Documente Academic

Documente Profesional

Documente Cultură

Adjust valves and unit injectors on Volvo D16F engine

Încărcat de

MabelRinaldiDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Adjust valves and unit injectors on Volvo D16F engine

Încărcat de

MabelRinaldiDrepturi de autor:

Formate disponibile

Volvo Trucks North America

Greensboro, NC USA

Service Bulletin

Trucks

Date

Group

No.

Page

3.2007

214

90

1(20)

Valves and Unit Injectors

Adjustment

D16F

Valves and Unit Injectors, Adjustment

W2005773

This information covers the correct procedure for adjusting the valves and unit injectors

on the Volvo D16F engine.

Contents

Special Tools page 2

Valves and Unit Injectors, Adjustment page 3

Note: Information is subject to change without notice.

Illustrations are used for reference only and may differ slightly from the actual

vehicle being serviced. However, key components addressed in this information are

represented as accurately as possible.

PV776-20177390

USA23060.ihval

Volvo Trucks North America

Service Bulletin

D

Date

Group

No.

Page

3.2007

214

90

2(20)

Tools

Special Tools

For special tools ordering instructions, refer to Tool Information, group 08.

W0002414

85111493

Dial Indicator Extension

T0010788

88800014

Flywheel Turning Tool

9989876

Dial Indicator

W0001790

9999696

Magnetic Base

85111377

Feeler Gauge Set

Volvo Trucks North America

Service Bulletin

Date

Group

No.

Page

3.2007

214

90

3(20)

Service Procedures

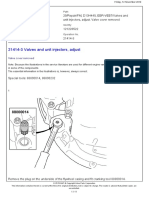

2140-05-02-03

Valves and Unit Injectors, Adjustment

You must read and understand the precautions and

guidelines in Service Information, group 20, "General

Safety Practices, Engine" before performing this

procedure. If you are not properly trained and certified

in this procedure, ask your supervisor for training

before you perform it.

Special tools: 85111493, 88800014,

9989876, 9999696, 85111377

1

Apply the parking brake and place the shift lever

in neutral.

2

Remove all cables from ground (negative) battery

terminals to prevent personal injury from electrical shock.

W2003815

3

Disconnect and remove the air filter restriction gauge

wiring harness from air filter housing.

W2003861

Volvo Trucks North America

Service Bulletin

Date

Group

No.

Page

3.2007

214

90

4(20)

4

Unplug the air temperature sensor wiring harness

connector. Remove the lock tab and separate the

connector from the sensor. Remove the sensor harness

clamp from the main fresh air pipe.

W2004720

5

Loosen the hose clamp and disconnect the air

compressor air inlet pipe from the main fresh air pipe.

W2004719

6

Loosen the clamps securing the main fresh air pipe at the

air filter housing and the turbocharger air inlet elbow.

Remove the pipe from the engine.

W2006005

Volvo Trucks North America

Service Bulletin

Date

Group

No.

Page

3.2007

214

90

5(20)

7

Remove the fasteners at the top of the air filter housing

and remove the housing from the cab.

W2003858

8

Remove the coupling hose clamp securing the air

inlet pipe at the air compressor. Remove the clamp

bracket fasteners at the cylinder head and remove the air

compressor air inlet pipe from the engine.

W5001571

9

Disconnect the crankcase ventilation tube from the side of

the valve cover. Remove the P-clamp securing the tube to

the intake manifold and position the tube out of the way.

W2005747

Volvo Trucks North America

Service Bulletin

Date

Group

No.

Page

3.2007

214

90

6(20)

10

Disconnect the air discharge pipe at the air compressor

and remove the clamp bracket securing the pipe to the

intake manifold. Position the pipe out of the way.

W5001572

11

Remove the engine wiring harness support bracket from

the front of the valve cover.

W2004679

12

Remove the spring-loaded attaching bolts from the

valve cover.

T2020552

13

Lift and remove the valve cover. Rotate the valve cover as

needed, to clear the camshaft gear and damper.

