Documente Academic

Documente Profesional

Documente Cultură

Well Check List - Qa

Încărcat de

Anonymous U5t9NYzhLWTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Well Check List - Qa

Încărcat de

Anonymous U5t9NYzhLWDrepturi de autor:

Formate disponibile

CORPORATE ASSURANCE & QC

ALL SERVICES

Item

Desription

Resonsibility

Response

Photo

Well:

Revision Date

Revision Number:

Originator:

22 May 2015

1.0

Martin Doig

Comments

Completed

2.0

HEALTH, SAFETY &

ENVIRONMENT

2.1 "T" Card System for drilling

location

2.2 Updated Emergency Contact

Details

3.0

DRILLING UNIT

6-5/8" Landing String

3.1 9.0 inch Drill Collars

3.2 All necessary casing handling and

running equipment

Indicated as range 2 and 2,000m present

T/Jnt OD/ID = 8.5"/ 4"

FOR ALL HOLE SECTIONS BY PROGRAM

3.3 Check BOP stack and cavities

3.4 Check ram block elastomers

ELASTOMERS TO BE SUITABLE FOR

DRILLLING FLUIDS PROPOSED

Page 1 of 13 Pages

CORPORATE ASSURANCE & QC

ALL SERVICES

Item

Desription

Resonsibility

Response

Photo

Well:

Revision Date

Revision Number:

Originator:

22 May 2015

1.0

Martin Doig

Comments

Completed

3.5 ALL RAMS TO BE CHECKED

3.6 Check Kill Line Check Valve

3.7 Rig site communications

3.8 Cellar casing drain ball valves

3.9 Mud engineers shack

3.10 Elvatoros & Links

3.11 Third party contractor

accommodation

Currently esimated at 24

3.12 TUBULAR INSPECTION REPORT

[THIRD PARTY]

Page 2 of 13 Pages

CORPORATE ASSURANCE & QC

ALL SERVICES

Item

Desription

3.13 Drilling Unit Grounding (Earth)

Resonsibility

Response

Photo

Well:

Revision Date

Revision Number:

Originator:

22 May 2015

1.0

Martin Doig

Comments

Completed

To confirm quality of grounding

3.14 Mud System Level Control Hand

Winch

Check serviceability of hand

winches and "U"Tubes

3.15 Mixing Hoppers

Check location of mixing

hoppers. Mixing hoppers are to

be hard piped.

3.17 Rotating Mixers

Check Oil Seals in gearboxes

3.18 Pit #1 Shale Shaker Installation

3.19 Pit #1 SCE

Page 3 of 13 Pages

CORPORATE ASSURANCE & QC

ALL SERVICES

Item

Desription

3.20 Bell Nipple Flowline Jets

Resonsibility

Response

Photo

Well:

Revision Date

Revision Number:

Originator:

22 May 2015

1.0

Martin Doig

Comments

Completed

Jetting lines need to be installed

in mud flowline and connected to

low pressure mud system and

the washdown system

POLLUTION PANS

3.21 Centrifuge

Page 4 of 13 Pages

CORPORATE ASSURANCE & QC

ALL SERVICES

Item

Desription

Resonsibility

Response

Photo

Well:

Revision Date

Revision Number:

Originator:

22 May 2015

1.0

Martin Doig

Comments

Completed

3.22 Chemical Tanks

BIG BAG HANDLING EQUIP

3.23 Slush Pump Suction Strainers

Slush Pump Fluid End

Page 5 of 13 Pages

CORPORATE ASSURANCE & QC

ALL SERVICES

Item

Desription

3.24 Pressure Gauges

Resonsibility

Response

Well:

Revision Date

Revision Number:

Originator:

Photo

22 May 2015

1.0

Martin Doig

Comments

Completed

All pressure gauges to be

inspected and checked. Replace

units that are not working

3.25 Rig Instrumentation

3.26 Computer - Rig Instrumentation

3.27 Rig Instrumentation - Pit Sensors

3.28 Rig Instrumentation - Pit Sensors

3.29 Mud Cleaners

??????

Page 6 of 13 Pages

CORPORATE ASSURANCE & QC

ALL SERVICES

Item

Desription

Resonsibility

Response

Photo

Well:

Revision Date

Revision Number:

Originator:

22 May 2015

1.0

Martin Doig

Comments

3.30 Make-up Water Lines

Solid piping with shut-off and

isolation valves incorporated. No

hoses to be used!!

