Documente Academic

Documente Profesional

Documente Cultură

Salt Catalogue

Încărcat de

isosicaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Salt Catalogue

Încărcat de

isosicaDrepturi de autor:

Formate disponibile

SALT PROCESSING PLANT

Vacuum Salt Refinery Plant

THE PROJECT PEOPLE

Vapour Separator

Centrifuge

Refined Iodised

Concentrate

Filter

Balance Tank

Transfer

Pump

Intermediate Transfer Pump

To Drying Section

Condensor

Calandria

Vapour Separator

Calandria

Calandria

Steam in

Vapour Separator

Thickner

Salt Processing Plant

Transfer Pump

Iodine Mixing

Silica Feed In

Exhaust Air Duct

Fines with Air

Exhaust Fan

Hopper

Cyclone

Separator

Drying Chamber

Elevator

Supply Air Fan

Atmospheric

Air In

Drain

Salt Packing

Hot Air Duct

Condensate

Out

Air Heater

(Steam Radiator)

Our Esteemed Clients

Indo Brine Industries Ltd., India

n

DS Foods Limited, India

n

Pubali Salt Industries Ltd., Bangladesh

n

Ekango Salt Refineries (Pty) Ltd., Namibia

n

Groupe Kadur Ltd. Algeria

n

Royal Salt, Lagos, Nigeria

n

Nyanza Mines Ltd., Tanzania

n

Yosuf Ishaq Co. Ltd. , Afghanistan

n

n

Yousef Ahmad Husein & Partners Co., Jordan

n

Ken salt, Mombasa, Kenya

n

Sea Salt, Tanzania

n

BRAC Salt, Bangladesh

n

Saboo Sodium Chloro Ltd., India

n

Patel Salt & Marine Chemicals (P) Ltd., India

SSP PVT LIMITED

ISO 9001:2008 CERTIFIED & ASME U STAMP HOLDER

THE PROJECT PEOPLE

13 Milestone, Mathura Road, Faridabad-121 003 Haryana (INDIA);

Phone: +91 (0) 129-4183700; Fax: +91 (0) 129-4183777

E-mail: info@ssp.co.in; marketing@ssp.co.in, Website: www.sspindia.com

SSP:MKD:CTG:06:REV:03:01/2012

www.sspindia.com

SSP PVT LIMITED

ISO 9001:2008 CERTIFIED & ASME U STAMP HOLDER

Salt Processing Plant

Introduction

Main source of salt is rocks, sea & lake. Maximum consumption of salt is in its natural form after being produced from

sea or directly from rock. But with time, awareness on uses of salt have grown manifold and the demand for refined

iodised salt has increased tremendously during the last few years. Refining not only helps in increasing purity of salt,

but also improves flowability and use of anti-caking agents helps in maintaining quality too. During refining and

drying process, iodisation is done which is important for human body to avoid various diseases. Refined salt is further

graded for various applications like kitchen salt, table salt and industrial salt.

Two types of Salt Refinery System:

- Mechanical Salt Refinery

- Vacuum Salt Refinery

Mechanical Salt Refinery

Basic principle of mechanical salt refinery is to separate the solid & soluble

impurities present in the crude salt. In this process first the salt crystals are

broken down to the desired crystal size distribution. Crushing also helps to

take out impurities from within the crude salt.

After crushing, the soluble and insoluble impurities are separated by

dissolution and hydro-mechanical classification steps.

The gypsum crystals and other solid impurities like sand, earth can be

separated by using agitated dissolving vat followed by counter current

washing system, thickener and centrifuge.

Dissolvable impurities MgCl2 MgSO4 & Kcl remain along with the saturated

brine solution until the impurities concentration equals to that of sodium

chloride.

SSP standard refinery consists of three stage washing and a centrifuge.

Counter current washings help removal of fine impurities and purge from

the bottom of these systems removes impurities like sand, earth etc.

