification

of stones

,may be done in accordance with IS 1123.

5 BASE

An inward

SLOPE

slope provides

good keying

of the wall

IS 14458

(Part 3) : 1998

thickness which shall be made as impervious

as

possible to minimize ingress of water from top surface.

in the hill face and also reduces the toe pressure,

besides greatly increasing the sliding strength of the

wall at base.

Therefore, the base shall preferably

be at right angles to the face of the wall. A minimum

inward slope of 1 (Vertical) in 6 (Horizontal) shall

be provided and it shall not be more than 1 (Vertical)

in 3 (Horizontal).

Base slope is very effective in

seismic stability of walls.

6 STONE

8 DRAINAGE

8.1 The dry stone masonry retaining walls have the

advantage that the masonry remains quite permeable

to the flow of water and pressure normally does not

build up. However, efficient drainage system above

the top of the retaining wall is most essential.

The

top layer of backfill shall be laid at a proper camber

and shoulder slope. The water flowing in the hill

side drain shall be drained off through scuppers of

appropriate design at regular intervals. The retaining

wall top shall be kept slightly lower than the shoulder

sloping outward so that water runs over the wall

instead of seeping

into the backfill.

For site

development, a 300 mm thick impervious soil layer

(properly compacted) with boulders shall be laid above

the top surface and backfill to prevent ingress of drain

water. Typical sketch showing best retaining wall

with good filling is shown in Fig. l(d).

WORK

6.1 Rough flat stones shall be preferred as they give

better contact and friction at joints.

There shall be

no dumping of stones. Stones shall be placed well

interlocked at close proximity with each other. Size

of stones below 225 mm x 100 mm x 75 mm (with

mass of about 5 kg) shall not be used. The maximum

size of stone shall be 600 mm x 200 mm x 300 mm

with mass of about 45 kg. The largest dimension,

that is. the length shall be placed across the length

of the retaining wall for maximum stability as with

this arrangement the wall face will not easily separate

from the hearting.

It shall result in greater unity

and interlocking

among the stones placed around it.

8.2 Excavated material from foundation if dumped

by the side of the toe obstructs drainage. It must be

sloped down below the top level of the toe projection.

6.2 In dry stone masonry it shall be necessary to

spread broken stone dust, stone chips, soil (gravelly

or sandy soils) and soil mixtures, after placing each

layer of stones to fill the voids.

Filling of voids

prevent filling of cavities by mud which is injurious

to the wall as it makes it impervious to the flow of

water. Fine grained soils and smooth river shingle

shall not bc used as these may lubricate the joint

decreasing

the frictional

resistance.

Only coarse

angular particles shall be made use of. If available

in the vicinity, water may also be sprinkled to moisten

the filler material.

Some ramming shall also be

preferred.

This helps in spreading the load of the

overlying

stones more evenly and increasing

the

weight of the wall and in turn increases the strength

of the wall. Fig. 1(a), Fig. 1(b) and Fig. 1(c) represent

bad construction practices liable to damage or cause

failure of wall and shall be avoided.

7

PLACEMENT

9 TOE

PROTECTION

The water coming out at high velocity from top of

retaining wall can cause soil erosion at the toe and

even below it by back erosion of soft rock or shale.

Toe protection shall always be provided particularly

in walls having height more than 3 m except where

the toe rests on hard non-erodable

rock.

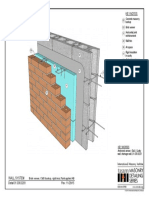

10 RCC BONDING

ELEMENT

In thicker wall sections and tall retaining walls, say

greater than 3 m, special duly staggered bonding

elements through the masonry, going from earth face

of the wall to its front face at regular spacing along

the length and height, shall be used. The bonding

elements shall be spaced at 1 m interval along the

length of the wall. These elements may consist of

with overlapping bond stones (scissor bond stones),

wooden ballies or bamboos but considering

the

durability these may consist of reinforced concrete

member of square cross-section of 75 mm x 75 mm

or 100 mm x 100 mm and having a length equal

to the thickness of the wall plus 150 mm so that

it may project out of wall by 75 mm on both sides

for easy checking as shown in Fig. 2.

OF BACKFILL

No dumping of stones shall be done. The backfill

shall preferably be done by hand packing to achieve

the maximum angle of internal friction.

