Documente Academic

Documente Profesional

Documente Cultură

Molded Case Circuit Breakers PDF

Încărcat de

MohamedAhmedFawzyDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Molded Case Circuit Breakers PDF

Încărcat de

MohamedAhmedFawzyDrepturi de autor:

Formate disponibile

MAJARRAH BUSINESS COMPLEX

6th October

SECTION 16478

MOULDED CASE CIRCUIT BREAKERS

PART 1 - GENERAL

1.1

RELATED DOCUMENTS

A. Drawings and general provisions of Contract, including General and special

Conditions and Division-1 (General requirements), apply to work of this section.

B. General Provisions for Electrical Work, Section 16010, apply to work of this section.

C. The requirements of this section apply to moulded case circuit breakers solid state type

specified elsewhere in these specifications.

D. Low voltage switchgear assemblies main distribution boards. Section 16425.

E. Distribution boards section 16470.

F. Testing and commissioning section 16950.

1.2

DESCRIPTION OF WORK

A. Work includes providing all materials, equipment, accessories, services and tests

necessary to complete and make moulded case circuit breakers ready for operation in

accordance with Drawings and Specifications.

1.3

QUALITY ASSURANCE

A. Manufacturers: Firms regularly engaged in the manufacture of moulded case circuit

breakers solid state type whose products have been in satisfactory use in similar

service for not less than 5 years. produced by a manufacturer listed as an Acceptable

Manufacturer in this section.

B. Standards Compliance: Comply with requirements of applicable local codes, IEC

60947-2, IEC 60947-4, IEC 60947-4-1 and Standards pertaining to moulded case circuit

breakers solid state type (adjustable for long time , short time and instantaneous

protection features).

C. In case of conflict among the referenced standards and codes, the more stringent

provision will govern.

1.4

SUBMITTALS

A. Product Data: Submit manufacturer's data for all types of moulded case circuit

breakers, including solid state type.

PART 2 - PRODUCTS

2.1

GENERAL REQUIREMENTS

A. DEFINITIONS

The definitions of terms and symbols used in this Specification are those used in IEC

60947-2.

MOULDED CASE CIRCUIT BREAKERS

FEB. 2014. REV. 01

PAGE 1 OF 7

16478

MAJARRAH BUSINESS COMPLEX

6th October

B. STANDARDS

Moulded case circuit-breakers solid state type, all MCCB's shall comply with IEC

60947-2 plus any additional requirements of this Specification.

All MCCB's shall be equipped with solid state release (adjustable for long time and

short time and/or instantaneous protection depends on the selectivity achievements

features).

Breakers of 1000A rating and above shall be provided with ground fault protection as

per NEC requirements.

C. GENERAL

Minimum short-circuit capacities of circuit breakers shall be as indicated on the

drawings.

All MCCB's connected in one electrical circuit shall be selected to ensure full

discrimination up to and including the prospective short-circuit, and earth fault

currents as specified on drawings and Schedules for prospective earth fault currents the

disconnection times shall not exceed 5s.

All MCCBs should be rated at service short circuit entrance level for all incoming and

outgoing.

All circuit breakers in one electrical circuit shall be fully selective and coordinated, if

selectivity coordination study is failed for any reason, contractor is responsible to add

or change any number of breakers, relays, such that the selectivity coordination shall be

fully achieved with no extra cost to the owner.

2.2

CONSTRUCTION

A. MANUFACTURE

MCCB's shall be manufactured with double insulation of the front face, insulating

auxiliary components from the main power poles thereby allowing as far as reasonable

the fitting of auxiliary units on site without full isolation of the unit.

B. CURRENT RATINGS

Rated currents, rated service short-circuit breaking capacities and trip release settings

shall be as specified in cable installation schedules and on drawings.

Current ratings as specified in the schedules and drawings are for interrupted duty at

220/380V in the final installed location on site under full load operating conditions of

the complete installation, i.e. taking account of heat produced by other devices and the

ambient temperature, physical situation, enclosure, position and attitude of the MCCB.

The appropriate de-rating factors shall be applied to manufacturer's standard ratings

when selecting MCCB's to meet the specified ratings.