Mechanical

Salt Refinery

Process Flow for

Mechanical Salt Refinery

Crude Salt

Crushing

Washing (with Brine)

Elutriation Tank

Thickener

Centrifuge

Iodine Dosing

Fluid Bed Dryer

Anti-Caking Dosing

Storage

Packing

After removal of impurities, the salt cake coming out of the

centrifuge gets mixed with Iodine solution and dried in a fluid bed

dryer < 0.2% moisture content. Anti-caking agents are added before

packing.

Vacuum Salt Refinery

The process involves dissolving of solar salt in water and making a

saturated solution of salt. The saturated brine is pumped out to a

brine clarifier, where the insolubles settles at the bottom of the

clarifier and clear brine solution is taken to a brine tank. In the brine

tank required chemicals are added to precipitate out magnesium

and calcium salts present along with the salt. The brine is then filtered

and taken to the final brine tank. From this tank saturated brine is fed

to the continuous evaporation plant where Crystallisation takes

place and slurry is pumped out to a concentrate tank. This salt slurry is

then pumped to a hydro-cyclone battery to get a slurry

concentration up to 50-60%.

This slurry is fed to a centrifuge, and from the centrifuge salt cakes

with 4-5% moisture are obtained. The salt with 4-5% moisture is fed to

a fluid bed dryer through a screw conveyor where the iodisation

takes place and the salt is dried in a fluid bed dryer up to 0.2%

moisture content and cooled to ambient temperature. The salt is

then taken through a bucket elevator to a sieving machine. The

oversize particles are collected and sent for re-dissolving in the final

brine tank. Free flowing agent is then added to the crystalline salt in a

screw mixer and finally sent to a storage silo.

The salt packaging is done from the silo by FFS machine in different

quantity (1 kg, kg packs). It can be packed in bags also.

Vacuum

Salt Refinery

Process Flow for

Vacuum Salt Refinery

Crude Salt

Dissolving Vats

Clarifier

Saturated Brine

Chemical Treatment

Filteration

Evaporative Crystalizer

Thickener

Centrifuge

Iodine Dosing

Fluid Bed Dryer

Anti-Caking Dosing

Storage

Packing

Salt Processing Plant

Introduction

Main source of salt is rocks, sea & lake. Maximum consumption of salt is in its natural form after being produced from

sea or directly from rock. But with time, awareness on uses of salt have grown manifold and the demand for refined

iodised salt has increased tremendously during the last few years. Refining not only helps in increasing purity of salt,

but also improves flowability and use of anti-caking agents helps in maintaining quality too. During refining and

drying process, iodisation is done which is important for human body to avoid various diseases. Refined salt is further

graded for various applications like kitchen salt, table salt and industrial salt.

Two types of Salt Refinery System:

- Mechanical Salt Refinery

- Vacuum Salt Refinery

Mechanical Salt Refinery

Basic principle of mechanical salt refinery is to separate the solid & soluble

impurities present in the crude salt. In this process first the salt crystals are

broken down to the desired crystal size distribution. Crushing also helps to

take out impurities from within the crude salt.

After crushing, the soluble and insoluble impurities are separated by

dissolution and hydro-mechanical classification steps.

The gypsum crystals and other solid impurities like sand, earth can be

separated by using agitated dissolving vat followed by counter current

washing system, thickener and centrifuge.

Dissolvable impurities MgCl2 MgSO4 & Kcl remain along with the saturated

brine solution until the impurities concentration equals to that of sodium

chloride.

SSP standard refinery consists of three stage washing and a centrifuge.

Counter current washings help removal of fine impurities and purge from

the bottom of these systems removes impurities like sand, earth etc.

Mechanical

Salt Refinery

Process Flow for

Mechanical Salt Refinery

Crude Salt

Crushing

Washing (with Brine)

Elutriation Tank

Thickener

Centrifuge

Iodine Dosing

Fluid Bed Dryer

Anti-Caking Dosing

Storage

Packing

After removal of impurities, the salt cake coming out of the

centrifuge gets mixed with Iodine solution and dried in a fluid bed

dryer < 0.2% moisture content. Anti-caking agents are added before

packing.