The width

of backfill shall be at least 500 mm. The backfill

material shall be non-cohesive

and as free draining

as possible except the top layer of 300 to 500 mm

IS 14458 (Part 3) : 1998

ONLY

FACE

STONES

ARE

WELL

PLACED

REST

IS

STONE

SLOPtNG

TOP

IN SHOULDER

SLOPE

!JENSE

FILLING

__

LAYERS

OUTWARDS

SOIL

IN 03m

^^..^..

TONE

GOtiD

HAND

PACKED

STONE

FILLING

IN

STEPPED

FACE

PR&URE

WALL

GOOD

MASONRY

PITCHING

16)

RETAINING

GOOD

1 (d)

WALL OF VERY SMALL

RETAINING

STRENGTH

WALL BUT UNSTABLE

FIG.1 TYPICAL

FILLING

l(b)

RETAINING

l(d)

BEST RETAINING

WALL OF POOR STRENGTH

WALL WITH GOOD

CONSTRUCTIONDETAILSFOR DRY STONE MASONRY WALL

75 OR100

l----

b+150mm -4

75 OR 100mm

FIG. 2 RCC BONDING ELEMENTS

3

FILLING

IS 14458 (Part 3) : 1998

ANNEX A

(Foreword)

COMMITTEE

Hill Area Development

COMPOSITION

Engineering

Sectional

Committee,

CED 56

Representing

DR GWAL RANJAN

University of Roorkee, Roorkee

SHRI SHEIKII NAZIR ANMED

Public Works Department,

Jammu

PROF A

Indian Institute of Remote

Sensing,

SW

K. CflAKRABORTY

& Kashmir

Dehra Dun

R. C. LAKHERA (Alrernufe)

CHAIR~~AN-CUM~MANAGING

DIRECTOR

National

Buildings

Construction

Corporation,

New Delhi

Organization,

Roorkee

91~1 B. B. KUMAR (Altern&)

CHIEF ENGINEER(DAM DESIGN)

Uttar Pradesh

Irrigation

Design

SupToc; ENGINEER (TEHRI DAM

DESIGN CIRVLE) (Alternclte)

CHIEF EN(;INEER (ROADS)

Ministry

of Surface

Transport,

New Delhi

S[lrrr)n ENGINEER (R~~~~)(Altern&e)

DEWTY DIRwIoR GENERAL (D&S

DI:PUTY SECRETARY (T),

DTE, DGBR)

Indian Roads Congress,

New Delhi

IRC (Alrernnte)

DIRWTC)R, HCD (N&W)

Central

Water

Commission,

New Delhi

DIREVTOR (SARDAR SAROVAR)(A~~WW~)

DR Ii. K. DIJR~Y

DR 1). S. UIADfIYAY (Alferncffe)

SHRI

PAWAN K~MAR GI_IPTA

Indian Meteorological

Society

Department,

for Integrated

New Delhi

Development

of Himalayas,

Mussoorie

FIELU COORDINATOR(A~femafe)

StIRI T. N. GljPTA

Building

Materials

and Technology

Promotion

Council,

New Delhi

SIIRI J. SENGUPTA (Alferncde)

SHRI M. M. HARBOLA

Forest Survey

of India, Dehra Dun

SI-IRIP. K. PATHAK (Alfernctfe)

DR U. C. KALI~A

Regional

Research

Laboratory,

Jorhat

SHRI B. C. BORTHAKUR (Alfermfe)

SHRIS. KAIJI.

~Ministry of Railways,

SHRI KIREET KUMAR

G.B. Pant Institute

of Himalayan

&OF A. k. MalTRA

PROF ARVIND KRISHAN (Alferncree-)

School of Planning

and Architecture,

DR G. S. MEHKOTRA

Central Building

New Delhi

Research

Environment

Institute,

and Development,

Almwa

New Delhi

Roorkee

SHRI N. C. BHA~AT (Alfrrnufe)

SHRI P. L. NARULA

SHKI S. DASGUPTA (Alfernufe)

Geological

SHRIMATI M. PARTHASARATHY

Engineer&-Chiefs

SHRI N

Survey of India, Calcutta

Branch,

Army Headquarters,

New Delhi

K.. BALI (Alferntrfe)

SILFU

D.P. PRADI-~AN

Sikkim

Hill Area Development

SHRI P. JAGANNATVA RAO

SHRI D. S. TOLIA (Alfermfe)

