Documente Academic

Documente Profesional

Documente Cultură

Alfa Romeo 164 - Group 75 - External Trim

Încărcat de

tecnoinc0 evaluări0% au considerat acest document util (0 voturi)

127 vizualizări35 paginiAlfa Romeo 164 - External Trim - Group 75 - From the series of Alfa Romeo 164 overhauling and service manual manuals

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentAlfa Romeo 164 - External Trim - Group 75 - From the series of Alfa Romeo 164 overhauling and service manual manuals

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

127 vizualizări35 paginiAlfa Romeo 164 - Group 75 - External Trim

Încărcat de

tecnoincAlfa Romeo 164 - External Trim - Group 75 - From the series of Alfa Romeo 164 overhauling and service manual manuals

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 35

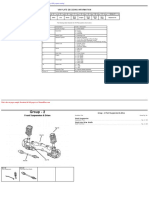

EXTERNAL TRIM

164

GROUP 75

EXTERNAL TRIM

TABLE OF CONTENTS

CENTER AND SIDE GRILL!

Removaliinstaliation ..

. 75-4

1564

FRONT COMBINATION LAMPS AND RADIATOR

FINISHERS . 75-4

+ Removalinstaliation .. 75-4

FRONT SIDE TRIM. 75-5

+ Removal/installation .. 75-5

DOOR STRIPS .. 75-5

+ Removaliinstaliation 75-5

UNDER - DOOR TRIM AND KICKPLATE 75-5

+ Removal/instaliation .. 75-5

ORIP..,

Removal

installation

FRONT GRAVEL GUARD

+ Removal/installation

REAR GRAVEL GUARD.

+ Removalinstallation

WINDSHIELD.

Removal ..

+ Preparation tor instatiation ...

installation

REAR WINDOW ..

- Removal

Preparation for Installation ..

Installation

FRONT BUMPER, sessiccssssss

Removalinstallation ..

REAR BUMPER

Removalinstallation ..

SPOILER ("S" VERSION ONLY),

Removal installation

SUN ROOF ..

Sun roof opening

Sun root closing

«+ Opening to “Quarter light” position ..

+ Closing from “Quarter light position

Inner trim and spoiler operation

Metal panel

Disassembly

Reassembly

Adjustment ..

Tle-strap guide and meta! pane! seal

+ Disassembly/Reassembly

‘Spoiler components.

+ Disassembly/Reassembly

Electric motor

EXTERNAL TRIM

SS 868

TECHNICAL CHARACTERISTICS AND

SPECIFICATION

+ Tightening torques.

75-28 + FIUIGS @fd LUDFICAIIS essersssseerserrrererssstee

78-28 | - Sealing compounds

75+ 28 + Products for windshield and rear

75-28 window bonding

Windshield washer mixture

+ Disassembly/Reassemb);

+ TIMING sssesssereteee

+ Manual operation

+ Mobile ralt.. rs

+ Disassembly Reassembly

+ Inner trim.

+ Disassembly Reassembly..

> Frame. 78-29 :

+ Removal 75-29

+ Installation 75-29 TROUBLESHOOTING PROCEDURE...

Sliders and flexible racks

+ Disassembly Reassembly ..

75-2

EXTERNAL TRIM =

183 SYN re

ILLUSTRATED INDEX

‘SOLER

RENOVALINSTALLATION (page 75-18)

REAR WINDOW

REMOVAL (ooge 75 - 12)

PREPARATION FOR

INSTALLATION (page 75-13)

INSTALLATION (page 75-13)

PANEL SEAL (page 75-21)

SPOILER (page 76 -24)

SPOILER COMPONENTS (page 75-28)

ELECTRIC MOTOR page 75-28)

MOBILE RAIL (page 78-25)

‘NNER TAIM (page 78 - 28)

FRAME (page 75.29)

SUDERSANO FLEXIBLE © nip

MMR (mee 7-32) REMOVAL (age =}

FALLATION (page 75 6)

: wonosiieio =

REMOVAL (ge 75-5) EN

PREPARATION FOR

SNSTALLATION page 78-10)

WSTALLATION (page 75.13)

‘FRONT COMBINATION LAMPS AND

RADIATOR FINSHERS

REMOVALANSTALLATION (page 78-4)

REAR GRAVEL GUARD

REMOVALACSTALLATION

REMOVALANSTALLATION (age 75-2)

UNDER-DOOR Thum AND

CENTER AND Side GRILLS. KOCKPLATE,

Sa RUINETALLATION REMOVALINSTALLATION

(age 75-4) a

IREMOVALINSTALLATION (page 75-7) woe

FRONT BUMPER

AEMOVALINBTALLATION (page 75. 14) POON STRIPE sn gage .

REAR BUMPER

REMOVALINSTALLATION (page 78-18)

75-3

CENTER AND SIDE GRILLS

REMOVALINSTALLATION

o

1. Disconnect negative (-) lead trom battery.

2. Remove Atfa Romeo badge.

3.

4. Unscrew and remove three nuts and washers secur-

‘Open bonnet.

ing center gril

Remove center grill.