3.31 Vacuum Degasser

Check on installation

Completed

3.32 De-Sander

3.33 De-Silter

Page 7 of 13 Pages

CORPORATE ASSURANCE & QC

ALL SERVICES

Item

Desription

3.34 Wilden Pump

Resonsibility

Response

Photo

Well:

Revision Date

Revision Number:

Originator:

22 May 2015

1.0

Martin Doig

Comments

Completed

Provide an air operated pump

with all the necessary suction

and discharges hoses and air

drive hoses

3.35 Rig Engine Controls

3.36 Rig Power Unit

3.37 Mud Tank Valves

3.38 Equalizing Skimmers

Fill mud system with water and

check whether valves are

leaking

Page 8 of 13 Pages

CORPORATE ASSURANCE & QC

ALL SERVICES

Item

Desription

Resonsibility

Response

Photo

Well:

Revision Date

Revision Number:

Originator:

22 May 2015

1.0

Martin Doig

Comments

Completed

3.39 Reserve Tank mixing System

3.40 Mixing Tank Roof

3.41 Mud Tank Layout

Page 9 of 13 Pages

CORPORATE ASSURANCE & QC

ALL SERVICES

Item

Desription

Resonsibility

Response

Photo

Well:

Revision Date

Revision Number:

Originator:

22 May 2015

1.0

Martin Doig

Comments

Completed

3.42 Mixing/Suction Tank Pumps

3.43 Reserve Tank Mixing Pump

3.44 TransferTank Pumps

3.45 No. 1 Tank Pumps

Page 10 of 13 Pages

CORPORATE ASSURANCE & QC

ALL SERVICES

Item

Desription

3.46 Reserve & Mixing Tank

Resonsibility

Response

Photo

Well:

Revision Date

Revision Number:

Originator:

22 May 2015

1.0

Martin Doig

Comments

Completed

Requires hard piped hopper

discharge line

3.47 Flowline Rate Sensor

3.48 Standpipe Pressure Sensor

3.49 Torque Sensor

Page 11 of 13 Pages

CORPORATE ASSURANCE & QC

ALL SERVICES

Item

Desription

Resonsibility

Response

Photo

Well:

Revision Date

Revision Number:

Originator:

22 May 2015

1.0

Martin Doig

Comments

Completed

3.50 Choke Manifold/Well head

Pressure Sensor

3.51 Drilling Line

3.52 Standpipe Connection for Casing

Circulating Fill-up tool

3.53 Mud Storage Off Ground

Page 12 of 13 Pages

CORPORATE ASSURANCE & QC

ALL SERVICES

Item

Desription

Resonsibility

Response

Photo

Well:

Revision Date

Revision Number:

Originator:

22 May 2015

1.0

Martin Doig

Comments

Completed

3.54 Wellhead Adaptor

Mud Logging Sensor Out puts

Page 13 of 13 Pages

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Ambus 1Document1 paginăAmbus 1Anonymous U5t9NYzhLWÎncă nu există evaluări

- Russ Well MontageDocument3 paginiRuss Well MontageAnonymous U5t9NYzhLWÎncă nu există evaluări

- 17.5 Hole Section ExtractDocument3 pagini17.5 Hole Section ExtractAnonymous U5t9NYzhLWÎncă nu există evaluări

- 2015 Wireline Services Catalog (Full Permission)Document233 pagini2015 Wireline Services Catalog (Full Permission)SanPer86Încă nu există evaluări

- SLB Cementing Guidelines ExtractsDocument4 paginiSLB Cementing Guidelines ExtractsAnonymous U5t9NYzhLWÎncă nu există evaluări

- Oryx Timeline For Proposal Rev 0Document1 paginăOryx Timeline For Proposal Rev 0Anonymous U5t9NYzhLWÎncă nu există evaluări

- SLB Cementing Guidelines ExtractsDocument4 paginiSLB Cementing Guidelines ExtractsAnonymous U5t9NYzhLWÎncă nu există evaluări

- Relief Plan TemplateDocument26 paginiRelief Plan TemplateAnonymous U5t9NYzhLWÎncă nu există evaluări

- Wells Study 2Document6 paginiWells Study 2Anonymous U5t9NYzhLWÎncă nu există evaluări