Central

Road Research

Institute,

Board,

Gangtok

New Delhi

(Continued on page S)

IS 14458

(Part 3) : 1998

Representing

Merrtbef .r

DR K. S. RAO

IIT, New Delhi

DR BIHAWANISINGH

DR P. C. JAIN (Altmrure)

University

SHRI BHOOP SlNcti

Depaament

of Science

SHRI RAMAN

Directorate

General

SIN(ilf

of Roorkee,

Roorkee

and Technology,

Border

Roads

New Delhi

(D&S),

New Delhi

SHRI J. GOPALAKRISHNA(Aster&)

SHRI

R. II. SIN(IH

DR SLJMIIK KVMAR (Altumfe)

National

Institute

of Hydrology,

PROF C. 1. SINIIA

SHRI I1.K SING13 (,d/ter~trlc)

North-Eastern

Regional

SIW

Public Works

Department,

LAKHBIR SINCH SONKHLA

SHRI A. K. SONI

DR P.

SRINIVASIJLU

SHRI

Central

Mining

Institute

Research

Structural

Engineering

Central

Public Works

Roorkee

of Water and Land Management,

Assam

Simla

Institute,

Research

Dhanbad

Centre,

Chennai

N. GOPALAKKISIINAN(Alternqt?)

SWDRINTFNLXNG

SURVEYOROF WORKS (NZ)

SLJRVEYOROF W~IRKS - I (NZ) (Alteuute)

Housing

and Urban

Department,

Development

SHRI S. C. TIWARI

U.P. Hill Area Development

SHRI Y. VENKXTA(IIALAM

SIIRI S. K. BABBAR (Alterma)

Central

DR

Wadia

N.S. VIRIJHI

SIIRI VINOI) KUMAR,

Director (CIV Fngg)

Soil and Material

Institute

Director

Research

BIS (Ex-otficio

Member-Secretctry

SHRI T.B. NARAYANAN

Joint Director

(Civ Engg),

Corporation

(HUDCO),

Board, Lucknow

of Himalayan

General,

New Delhi

BIS

Station,

Geology,

Member)

New Delhi

Dehra

Dun

New Delhi

Bureau of Indian Standards

BIS is a statutory institution established under the Bureau of Indian Standards Act, 1986 to promote

harmonious development of the activities of standardization, marking and quality certification of goods and

attending to connected matters in the country.

Copyright

No part of these publications may be reproduced in any forn

BIS has the copyright of all its publications.

without the prior permission in writing of BIS. This does not preclude the free use, in the course oi

implementing the standard, of necessary details, such as symbols and sizes, type or grade designations.

Enquiries relating to copyright be addressed to the Director (Publication), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed

periodically; a standard along with amendments is reaffirmed when such review indicates that no changes are

needed; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standards

should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue

of BIS Handbook and Standards Monthly Additions

This Indian Standard has been developed from Dot: No. CED 56 (5599).

Amendments

Amend No.

Issued Since Publication

Date of Issue

Text Affected

-_

BUREAU

OF INDIAN

STANDARDS

Headquarters:

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002

Telephones: 323 0131,323 33 75,323 94 02

Telegrams: Manaksanstha

(Common to all offices)

Regional Offices:

Central

Telephone

: Manak Bhavan, 9 Bahadur Shah Zafar Marg

323 76 17,323 38 41

NEW DELHI 110002

Eastern

: l/14 C.I.T. Scheme VII M, V.I.P. Road, Maniktola

CALCUTTA

337 84 99,337 85 61

337 86 26,337 9120

700054

Northern

: SC0 335-336, Sector 34-A, CHANDIGARH

Sotihern

: C.I.T. Campus, IV Cross Road, CHENNAI

Western

: Manakalaya,

Branches

: AHMADABAD.

160022

60 38 43

{ 60 20 25

600113

235 02 16,235 04 42

{ 235 15 19,235 23 15

E9 MIDC, Marol, Andheri (East)

MUMBAI 400093

832 92 95,832 78 58

1 832 78 91,832 78 92

BANGALORE. BHOPAL. BHUBANESHWAR.

COIMBATORE.

FARIDABAD.

GHAZ3ABAD:

GUWAHATI.

HYDERABAD.

JAIPUR. KANPUR. LUCKNOW.

NAGPUR.

PATNA.

PUNE. THIRUVANANTHAPURAM.