Vacuum Salt Refinery

The process involves dissolving of solar salt in water and making a

saturated solution of salt. The saturated brine is pumped out to a

brine clarifier, where the insolubles settles at the bottom of the

clarifier and clear brine solution is taken to a brine tank. In the brine

tank required chemicals are added to precipitate out magnesium

and calcium salts present along with the salt. The brine is then filtered

and taken to the final brine tank. From this tank saturated brine is fed

to the continuous evaporation plant where Crystallisation takes

place and slurry is pumped out to a concentrate tank. This salt slurry is

then pumped to a hydro-cyclone battery to get a slurry

concentration up to 50-60%.

This slurry is fed to a centrifuge, and from the centrifuge salt cakes

with 4-5% moisture are obtained. The salt with 4-5% moisture is fed to

a fluid bed dryer through a screw conveyor where the iodisation

takes place and the salt is dried in a fluid bed dryer up to 0.2%

moisture content and cooled to ambient temperature. The salt is

then taken through a bucket elevator to a sieving machine. The

oversize particles are collected and sent for re-dissolving in the final

brine tank. Free flowing agent is then added to the crystalline salt in a

screw mixer and finally sent to a storage silo.

The salt packaging is done from the silo by FFS machine in different

quantity (1 kg, kg packs). It can be packed in bags also.

Vacuum

Salt Refinery

Process Flow for

Vacuum Salt Refinery

Crude Salt

Dissolving Vats

Clarifier

Saturated Brine

Chemical Treatment

Filteration

Evaporative Crystalizer

Thickener

Centrifuge

Iodine Dosing

Fluid Bed Dryer

Anti-Caking Dosing

Storage

Packing

SALT PROCESSING PLANT

Vacuum Salt Refinery Plant

THE PROJECT PEOPLE

Vapour Separator

Centrifuge

Refined Iodised

Concentrate

Filter

Balance Tank

Transfer

Pump

Intermediate Transfer Pump

To Drying Section

Condensor

Calandria

Vapour Separator

Calandria

Calandria

Steam in

Vapour Separator

Thickner

Salt Processing Plant

Transfer Pump

Iodine Mixing

Silica Feed In

Exhaust Air Duct

Fines with Air

Exhaust Fan

Hopper

Cyclone

Separator

Drying Chamber

Elevator

Supply Air Fan

Atmospheric

Air In

Drain

Salt Packing

Hot Air Duct

Condensate

Out

Air Heater

(Steam Radiator)

Our Esteemed Clients

Indo Brine Industries Ltd., India

n

DS Foods Limited, India

n

Pubali Salt Industries Ltd., Bangladesh

n

Ekango Salt Refineries (Pty) Ltd., Namibia

n

Groupe Kadur Ltd. Algeria

n

Royal Salt, Lagos, Nigeria

n

Nyanza Mines Ltd., Tanzania

n

Yosuf Ishaq Co. Ltd. , Afghanistan

n

n

Yousef Ahmad Husein & Partners Co., Jordan

n

Ken salt, Mombasa, Kenya

n

Sea Salt, Tanzania

n

BRAC Salt, Bangladesh

n

Saboo Sodium Chloro Ltd., India

n

Patel Salt & Marine Chemicals (P) Ltd., India

SSP PVT LIMITED

ISO 9001:2008 CERTIFIED & ASME U STAMP HOLDER

THE PROJECT PEOPLE

13 Milestone, Mathura Road, Faridabad-121 003 Haryana (INDIA);

Phone: +91 (0) 129-4183700; Fax: +91 (0) 129-4183777

E-mail: info@ssp.co.in; marketing@ssp.co.in, Website: www.sspindia.com

SSP:MKD:CTG:06:REV:03:01/2012

www.sspindia.com

SSP PVT LIMITED

ISO 9001:2008 CERTIFIED & ASME U STAMP HOLDER

S-ar putea să vă placă și

- TQM Practices of Aci Salt Industries Bangladesh PDFDocument21 paginiTQM Practices of Aci Salt Industries Bangladesh PDFKamrul HasanÎncă nu există evaluări

