Documente Academic

Documente Profesional

Documente Cultură

Method Statement Holding

Încărcat de

qoci5koDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Method Statement Holding

Încărcat de

qoci5koDrepturi de autor:

Formate disponibile

Method Statement -Erection of Temporary

Hoarding

1.

OBJECTIVE

To outline the sequence of activities, method and resources needed for the operation of

erecting temporary hoarding.

2.

SCOPE

The work shall include all labour, material, equipment, safety requirement and services

necessary for the execution erecting temporary hoarding.

3.

WORK SEQUENCE FLOW

_to attach drawing_

4.

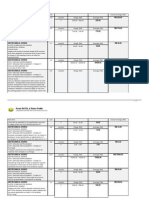

MATERIAL

Material to be used is as follows:-

5.

4.1

50 x 50 x 1.6mm thick SHS M.S Posts

4.2

50 x 25 x 1.2mm thick RHS M.S Nogging

4.2

50 x 25 x 1.6mm thick SHS M.S Braces

4.3

0.3mm thick metal decking

4.4

Nail

4.5

Cement

4.6

Sand

4.7

Water

EQUIPMENTS & MACHINERIES REQUIRED

Equipments and machineries to be used are as follows:-

5.1

6.

Minimum: One (1) number of JCB Backhoe (if required)

5.2

Minimum: One (1) set of hand excavating equipment

5.3

Minimum: One (1) set of steel work equipment

5.4

Minimum: One (1) set of water levelling

5.5

Minimum: One (1) number of spirit level

SITE PREPARATION WORK

6.1

7.

Setting out boundaries of ground in the proposed perimeter.

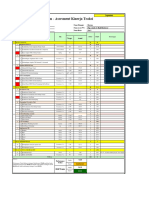

METHOD OF WORK

7.1

Determine the location of the temporary hoarding will be established with

confirmation from the surveyor.

7.2

After getting confirmation, using the given point and mark the main pole as per

alignment shown in the drawings (Appendix A). Center to center of the main column is

3000mm.

7.3

Preparation of the main pillars started by using hand digging to the depth 400mm.

7.4

Pole-sized 50X50X1.6mm thk SHS M.S constructed using equipment such as spirit

level, water level, and tape measure. Two workers used to establish the main pillars.

7.5

Pillars need to ensure accurate position along the fence line at 3.0m (panel width)

intervals and make sure the base are sitting on an even level surface.

7.6

Erect the remaining pillars along the line as noted previously until the hoarding line

is complete.

7.7

50x25x1.2mm thk nogging need to install three (3) lines to support metal deck

panels.

7.8

Metal deck panels will be installed with the frame hoarding as per Appendix A

(spacing 4 for every panels).

7.9

This work will be repeated until completion.

7.10

Entrance gate will be erected at remaining area (refer item no.3) with support at

both side (left and right) using welded angles.

8.

QUALITY ISSUES

Boundaries demarcation required to ensure no double handling or trespassing to others

people land.

View inspection required during the process of erection hoarding.

Regular inspection to be carried out by weekly basis to ensure the hoarding in good

condition.

9.

SAFETY ISSUES

Safety helmets and safety footwear should always be worn.

All soft spots or holes shall be identified and barricade if necessary.

The site shall be kept clear of unnecessary obstruction.

First aid kit boxes will be provided at site office.

During raining, no erection hoarding activities are allowed to work.

10.

ENVIRONMENTAL ISSUES

All workers shall ensure that tools and machinery are in a good condition to avoid any

oil leakage that could harm to environment.

Construction waste from construction area must be collected into centralized garbage

bin and disposed at the designated area.

S-ar putea să vă placă și

- MOS Temporary HoardingDocument4 paginiMOS Temporary Hoardinganiesbaek88% (8)

- Set Calculation For Hammer Driven Piles Using Modofoed HILLEY's FormulaDocument2 paginiSet Calculation For Hammer Driven Piles Using Modofoed HILLEY's Formulaqoci5ko89% (9)

- Renovations Method StatementDocument6 paginiRenovations Method StatementOfentse Ledwaba100% (2)

- Method Statement For Drywall PartitionDocument5 paginiMethod Statement For Drywall PartitionAr John Ronald Ladaban100% (2)

- 5 Method Statement For BRICK WORKSDocument4 pagini5 Method Statement For BRICK WORKSSana Nazir50% (2)

- Method Statement Slab & Beam ConcretingDocument3 paginiMethod Statement Slab & Beam Concretingudithairesha100% (6)

- Method Statement For PlasteringDocument6 paginiMethod Statement For PlasteringSana NazirÎncă nu există evaluări

- Method Statement of CORBEL HACKING WORKSDocument11 paginiMethod Statement of CORBEL HACKING WORKSFaiz Bukhari100% (4)