Printed at Dee Kay Printers, New Delhi, India

S-ar putea să vă placă și

- Vibroreplacement PDFDocument9 paginiVibroreplacement PDFthadikkaranÎncă nu există evaluări

- Stabilization of Black Cotton Soil by Admixtures PDFDocument19 paginiStabilization of Black Cotton Soil by Admixtures PDFSantosh NaikÎncă nu există evaluări

- Sheeting Wall Analysis by The Method of Dependent PressuresDocument7 paginiSheeting Wall Analysis by The Method of Dependent PressuresRosey DalÎncă nu există evaluări

- Bbs of All StructureDocument420 paginiBbs of All StructureRitesh kumarÎncă nu există evaluări

- KDS 11 70 20 Rockfall and Debris Prevention Facility Design StandardsDocument15 paginiKDS 11 70 20 Rockfall and Debris Prevention Facility Design StandardsSH Big ShimÎncă nu există evaluări

- Ch4 Settlement of Buildings (1-34) - 2016Document36 paginiCh4 Settlement of Buildings (1-34) - 2016Rafi SulaimanÎncă nu există evaluări

- 03 Frame Cardinal PointsDocument2 pagini03 Frame Cardinal PointsMayckolÎncă nu există evaluări

- E-Rock Index PropertiesDocument37 paginiE-Rock Index Propertiessamwel juliusÎncă nu există evaluări

- Gabion Wall Design - 4.0 MTR Above GLDocument8 paginiGabion Wall Design - 4.0 MTR Above GLAnkush SharmaÎncă nu există evaluări

- Seizmic Design of RE WallsDocument49 paginiSeizmic Design of RE Wallsljubomirjocic@yahoo.com100% (1)

- Geotechnical Investigation Kargil ProposalDocument71 paginiGeotechnical Investigation Kargil ProposalJack DoverÎncă nu există evaluări

- Chapter 19Document55 paginiChapter 19betonglee100% (1)

- Design of PileDocument12 paginiDesign of PileAniket DÎncă nu există evaluări

- Analysis of Basal Heave Stability For Excavations in Soft Clay Using The Finite PDFDocument8 paginiAnalysis of Basal Heave Stability For Excavations in Soft Clay Using The Finite PDFJuan Carlos Patiño BautistaÎncă nu există evaluări

- Pile Capacity Comp./UpliftDocument2 paginiPile Capacity Comp./UpliftPankaj Sherwal100% (1)

- Basic Civil Engineering-Foundation: Mr.B.RameshDocument35 paginiBasic Civil Engineering-Foundation: Mr.B.RameshacroxmassÎncă nu există evaluări

- TCXD 205-1998 Pile Foundation-Specifications For DesignDocument68 paginiTCXD 205-1998 Pile Foundation-Specifications For Designrpb10Încă nu există evaluări

- Concrete Pavement Design: Technical SummaryDocument2 paginiConcrete Pavement Design: Technical SummaryHaris Restu UtamaÎncă nu există evaluări

- Rankine Earth Pressure Theory PDFDocument4 paginiRankine Earth Pressure Theory PDFgitrixÎncă nu există evaluări

- Analysis On The Causes of Cracks in BridgesDocument14 paginiAnalysis On The Causes of Cracks in BridgesNguyễn Văn MinhÎncă nu există evaluări

- Optimal Deign of Pile FoundationDocument13 paginiOptimal Deign of Pile FoundationJustin Johnson100% (1)

- 14 Comparison of Geotechnic Softwares Geo FEM Plaxis Z-SoilDocument6 pagini14 Comparison of Geotechnic Softwares Geo FEM Plaxis Z-SoilWondwosen BelayÎncă nu există evaluări

- Seepage and StabilityDocument6 paginiSeepage and StabilityChengHian Yap100% (2)

- Foundations For The Future - Removal of Existing PilesDocument8 paginiFoundations For The Future - Removal of Existing PilesskkongÎncă nu există evaluări

- Foundations On Deep Alluvial Soils PDFDocument41 paginiFoundations On Deep Alluvial Soils PDFMardi RahardjoÎncă nu există evaluări

- 2D Numerical Simulations of Soil Nail WallsDocument12 pagini2D Numerical Simulations of Soil Nail WallsShahab KhaledÎncă nu există evaluări

- Ch1-Soil Definition & FormationDocument20 paginiCh1-Soil Definition & FormationRafi SulaimanÎncă nu există evaluări