- Design Qualification: Cip Skid & Distribution Piping (Veg Blender Flavours Powder)Document12 paginiDesign Qualification: Cip Skid & Distribution Piping (Veg Blender Flavours Powder)Chay Nag100% (1)

- Salt 3 PDFDocument29 paginiSalt 3 PDFafsalmohmd100% (1)

- How To Prevent Caking in NPK Fertilizer Production ProcessDocument2 paginiHow To Prevent Caking in NPK Fertilizer Production Processluna leÎncă nu există evaluări

- Process For The Polymerization of Vinyl ChlorideDocument32 paginiProcess For The Polymerization of Vinyl ChlorideThu TongÎncă nu există evaluări

- Project Engineering Handbook: P&ID GuidelinesDocument62 paginiProject Engineering Handbook: P&ID GuidelinesVishal MistryÎncă nu există evaluări

- Dishwasher Explanation TextDocument3 paginiDishwasher Explanation TextMai - Patcharee RushÎncă nu există evaluări

- Steel Alloy Testing OpDocument14 paginiSteel Alloy Testing OpOm PrakashÎncă nu există evaluări

- Avocado-Flottweg Decanter 2 y 3 PhasesDocument12 paginiAvocado-Flottweg Decanter 2 y 3 PhasesRenzo Saavedra100% (1)

- Salt Presentation2Document41 paginiSalt Presentation2asivachemÎncă nu există evaluări

- Ultra Filtration SystemDocument5 paginiUltra Filtration SystemAbdul SamadÎncă nu există evaluări

- Caustic Soda ManufactureDocument14 paginiCaustic Soda Manufacturenikhilchhatre100% (1)

- Valerio Whirlpool CaseDocument2 paginiValerio Whirlpool CaseBeatrize ValerioÎncă nu există evaluări

- Design of Control System For Cover Washing Machine PDFDocument7 paginiDesign of Control System For Cover Washing Machine PDFYeron GelayeÎncă nu există evaluări

- AlfaLaval Corn Gluten Dewatering BrochureDocument2 paginiAlfaLaval Corn Gluten Dewatering BrochureI. Murali KrishnaÎncă nu există evaluări

- Liquid Urea-Formaldehyde Resin Manufacturing Industry-217599 - 4Document65 paginiLiquid Urea-Formaldehyde Resin Manufacturing Industry-217599 - 4Sanzar Rahman 1621555030Încă nu există evaluări

- Full Proposal Template - Tech Tranfer Simple FormatDocument15 paginiFull Proposal Template - Tech Tranfer Simple FormatSaddam Ali KhanÎncă nu există evaluări

- Extraction of Cottonseed Oil Expeller Method One Ton Per Day PDFDocument2 paginiExtraction of Cottonseed Oil Expeller Method One Ton Per Day PDFHenryÎncă nu există evaluări

- Accounts List (Detail) : Account # Account Type DR/CR Header/Detail Level ChequeDocument4 paginiAccounts List (Detail) : Account # Account Type DR/CR Header/Detail Level ChequeEka RatihÎncă nu există evaluări

- EPC AgreementDocument139 paginiEPC AgreementSwanandÎncă nu există evaluări

- Managing Cyanide in Metal FinishingDocument31 paginiManaging Cyanide in Metal FinishingWONG TSÎncă nu există evaluări

- 1012.membrane Separations in Biotechnology, Second Edition, (Biotechnology and Bioprocessing) by William K. WangDocument412 pagini1012.membrane Separations in Biotechnology, Second Edition, (Biotechnology and Bioprocessing) by William K. WangBioxim100% (1)

- Working CapitalDocument18 paginiWorking Capitaldarshanjoshi07Încă nu există evaluări

- Vdocuments - MX Petroleum Development Oman LLC Petroleum Development Oman LLC Er DocumentsDocument60 paginiVdocuments - MX Petroleum Development Oman LLC Petroleum Development Oman LLC Er DocumentsOussama BaddadiÎncă nu există evaluări