- Method Statement-Concrete Site MixDocument3 paginiMethod Statement-Concrete Site MixT Yong Chiam100% (2)

- Method Statement For Interlock WorksDocument3 paginiMethod Statement For Interlock Worksqoci5ko75% (4)

- Concrete Pumping Risk AssessmentDocument1 paginăConcrete Pumping Risk Assessmentqoci5ko50% (2)

- Method Statement of Hoarding PDFDocument1 paginăMethod Statement of Hoarding PDFAMIR ASYRAF ZAINUDINÎncă nu există evaluări

- Method Statement Pressure GroutingDocument2 paginiMethod Statement Pressure GroutingStephen David Gozun100% (5)

- Method Statement For BlockworkDocument3 paginiMethod Statement For BlockworkPunk GowthamanÎncă nu există evaluări

- Concrete Pumping With Boom PumpDocument11 paginiConcrete Pumping With Boom PumpAnshuman GÎncă nu există evaluări

- Method Statement of Floor HardenedDocument2 paginiMethod Statement of Floor HardenedTaqiuddinHarith100% (1)

- Method Statement For False Ceiling WorksDocument2 paginiMethod Statement For False Ceiling WorksTAHER AMMAR33% (3)

- Method Statement For Ground Improvement (Removal & Replacement) at Approach of VBC Kg. Titi Besi (CH 232.457)Document7 paginiMethod Statement For Ground Improvement (Removal & Replacement) at Approach of VBC Kg. Titi Besi (CH 232.457)MAYMODERN STEELÎncă nu există evaluări

- Method Statement Bundwall GSUT Spare Unit 3Document4 paginiMethod Statement Bundwall GSUT Spare Unit 3MarhendraÎncă nu există evaluări

- Anti Termite Method StatementDocument5 paginiAnti Termite Method StatementTijjani BelloÎncă nu există evaluări

- Method Statement For Excavation (Earth Works)Document2 paginiMethod Statement For Excavation (Earth Works)Badhur Zaman100% (1)

- Method of Statement For Random Rubble Retaining Wall PDFDocument8 paginiMethod of Statement For Random Rubble Retaining Wall PDFriel ramosÎncă nu există evaluări

- Example Method Statement For The Installation of Roof TrussesDocument8 paginiExample Method Statement For The Installation of Roof TrussesSai Shankar LakshminarayananÎncă nu există evaluări

- Example Method Statement For The Installation of Concrete Floor SlabsDocument8 paginiExample Method Statement For The Installation of Concrete Floor SlabsMohammad Ali ElhamÎncă nu există evaluări

- Doors Method StatementDocument5 paginiDoors Method StatementTAHER AMMAR100% (2)

- Example Method StatementDocument9 paginiExample Method StatementMuhammadWazimAkramÎncă nu există evaluări

- Method Statement Demolition MS 873 Non Load Bearing WallDocument6 paginiMethod Statement Demolition MS 873 Non Load Bearing WallShruti Sinha100% (1)

- Method of Statement For Blinding WorkDocument6 paginiMethod of Statement For Blinding WorkMohd Muksin100% (1)

- Work Method Statement - TEXTURE PAINTDocument3 paginiWork Method Statement - TEXTURE PAINTSathish Gowda0% (1)

- Method Statement For Slab On GradeDocument3 paginiMethod Statement For Slab On Grademustafa75% (4)

- Method Statement - Site ClearanceDocument6 paginiMethod Statement - Site Clearanceqoci5ko100% (1)

- Komatsu 170 Parts ManualDocument5 paginiKomatsu 170 Parts Manualmuhammad ali100% (1)

- Manual de Partes 580 SN ESP PDFDocument1.683 paginiManual de Partes 580 SN ESP PDFhernando ramos100% (6)

- Method Statement HoldingDocument4 paginiMethod Statement Holdingqoci5koÎncă nu există evaluări

- Method of StatementDocument2 paginiMethod of StatementMuhammad AffizalÎncă nu există evaluări

- Ms - Carpet InstallationDocument9 paginiMs - Carpet Installationlinga2014Încă nu există evaluări

- MOS DrainageDocument16 paginiMOS DrainageMohammad Hadoumi Saldan100% (1)

- Method Statement For Earth WorkDocument5 paginiMethod Statement For Earth Workgvs raoÎncă nu există evaluări

- WMS (Method Statement For Formwork, Reinforcement and Concrete Works)Document9 paginiWMS (Method Statement For Formwork, Reinforcement and Concrete Works)PUI CHEE KHIAN100% (1)

- Method Statement - Plastering, Dated. Jan. 03. 2007Document5 paginiMethod Statement - Plastering, Dated. Jan. 03. 2007mohamed4879Încă nu există evaluări