MCCB's shall be suitable for operation in both the horizontal and vertical mounting

position without detrimental effect on operation or rating.

MOULDED CASE CIRCUIT BREAKERS

FEB. 2014. REV. 01

PAGE 2 OF 7

16478

MAJARRAH BUSINESS COMPLEX

6th October

C. TRIPPING CHARACTERISTICS

Details of tripping characteristics shall be provided for each type of MCCB. The

details shall include manufacturer's full current discrimination tables showing overload

and short-circuit discrimination and, additionally, a full set of overlay transparency

discrimination curves or software program to enable discrimination settings to be

checked.

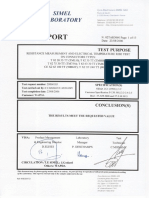

D. TEST CERTIFICATES

Complete certificates shall be provided for each type of MCCB, stating the service and

ultimate short-circuit capacities.

E. CONTACTS

The contact arrangement of current-limiting MCCB's where applicable shall be such

that the current-limiting contacts are in series with the main contacts and remain closed

in normal operation, including time delayed over current tripping.

Contacts shall be arranged so that normal current is carried by low-resistance silver

alloy or other non-welding material while arcing is handled by tungsten contacts.

Multi-set contact MCCB's shall be arranged using one set of contacts for thermal

current and other for arc interruption.

F. TERMINALS

Terminals shall be sized to accommodate the size and type of cable of incoming and

outgoing circuits as specified in the schedules or drawings. MCCB's shall be provided

complete with terminal shields.

Terminals shall be arranged for direct connection to busbars, front or rear as required

by the switchboard design.

All poles of multi-pole circuit-breakers shall be constructed so that contacts open,

close and trip simultaneously. It shall not be possible for one or more poles to be

closed while another remains open and vice-versa.

G. OPERATING MECHANISMS

Operating mechanisms shall be over-center, quick-make, quick-break type having

operation in which speed of operation of the breaker is independent of the operator.

All hand-operated circuit breakers shall be fitted with rotary action handles only in the

main distribution boards. The handles shall be lockable in open position.

Where motor operated MCCB's are specified in the schedules or drawings, the motors,

the clutches shall be as scheduled. Direct action operating handles shall be provided

for local operation.

Where solenoid operated MCCBs are specified in the schedules or drawings, the

operating voltage shall be as scheduled. Separate solenoids shall be provided for

opening and closing operations. Built-in push buttons shall be provided for local

operation.

MOULDED CASE CIRCUIT BREAKERS

FEB. 2014. REV. 01

PAGE 3 OF 7

16478

MAJARRAH BUSINESS COMPLEX

6th October

Indication of the "ON", "OFF" and "TRIPPED" conditions shall be provided not only

by the position of the handle but also by means of a colored band, or line which shall

be visible when the circuit-breaker is on but not when it is off or tripped.

The "TRIPPED" condition shall be indicated by the handle assuming a mid-point

position between "ON" and "OFF" It shall not be possible to manually place the handle

in the tripped position.

Indication shall be provided to confirm that all main contacts have separated.

H. ENCLOSURES

Moulded case covers and non-interchangeable trip elements shall be permanently

sealed at works to prevent tampering, but the trip elements may be changed/Adjusted

and re-sealed on site by using suitable tools.

All internal components of MCCB's shall be replaceable on site.

MCCB's shall be certified as satisfying the leakage current testes called for in IEC

60947-2 with regards to safety isolation.

MCCB's used for motor starting shall satisfy the Type 2 coordination requirements

called for in IEC 60947-2.The MCCB and the starter shall preferably be of the same

manufacture, and in all cases shall be tested together and certified as satisfying the coordination requirements.

All MCCB's shall be of the same manufacture and those of like kind shall be of the

same type. This requirement applies to loose or individually mounted MCCB's as well

as to those incorporated within assemblies such as control panels, switchboards and

distribution boards.

I.

PROTECTION MECHANISMS

Each pole shall provide inverse time over current protection and adjustable high set

instantaneous tripping and in accordance to item 2.1 (B) above. All poles shall be

tripped simultaneously if one detects a fault.