Note: Depending on the chassis, the engine cover may

need to be removed to provide clearance for removal of

the valve cover.

Volvo Trucks North America

Service Bulletin

Date

Group

No.

Page

3.2007

214

90

7(20)

14

Remove the plug from the lower right side of the flywheel

housing and install flywheel turning tool 88800014.

Note: Ensure the turning tool is well greased before

attempting to turn the flywheel.

88800014

W0002368

Volvo Trucks North America

Service Bulletin

Date

Group

No.

Page

3.2007

214

90

8(20)

Valve and Unit Injector Adjustment Procedure

15

On engines equipped with an engine compression brake,

loosen the fasteners retaining the leaf springs to release

spring tension on the VCB rocker arms.

T2022951

16

Using the flywheel turning tool, turn the engine in the

normal direction of rotation to the next camshaft marking

for the adjustment of the valves and unit injector.

Camshaft settings for adjustment of the valves and unit

injectors are shown in the following chart.

Markings 16 apply to adjustment of inlet valves

and unit injectors.

Markings E1E6 apply to adjustment of exhaust

valves and VCB rockers.

Camshaft Markings

Cam

Position

Injector

Intake

E6

T2022952

V3

E5

1

E1

4

E4

2

VCB

E2

6

Exhaust

For the camshaft setting in this example (5 | E6), the inlet

valves and unit injector can be adjusted for cylinder No.

5, and the exhaust valves (including VCB rockers) for

cylinder No. 6.

Volvo Trucks North America

Service Bulletin

Date

Group

No.

Page

3.2007

214

90

9(20)

Inlet Valve Adjustment

17

With the engine cold, check the inlet valve clearance for

cylinder No. 5 by pushing down on the back of the rocker

and inserting a feeler gauge of the proper specification

between the bridge and the adjustment screw. If the

clearance is not within specification, 0.30 0.05 mm

(0.012 0.002 inch), loosen the locknut on the rocker and

adjust the plunger as required. Once the adjustment is

within specification, hold the adjusting screw in place and

tighten the locknut to 38 4 Nm (28 3 ft-lb).

38 4 Nm

(28 3 ft-lb)

W2005814

18

Recheck the valve clearance after the nut is tightened.

Note: Mark the rocker arm with a marker pen as each

adjustment is completed.

Unit Injector Adjustment

19

To adjust the injector at the same cylinder location, loosen

the locknut and back off the adjusting screw until it no

longer makes contact.

W2005816

20

Turn the adjusting screw in until it contacts the unit

injector (zero clearance).

Volvo Trucks North America

Service Bulletin

Date

Group

No.

3.2007

214

90

Page

10(20)

21

Tighten the adjusting screw an additional 4 flats or 240

degrees of clockwise rotation.

T2022954

22

Torque-tighten the adjusting screw locknut to 52 4

Nm (38 3 ft-lb).

52 4 Nm

(38 3 ft-lb)

Exhaust Valve Adjustment

23

At the current camshaft setting (5 | E6 in this example),

adjust the exhaust valves for cylinder No. 6.

T2022952

Volvo Trucks North America

Service Bulletin

Date

Group

No.

3.2007

214

90

Page

11(20)

24

Loosen the locknut (A) and turn the bridge adjusting

screw out so that there is clearance between the screw

and the valve stem end.

T2023642

25

Press down on the center of the bridge and tighten

the adjusting screw (B) until it just contacts the valve

stem end. Then, tighten the screw an additional 1

flat or 60 20 degrees.

26

Tighten the locknut to 38 4 Nm (28 3 ft-lb).

38 4 Nm

(28 3 ft-lb)

27

Check the exhaust rocker valve clearance. Push down

on the back of the exhaust rocker and measure the

clearance between the bridge and the plunger, using

a feeler gauge. The clearance should be 0.60 0.05

mm (0.024 0.002 inch).

T2022958

Volvo Trucks North America

Service Bulletin

Date

Group

No.

3.2007

214

90

Page

12(20)

28

If the exhaust rocker requires adjustment, loosen the

locknut on the rocker. Place a 0.60 mm (0.024 inch)

feeler gauge between the bridge and plunger and adjust

the screw accordingly.