Unscrew and remove three nuts and washers secur-

Ing each skie gril

Remove side grils.

Remove engine hood safety lock (see Group 56).

75-4

EXTERNALTRIM

16a

For parts and/or components described in

‘other pages of same Group or in other Groups,

refer to related procedures and information,

FRONT COMBINATION LAMPS AND

RADIATOR FINISHERS

REMOVAL /INSTALLATION

1. Disconnect negative (-} lead from battery.

2, Remove radiator seal

3. remove plastic rivets securing seal to each combi-

nation lamp.

4. Remove seals from both headlamp units.

5. Remove screws and washers securing radiator pip-

ing cowls.

6. Remove radiator piping cowls.

7, Rettove four bolls and washers securing upper

finisher to radiator.

8. Remove radiator upper finisher.

Repeal procedure in reverse order tor installa-

tion.

EXTERNAL TRIM

ss

164

FRONT SIDE TRIM 4. Remove plastic rivets, trom door inner side, which

‘secure strip to lower end of door.

REMOVAL/INSTALLATION 5, Withdraw door strip rearwards and remove it.

1. Disconnect negative (-) lead from battery.

2. Remove trim cover.

3. Remove two screws Securing side trim screw

4. Disjoint front side trim from plastic clips and remove

eM

coven

Repeat procedure in reverse order for installa.

tion.

DOOR STRIPS

REMOVAL/INSTALLATION

1. Disconnect negative (-) lead trom battery

2. Remove screw protective cap on inner side of

door

3. Remove strip securing screw trom inner side of

oor.

YQ

PROTECTIVE CAP

Ne

Repeat procedure in reverse order for installa-

tion.

UNDER - DOOR TRIM AND KICK-

PLATE

REMOVAL/NSTALLATION

1. Disconnect negative (-) lead trom battery

75-5

EXTERNALTRIM

8 $$$ _ 4

2. Remove front side trim.

Remove sctews securing trim on the lower end.

4. Remove plastic rivets, which secure trim on lower

side.

5. Unlock the plastic catches.

6. Raise door seats.

7. Remove plastic rivets, which secure trim on upper

side

8. Remove under-door trim and kickplate.

‘TRIM AND

KICKPLATE

SCREW: \

For parts andior components described in

other pagesot same Group or in ather Groups,

refer to related procedures and informations.

NOTE: The above procedure for under-door trim and

kickplate removal and installation, is also appli-

cable to “5” version.

DRIP

REMOVAL

1.

2

Disconnect negative (-) kaad from batiery

Remove plastic rivets which secure drip in area ot

rear door.

Rlemove drip (the dripis bounded in area of reardoor

and is tongued in area of front door).

INSTALLATION

1

Replace plastic catches securing drip in area of front

oor, if damaged.

Insert drip front edge in its seat on wing.

Bond drip rear section (self-adhesive) in area of rear

door.

‘Secure drip rear section with plastic rivets in area of

rear door.

insert drip rear edge between rear pillarand roof. The

edge must be inserted under rear window channels.

Position drip center section so as drip holes mate

with holes for roof rack/sky holder installation.

Position wire under drip lower edge.

75-6

EXTERNAL TRIM

164

8. Engage drip on plastic catches by tapping lightly on

while pulling wire; insert drip lower edge on metal

fim.

9. Connect negative (-) lead to battery.

Re

REAR EDGE

(BETWEEN

REAR PILLAR

‘DAUP FRONT EDGE

(BEAT Cn WING)

FRONT GRAVEL GUARD

REMOVALINSTALLATION

1

2.

Remove frontwheelby removing five attaching bots,

Remove two tront-hal gravel guard securing screws

(side and lower) and screw connecting gravel guard

front-hal to rear-half.

Remove bolt and nut connecting gravel guard front-

half to rear-halt.

Remove front-halt grave! guard.

Remove three rearhalt gravel guard securing

‘screws (side and lower).

. Remove rear-halt gravel guard,

SECURING)

Repeat procedure in reverse order for installa:

tion.

75-7

REAR GRAVEL GUARD

REMOVALANSTALLATION

1. Remove rearwheel by removing five attaching bots

2. On right-hand gravel guard, remove tank filler pipe

(see Group 04).

3. Remove four side seouring screws.

Remove aff securing screw with related washer.

5. Using a suitable punch, push inwards the nails of ex-

pansion blocks on forward side of gravel guard.

6. Retrove expansion blocks.

7. Remove rear gravel guard.

REAR

‘GRAVEL GUARD

mais,

EXTERNALTRIM

164

For parts and/or components described in

other pages of same Group or in other Groups,

refer to related procedures and informations.

WINDSHIELD

REMOVAL

x

2gean

12.

13.

Disconnect negative (-} lead from battery

Remove front pillar trims (see Group 66)

Rlemove sun visors, rearview mirror and courtesy

lamp (see Group 66)

CAUTION:

Protect adequately roof trim to avold dam-

age or soiling.