Trip units of ratings up to and including 250A shall be built in. Trip units above 250A

shall be replaceable.

Tripping mechanisms shall be selective limiting type to obtain discrimination or by

interconnection with other MCCB trip units.

All adjustable trips shall be visible and adjustable from the front with the breaker in

position. Adjustments to trip settings shall be made to all poles simultaneously by

means of a common adjustment mechanism.

J. OPERATING FACILITIES

Facilities shall be provided for the use of a hand-held tester for on-site testing of all

operational features.

Where specified in the schedules/drawings, earth leakage trips, shunt trips,

undervoltage trips and remote operation shall be provided. These accessories shall all

be factory assembled and tested.

MOULDED CASE CIRCUIT BREAKERS

FEB. 2014. REV. 01

PAGE 4 OF 7

16478

MAJARRAH BUSINESS COMPLEX

6th October

Energy based limiting MCCB's which require replacement of the current limiters after

operatic shall not be re-settable until such replacement has been made.

2.3

AUXILIARY CONTACTS

A. Auxiliary contacts shall be provided where specified in the schedule or drawings,

auxiliary contacts shall operate simultaneously with the main breaker contacts.

2.4

INSPECTION AND TEST PROCEDURES

The tests to be carried out shall include but not necessarily be limited to:1.

2.

Visual and Mechanical Inspection

1.

Inspect physical and mechanical condition.

2.

Inspect anchorage and alignment.

3.

Prior to cleaning the unit, perform as-found tests, if required.

4.

Clean the unit.

5.

Operate the circuit breaker to insure smooth operation.

6.

Inspect bolted electrical connections for high resistance using one of the

following methods:

1.

Use of low-resistance ohmmeter.

2.

Verify tightness of accessible bolted electrical connections by

calibrated torque-wrench method in accordance with

manufacturer's published data.

3.

Perform thermographic survey.

7.

Inspect operating mechanism, contacts, and arc chutes in unsealed units.

8.

Perform as-left tests.

Electrical Tests

1.

Perform resistance measurements through bolted connections with a low-resistance

ohmmeter, if applicable.

2.

Perform insulation-resistance tests on each pole, phase-to-phase and phase-toground with the circuit breaker closed and across each open pole for one minute.

Test voltage shall be in accordance with manufacturers published data.

3.

Perform a contact/pole-resistance test.

4.

Perform insulation-resistance tests on all control wiring with respect to ground.

Applied potential shall be 500 volts dc for 300 volt rated cable and 1000 volts dc

for 600 volt rated cable. Test duration shall be one minute. For units with solidstate components, follow manufacturers recommendation.

MOULDED CASE CIRCUIT BREAKERS

FEB. 2014. REV. 01

PAGE 5 OF 7

16478

MAJARRAH BUSINESS COMPLEX

6th October

3.

2.5

5.

Perform long-time delay time-current characteristic tests by passing 300 percent

rated primary current through each pole separately.

6.

Determine short-time pickup and delay by primary current injection.

7.

Determine ground-fault pickup and time delay by primary current injection.

8.

Determine instantaneous pickup current by primary injection using run-up or pulse

method.

9.

Test functions of the trip unit by means of secondary injection.

10.

Perform minimum pickup voltage test on shunt trip and close coils.

11.

Verify correct operation of any auxiliary features such as trip and pickup

indicators, zone interlocking, electrical close and trip operation, trip-free, and

antipump function.

Test Values

1.

Compare bolted connection resistances to values of similar connections.

2.

Bolt-torque levels.

3.

Microhm or millivolt drop values shall not exceed the high levels of the normal

range as indicated in the manufacturer's published data. If manufacturer's data is

not available, investigate any values which deviate from adjacent poles or similar

breakers by more than 50 percent of the lowest value.

4.

Circuit breaker insulation resistance.

5.

Control wiring minimum insulation-resistance values should be comparable to

previously obtained results but not less than two megohms.

6.

Trip characteristic of breakers shall not exceed manufacturer's published

time-current characteristic tolerance band, including adjustment factors. Circuit

breakers exceeding specified trip time at 300 percent of pickup shall be tagged

defective.