- Method Statement Tiling WorksDocument8 paginiMethod Statement Tiling WorksNara Kong100% (2)

- Work Method Statement FOR Laying of Pipe Culvert and Concrete Sump at Existing DrainDocument3 paginiWork Method Statement FOR Laying of Pipe Culvert and Concrete Sump at Existing DrainLynn Mail100% (1)

- Casting of RC Slab MosDocument2 paginiCasting of RC Slab MosEngr Badz de DiosÎncă nu există evaluări

- Turfing ChecklistDocument1 paginăTurfing ChecklistshukriÎncă nu există evaluări

- Method Statement FlooringDocument11 paginiMethod Statement Flooringmanish100% (1)

- Method Statement For Door FrameDocument12 paginiMethod Statement For Door FrameMin Luo100% (3)

- Method Statement of Plaster Ceiling Installation: ContentDocument3 paginiMethod Statement of Plaster Ceiling Installation: ContentChezy629100% (5)

- Method Statement For Earth WorksDocument3 paginiMethod Statement For Earth WorksMin Min Soe0% (1)

- Mos DrainageDocument3 paginiMos DrainageaniesbaekÎncă nu există evaluări

- Method Statement For Conventional Formwork BlogDocument9 paginiMethod Statement For Conventional Formwork BlogMohasin KhanÎncă nu există evaluări

- Method Statements InterLock WorksDocument3 paginiMethod Statements InterLock WorksNino Celso AstilleroÎncă nu există evaluări

- Method Statement - Crack Control Joint For CCB RC WallDocument7 paginiMethod Statement - Crack Control Joint For CCB RC WallReza RosenoÎncă nu există evaluări

- Method Statement of Tiling Works: ContentDocument4 paginiMethod Statement of Tiling Works: ContentChezy629Încă nu există evaluări

- Method of Statement For R.C Piling WorkDocument10 paginiMethod of Statement For R.C Piling WorkMacgjoyner SaLauÎncă nu există evaluări

- Method Statement For Concrete WorkDocument6 paginiMethod Statement For Concrete WorktotA ahmedÎncă nu există evaluări

- Method Statement For Masonry WorksDocument10 paginiMethod Statement For Masonry WorksLabanKaruhangaÎncă nu există evaluări

- Method Statement For PLASTERINGDocument6 paginiMethod Statement For PLASTERINGVinodh Palanichamy100% (1)

- Method Statement and SpecificationDocument17 paginiMethod Statement and SpecificationApai MfarÎncă nu există evaluări

- Method Statement For Interlock PaversDocument3 paginiMethod Statement For Interlock PaversSumit Gupta100% (2)

- Method Statement For ExcavationDocument7 paginiMethod Statement For Excavationspwong99100% (3)

- RC Retaining Wall: Method Statement For Concreting Vertical Elements Setting OutDocument3 paginiRC Retaining Wall: Method Statement For Concreting Vertical Elements Setting OutAnonymous ze9ag1Încă nu există evaluări

- Method Statement Concrete Works PDFDocument18 paginiMethod Statement Concrete Works PDFdndudc95% (22)

- MS For Form - WorksDocument8 paginiMS For Form - WorksImho Tep100% (1)

- MS For MasonryDocument23 paginiMS For MasonryThimira Bandara EkanayakeÎncă nu există evaluări

- WMS - Pipe Laying OutsideDocument4 paginiWMS - Pipe Laying OutsideLasandu WanniarachchiÎncă nu există evaluări

- MOS Temporary HoardingDocument3 paginiMOS Temporary HoardingAhmad Fauzi Bin OmarÎncă nu există evaluări

- Concrete Core FactorDocument7 paginiConcrete Core Factorjafary007Încă nu există evaluări

- Survey Using A TheodoliteDocument40 paginiSurvey Using A TheodoliteshinobiÎncă nu există evaluări

- Faça o Que Tem de Ser FeitoDocument1 paginăFaça o Que Tem de Ser Feitowagnerjohny100% (2)

- Material Take-Off PDFDocument4 paginiMaterial Take-Off PDFRanilo SumalinogÎncă nu există evaluări

- Method Statement SurveyDocument3 paginiMethod Statement Surveyqoci5koÎncă nu există evaluări

- 02 SurveysDocument27 pagini02 Surveysqoci5koÎncă nu există evaluări

- Rates 02032015Document5 paginiRates 02032015qoci5koÎncă nu există evaluări

- RCC Rate AnalsysisDocument2 paginiRCC Rate AnalsysisjowarÎncă nu există evaluări