- Deep FoundatioDocument49 paginiDeep FoundatioSanthosh PurushothamanÎncă nu există evaluări

- RCC Design of Bus Shelter at VelpuruDocument81 paginiRCC Design of Bus Shelter at VelpuruD.V.Srinivasa RaoÎncă nu există evaluări

- 3D Tunnel Simulation Using Core Replacement 1.0 IntroductionDocument27 pagini3D Tunnel Simulation Using Core Replacement 1.0 IntroductionCarlosMarioVargasMoralesÎncă nu există evaluări

- Irc 58 2002Document40 paginiIrc 58 2002Hari Prasad Paruchuri100% (1)

- BhattacharyaDocument10 paginiBhattacharyavoraciousvÎncă nu există evaluări

- EarthPressures, SAMUEL G. PAIKOWSKY PDFDocument38 paginiEarthPressures, SAMUEL G. PAIKOWSKY PDFRakesh7770Încă nu există evaluări

- Soil NailDocument305 paginiSoil Nailosamosa33% (3)

- FEB 402 Slope Stability AnalysisDocument26 paginiFEB 402 Slope Stability AnalysislucyÎncă nu există evaluări

- Challenges Associated With Expansive Soils and Remedial MeasuresDocument13 paginiChallenges Associated With Expansive Soils and Remedial MeasuresSaurav BhattacharjeeÎncă nu există evaluări

- Soil Test Report KhagariaDocument28 paginiSoil Test Report KhagariaSajan SinghÎncă nu există evaluări

- Design and Construction of Mat (Raft) Foundations - BookDocument10 paginiDesign and Construction of Mat (Raft) Foundations - BookbatteekhÎncă nu există evaluări

- Finite Element Analysis of Soil Bearing Capacity Using PlaxisDocument5 paginiFinite Element Analysis of Soil Bearing Capacity Using PlaxisRehan HakroÎncă nu există evaluări

- Backward Calculation For Bearing Capacity Estimation of Geogrid Reinforced Foundation by Finite Element MethodDocument13 paginiBackward Calculation For Bearing Capacity Estimation of Geogrid Reinforced Foundation by Finite Element MethodFoolad GharbÎncă nu există evaluări

- Ch5 Retaining Walls (1-37)Document37 paginiCh5 Retaining Walls (1-37)Rafi Sulaiman100% (1)

- Alluvial Soil CharacteristicsDocument7 paginiAlluvial Soil CharacteristicsasebdcivilengÎncă nu există evaluări

- 14h00 Samuel Paikowsky 23 06 Plenaria 4x3Document78 pagini14h00 Samuel Paikowsky 23 06 Plenaria 4x3Paula NejaimÎncă nu există evaluări

- IS 2911 (Part 1 Section 4) 1984 R 2002Document31 paginiIS 2911 (Part 1 Section 4) 1984 R 2002Nagaraju ChintaÎncă nu există evaluări

- Types of PavementDocument10 paginiTypes of Pavementmohsen.911.mkÎncă nu există evaluări

- Appendix 4 - Design of Foundation SystemDocument18 paginiAppendix 4 - Design of Foundation SystemMois DanielÎncă nu există evaluări

- PDS STAAD Foundation Advanced LTR EN LR PDFDocument2 paginiPDS STAAD Foundation Advanced LTR EN LR PDFAndres Felipe Forero GacharnáÎncă nu există evaluări

- Seismic Behavior Retaining WallsDocument29 paginiSeismic Behavior Retaining WallsSaeedÎncă nu există evaluări

- Tutorial MSEWDocument1 paginăTutorial MSEWSUNDARAVELÎncă nu există evaluări

- 5-Design of Raft FoundationDocument2 pagini5-Design of Raft FoundationheshamÎncă nu există evaluări

- PreviewpdfDocument90 paginiPreviewpdfSheeraz AhmedÎncă nu există evaluări

- Tunnelling in Bukit Timah Granite Formation - Challenges in Tunnelling From Newton To Stevens StationDocument14 paginiTunnelling in Bukit Timah Granite Formation - Challenges in Tunnelling From Newton To Stevens StationfreezefreezeÎncă nu există evaluări

- Thermal Stresses and Temperature Control of Mass ConcreteDe la EverandThermal Stresses and Temperature Control of Mass ConcreteÎncă nu există evaluări