7.

Instantaneous pickup values of molded-case circuit breakers shall be within the

tolerances.

8.

Minimum pickup voltage on shunt trip and close coils should be comparable to

previously obtained results but not less than two megohms.

GENERAL INFORMATION

A. The following information shall be provided for each MCCB.

-

Voltage and rated insulation voltage.

Rated current

Rated operational voltage and rated insulation voltage.

Number of poles

Rated service and ultimate short-circuit capacities.

Method of mounting

Method of connection

Protection against external influence

Current time characteristic curves on log scale.

The It tripping characteristic curves and the peak let-through currents at prospective

fault levels,

- Rated short time withstand current

MOULDED CASE CIRCUIT BREAKERS

FEB. 2014. REV. 01

PAGE 6 OF 7

16478

MAJARRAH BUSINESS COMPLEX

6th October

- Rated short-circuit making capacity

2.6

LABELLING

A. On the front of each MCCB a visible label shall be fitted and described as follows:

Labelling shall be marked as follows:

- Rated current and trip setting (for MCCB's with multiple current ratings the

maximum value shall be marked plus, without ambiguity, the value for which the

MCCB has been adjusted)

- Rated voltage

- Manufacturer's name or trade mark

- Type designation, catalogue number or serial number

- Rated short-circuit capacity in amperes

- Reference ambient temperature if different from 30 oC

A label shall be provided, in a clearly visible position on the front of each circuitbreaker, on which the final commissioned release setting for that circuit-breaker shall

be displayed

2.7

ACCEPTABLE MANUFACTURERS

Refer To The Attached Manufacturer's List.

PART 3 - EXECUTION

3.1

INSPECTION

A. Examine conditions under which moulded case circuit breakers are to be installed and

notify in writing of conditions detrimental to proper completion of the work. Do not

proceed with the work until unsatisfactory conditions have been corrected.

3.2

INSTALLATION

A. Install moulded case circuit breakers as indicated, in accordance with manufacturer's

written instructions, requirements of applicable Standards, and in accordance with

recognized industry practices to ensure that installation complies with requirements

and serves intended function.

B. Coordinate, as necessary to interface installation of moulded case circuit breakers.

3.3

FIELD QUALITY CONTROL

A. Prior to energization of moulded case circuit breakers test devices for continuity of

circuitry and for short circuits. Replace malfunctioning breakers with new breakers

and then demonstrate compliance with requirements.

END OF SECTION 16478

MOULDED CASE CIRCUIT BREAKERS

FEB. 2014. REV. 01

PAGE 7 OF 7

16478

S-ar putea să vă placă și

- 7SJ61 As High Impedance RelayDocument36 pagini7SJ61 As High Impedance Relayzarun1Încă nu există evaluări

- Case Study of Load Balancing and Relay Coordination of 132KV Transmission GridDocument6 paginiCase Study of Load Balancing and Relay Coordination of 132KV Transmission GridsivaÎncă nu există evaluări

- FM Spae01 en BDocument12 paginiFM Spae01 en BSudhakar YsÎncă nu există evaluări

- Protective System ANSI NumbersDocument3 paginiProtective System ANSI Numbersumarnair1105Încă nu există evaluări

- Generator Earthing and Stator Earth Fault Protection - EEPDocument13 paginiGenerator Earthing and Stator Earth Fault Protection - EEPABHINAV SAURAVÎncă nu există evaluări

- Temporary Paralleling of Transformer For Changing Over SupplyDocument2 paginiTemporary Paralleling of Transformer For Changing Over SupplyBiswajit BiswasÎncă nu există evaluări

- Upgrading The ProtectionDocument4 paginiUpgrading The ProtectionMukesh KumarÎncă nu există evaluări

- Electrical PresentationDocument54 paginiElectrical PresentationSupriyo Mehta100% (1)

- Simocode TermsDocument2 paginiSimocode TermsArunava BasakÎncă nu există evaluări

- Spec VSDDocument8 paginiSpec VSDNicodemus Ervino MandalaÎncă nu există evaluări