Disconnect and lower forward edge of roof trim (see

Group 66)

Remove engine hood (see Group 66)

Remove protective caps from windshield wipers

nuts.

Remove windshield wipers nuts,

Remove windshield wipers arms.

Remove windshield lower finisher.

. Remove drips (refer to relevant paragraph).

Remove windshield side housing panels, complete

with plastic rim.

Cut bonding fine round the whole edge of windshield

using electric cutters and blades as depicted in

figure.

Remove windshield.

75-8

EXTERNAL TRIM

8195

PREPARATION FOR INSTALLATION

1. Install seal, observing positioning measures as de-

pkcted in figure.

14 rum 0.71 in)

WEASURE 0 FR

jou] MEASURED FROM

WINDSHIELD CENTER,

WINDSHIELD EOCE.

7:1 2002 000)

NOTE: I windshield was previously Installed, re-

move old seal and any trace of adhesive

from glass edge.

CAUTION:

+ Use only Alfa Romeo adhesive kit (P/N

162.00.76.001.99).

+ Open container just before application;

observe manufactures Instructions on

adhesive container.

NO Ee

EXTERNALTRIM

184

‘Apply adhesive strip to upper and side edges of

windshield,

Install upper and side channels.

Install lower channel.

Clean windshield edges and channels with degreas-

ing compound contained in ki.

‘Allow to dry.

Apply adhesive primer on windshield edges and on

channels.

Allow primer to dry.

|. Just before installation of windshield, apply adhesive

between seal and channels. The width of adhesive

‘bead ("a” or “b" dimension) could be as depicted in

figure.

75-10

EXTEANAL TRIM

164

INSTALLATION

CAUTION:

A + Use only Alfa Romeo adhesive kit (P/N

162.00.76.001.99).

+ Open container just before application;

observe manufactures Instructions on

adhesive container.

1. Smooth any trace of adhesive (referto step Sof topic

“Preparation for installation”) and wipe otf withdry:

oth or compressed air any residual of works; apply

primer and allow it 10 dry.

2. Reinstall side housing panels using rivets.

3. Reinstall plastic edges.

75-14

a=

Using sucker pads, position windshield in ts seat

‘Adjust two positioning spacers. as necessary until

windshield is property positioned.

6. Apply light, uniform pressure all around windshiels

oa

edge.

7. Allow adhesive to cure thoroughly.

8. Reinstall windshield lower tinisher.

9. Reinstall all components removed.

10. Correct negative (-) lead to battery.

For parts and/or components described in

‘other pages of same Group or in other Groups,

refer to related procedures and informations.

EXTERNALTRIM

Bes

REAR WINDOW

REMOVAL

1.

2.

3.

Disconnect negative (-) lead from battery.

Remove rear pillars trims (see Group 68)

Remove rear seats (vehicles equipped with spilt

seat) or complete rear seat (vehicles equipped with

standard - type seat) (see Group 66).

Remove rearstop (S version excluded) and rearwin-

dow parcel shett (see Group 66).

Remove trunk lid (see Group 56).

Raise forward section of trunk seal.

Remove three plastic rivets securing roof trim rear

edge.

164

CAUTION:

Protect adequately roof trim to avoid dam-

‘age or solling.

Lower root trim rear edge.

Disconnect heated rear window wiring.

Remove rear window lower finisher.

Gut bonding line round the whale edge of rear win-

dow using electric cutters and blades as depicted in

figure,

REARSEAT

HEATED REAR

WINDOW Win

‘TYPES OF CUTTER:

‘A: WITH LONG BLADE (ANGULAR AREA

IB: WITH SHORT BLADE (STRAIGHT AREA)

75-12

EXTERNAL TRIM

166 — ic

PREPARATION FOR INSTALLATION

1. Install seal, observing positioning measures as de-

pected in figure.

LAs AND

CHANNEL SIE

UPPER AND:

‘SIDE CHANNELS.

NOTE: If reat window was previously installed, re-

move old seal and any trace of adhesive

from glass edge.

CAUTION:

+ Use only Alfa Romeo adhesive kit (P/N

162.00.76.001.99).

+ Open container just betore application;

observe manufactures Instructions on

adhesive container.

install upper and side channels on rear window.

{install lower channel.

Clean glass edges and channels with degreasing

‘ompound contained in kit

sen

75-13

5. Allow to dry.

6. Apply adhesive primer on glass edges and on chan-

nels.

7. Allow primer to dry.

INSTALLATION

CAUTION:

+ Use only Alfa Romeo adhesive kit (P/N

162.00.76.001.99).

+ Open container just before application;

observe manutactures instructions on

adhesive container.

1. dust before installation of rear window, apply adhe-

sive between seal and channels.

2. Smooth any trace of adhesive and wipe off with dry

Cioth or compressed air any residual of works; apply

Primer and allow it to dry.

3. Using sucker pads, position rear window on its seat

4. Adjust two positioning spacers as necessary unti

ear window is property positioned.

5. Apply light, uniform pressure all around rear window

edge.

Allow adhesive to cure thoroughly.

Reinstall rear window lower finisher.

Reinstall all components. removed.