- Draft Statement of Accounting For:-Mr J Sale of Subjects: - Hillside Road, Portlethen, AB12 4XX Date of EntryDocument1 paginăDraft Statement of Accounting For:-Mr J Sale of Subjects: - Hillside Road, Portlethen, AB12 4XX Date of EntryAnonymous U5t9NYzhLWÎncă nu există evaluări

- Organo GramDocument1 paginăOrgano GramAnonymous U5t9NYzhLWÎncă nu există evaluări

- Drilling Engineer - Job Details For AdvertsDocument3 paginiDrilling Engineer - Job Details For AdvertsAnonymous U5t9NYzhLWÎncă nu există evaluări

- IPM Flow Chart TempDocument1 paginăIPM Flow Chart TempAnonymous U5t9NYzhLWÎncă nu există evaluări

- Drilling Engineer - Job DetailsDocument3 paginiDrilling Engineer - Job DetailsAnonymous U5t9NYzhLWÎncă nu există evaluări

- Tyra South East A - Design of Unmanned Wellhead Platform For Gas Condensate Field - Ramboll UK LimitedDocument1 paginăTyra South East A - Design of Unmanned Wellhead Platform For Gas Condensate Field - Ramboll UK LimitedAnonymous U5t9NYzhLWÎncă nu există evaluări

- 01 MOC For Mud Change For 17.5inch Hole Rev 1Document4 pagini01 MOC For Mud Change For 17.5inch Hole Rev 1Anonymous U5t9NYzhLWÎncă nu există evaluări

- Best Practices For Jetting 1Document8 paginiBest Practices For Jetting 1Anonymous U5t9NYzhLWÎncă nu există evaluări

- 13 3 8 Tally SheetDocument30 pagini13 3 8 Tally SheetAnonymous U5t9NYzhLWÎncă nu există evaluări

- Daily Report Pipe Inspection: Date: 25th February 2017Document6 paginiDaily Report Pipe Inspection: Date: 25th February 2017Anonymous U5t9NYzhLWÎncă nu există evaluări

- 2016.03.15 - CI-508 - TCM Without Subsurface v1 RevDocument4 pagini2016.03.15 - CI-508 - TCM Without Subsurface v1 RevAnonymous U5t9NYzhLWÎncă nu există evaluări

- Wells Study 2Document6 paginiWells Study 2Anonymous U5t9NYzhLWÎncă nu există evaluări

- Finding Petroleum - Decommissioning - The D Word!Document3 paginiFinding Petroleum - Decommissioning - The D Word!Anonymous U5t9NYzhLWÎncă nu există evaluări

- Logdata Toolbox 23 Releasenotes SLBDocument4 paginiLogdata Toolbox 23 Releasenotes SLBAnonymous U5t9NYzhLWÎncă nu există evaluări

- Technical Analysis-Forex Trading With Candlestick and PatternDocument49 paginiTechnical Analysis-Forex Trading With Candlestick and PatternmangueeeeÎncă nu există evaluări

- Logdata Toolbox 23 Releasenotes SLBDocument4 paginiLogdata Toolbox 23 Releasenotes SLBAnonymous U5t9NYzhLWÎncă nu există evaluări

- Daily Drilling Report For BBC1 Decom: No Data Available in TableDocument4 paginiDaily Drilling Report For BBC1 Decom: No Data Available in TableAnonymous U5t9NYzhLWÎncă nu există evaluări

- Kite 2Document2 paginiKite 2Anonymous U5t9NYzhLWÎncă nu există evaluări

- Vitol Ivc - Feb 2016 Post Rental NDT - DRT Tracker Sheet SignedDocument1 paginăVitol Ivc - Feb 2016 Post Rental NDT - DRT Tracker Sheet SignedAnonymous U5t9NYzhLWÎncă nu există evaluări

- 2016.03.15 - CI-508 - TCM Without Subsurface v1 RevDocument4 pagini2016.03.15 - CI-508 - TCM Without Subsurface v1 RevAnonymous U5t9NYzhLWÎncă nu există evaluări

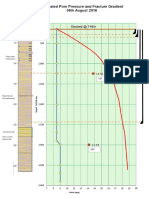

- Presentation 1 Pore and Frac With LithDocument2 paginiPresentation 1 Pore and Frac With LithAnonymous U5t9NYzhLWÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Bltn0045 PDFDocument7 paginiBltn0045 PDFcemsavantÎncă nu există evaluări