- Circuit BreakersDocument48 paginiCircuit BreakerspitambervermaÎncă nu există evaluări

- AVR DECS200 Instalation and CommissioningDocument1 paginăAVR DECS200 Instalation and CommissioningralphholingsheadÎncă nu există evaluări

- Adr241a Do 01 810Document17 paginiAdr241a Do 01 810Vishwanath TodurkarÎncă nu există evaluări

- Suspension Insulation String BuDocument11 paginiSuspension Insulation String BuM_D_MendisÎncă nu există evaluări

- MVAJ 05 Trip RelayDocument9 paginiMVAJ 05 Trip RelayKT MENON100% (1)

- FuseologyDocument9 paginiFuseologyalvincent72Încă nu există evaluări

- Technical Note: Trip-Circuit Supervision (TCS)Document30 paginiTechnical Note: Trip-Circuit Supervision (TCS)feromagnetizamÎncă nu există evaluări

- Jvs Manual JRD 011Document5 paginiJvs Manual JRD 011ashutosh20090% (1)

- Transformer PtotectionsDocument19 paginiTransformer Ptotectionsbiju singhÎncă nu există evaluări

- Fault Level Calculation: For Two Transformers in Parallel For Single Transformer ParallelDocument3 paginiFault Level Calculation: For Two Transformers in Parallel For Single Transformer ParallelRajkumar P. RautÎncă nu există evaluări

- Transformers STDMDocument79 paginiTransformers STDMjunfaÎncă nu există evaluări

- Switch Gear &protection: Role of SCADA in AnDocument10 paginiSwitch Gear &protection: Role of SCADA in AnNicholas SheltonÎncă nu există evaluări

- Coordinacion Protecciones EtapDocument1 paginăCoordinacion Protecciones Etaplacan021Încă nu există evaluări

- Typical Limiting Values of SubStation Equipments.Document10 paginiTypical Limiting Values of SubStation Equipments.Jeya KannanÎncă nu există evaluări

- Transmission Line ProtectionDocument111 paginiTransmission Line ProtectionfengstaÎncă nu există evaluări

- Off Load Tap Changer - Part 1Document20 paginiOff Load Tap Changer - Part 1Moncoz Aye100% (3)

- Hazards ZoneDocument4 paginiHazards Zonedarsh2001patelÎncă nu există evaluări

- Substation Testing and Commissioning: High Impedence Busbar ProtectionDocument8 paginiSubstation Testing and Commissioning: High Impedence Busbar ProtectionThirumal100% (1)

- Switch Gear: Types of Switch GearsDocument6 paginiSwitch Gear: Types of Switch GearsAdeel Mustafa100% (1)

- Power Systems Protection Course: Al-Balqa Applied UniversityDocument37 paginiPower Systems Protection Course: Al-Balqa Applied Universityrodruren01Încă nu există evaluări

- Excitation SystemDocument10 paginiExcitation SystembhulookÎncă nu există evaluări

- Excitation Current in TransformersDocument2 paginiExcitation Current in TransformersHamayoun Murtaza100% (1)

- Fault Level One PointDocument19 paginiFault Level One Pointkapil100% (1)

- Mvar PDFDocument48 paginiMvar PDFishwer kushwahÎncă nu există evaluări

- 03 Directional OvercurrentDocument10 pagini03 Directional OvercurrentM Kumar MarimuthuÎncă nu există evaluări

- Motors and GeneratorsDocument8 paginiMotors and GeneratorsHealthyCut FarmsÎncă nu există evaluări

- ABB Busbar Protection REB670 2.0 ANSIDocument498 paginiABB Busbar Protection REB670 2.0 ANSIksg9731Încă nu există evaluări

- Power PlantDocument28 paginiPower PlantSanjay SharmaÎncă nu există evaluări

- Transformers&ReactorsDocument56 paginiTransformers&ReactorsDilip KumarÎncă nu există evaluări

- Circuit Modelling Imon PscadDocument9 paginiCircuit Modelling Imon PscadKishore DMÎncă nu există evaluări

- Micom P740: Numerical Busbar ProtectionDocument386 paginiMicom P740: Numerical Busbar ProtectionDinh Xuan Duyet100% (1)