Note: After adjustment, leave the feeler gauge in place. It

is required for adjustment of the VCB rocker clearance.

W2005812

29

Hold the plunger adjusting screw in place to prevent it

from turning and tighten the locknut to 38 4 Nm (28

3 ft-lb).

38 4 Nm

(28 3 ft-lb)

VCB Rocker Adjustment

30

With the exhaust valve adjustment completed, check the

VCB rocker clearance for cylinder No. 6.

31

Loosen the locknut (A) on the VCB rocker adjusting screw

(B). Then, place a dial indicator in position on the feeler

gauge (still in place from exhaust valve adjustment) and

set the gauge to zero.

W2006207

Volvo Trucks North America

Service Bulletin

Date

Group

No.

3.2007

214

90

Page

13(20)

32

Turn the adjusting screw so that it removes all clearance

in the ball socket. Continue to tighten the adjusting screw

until the dial indicator shows that the valve bridge has

moved down 0.25 0.05 mm (0.010 0.002 inch).

33

Back out the adjusting screw 2 turns plus 1 flat or

780 degrees.

34

Hold the adjusting screw to prevent it from turning and

tighten the locknut to 52 4 Nm (38 3 ft-lb).

52 4 Nm

(38 3 ft-lb)

35

Remove the dial indicator and feeler gauge.

36

Using a 4.2 mm (0.165 inch) feeler gauge, 85111377,

check the VCB rocker arm clearance by placing the shim

and feeler gauge between the rocker arm roller and the

cam lobe. The clearance should be 4.2 0.10 mm (0.165

0.004 inch). If not within specification, repeat the VCB

rocker adjustment procedure.

85111377

W2005815

Volvo Trucks North America

Service Bulletin

Date

Group

No.

3.2007

214

90

Page

14(20)

Adjusting Remaining Cylinders

37

Repeat the preceding procedure to adjust all other unit

injector and valve locations by rotating the engine to the

next nearest camshaft mark. Adjust the inlet, exhaust and

unit injectors using the pattern outlined in the chart below.

Use the flywheel turning tool 88800014 to advance the

engine to the next setting.

88800014

W0002368

38

Note: Ensure the turning tool is well greased before

attempting to turn the flywheel.

Camshaft Markings

Cam

Position

Injector

Intake

E6

3

E3

E5

1

E1

4

E4

2

VCB

E2

6

Exhaust

Volvo Trucks North America

Service Bulletin

Date

Group

No.

3.2007

214

90

Page

15(20)

39

After all unit injectors and valves have been checked

and adjusted, tighten all mounting screws on the VCB

rocker leaf springs. Tighten the screws to specification,

25 3 Nm (19 2 ft-lb), using an Allen wrench and

suitable torque wrench.

25 3 Nm

(19 2 ft-lb)

W2005845

40

Clean and inspect the mating surface of the valve cover

gasket. Replace the gasket if it is damaged or deformed.

41

Clean the valve cover contact surface on the cylinder

head and the timing cover. All surfaces should be

completely free of grease and oil.

42

Apply a 2 mm (0.079 inch) bead of Volvo sealant to the

area where the timing cover and the cylinder head meet.

This parting line is on both sides of the cylinder head.

W2005157

43

Carefully position the valve cover on the cylinder head,

making sure that the seal remains properly seated.

Note: The valve cover must be installed within 20

minutes of applying sealant to the parting line area.

Volvo Trucks North America

Service Bulletin

Date

Group

No.

3.2007

214

90

Page

16(20)

44

Install the spring-loaded attaching bolts in the valve cover.

Tighten the attaching bolts to 24 3 Nm (18 2 ft-lb) in

the sequence shown.

Note: The bolt spring provides even tension on the

valve cover gasket.

24 3 Nm

(18 2 ft-lb)

T2020552

45

If removed for clearance, install the engine cover.

46

Remove the flywheel turning tool, 88800014, and

reinstall the dust plug.