- Shokti DoiDocument34 paginiShokti Doitoxictouch100% (1)

- Industrial Training - Report - Format MU (1) (1) FINAL REPORTDocument36 paginiIndustrial Training - Report - Format MU (1) (1) FINAL REPORTniraj kumarÎncă nu există evaluări

- Glascoat 2Document84 paginiGlascoat 2MoinÎncă nu există evaluări

- Mechanical Desktop R6 PDFDocument770 paginiMechanical Desktop R6 PDFMass Giovani50% (2)

- YSTRAL Disperser & Homogenizer Machines PDFDocument4 paginiYSTRAL Disperser & Homogenizer Machines PDFMiguel Angel Pérez GascaÎncă nu există evaluări

- WL130 PE4710 FM Approved Pipe: IPS & DIPS Pipe Sizes - Class 150, 200 & 267Document3 paginiWL130 PE4710 FM Approved Pipe: IPS & DIPS Pipe Sizes - Class 150, 200 & 267Tanwir AhmadÎncă nu există evaluări

- Declaration: Liquid Detergent Production From Castor SeedDocument117 paginiDeclaration: Liquid Detergent Production From Castor SeedZemariyam BizuayehuÎncă nu există evaluări

- Water TreatmentDocument19 paginiWater TreatmentRujem CuliÎncă nu există evaluări

- 154 Mandatory Product List (17-10-2016)Document5 pagini154 Mandatory Product List (17-10-2016)Mir MohiuddinÎncă nu există evaluări

- Povidone Iodine Solution 10%Document3 paginiPovidone Iodine Solution 10%NAVNEET BAGGAÎncă nu există evaluări

- BRINE REPORT Naeem PDFDocument24 paginiBRINE REPORT Naeem PDFKaleem AhmedÎncă nu există evaluări

- Environmental Assessment and Risk Screening For Rural Water Supply: Guidance Note Developed For The SWIFT ConsortiumDocument56 paginiEnvironmental Assessment and Risk Screening For Rural Water Supply: Guidance Note Developed For The SWIFT ConsortiumOxfamÎncă nu există evaluări

- Organic Fertilizer Production Line EquipmentDocument2 paginiOrganic Fertilizer Production Line Equipmentluna leÎncă nu există evaluări

- Food Processing MachineryDocument6 paginiFood Processing MachinerymukulÎncă nu există evaluări

- Product Reseach: Product Development and The Commercialisation of Their R&D Work. Much of The DisappointmentDocument2 paginiProduct Reseach: Product Development and The Commercialisation of Their R&D Work. Much of The DisappointmentJoanna George - JosephÎncă nu există evaluări

- Zeofree SlicaDocument2 paginiZeofree Slicas.sabapathyÎncă nu există evaluări

- Case Study-Wastewater Treatment - Leather ManufactureDocument21 paginiCase Study-Wastewater Treatment - Leather ManufactureAG-Metal /Tretman Otpadnih Voda/Wastewater TreatmentÎncă nu există evaluări

- ESAPA Soda Ash Process BREF3 PDFDocument76 paginiESAPA Soda Ash Process BREF3 PDFUmar OmarÎncă nu există evaluări

- National Liquid Detergents Feasibility StudyDocument14 paginiNational Liquid Detergents Feasibility StudyMariel Gulane PenionesÎncă nu există evaluări

- SOP - Centrifuge - 055Document4 paginiSOP - Centrifuge - 055Md. Ahedul IslamÎncă nu există evaluări

- Water Champ - FX Series (Jul'14)Document47 paginiWater Champ - FX Series (Jul'14)PATRICIA GALINDO100% (1)

- Purification of Salt For Chemical and Human ConsumptionDocument20 paginiPurification of Salt For Chemical and Human Consumptionmr sinaÎncă nu există evaluări

- Cetp Membership FormDocument4 paginiCetp Membership Form555angel100% (1)