- Testing of RelaysDocument9 paginiTesting of RelaysAnimesh Jain100% (1)

- BCUDocument8 paginiBCUJigyesh SharmaÎncă nu există evaluări

- Circuit Breakers MaintenanceDocument78 paginiCircuit Breakers MaintenanceAldo Sempértegui TapiaÎncă nu există evaluări

- REF Fuse Application GuideDocument17 paginiREF Fuse Application GuidemuskanumeedÎncă nu există evaluări

- Per Unit System PPDocument15 paginiPer Unit System PPfatank04100% (1)

- Commissioning of DAVRDocument70 paginiCommissioning of DAVRPMG Bhuswal Project100% (1)

- Seminar Topic On: Circuit Breaker-IDocument25 paginiSeminar Topic On: Circuit Breaker-IParameshwar TummetiÎncă nu există evaluări

- Novel Method PMDC Motor Speed ControlDocument15 paginiNovel Method PMDC Motor Speed ControlTravis WoodÎncă nu există evaluări

- HR003-05 High Resistance Ground GdeDocument28 paginiHR003-05 High Resistance Ground GderrrajaashokÎncă nu există evaluări

- Ten - Doc. TR 20 01 (Vol. II)Document309 paginiTen - Doc. TR 20 01 (Vol. II)Manoj OjhaÎncă nu există evaluări

- Bus Switching Scheme PDFDocument6 paginiBus Switching Scheme PDFJAYKUMAR SINGHÎncă nu există evaluări

- LV PFC PB Guide (Print) PDFDocument76 paginiLV PFC PB Guide (Print) PDFionutÎncă nu există evaluări

- Harmonics Transformer de RatingDocument6 paginiHarmonics Transformer de RatingFabricio Dias CoimbraÎncă nu există evaluări

- NGR Sizing Calculation As Per IEEE 32Document3 paginiNGR Sizing Calculation As Per IEEE 32Soumya MukherjeeÎncă nu există evaluări

- Bhel Lem ReportDocument33 paginiBhel Lem ReportHarshita GautamÎncă nu există evaluări

- Knowledge is "Real Power": Introduction to Power QualityDe la EverandKnowledge is "Real Power": Introduction to Power QualityÎncă nu există evaluări

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsDe la EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsÎncă nu există evaluări

- BS 4678-1 Steel Surface TrunkingDocument11 paginiBS 4678-1 Steel Surface TrunkingMohamedAhmedFawzy100% (1)

- DUO Series: Ref. 18113 18213 18113EL 18213ELDocument2 paginiDUO Series: Ref. 18113 18213 18113EL 18213ELMohamedAhmedFawzyÎncă nu există evaluări

- How To Find The Proper Size of Circuit Breaker With CalDocument8 paginiHow To Find The Proper Size of Circuit Breaker With CalMohamedAhmedFawzyÎncă nu există evaluări

- Tracked by h33t ComDocument1 paginăTracked by h33t ComMohamedAhmedFawzyÎncă nu există evaluări

- Transformer 1 MosDocument5 paginiTransformer 1 MosMohamedAhmedFawzyÎncă nu există evaluări

- PWR Sys Selectivity - Prot Coord GE PDFDocument9 paginiPWR Sys Selectivity - Prot Coord GE PDFarturoncÎncă nu există evaluări

- BS 4678-1 Steel Surface TrunkingDocument11 paginiBS 4678-1 Steel Surface TrunkingMohamedAhmedFawzy100% (1)

- Letter To SchneiderDocument3 paginiLetter To SchneiderMohamedAhmedFawzyÎncă nu există evaluări

- 11Document3 pagini11MohamedAhmedFawzyÎncă nu există evaluări

- Raya Bank & Office Building: Rev. 0 Page 1 of 6 Feb, 2012 16 490Document6 paginiRaya Bank & Office Building: Rev. 0 Page 1 of 6 Feb, 2012 16 490MohamedAhmedFawzyÎncă nu există evaluări

- Schneider Load PlanningDocument6 paginiSchneider Load Planningshadi22Încă nu există evaluări