Connect negative (-) lead to battery

Pore

EXTERNALTRIM

== 164

NOTE: - For parts and/or components described in sions lights; disconnect wirings then remove traspar-

other pages of same Group or in other ents.

Groups, refer to related procedures and | 9. Remove seven upper screws and washers.

informations. 10, Move the bumper aside and disconnect the piping of

- Check that wires are correctly secured to the telescopic headlamp washer.

connectors before connecting wiring. 11. Loosen the screws, remove the headlamp washer

and the sprayer from the bumper.

FRONT BUMPER 12. Remove front bumper.

REMOVAL /INSTALLATION For parts and/or components described in

other pages of same Groups or in other

1. Disconnect negative (-} lead {rom battery Groups, refer to related procedures and

2. Remove two lower side sorews and washers, informations.

3. Remove two inner side sorews and washers. - Check that wires are correctly secured to

4, Remove four lower front plastic rivets. connector before connecting wiring.

5. Remove two front screws and washers.

6. Remove headlamp units (see Group 40) NOTE: As for “S" version, removal and installation

7. Remove fogiamps (see Group 40). procedures of the front bumper are identical.

8. Withdraw LH. and R.H. trasparents of overall dimen-

‘TRANSPARENT

oo screw

TELEsconic

HEADLAMP.

WASHER

wining

‘TRANSPARENT

(OVERALL

DIMENSIONS

uGkT)

EXTERNAL TRIM

164

REAR BUMPER ‘9. Remove four side bolts and washers securing

bumper.

REMOVAL/INSTALLATION 10. Rlemove four afi nuts and washers securing bumper.

11. Draw back rear bumper and remove it.

1. Disconnect negative (-) lead from battery.

2 Removes three Screws and washers securing under- For parts andior components de in

, other pages of same Group or in other

a Remove wonutsand washers securing vunder-trunk Groupe, refer to related es and in

4, Remove under-trunk trim. formations:

5. Withdraw L.H. and F.H. trasparents of overall dimen- ~ Check that wires are correctly secured to

sions lights; disconnect wiring then remove traspar- ‘connector before connecting wiring.

ents.

6. Remove three aft screws and washers securing | NOTE: As for “S “version, removal and installation

bumper. procedures of the rear bumper ara identical.

7. Remove two side forward screws and washers se-

curing bumper.

8 Remove side and aff trunk trims (see Group 66),

TRANSPARENT

(OVERALL

DIMENSIONS

eH

‘em

5S

EXTERNALTRIM

4

SPOILER (“S"” VERSION ONLY)

REMOVAL/INSTALLATION

1. Disconnect negative (-) lead from battery.

Remove trunk trim (see Group 66).

3. Remove four botts and washer securing spoiler to

trunk id,

4, Lower trunk lid and remove spoiler.

x

Repeat procedure in reverse order for installa-

tlon.

‘See Group 40 for removal and Installation

Of rear stop light.

REAR STOPLIOHT

184

SUN ROOF

DESCRIPTION

‘The sun-roof is of the metai-type. without sunshade

curtain, and can be completely opened or positioned to

"quarter light" position, which allows air to escape from

passenger compariment with kmited ventilation.

The sun roof consists of an outer metal panel and inner

trim with spoiler.

“The frame of sun root, complete with guides and siders

for movement, is located under root skin, in non-visible

(position: shders are connected to metal panel anditoinner

skin, and are actuated by flexible racks.

Flexible racks are driven by motorpinion gear andactuate

sliders movement,

When sun roof is open, spoiler automatically moves toa

position which corrects the air flow.

Water that eventually drips through sealof metalpanel, is

collected by four channels located on frame comers and

then is drained outboard through three four drain hoses,

which are routed inengine compartment (from drain ines)

and in the trunk (rear drain lines)

‘The sun roof is actuated by means of two pushbutions

focatadonthe centraldome. One switch controls opening

of the sun root, the other controls the closure, as well as

the rear edge of the sun roof.

75-16

EXTERNAL TRIM

75-17

EXTERNALTRIM

Es 1ea

OPERATION

‘SUN ROOF OPENING

Position (a) : Roof closed

‘When pushbutton switch is actuated to open position - The sliding pin follows the cam, and moves trom Mto

N position.

- Middle slider moves to aft position. - The cam, fixed to metal panel, moves downward.

Position (b): Roof lowered an aft side to

avold interierence with

body during opening.

= 75-18

16a a=

+ The metat panel rotates, lowering on ks rear side. + The middie slider moves rear slider rearward.

~The middie slider moves rearward and disengages | - The rear slider, connected to front slider with a rod,

ratchet of notched rod ratchet gear. rags It in ks movement.

- The ratchet gear lowers and allows front rearsliders | - Themetalpane! moves trom position (b} to tull-travel

to move. position (b’).

wet. suoma

PANEL Pw RATCHET GEAR

~2

\ \ — \ {

Front

SUDER cm

ROD (CONNECTION wo super NEAR SUDER

BETWEEN REAR AND FRONT

ao Suber

a Position (b') ; Roof open

‘SUN ROOF CLOSING | tS depressed to “quarter light" position:

- The middie slider moves toward front slider.