- Cryogenics & LNG Application GuideDocument16 paginiCryogenics & LNG Application GuidesusantoÎncă nu există evaluări

- SMPV RulesDocument48 paginiSMPV RulesAnonymous LFgO4WbID100% (1)

- Information On Fire Flow Testing of Hydrants PDFDocument5 paginiInformation On Fire Flow Testing of Hydrants PDFMohamed MasryÎncă nu există evaluări

- Pulsation DampenerDocument12 paginiPulsation DampenerAnibal Jose Cruz Larez100% (1)

- Rac Table and GraphDocument8 paginiRac Table and GraphIrfan AminÎncă nu există evaluări

- Trickle Bed by WillyDocument8 paginiTrickle Bed by WillyDocument PTKI MedanÎncă nu există evaluări

- Thermo LQ3Document2 paginiThermo LQ3Su-ho HanÎncă nu există evaluări

- Subsea Production System - OverviewDocument24 paginiSubsea Production System - OverviewMuhammad NursalamÎncă nu există evaluări

- Elec & I&C Cable Construction Progress (As of 21 June, 2018)Document7 paginiElec & I&C Cable Construction Progress (As of 21 June, 2018)Kharisma Pangeran LanangÎncă nu există evaluări

- Experiment 2 CHM207 Intermediate Organic Chemistry Distillation Technique and To Determine The Boiling Point of A LiquidDocument3 paginiExperiment 2 CHM207 Intermediate Organic Chemistry Distillation Technique and To Determine The Boiling Point of A LiquidMUADZ ARÎncă nu există evaluări

- A Case Study of High-Pressure, Light-Oil Steam Flooding in A Low-Permeability ReservoirDocument7 paginiA Case Study of High-Pressure, Light-Oil Steam Flooding in A Low-Permeability ReservoirDanna Kornz100% (1)

- Petroleum Development Oman L.L.C.: Document Title: Hydrogen Sulphide (H S) ManagementDocument22 paginiPetroleum Development Oman L.L.C.: Document Title: Hydrogen Sulphide (H S) ManagementSiva100% (1)

- Absorption Test RigDocument7 paginiAbsorption Test RigMurali VakadaÎncă nu există evaluări

- Fluid FlowDocument15 paginiFluid Flowdekra abdoÎncă nu există evaluări

- Sheet 2 Properties of Pure SubstancesDocument2 paginiSheet 2 Properties of Pure SubstancesZainhumÎncă nu există evaluări

- Reboiler HydraulicDocument3 paginiReboiler Hydraulic54yreyeÎncă nu există evaluări

- Material Balance Equation ApplicationDocument59 paginiMaterial Balance Equation Applicationweldsv100% (1)

- Piping Thickness Calculation (ASME B31.3)Document8 paginiPiping Thickness Calculation (ASME B31.3)got youfour onlinesomÎncă nu există evaluări

- ME6301 Engineering ThermodynamicsDocument19 paginiME6301 Engineering ThermodynamicsJeevanandam ShanmugaÎncă nu există evaluări

- E3sconf Icenis2019 14009Document8 paginiE3sconf Icenis2019 14009agungtiyo21Încă nu există evaluări

- Turbina ms6001bDocument64 paginiTurbina ms6001bAangel HHernande100% (1)

- 2016CT Compressor Specs at GlanceDocument4 pagini2016CT Compressor Specs at GlanceabsahkahÎncă nu există evaluări

- Re92801 - 2020 10 01Document68 paginiRe92801 - 2020 10 01Rohit MehtaÎncă nu există evaluări

- Fanno PDFDocument38 paginiFanno PDFddubokaÎncă nu există evaluări

- Plano Hidraulico PDFDocument2 paginiPlano Hidraulico PDFsantosÎncă nu există evaluări

- Whrs ManualDocument41 paginiWhrs ManualAKHLESH JHALLAREÎncă nu există evaluări

- Calibration PDFDocument289 paginiCalibration PDFRaj ManovaÎncă nu există evaluări

- Panametrics Mms3 0707 enDocument80 paginiPanametrics Mms3 0707 enjoelÎncă nu există evaluări