- Commercial Offer & Price LListDocument8 paginiCommercial Offer & Price LListMohamedAhmedFawzyÎncă nu există evaluări

- Load CalculationsDocument6 paginiLoad CalculationsMohamedAhmedFawzyÎncă nu există evaluări

- VOLTAGE DROP 1600-3200 - Majarrah Business Complex Dated 31-5-2016 Up Dated Till Part 2Document22 paginiVOLTAGE DROP 1600-3200 - Majarrah Business Complex Dated 31-5-2016 Up Dated Till Part 2MohamedAhmedFawzyÎncă nu există evaluări

- Hospital Design PDFDocument56 paginiHospital Design PDFChristy JosephÎncă nu există evaluări

- BS 4678-1 Steel Surface TrunkingDocument11 paginiBS 4678-1 Steel Surface TrunkingMohamedAhmedFawzy100% (1)

- Letter From Shaker To Price Variation OrderDocument3 paginiLetter From Shaker To Price Variation OrderMohamedAhmedFawzyÎncă nu există evaluări

- Electrical Guidelines - Second EditionDocument271 paginiElectrical Guidelines - Second EditionMohamedAhmedFawzy63% (8)

- Harmonic Filter Calculations PQSoftDocument1 paginăHarmonic Filter Calculations PQSoftMauricio AguilarÎncă nu există evaluări

- Transformer 1 MosDocument5 paginiTransformer 1 MosMohamedAhmedFawzyÎncă nu există evaluări

- ODLI20150821 002 UPD en AA Office Application Guide INTDocument29 paginiODLI20150821 002 UPD en AA Office Application Guide INTMohamedAhmedFawzyÎncă nu există evaluări

- Harmonic Filter Calculations PQSoftDocument1 paginăHarmonic Filter Calculations PQSoftMauricio AguilarÎncă nu există evaluări

- RG47 0162 SW SWPDocument8 paginiRG47 0162 SW SWPMohamedAhmedFawzyÎncă nu există evaluări

- 58 090 006e V2.0 Hospital BrochureDocument16 pagini58 090 006e V2.0 Hospital BrochureMohamedAhmedFawzyÎncă nu există evaluări

- GK BrochureDocument4 paginiGK BrochureMohamedAhmedFawzyÎncă nu există evaluări

- Access Control Single Line-Eg-29Document1 paginăAccess Control Single Line-Eg-29MohamedAhmedFawzyÎncă nu există evaluări

- Aly FD Com Mom - 01Document68 paginiAly FD Com Mom - 01MohamedAhmedFawzyÎncă nu există evaluări

- Technical Specifications Cables and Wires: Beyti - New Juice Bottling PlantDocument6 paginiTechnical Specifications Cables and Wires: Beyti - New Juice Bottling PlantMohamedAhmedFawzyÎncă nu există evaluări

- Cisco Press - Datacenter Design and ImplementationDocument85 paginiCisco Press - Datacenter Design and ImplementationJamile Katiuska García ZarcosÎncă nu există evaluări

- MN225014EN - Pad-Mounted Voltage Regulator Installation Operation and Maintenance PDFDocument48 paginiMN225014EN - Pad-Mounted Voltage Regulator Installation Operation and Maintenance PDFMohamedAhmedFawzyÎncă nu există evaluări

- Voltage Amplification, Trail Cable Length & Power ShovelsDocument9 paginiVoltage Amplification, Trail Cable Length & Power ShovelsMaikPortnoyÎncă nu există evaluări

- Advantage: Owner'S Manual Installation, Operation & PartsDocument10 paginiAdvantage: Owner'S Manual Installation, Operation & PartsRetep Nhoj SelipamidÎncă nu există evaluări

- TPG DFR 150kV - R1 - KSDocument4 paginiTPG DFR 150kV - R1 - KSAdhit NovalÎncă nu există evaluări

- PLC DdcmisDocument63 paginiPLC DdcmisNicole LeeÎncă nu există evaluări

- Unidrive M Modular Installation Guide Issue 5 (0478-0141-05) - ApprovedDocument158 paginiUnidrive M Modular Installation Guide Issue 5 (0478-0141-05) - Approvedskv004Încă nu există evaluări