‘The operation is the reverse of opening. = The sliding pin moves forward, following cam profile.

+ The cam raises, together with metal panel.

OPENING TO “QUARTER LIGHT” POSITION = The metal panel opens to “quarter light" position.

With sun root in closed position, when the control switch

suns

wea Oi om —_—,

BETWEEN REAR AND.

FRONT SLER) woTeHED ROO

oe Position (e) : Roof open to “quarter light” position

75219

EXTERNALTRIM

Se

CLOSING FROM “QUARTER LIGHT POSITION”

The operation is the reverse of opening to “quarter light”

position

INNER TRIM AND SPOILER OPERATION

Inner trim

STRAP SLIDE

‘ne inner trim is connected to front slider by means of

strap slides, which allow manual operation of inner trim.

it necessary, regardless of metal panel position

75-20

164

Inner spotter

Root Closed

METAL PANEL,

HEUCAL SPANO,

NNER SPOILER

Roof open to “Quarter light” position

‘The inner spoiler is connected to metal panel coupler

fitings (one on each side) which maintain it in open

position even if metal panelis in “quarler light” position,

‘The closed positionot inner spoiler is assured by a roller

(one on each side) of middie slider sliding pin.

The tie-strap, connecting middie slider sliding pin to metal

panel, adjusts tension of metal helical spring in regard to

its position.

EXTERNAL TRIM

184

METAL PANEL 4. Slightly push downwards inner trim supports and

manually refit inner trim.

DISASSEMBLY 5. Close sun roof unt'l sliding pins are in position corre-

sponding to maximum straps slacnen ng

NOTE: Make sure that hands are ciean betore dis- | § Disconnect negave ()) lead from battery.

assembly (or reassembly) the metal panel. | 7 ®y operating as shownintigure, push tle-sirap guide

(€) onwards along strap sider, winning spring reac-

thon.

1. Open sun roo! to “quarter ight” postion. 8. Set rap tee trom sicing pin.

5 EE en ani vere 9. Repeat steps 7 and for other tie-strap.

isconnect innar spoiler from metal panel. 10. Remove screws and washers securing adjusting

plates (two each side) to metal panel.

- 11. Remove four adjusting plates.

CAUTION: 12, Remove metal panel complete with tie-strap guide

During movement of inner trim, avold inter-

ference with mobile rail.

and seal.

6-230. me

EXTERNALTRIM

REASSEMBLY

NOTE: Make sure that your hands are clean before

reassembly.

1. With inner trim in fullaft position, set sicies forward

toa maximum “quarter light” position.

2. Position metal panel, complete with tie-strap guide

and seal.

———_——— waa 75 22

164

»

install four adjusting piaies with screws andwashers.

Do not torque screws.

Close sun root. .

Perform sun root adjustment as described below.

Check sun-roof proper operation.

oop

CAUTION:

During movement of inner trim, avoid inter-

ference with mobile rail,

7. Manwally refit inner trim

8. Open sun roof to “quarter light" position

9. Push upwards inner spoiler.

10. Connect inner spoiler to metal pane! by coupler

fitting,

EXTERNAL TRIM

184

= In order to avoid vibrations vehicle run,

check felts for condition betore reassembly

metal panel. Replace felts as necessary.

- Check seal for condition betore reassembly

‘metal panel. Replace seal as necessary.

ADJUSTMENT

For coupling with the following procedures, two operators

are required: one operating from vehicle outside, the

‘other working inside the vehicle.

‘The extarnal operator lines up and matches each angie of

‘metal with sun roof frame, while the internal operator set

Position of adjusting plates and torque related bolts.

1. Check thatallcomers of metal panel are aligned with

frame and that metal panel is centered: adjust posi-

tion o plates as necessary.

2. Engage tie-straps on sliding pins.

3. Open and close sun root several times to check

” proper operation

4, Repeat agjusiment check

5. Torque adjusting plates bolts to prescribed values.

METAL PANEL SECURING

outs:

75-23

TIE-STRAP GUIDE AND METAL

PANEL SEAL

DISASSEMBLY/REASSEMBLY

NOTE: Make surethat yourhands are clean before

disassembly/reassembly.

Disassembly metal panel.

Disconnect retum springs from both tie strap guide.

Orit rivet strap uice to metal pane.

Remove strap guides.

H necessary, remove seal from metal panel.

o_ me

eee

‘TesTRAP

|

mut | LP

Lo SS

&

ST

sea

NOTE:

XTERNALTRIM

Check condition of anti-triction tans; replace

aS necessary.

Apply sealant, as indicated in figure, onto

seal groove before installation.

Aiter seal installation, its junction should be

Positioned halt-way on the front side.

The replacement seals are factory:

coated with sealant.

fa replacement seal Is installed, cut the

‘exceeding part.

+ For parts and/or components described in

other pages of same Group or in other

Groups, refer to related procedures and in-

formations.