- Gas Equipment SolutionDocument19 paginiGas Equipment SolutionKuntari Tri SulistyawardaniÎncă nu există evaluări

- Mr. Manish Kharwade - PrajDocument41 paginiMr. Manish Kharwade - PrajNithi AnandÎncă nu există evaluări

- Tablet:Problems in Tablet Manufacturing: From PharmpediaDocument15 paginiTablet:Problems in Tablet Manufacturing: From PharmpediaMuhammad AyubÎncă nu există evaluări

- Taye Teachingh PractiseDocument9 paginiTaye Teachingh Practisetsegaye atnafuÎncă nu există evaluări

- 5 Ways To Reduce COD in WastewaterDocument2 pagini5 Ways To Reduce COD in WastewaterSo MriÎncă nu există evaluări

- PB Filter Press Sidebar Me1500 Me2500 en Web DataDocument4 paginiPB Filter Press Sidebar Me1500 Me2500 en Web DataTiago J C MachadoÎncă nu există evaluări

- Membrane Filtration Technology Koch Membrane SystemsDocument8 paginiMembrane Filtration Technology Koch Membrane SystemsRamonik RbelaÎncă nu există evaluări

- Description of Process - Nbsm-1Document10 paginiDescription of Process - Nbsm-1avisheklochunÎncă nu există evaluări

- Salt WasheryDocument7 paginiSalt WasheryAÎncă nu există evaluări

- Sugar Plant Project ReportDocument5 paginiSugar Plant Project ReportBryan TanÎncă nu există evaluări

- Final SugarDocument26 paginiFinal SugarMengistu Gosalo0% (1)

- Brine PlantDocument16 paginiBrine PlantJerrySheikh100% (1)

- Chemistry at Home - A Collection of Experiments and Formulas for the Chemistry EnthusiastDe la EverandChemistry at Home - A Collection of Experiments and Formulas for the Chemistry EnthusiastÎncă nu există evaluări

- (Lyrics) Eric Clapton - Wonderful TonightDocument1 pagină(Lyrics) Eric Clapton - Wonderful TonightisosicaÎncă nu există evaluări

- CO 2 Capture by Aqueous Na 2 CO 3 Integrated With High-Quality Caco3Document9 paginiCO 2 Capture by Aqueous Na 2 CO 3 Integrated With High-Quality Caco3isosicaÎncă nu există evaluări

- Chemical Engineering and Processing: Process IntensificationDocument10 paginiChemical Engineering and Processing: Process IntensificationisosicaÎncă nu există evaluări

- Problema - 1 (Op Aritm Simple)Document1 paginăProblema - 1 (Op Aritm Simple)isosicaÎncă nu există evaluări

- Rows Numbering in ExcelDocument5 paginiRows Numbering in ExcelisosicaÎncă nu există evaluări

- Flowserve General Product Guide PDFDocument84 paginiFlowserve General Product Guide PDFSIMON S. FLORES G.Încă nu există evaluări

- ParChem - Hexachloroacetone Supplier DistributorDocument10 paginiParChem - Hexachloroacetone Supplier DistributorisosicaÎncă nu există evaluări

- Funke Shell Tube He eDocument24 paginiFunke Shell Tube He eisosicaÎncă nu există evaluări

- Air - Composition and Molecular WeightDocument4 paginiAir - Composition and Molecular WeightisosicaÎncă nu există evaluări

- ExpressPCB2 PDFDocument1 paginăExpressPCB2 PDFisosicaÎncă nu există evaluări

- IHS - August 2011Document3 paginiIHS - August 2011isosicaÎncă nu există evaluări

- Metal Organic Frameworks (Mofs) :: Time For A Breakthrough in Material SupplyDocument5 paginiMetal Organic Frameworks (Mofs) :: Time For A Breakthrough in Material SupplyisosicaÎncă nu există evaluări

- Family eDocument24 paginiFamily eisosicaÎncă nu există evaluări

- Jinan Shandong, ChinaDocument2 paginiJinan Shandong, ChinaisosicaÎncă nu există evaluări