- Ground Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980De la EverandGround Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980Încă nu există evaluări

- Is 14458Document9 paginiIs 14458thirumalaichettiar0% (1)

- IS14458 Part5 2018Document9 paginiIS14458 Part5 2018Sinny D Miracle ManoharÎncă nu există evaluări

- IS14458 Part4 2018Document9 paginiIS14458 Part4 2018Sinny D Miracle ManoharÎncă nu există evaluări

- IS 14458 - 5 Cement Stone WallDocument9 paginiIS 14458 - 5 Cement Stone WallAnju Karki100% (2)

- Composite Girders (BG)Document1 paginăComposite Girders (BG)v2299Încă nu există evaluări

- Pipe Reinf CalsDocument1 paginăPipe Reinf Calsv2299Încă nu există evaluări

- Page 16Document1 paginăPage 16v2299Încă nu există evaluări

- Page 16Document1 paginăPage 16v2299Încă nu există evaluări

- Concept of Silo DesignDocument6 paginiConcept of Silo Designv2299Încă nu există evaluări

- Properties of Steel SectionsDocument43 paginiProperties of Steel Sectionsvenkatesh1970133% (6)

- TANK SeismicDocument25 paginiTANK SeismictadagidsÎncă nu există evaluări

- Appendix BDocument6 paginiAppendix BHari AnbazhaganÎncă nu există evaluări

- Curing Compound SikaDocument1 paginăCuring Compound Sikav2299Încă nu există evaluări

- Steel - SailDocument5 paginiSteel - Sailv2299Încă nu există evaluări

- Appc Soil Properties 718Document5 paginiAppc Soil Properties 718pinkuru100% (1)

- CPCC LiteratureDocument3 paginiCPCC Literaturev2299Încă nu există evaluări

- Precast SpecificationsDocument3 paginiPrecast Specificationsv2299Încă nu există evaluări

- Is 14961 Guidelines For Rain Water Harvesting in Hilly AreasDocument8 paginiIs 14961 Guidelines For Rain Water Harvesting in Hilly Areasv2299Încă nu există evaluări

- Is 14496#2 Preparation of Landslide Hazard Zonation Maps inDocument22 paginiIs 14496#2 Preparation of Landslide Hazard Zonation Maps inv2299Încă nu există evaluări

- 1883Document15 pagini1883v2299Încă nu există evaluări

- Composite Steel JoistsDocument10 paginiComposite Steel Joistsv2299100% (1)

- 12680Document7 pagini12680Sagar Saadolalu RÎncă nu există evaluări

- Is 14680 Landslide Control - GuidelinesDocument16 paginiIs 14680 Landslide Control - Guidelinesv2299Încă nu există evaluări

- Bridge BearingDocument162 paginiBridge BearingKabbilawsh Peruvazhuthi100% (6)

- Is 14458#2 Retaining Wall For Hill Area - GuidelinesDocument11 paginiIs 14458#2 Retaining Wall For Hill Area - Guidelinesv2299Încă nu există evaluări

- Retaining Wall For Hill Area Guidelines-1Document11 paginiRetaining Wall For Hill Area Guidelines-1Anil BishtÎncă nu există evaluări

- Water Tank DesignDocument58 paginiWater Tank DesignMoHaMmAd WaHeEd88% (17)

- Jamia Millia Architecture Gate ExamDocument3 paginiJamia Millia Architecture Gate ExamshmmkmÎncă nu există evaluări

- (Report) Storage Tanks (Japan)Document179 pagini(Report) Storage Tanks (Japan)RAJENDRA PRASADÎncă nu există evaluări

- 3D ProDocument3 pagini3D Prov2299Încă nu există evaluări

- ECE632 Mobile CommunicationDocument181 paginiECE632 Mobile CommunicationUsama LatifÎncă nu există evaluări

- House Construction - Structural Building - Wikibooks, Open Books For An Open WorldDocument8 paginiHouse Construction - Structural Building - Wikibooks, Open Books For An Open WorldJojo JojoÎncă nu există evaluări

- BT ReviewerDocument212 paginiBT ReviewerLyke Cris Toriaga MateoÎncă nu există evaluări

- Standard Stone Masonry Slope Protection NEW-ModelDocument1 paginăStandard Stone Masonry Slope Protection NEW-Modelpea yangÎncă nu există evaluări