164

SPOILER

DISASSEMBLY/REASSEMBLY

1. Open sun root.

2. Disconnect negative (-) lead trom battery

3. Remove front root-lamp.

4. Remove tworearscrews securing sun-root actuating

motor.

NOTE: Screws instep 4above,

in lower posttion,

78-28

EXTERNAL TRIM

16a

5. Remove two upper screws securing spoiler.

= =< anes

F DRT

rR

6 Using a drift, disengage side arms trom sliding

guides.

7. Remove spoiler.

=@=

|

[ag Repeat procedure in reverse order tor reas-

sembly.

75-25

SPOILER COMPONENTS

DISASSEMBLY/REASSEMBLY

1. Disassembly spoiler (refer to previous paragraph).

2, Remove retaining rings from pins connecting mobile

part to fixed part.

3. Removal pins and “o" rings that connect mobile part

to fixed part

4, Remove mobile part trom fixed part.

Remove retaining rings from pins securing side

arms.

6. Remove pins that secure side arms.

7. Withdraw side arms, complete with return springs,

from side of mobile part

8. Remove retum springs from side arms.

a

Repeat procedure in reverse order for reas-

sembly.

*—synee

RETURN

nN ne

N HOE AR

N

™

SS

“1 >

Pin

{SDE ARM

(ATTACHMENT) ——_og™

IETAINING

RING

FIKED PART

EXTERNALTRIM

164

ELECTRIC MOTOR

DISASSEMBLY/REASSEMBLY

NOTE: ff electric motor falls to operate, it is pos-

een

sible to move sun roo! to any required po-

sition by manually turing electric motor,

‘as described in paragraph “Manual Opera-

tion”.

Remove metal panel.

Remove two rear screw securing electric motor.

Remove front nut securing electric motor.

Remove bot that connects ground wire to chassis.

Disconnect wiring and ground wires from electric

motor.

Remove electric motor.

@ROUND wiRE.

SECURING BOLT 4 /

75-26

EXTERNAL TRIM

164

[ag - Perform timing of system before reassem MANUAL OPERATION

bly of electric motor.

~ For parts and/or components described in | 1. Pushcenter hub (a) of electric motor to allow manual

other pages of same Group or in other ‘operation.

Groups, referto related procedures andin | 2. Manually rotate gear of electric moter to set metal

formations. panal to desired position.

+ Check that wires are correctly secured to

‘connector before connecting wiring.

TIMING

1. Connect electric motorto a 12V DC source (battery)

and check that is at long full-trave! (corresponding to

close travel)

2. Manually set both sliding pins to M posilion as shown,

in figure.

3. Reassembly electric motor.

NOTE: Afterelectric motor has been reassembied,

check sun root for proper operation before

reinstalling metal panel.

75-27

EXTERNALTRIM

MOBILE RAIL

DISASSEMBLY/REASSEMBLY

4. Remove metal panel.

2. Remove two screws and washers securing mobile

3. Renove mobile rail

\ sonew

\ WASHER

X@

MOBILE Ral

ze

==

L

For parts andior components described in

other pages of same Group or in other Groups,

‘eter to related procedures and informations.

75 - 28

INNER TRIM

DISASSEMBLY/REASSEMBLY

1. Remove metal panel.

2. Manually set inner trim tully forward

3. Remove four trim sliding springs by means of a

punch.

ae

4, Remove inner trim.

+ Check that felt "F* installed on spring is in

good conditions: otherwise replace it to

avoid vibrations during vehicle 's run.

- Lubricate sliding spring after reassembly

with grease as indicated in figure.

For parls and/or components described in

other pages of same Group or in other

Groups, referto related procedures and in-

formations.

EXTERNAL TRIM:

{ea =e

FRAME 5. Remove forward bol that secures electric motor; re-

move also ground wire nut and disconnect wiring

REMOVAL from motor.

6. Remove trom, side and rear screws that secure

NOTE: Make sure that hands are clean before re- frame.

moving frame.

1. Disconnect negative (-) lead from battery.

2. Remove inner seal.

3. Remove torward, center and aft pillars tm and roof

trim (see Group 68)

4. Disconnect four drain lines from frame comers.

FORWARD, CENTER AND AFT

PILLARS TRI-ROOF TRIM

7 Remove trame trom vehicle.

INSTALLATION

NOTE: Make sure that hands are clean betore in-

stalling trame.

Position frame on vehicle.

Install front, side and rear screws that secure frame.

3. With inner trim in aft position, reassemble metal

panel,

»

CAUTION:

+ Apply pressure sensitive tape, 0.2 In (5

(mm) thick, on aft side before moving

metal panel.

If pressure sensitive tape interferes with

body work stiffening rail during metal

panel movement, Install washers (r) as

required between clips (s) and frame (on

rear side) and between frame and car

body (in central part). The total thickness:

installed In central part should be one -

third of thickness installed on rear side.

75-29

EXTERNALTRIM

164

4. Perform operational check. SLIDERS AND FLEXIBLE RACKS

5. Connect inner trim to metal panel.

6. Complete installation of sun root. DISASSEMBLY/REASSEMBLY

Remove complete irame from vehicie.