- Safety in Sulfuric Acid Storage Tanks - Chem. Eng. 11-2015Document6 paginiSafety in Sulfuric Acid Storage Tanks - Chem. Eng. 11-2015isosica100% (2)

- Hazard and Operability Study - WikipediaDocument5 paginiHazard and Operability Study - WikipediaisosicaÎncă nu există evaluări

- D:/Noi/Convertor CCIR-OIRT (PCB Design) /convertor - Express/convertor5.1.pcb (Top Layer, Bottom Layer)Document1 paginăD:/Noi/Convertor CCIR-OIRT (PCB Design) /convertor - Express/convertor5.1.pcb (Top Layer, Bottom Layer)isosicaÎncă nu există evaluări

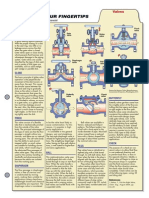

- Valves CHE Facts 0808Document1 paginăValves CHE Facts 0808isosicaÎncă nu există evaluări

- Heat Exchanger DutyDocument5 paginiHeat Exchanger DutyisosicaÎncă nu există evaluări

- Cooling Towers Design Feb12 - CHENG PDFDocument6 paginiCooling Towers Design Feb12 - CHENG PDFisosicaÎncă nu există evaluări

- Live Gold Price, Silver Price and Spot Precious Metals Quotes and ChartsDocument5 paginiLive Gold Price, Silver Price and Spot Precious Metals Quotes and ChartsisosicaÎncă nu există evaluări

- London Metal Exchange Prices - Markets Data Center - WSJDocument1 paginăLondon Metal Exchange Prices - Markets Data Center - WSJisosicaÎncă nu există evaluări

- Forbidden Chemistries Go Flow in API SynthesisDocument8 paginiForbidden Chemistries Go Flow in API SynthesisisosicaÎncă nu există evaluări

- Chlormequat RedDocument74 paginiChlormequat RedisosicaÎncă nu există evaluări

- Particle Size Reduction CHE - Facts - 1112 PDFDocument1 paginăParticle Size Reduction CHE - Facts - 1112 PDFisosicaÎncă nu există evaluări

- Metal Organic Frameworks (Mofs) :: Time For A Breakthrough in Material SupplyDocument5 paginiMetal Organic Frameworks (Mofs) :: Time For A Breakthrough in Material SupplyisosicaÎncă nu există evaluări

- Anti-Oxidant/pro-Oxidant Activity of Ascorbic AcidDocument6 paginiAnti-Oxidant/pro-Oxidant Activity of Ascorbic AcidisosicaÎncă nu există evaluări

- Marcare SOD-80 DiodesDocument2 paginiMarcare SOD-80 DiodesisosicaÎncă nu există evaluări

- Optimal Design of Experiments: For The Identification of Kinetic Models of Methanol Oxidation Over Silver CatalystDocument7 paginiOptimal Design of Experiments: For The Identification of Kinetic Models of Methanol Oxidation Over Silver CatalystisosicaÎncă nu există evaluări

- The Challenges of Ecotox Testing of Nanomaterials and The BPRDocument3 paginiThe Challenges of Ecotox Testing of Nanomaterials and The BPRisosicaÎncă nu există evaluări

- E GarageDocument36 paginiE GarageLidijaSpaseskaÎncă nu există evaluări

- Bubba - S Food MS-CDocument2 paginiBubba - S Food MS-CDũng Trần QuốcÎncă nu există evaluări

- Classroom Readiness ChecklistDocument2 paginiClassroom Readiness ChecklistRoseman Tumaliuan100% (1)

- Make Swiss RollDocument16 paginiMake Swiss RollFelicia LiÎncă nu există evaluări

- Hydraulic Fluid CategoriesDocument3 paginiHydraulic Fluid CategoriesJako MishyÎncă nu există evaluări

- IGACOS Marine Sanctuary Park and ResortDocument74 paginiIGACOS Marine Sanctuary Park and ResortPlusÎncă nu există evaluări