88800014

W0002368

47

Place the engine electrical wiring harness in position

at the front of the valve cover and install the harness

support brackets. Securely tighten the bolts.

Note: Ensure the same bolts removed at disassembly

are reinstalled in their respective bracket locations.

Damage to the valve cover will result if bolts that are too

long are installed in the wrong locations.

W2004679

Volvo Trucks North America

Service Bulletin

Date

Group

No.

3.2007

214

90

Page

17(20)

48

Connect the air discharge line to the air compressor

and install the clamp bracket securing the line to the

intake manifold.

W5001572

49

Inspect the crankcase ventilation tube O-ring and replace

if necessary.

W2004681

50

Place the ventilation tube in position at the side of the

valve cover and install the mounting bolts in the tube

flange. Tighten the bolts to 24 3 Nm (18 2 ft-lb). Install

the P-clamp to secure the tube to the intake manifold.

Note: Ensure that the bolts removed at disassembly are

reinstalled in the same location. Damage to the valve

cover will result if the bolts installed are too long.

24 3 Nm

(18 2 ft-lb)

W2005747

Volvo Trucks North America

Service Bulletin

Date

Group

No.

3.2007

214

90

Page

18(20)

51

Place the air compressor fresh air inlet pipe in position

over the valve cover and connect the pipe to the coupling

hose at the compressor. Tighten the coupling hose clamp

and install the clamp brackets to secure the pipe.

W5001571

52

Place the air filter housing in position against the cab and

install the two mounting bolts at the top of the housing.

W2003858

53

Install the main fresh air pipe between the air filter

housing and the turbocharger air inlet elbow. Position the

clamps and tighten them securely.

W2006005

Volvo Trucks North America

Service Bulletin

Date

Group

No.

3.2007

214

90

Page

19(20)

54

Connect the air compressor air inlet pipe to the main

fresh air pipe and tighten the hose clamp securely.

W2004719

55

Reattach the air temperature sensor harness connector

to the sensor (located on the fresh air pipe). Push in the

lock tab and install a new strap to secure the connector.

Install the bolt and clamp to secure the sensor harness to

the fresh air pipe.

W2004720

56

Install the clamps to secure the restriction gauge wiring

harness to the air filter housing.

W2003861

Volvo Trucks North America

Service Bulletin

Date

Group

No.

3.2007

214

90

Page

20(20)

57

Connect the wiring harness to the air restriction gauge.

W2004249

58

Install all previously removed cables to the ground

(negative) battery terminals.

W2003815

59

Start the engine and check for leaks. Once normal

operating temperature is attained, let the engine idle for

an additional five minutes. During this time, the EECU

will perform its own cylinder balancing, resulting in

smooth engine idling.

Note: During cylinder balancing, do not use any form of

power-consuming equipment, such as power take-off or

air conditioning.

60

After engine shutdown, replenish fluids as necessary.

S-ar putea să vă placă și

- Adjust Valves and Unit InjectorsDocument4 paginiAdjust Valves and Unit InjectorsSherzad Chem100% (3)

- 2 Valves and Injectors Adjustment VEBDocument21 pagini2 Valves and Injectors Adjustment VEBRuju RujuÎncă nu există evaluări

- Valves and Unit Injectors, AdjustmentDocument17 paginiValves and Unit Injectors, AdjustmentRolando Mancilla Flores91% (58)

- Volvo d12 Workshop Manual Less Specifications AbbyDocument709 paginiVolvo d12 Workshop Manual Less Specifications Abbykoaa8597% (60)

- Veb PDFDocument11 paginiVeb PDFIzz BaharÎncă nu există evaluări

- Lubrication and Oil SystemDocument6 paginiLubrication and Oil SystemIzz BaharÎncă nu există evaluări

- Sleeve Injector Cooper Volvo D13Document16 paginiSleeve Injector Cooper Volvo D13cheolll100% (2)

- Valve and Injector Adjustment With EPG PDFDocument9 paginiValve and Injector Adjustment With EPG PDFFranky Fernandez0% (1)