Posttion frame on tool.

Remove metal panal.

Remove inner trim.

Remove electric motor.

Remove mobile rail

1

2.

3.

4

5.

6.

NOTE: The following procedure applies to one or

both silders,

ADHESIVE TAPE

(Smm-0.2 In, thi

+ For parts and/or components described in

other pages of same Group or in other

Groups, refer to related procedures and

informations.

+ Check that wires are correctly secured to

connector before connecting wiring.

75-30

EXTERNAL TRIM

164 Bes

7. Depress on ratchet gear to release it from notched | NOTE: Rear silder is connected to front sliderby a

bar, fod.

8. Moved slider aftward by pulling on pin (k

9, Release ratchet gear. 13. Parllally withdraw middle slider.

10. Move slider fully rearward. 14. Remove retaining ring from sliding pin.

11. Remove att plug. 15. Remove sliding pin.

12. Withdraw rear slider. 16. Withdraw completely middle slider and flexible rack.

- 19, Remove retaining ring trom pin that connects front

CAUTION: slider to bracket.

A The complete disassembly of sliders, as | 20. Remove clip from pin.

per instruction below, should not be ac- | 21. Remove pin.

complished unless strictly necessary. 22. Remove front slider from bracket.

Particular care must be taken not to dam-

‘age front silderto an irrepalrabie condition, ~ Particular care must be taken during reas

sembly of front slider to avoid damage.

+ For parts and/or components described in

other pages of same Group or in other

17. Withdraw compietely front slider irom frame. Groups, refer to related procedures and

18. Disconnect at slider trom connecting rod. informations.

75-31

EXTERNALTRIM

16a

ews

75-32

EXTERNAL TRIM

634 —

TECHNICAL CHARACTERISTICS AND SPECIFICATIONS

TIGHTENING TORQUES

SUN ROOF

Metal panel securing screws: 2.9 10 3.7 ft. Ibs 4to5Nm

FLUIDS AND LUBRICANTS

Application Type | Name Quantity

Sliding guides of inner trim GREASE AMOCO-OPTIMOL

Optimoly-PasteWhite T

"SEALING COMPOUNDS

Application Type

‘Metal panel seal SEALANT

PRODUCTS FOR WINDSHIELD AND REAR WINDOW BONDING

Name Quantity

IVILSEALANT

WSC6 B51 006

‘Application Name Quantity

Body work primer Kit: ALFA ROMEO _

Glass primer P/N162.00.76.001.99

‘Sealing compound

Sealing compound canridge ALFA ROMEO

PYN 3521.00105.01

75-33

EXTERNALTRIM

ews

164

WINDSHIELD WASHER MIXTURE

Windshield washer mixture

@.9. WINDSHIELD

WASHER SOLVENT”,

Union Carbide Com.,

1209 - 34

Protection up to- 40°C/-40°F

Ready for use

75-34

EXTERNAL TRIM

TROUBLESHOOTING PROCEDURE

NOTE: One of the pos le inconveniences caused by the sun roof consists in an aerodynamic rustling causing a

disturbing rear noise at high speeds.

For a rapid solution, referto the troubleshooting conceming noise problems, Group 66 - INTERNAL TRIM.

75-35

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Alfa Romeo 164 - Group 40 - Electrical SystemDocument46 paginiAlfa Romeo 164 - Group 40 - Electrical Systemtecnoinc100% (1)

- Alfa Romeo 164 - Group 43 - On Board Instruments & Electronic DevicesDocument9 paginiAlfa Romeo 164 - Group 43 - On Board Instruments & Electronic Devicestecnoinc50% (2)

- Alfa Romeo 164 - Group 16 - Automatic TransmissionDocument66 paginiAlfa Romeo 164 - Group 16 - Automatic TransmissiontecnoincÎncă nu există evaluări

- Alfa Romeo 164 - Group 05 - Engine Electrical UnitsDocument43 paginiAlfa Romeo 164 - Group 05 - Engine Electrical UnitstecnoincÎncă nu există evaluări

- Alfa Romeo 164 - Group 07 - Cooling SystemDocument20 paginiAlfa Romeo 164 - Group 07 - Cooling SystemtecnoincÎncă nu există evaluări

- Alfa Romeo 164 - Group 12 - ClutchDocument14 paginiAlfa Romeo 164 - Group 12 - ClutchtecnoincÎncă nu există evaluări

- Alfa Romeo 164 - Group 01 - EngineDocument120 paginiAlfa Romeo 164 - Group 01 - Enginetecnoinc100% (1)

- Alfa Romeo 164 - V6 Turbo 1996Document41 paginiAlfa Romeo 164 - V6 Turbo 1996tecnoincÎncă nu există evaluări

- Alfa Romeo 164 - Group 00 - Complete CarDocument58 paginiAlfa Romeo 164 - Group 00 - Complete Cartecnoinc100% (1)