- Fire Alarm SymbolsDocument6 paginiFire Alarm Symbolscarlos vasquezÎncă nu există evaluări

- Rubric On Baking CakesDocument3 paginiRubric On Baking CakesshraddhaÎncă nu există evaluări

- Charla Krupp - How To Never Look Fat Again - Over 1,000 Ways To Dress Thinner - Without Dieting!-Grand Central Publishing (2010) PDFDocument316 paginiCharla Krupp - How To Never Look Fat Again - Over 1,000 Ways To Dress Thinner - Without Dieting!-Grand Central Publishing (2010) PDFben0% (1)

- Practice Questions Human Nutrition Part 1Document4 paginiPractice Questions Human Nutrition Part 1PeiYi TanÎncă nu există evaluări

- 2mw Biomass Gasification Gas Power Plant ProposalDocument9 pagini2mw Biomass Gasification Gas Power Plant ProposalsabrahimaÎncă nu există evaluări

- Peoria County Booking Sheet 03/01/15Document8 paginiPeoria County Booking Sheet 03/01/15Journal Star police documentsÎncă nu există evaluări

- Father of Different Fields of Science & Technology PDFDocument3 paginiFather of Different Fields of Science & Technology PDFJacob PrasannaÎncă nu există evaluări

- PAP and PAPE ReviewDocument9 paginiPAP and PAPE ReviewYG1Încă nu există evaluări

- B1 SpeakingDocument5 paginiB1 SpeakingHoàng Nam Thắng100% (2)

- Jean-Pierre Wybauw - Fine Chocolates 2 - Great Ganache Experience-Lannoo (2008)Document209 paginiJean-Pierre Wybauw - Fine Chocolates 2 - Great Ganache Experience-Lannoo (2008)Mi na100% (1)

- Recipe Booklet PRINT VERSIONDocument40 paginiRecipe Booklet PRINT VERSIONjtsunami815100% (1)

- CRISIL Mutual Fund Ranking: For The Quarter Ended September 30, 2020Document48 paginiCRISIL Mutual Fund Ranking: For The Quarter Ended September 30, 2020MohitÎncă nu există evaluări

- Remote Control RC902V1 ManualDocument3 paginiRemote Control RC902V1 ManualdezdoÎncă nu există evaluări

- Nuclear Over Hauser Enhancement (NOE)Document18 paginiNuclear Over Hauser Enhancement (NOE)Fatima AhmedÎncă nu există evaluări

- 3 Ways To Move Like A NinjaDocument4 pagini3 Ways To Move Like A NinjaWisnu Wicaksono100% (1)

- Phillips LoFloDocument29 paginiPhillips LoFlokawaiiriceÎncă nu există evaluări

- Efficiency Improvement Oppertunities With BLDC Fan PDFDocument14 paginiEfficiency Improvement Oppertunities With BLDC Fan PDFjust_4_u_dear_in9549Încă nu există evaluări

- Review Related LiteratureDocument3 paginiReview Related LiteratureHanz EspirituÎncă nu există evaluări

- Gec 014 Prelim ExaminationDocument2 paginiGec 014 Prelim ExaminationcykablyatÎncă nu există evaluări

- Ujian Diagnostik Ting 2 EnglishDocument9 paginiUjian Diagnostik Ting 2 EnglishJ-Gie JaulahÎncă nu există evaluări

- Cen-Tech 63759Document8 paginiCen-Tech 63759GregÎncă nu există evaluări

- Facebow Tech Spec Gen LRDocument1 paginăFacebow Tech Spec Gen LRrojÎncă nu există evaluări

- Steel Scrap Recycling Policy 06.11.2019 PDFDocument31 paginiSteel Scrap Recycling Policy 06.11.2019 PDFAnshul SableÎncă nu există evaluări

- Rotorcraft-Flight-Manual 5ab11c331723dd329c63732fDocument12 paginiRotorcraft-Flight-Manual 5ab11c331723dd329c63732fpilot digitalÎncă nu există evaluări