- Camshaft, ServiceDocument31 paginiCamshaft, ServiceIzz Bahar100% (7)

- Timing Cover d13Document25 paginiTiming Cover d13SsÎncă nu există evaluări

- Volvos I - ShiftDocument60 paginiVolvos I - ShiftStephenson100% (8)

- Volvo d12d Valve AdjustmentDocument7 paginiVolvo d12d Valve Adjustmentali78% (9)

- Valve and Injector Adjustment With EPG D12, D12A, D12B, D12CDocument9 paginiValve and Injector Adjustment With EPG D12, D12A, D12B, D12CRioga Rioga100% (1)

- Volvo D13B Camshaft Replacement GuideDocument37 paginiVolvo D13B Camshaft Replacement Guidecheolll100% (3)

- Service Bulletin Trucks: EngineDocument46 paginiService Bulletin Trucks: EngineAndrey GaivoronskyÎncă nu există evaluări

- Volvo Trucks North America Fuel System Design and FunctionDocument12 paginiVolvo Trucks North America Fuel System Design and FunctionEduardo Pai Tocarlo90% (40)

- BooksrvtDocument27 paginiBooksrvtGabriel Balcazar100% (4)

- 21414-3 Valves and Unit Injectors, AdjustDocument11 pagini21414-3 Valves and Unit Injectors, AdjustTeguh Imam Adri100% (1)

- VOLVO D13 Main BearingDocument3 paginiVOLVO D13 Main BearingHarsimranSidhu67% (3)

- Volvo Auto ShiftDocument350 paginiVolvo Auto Shiftsengottaiyan100% (6)

- Valves and JAK, AdjustDocument6 paginiValves and JAK, AdjustSherzad ChemÎncă nu există evaluări

- Volvo cylinder head replacement guideDocument29 paginiVolvo cylinder head replacement guideCEVegaO100% (2)

- Cylinder Compression, Manual Test D12DDocument16 paginiCylinder Compression, Manual Test D12DHamilton Miranda100% (1)

- 431-168 Input Shaft, Overhaul FM9, FM12, FH12, FH16, FH, FM PDFDocument7 pagini431-168 Input Shaft, Overhaul FM9, FM12, FH12, FH16, FH, FM PDFautoeletricamalaquiaÎncă nu există evaluări

- Service Bulletin Trucks: Valves and Engine Injectors, AdjustmentDocument13 paginiService Bulletin Trucks: Valves and Engine Injectors, Adjustmentاحمد ابو عبدالله100% (1)

- Valve and Injector Adjustment With VEBDocument9 paginiValve and Injector Adjustment With VEBFranky Fernandez100% (1)

- Service Bulletin Trucks: SpecificationsDocument53 paginiService Bulletin Trucks: SpecificationsGustavo ViñasÎncă nu există evaluări

- 431-305 Main Shaft, OverhaulDocument18 pagini431-305 Main Shaft, Overhauljmbad2100% (3)

- Volvo Truck Fuel Bleeding GuideDocument2 paginiVolvo Truck Fuel Bleeding GuideSherzad Chem100% (1)

- VOLVO Oil Pump Replacement D13Document13 paginiVOLVO Oil Pump Replacement D13Miguel Angel Sancho100% (1)

- Volvo d12d TimingDocument9 paginiVolvo d12d Timingali100% (1)

- Volvo Engine BrakeDocument7 paginiVolvo Engine BrakeIzz Bahar100% (1)

- Engine Brake, Fault TracingDocument21 paginiEngine Brake, Fault TracingWilson Bueno97% (36)

- Service Manual Trucks: Volvo 5.7, 6.7 Ton Front Axle VTDocument56 paginiService Manual Trucks: Volvo 5.7, 6.7 Ton Front Axle VTErnesto Turpo50% (2)

- Valves Adjustment Cummins B SeriesDocument4 paginiValves Adjustment Cummins B Seriesroy cayabyab100% (1)

- Engine Specifications GuideDocument94 paginiEngine Specifications GuideGeorge Jhonson83% (90)