- Bangaon Division ConsumptionDocument2 paginiBangaon Division ConsumptionJuBeeÎncă nu există evaluări

- TM 11 1520 221 20Document162 paginiTM 11 1520 221 20Tod A. WulffÎncă nu există evaluări

- Impulse Voltage: Generation of ANDDocument22 paginiImpulse Voltage: Generation of ANDrare machineÎncă nu există evaluări

- DGW200MS/UK: Operator'S ManualDocument36 paginiDGW200MS/UK: Operator'S ManualthuanÎncă nu există evaluări

- Kenwood - TK-2000E - 3000E - BrochureDocument2 paginiKenwood - TK-2000E - 3000E - BrochureAndriantsoa HeritianaÎncă nu există evaluări

- Delta Electronics Inc Dps-650xb X 650w Ecos 3293 ReportDocument1 paginăDelta Electronics Inc Dps-650xb X 650w Ecos 3293 ReportHector Villarreal100% (1)

- HV Connectors Test Report PDFDocument21 paginiHV Connectors Test Report PDFMohammed ShoaibÎncă nu există evaluări

- DeviceNet Drop 2x24 AWG + 2x22 AWG SFTP FR-PVC - 982VD14101 - V - 1 - R - 2 PDFDocument2 paginiDeviceNet Drop 2x24 AWG + 2x22 AWG SFTP FR-PVC - 982VD14101 - V - 1 - R - 2 PDFᕱᕱᗋᖇᓾᗅ ᙍᕠÎncă nu există evaluări

- General Physics Lesson 2Document9 paginiGeneral Physics Lesson 2Green GrembloÎncă nu există evaluări

- Z600EDocument2 paginiZ600Esaleemut3Încă nu există evaluări

- E&I QAP's - Submitted To Contractor HZADocument33 paginiE&I QAP's - Submitted To Contractor HZASuraj ShettyÎncă nu există evaluări

- Reciprocity Theorem: Namrata V. L. Assistant Professor Government Engineering College, RajkotDocument23 paginiReciprocity Theorem: Namrata V. L. Assistant Professor Government Engineering College, RajkotKarthi Keyan100% (1)

- Organic Molecules in ElectronicsDocument32 paginiOrganic Molecules in ElectronicsRachelle McKeownÎncă nu există evaluări

- Delhi Directory 2022 EvDocument30 paginiDelhi Directory 2022 EvVipul Khandelwal100% (1)

- Practice Midterm 03-SolutionsDocument7 paginiPractice Midterm 03-SolutionsElizabeth DouglasÎncă nu există evaluări

- 2a.ALTERNATING CURRENT (69-94)Document27 pagini2a.ALTERNATING CURRENT (69-94)KeertanaÎncă nu există evaluări

- Chapter 4: AC Circuits and Passive Filters: Learning ObjectivesDocument45 paginiChapter 4: AC Circuits and Passive Filters: Learning ObjectivesMariam EvaristÎncă nu există evaluări

- RSL Info and TroubleshootingDocument18 paginiRSL Info and TroubleshootingTolgahan Karadag100% (2)

- Bhatinda O&m TGDocument897 paginiBhatinda O&m TGDeepak Gupta100% (2)

- YTA610 Temperature TransmitterweDocument20 paginiYTA610 Temperature TransmitterweFasil AkramÎncă nu există evaluări

- Lead Acid Battery Training by EnerSys at IEEE 02-21-13 PDFDocument134 paginiLead Acid Battery Training by EnerSys at IEEE 02-21-13 PDFDanny NjomanÎncă nu există evaluări

- Post Lab-4Document5 paginiPost Lab-4Gaffar KhanÎncă nu există evaluări

- Brushless DC MotorDocument14 paginiBrushless DC Motorir_yusriÎncă nu există evaluări

- ALLDATA Repair - pdf5Document3 paginiALLDATA Repair - pdf5Yassir PerezÎncă nu există evaluări

- Hatta PropagationDocument2 paginiHatta PropagationnikoabdulÎncă nu există evaluări