- RC Design Aci318m 19 v4.0Document43 paginiRC Design Aci318m 19 v4.0Mohammed HanafiÎncă nu există evaluări

- BOQ - Rate AnalysisDocument9 paginiBOQ - Rate AnalysisKeyur GajjarÎncă nu există evaluări

- BPM 305 (Tma01) - Project Scheduling and Control (Mohamed Ali B1210887) BPM 305 (Tma01) - Project Scheduling and Control (Mohamed Ali B1210887)Document1 paginăBPM 305 (Tma01) - Project Scheduling and Control (Mohamed Ali B1210887) BPM 305 (Tma01) - Project Scheduling and Control (Mohamed Ali B1210887)ThanveerÎncă nu există evaluări

- Kale Floor Tiles CatalogueDocument20 paginiKale Floor Tiles CatalogueAshiq ThoÎncă nu există evaluări

- EastBook 2018 WebDocument96 paginiEastBook 2018 WebJasonÎncă nu există evaluări

- Construction MethodDocument12 paginiConstruction MethodKahlua ShuzenÎncă nu există evaluări

- Unit Rate Analysis of AdisuDocument8 paginiUnit Rate Analysis of AdisuAbiyot HordofaÎncă nu există evaluări

- Exam Tle 7Document2 paginiExam Tle 7Brille Anthony BunielÎncă nu există evaluări

- Rate AnalysisDocument6 paginiRate AnalysisRaj BharathÎncă nu există evaluări

- Title-Basic Mterial Price Sheet Title-Labour Wage/cost SheetDocument180 paginiTitle-Basic Mterial Price Sheet Title-Labour Wage/cost Sheetmalik macÎncă nu există evaluări

- BT Bu RevDocument26 paginiBT Bu RevArriane CausingÎncă nu există evaluări

- 1.5 Project Cost Estimation PDFDocument18 pagini1.5 Project Cost Estimation PDFnira365100% (1)

- 016 Bricklaying WorkDocument4 pagini016 Bricklaying WorkFara Atika Bha Ney100% (1)

- B03-S01 Rev 1 Mar 2018 Design and Construction of Concrete Masonry StructuresDocument7 paginiB03-S01 Rev 1 Mar 2018 Design and Construction of Concrete Masonry Structures15150515715Încă nu există evaluări

- BOQ Godrej Golf LInkDocument14 paginiBOQ Godrej Golf LInkBittudubey officialÎncă nu există evaluări

- Scope of Bridge DesignDocument9 paginiScope of Bridge DesignoundhakarÎncă nu există evaluări

- Group 2-Masonry-Ce22fa3Document13 paginiGroup 2-Masonry-Ce22fa3Aira Joy AnyayahanÎncă nu există evaluări

- Product Data Sheet - GBP Build FastDocument2 paginiProduct Data Sheet - GBP Build FastVikram DhabaleÎncă nu există evaluări

- Sampling and Testing Concrete Masonry Units and Related UnitsDocument25 paginiSampling and Testing Concrete Masonry Units and Related UnitsSurya MahapatraÎncă nu există evaluări

- Measurement of Water Absorption Under Low PressureDocument4 paginiMeasurement of Water Absorption Under Low Pressurejjemp100% (1)

- Key Notes: Wall SystemDocument1 paginăKey Notes: Wall SystemMyo Min ThuÎncă nu există evaluări

- Measurement of Masonry Flexural Bond Strength: Standard Test Method ForDocument11 paginiMeasurement of Masonry Flexural Bond Strength: Standard Test Method ForFranky HernandezÎncă nu există evaluări

- Documentation Schedule - Drum Filling SystemDocument7 paginiDocumentation Schedule - Drum Filling SystemRanjithÎncă nu există evaluări

- Construction Advance Design: Submitted By:-Munira Pithawala Submitted To: - Ar. Richa Joshi, Mrs Rohini KushwahDocument16 paginiConstruction Advance Design: Submitted By:-Munira Pithawala Submitted To: - Ar. Richa Joshi, Mrs Rohini KushwahMunira PithawalaÎncă nu există evaluări

- Three Storey General SpecificationsDocument5 paginiThree Storey General SpecificationsCarlos Gozon100% (1)

- FalbababablalaDocument8 paginiFalbababablalabonobo5Încă nu există evaluări

- Tanginl SeawallDocument12 paginiTanginl SeawallKing LemuelÎncă nu există evaluări