- Alfa Romeo 164 - Wiring Driagrams and Electrical Diagnosis ManualDocument955 paginiAlfa Romeo 164 - Wiring Driagrams and Electrical Diagnosis Manualtecnoinc80% (5)

- Alfa Romeo 164 - Group 56 - Hood & TrunkDocument9 paginiAlfa Romeo 164 - Group 56 - Hood & TrunktecnoincÎncă nu există evaluări

- Alfa Romeo 164 - V6 24V 2959Document47 paginiAlfa Romeo 164 - V6 24V 2959tecnoincÎncă nu există evaluări

- Alfa Romeo 164 - WelcomeDocument1 paginăAlfa Romeo 164 - WelcometecnoincÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- AutoKey ProgrammerDocument22 paginiAutoKey ProgrammerDaniel Asandei60% (5)

- Dodge Chrysler Cirrus Sebering 1999 Ja Parts CatalogDocument20 paginiDodge Chrysler Cirrus Sebering 1999 Ja Parts Catalogmichael100% (28)

- Dokumen - Tips Catalogo Sachs Equivalencias Amortiguadores 2013Document19 paginiDokumen - Tips Catalogo Sachs Equivalencias Amortiguadores 2013lucassanchezjose199Încă nu există evaluări

- TS501 V6.26 FunctionList AUDocument36 paginiTS501 V6.26 FunctionList AURichie YeÎncă nu există evaluări

- Ajnšpric Pumpe Katalog SlikeDocument138 paginiAjnšpric Pumpe Katalog SlikezoografÎncă nu există evaluări

- Kyb CatalogDocument166 paginiKyb Catalogjr_1988Încă nu există evaluări

- Mercedes G-Wagen W463 ServiceManualDocument341 paginiMercedes G-Wagen W463 ServiceManualJane TaylorÎncă nu există evaluări

- Código Descrição Preço Ash / LuporiniDocument5 paginiCódigo Descrição Preço Ash / LuporiniHomero TeixeiraÎncă nu există evaluări

- Marketing Strategy of BMW (Automobile Industry)Document74 paginiMarketing Strategy of BMW (Automobile Industry)Vaibhav KalraÎncă nu există evaluări

- IndexDocument7 paginiIndexSyed Atif Hasan MahmoodÎncă nu există evaluări

- Fuse Box Diagram Audi A8 - S8 (D3-4E 2008-2009)Document16 paginiFuse Box Diagram Audi A8 - S8 (D3-4E 2008-2009)jorge luis guevara martinezÎncă nu există evaluări

- Special Connectors For CAT501SDocument6 paginiSpecial Connectors For CAT501SHernan PosadaÎncă nu există evaluări

- Ansari Shanawaz Ayaz S-Class ProjectDocument93 paginiAnsari Shanawaz Ayaz S-Class ProjectAli Ahmed KhanÎncă nu există evaluări

- Catcm901 PDFDocument32 paginiCatcm901 PDFfjaristizabalÎncă nu există evaluări

- Carrera Katalog 2015 US DS Ansicht Final PDFDocument74 paginiCarrera Katalog 2015 US DS Ansicht Final PDFlauraÎncă nu există evaluări

- TruFlow Catalogue Ed 4 PDFDocument248 paginiTruFlow Catalogue Ed 4 PDFbachcongphuocÎncă nu există evaluări

- Producer Series Build Model ModelyearDocument45 paginiProducer Series Build Model ModelyearJimmy BobbyÎncă nu există evaluări

- Bentley BrochureDocument8 paginiBentley BrochurekingmanmaximusÎncă nu există evaluări

- 05 ContinentalDocument83 pagini05 ContinentalGabriela San PedroÎncă nu există evaluări

- Auger CabinDocument442 paginiAuger CabinOsw GalatiÎncă nu există evaluări

- Immokeys AutelDocument39 paginiImmokeys AutelMCS Diagnostix100% (2)

- Tabela Carga de GásDocument6 paginiTabela Carga de GásClevio Marques de PaulaÎncă nu există evaluări

- ZP Cat Ebook Oil-Change-Kits-Pc in 2013Document80 paginiZP Cat Ebook Oil-Change-Kits-Pc in 2013Israel TomalaÎncă nu există evaluări

- Benefits: For The Shop... For The Customer..Document18 paginiBenefits: For The Shop... For The Customer..Helio RodriguesÎncă nu există evaluări

- Flex Car ListDocument692 paginiFlex Car ListOmar BeshrÎncă nu există evaluări

- HSD 9409Document464 paginiHSD 9409Pablo SastreÎncă nu există evaluări

- Comparatives ExercisesDocument2 paginiComparatives Exercises382294Încă nu există evaluări

- Empfehlungsliste PKW Recommendation List Car: Lukoil GenesisDocument52 paginiEmpfehlungsliste PKW Recommendation List Car: Lukoil GenesisRusu AndrianÎncă nu există evaluări

- Track: ST Pete - Category D Appendix A - v117: Balance of Performance FIA GT3Document5 paginiTrack: ST Pete - Category D Appendix A - v117: Balance of Performance FIA GT3jlee_296737Încă nu există evaluări