- Civil ReportsDocument68 paginiCivil Reportsqoci5koÎncă nu există evaluări

- Rates 02032015Document5 paginiRates 02032015qoci5koÎncă nu există evaluări

- Rates 02032015Document7 paginiRates 02032015qoci5koÎncă nu există evaluări

- Rates 02032015Document7 paginiRates 02032015qoci5koÎncă nu există evaluări

- Rates 02032015Document9 paginiRates 02032015qoci5koÎncă nu există evaluări

- Rates 02032015Document13 paginiRates 02032015qoci5koÎncă nu există evaluări

- JKR Spec 2005Document188 paginiJKR Spec 2005rex79x98% (60)

- FreameDocument5 paginiFreameqoci5koÎncă nu există evaluări

- Rates 02032015Document3 paginiRates 02032015qoci5koÎncă nu există evaluări

- Pile Set CalculationDocument2 paginiPile Set Calculationqoci5ko100% (1)

- TryDocument1 paginăTryqoci5koÎncă nu există evaluări

- Method Statement ClearingDocument5 paginiMethod Statement Clearingqoci5koÎncă nu există evaluări

- Backhoe Loader JCBDocument2 paginiBackhoe Loader JCBSayed Abbas100% (1)

- EX5600 6 - KS EN173Q SmallDocument12 paginiEX5600 6 - KS EN173Q SmalldooneyjayÎncă nu există evaluări

- Transmision 416D - 010753Document8 paginiTransmision 416D - 010753ronald enrique gareca ruedaÎncă nu există evaluări

- Hydraulic Pumps SiteDocument133 paginiHydraulic Pumps Siteeddy ortega100% (1)

- PHB-45 Part 1Document801 paginiPHB-45 Part 1osama bayoumiÎncă nu există evaluări

- Index of ElectricalDocument22 paginiIndex of Electricalsoftall100% (1)

- Service Manual BL70B 9 Hydraulic System DiagramsDocument15 paginiService Manual BL70B 9 Hydraulic System DiagramsJaret SandovalÎncă nu există evaluări

- Lifton Hydraulic BreakersDocument8 paginiLifton Hydraulic BreakersMohammedÎncă nu există evaluări

- Report JCBDocument18 paginiReport JCBAshok KumarÎncă nu există evaluări

- John Deere 410j TMCDocument40 paginiJohn Deere 410j TMCJesús David DíazÎncă nu există evaluări

- Electric MainDocument38 paginiElectric MainGarcia CruzÎncă nu există evaluări

- 851FX Parts Catalog - 17thmay2021Document398 pagini851FX Parts Catalog - 17thmay2021Plstina RamsÎncă nu există evaluări

- General: 00-01 Revision History 00 - 02 Foreword 00 - 03 SAFETY 00 - 04 StandartsDocument60 paginiGeneral: 00-01 Revision History 00 - 02 Foreword 00 - 03 SAFETY 00 - 04 StandartsJonathan WENDTÎncă nu există evaluări

- Manual de Retro CUKUROVADocument9 paginiManual de Retro CUKUROVAAxelEnetÎncă nu există evaluări

- 2a. Performance Traksi CKMT September 2023Document109 pagini2a. Performance Traksi CKMT September 2023yadiky12Încă nu există evaluări

- Tefra Corporate BrochureDocument20 paginiTefra Corporate BrochurepmpintoisqÎncă nu există evaluări

- 3CXCDocument8 pagini3CXCragkaraÎncă nu există evaluări

- Catalog Ia 2013Document72 paginiCatalog Ia 2013ioanÎncă nu există evaluări

- Parts Catalog: 410J and 410TMC Backhoe LoadersDocument697 paginiParts Catalog: 410J and 410TMC Backhoe LoadersNicolas Saravia100% (2)

- Cat 416DDocument24 paginiCat 416DJulio MeesÎncă nu există evaluări

- Daily Equipment Status Report Week 41Document11 paginiDaily Equipment Status Report Week 41Ashley ApilÎncă nu există evaluări

- Equipment For ConstructionDocument116 paginiEquipment For ConstructionShishupal Singh100% (1)

- DCM CatalogDocument116 paginiDCM CatalogHussin LempoyangÎncă nu există evaluări

- Machine Safety in ConstructionDocument27 paginiMachine Safety in ConstructionSawyu Nandar100% (1)

- JCB Tracked Excavator JS 210 LC: Static DimensionsDocument8 paginiJCB Tracked Excavator JS 210 LC: Static DimensionsВолодимир КривкоÎncă nu există evaluări

- Price List JCB 3cx1Document11 paginiPrice List JCB 3cx1indramuni100% (1)

- Sae J49-2020Document11 paginiSae J49-2020Marcos RosenbergÎncă nu există evaluări

- Open Cast Mining - 979 PDFDocument21 paginiOpen Cast Mining - 979 PDFAbdul JabbarÎncă nu există evaluări