- Volvo D12D EspecificacionDocument42 paginiVolvo D12D EspecificacionSilas F Pimenta92% (72)

- FM, FH - Gearbox RemovedDocument41 paginiFM, FH - Gearbox RemovedSlVÎncă nu există evaluări

- Cajas en InglesDocument25 paginiCajas en InglesJose sQ100% (1)

- Check for Air in Fuel System on Volvo D11, D13, D16 EnginesDocument16 paginiCheck for Air in Fuel System on Volvo D11, D13, D16 EnginesIzz Bahar100% (3)

- 431-228 I-Shift Generation C Design and Function PDFDocument31 pagini431-228 I-Shift Generation C Design and Function PDFJosiney Hungaro CardosoÎncă nu există evaluări

- FH FM GearboxesDocument16 paginiFH FM GearboxesKoper93% (29)

- Volvo I ShiftDocument2 paginiVolvo I ShiftHugh Sago67% (3)

- Volvo Truck Sensors - Fuel, Oil, Boost, EGR, Coolant, Humidity & Engine SpeedDocument1 paginăVolvo Truck Sensors - Fuel, Oil, Boost, EGR, Coolant, Humidity & Engine Speedram_thriveni100% (1)

- Injection Pump, Setting On EngineDocument2 paginiInjection Pump, Setting On EngineSherzad Chem86% (7)

- Volvo d13 Engine enDocument12 paginiVolvo d13 Engine enMelvin Cotrado89% (46)

- Camshaft Wear, CheckDocument4 paginiCamshaft Wear, CheckIzz BaharÎncă nu există evaluări

- ESPECIFICACIONES D12C Motor VolvoDocument44 paginiESPECIFICACIONES D12C Motor VolvoErika Salinas100% (4)

- Dokumen - Tips Volvo d13f Workshop Manual 20155Document94 paginiDokumen - Tips Volvo d13f Workshop Manual 20155김장운Încă nu există evaluări

- DAF XF, XE Engine PDFDocument336 paginiDAF XF, XE Engine PDFalex6696669692% (26)

- Cylinder Balancing, Fault TracingDocument8 paginiCylinder Balancing, Fault TracingIzz BaharÎncă nu există evaluări

- 2013-12-09 220734 Mack mp8 Valve and Injector Adj pv776-89119132Document13 pagini2013-12-09 220734 Mack mp8 Valve and Injector Adj pv776-89119132Ricardo75% (4)

- PV776-20 006218Document9 paginiPV776-20 006218Benjamin Miranda FloresÎncă nu există evaluări

- Cambio Arbol de LevasDocument12 paginiCambio Arbol de LevasgenaroÎncă nu există evaluări

- Actuator Variable Geometry Turbocharger ReplacementDocument11 paginiActuator Variable Geometry Turbocharger ReplacementZoltán Szecsődi100% (1)

- Flow Doc1Document6 paginiFlow Doc1Jozef100% (1)

- TSB Ajuste Válvulas e InyectorDocument13 paginiTSB Ajuste Válvulas e InyectorMASTERTECH_01100% (1)

- Volvo D13H Shop Armed Vol2Document34 paginiVolvo D13H Shop Armed Vol2Juan José AldanaÎncă nu există evaluări

- Guide to disassembling and reassembling a powershift transmissionDocument36 paginiGuide to disassembling and reassembling a powershift transmissionFrancisco Mariños100% (1)

- Engine Alternator Repower GiudeDocument64 paginiEngine Alternator Repower Giudedrishk100% (2)

- Circuitos Freno - KNORRDocument352 paginiCircuitos Freno - KNORRPaulo Jorge Oliveira100% (6)

- Construir Antena Wifi Con Adaptador Usb by PepesitoDocument61 paginiConstruir Antena Wifi Con Adaptador Usb by Pepesitogarcia1976100% (2)

- Operation of SRS Airbag ComponentsDocument4 paginiOperation of SRS Airbag Componentsenzo7259Încă nu există evaluări

- SCRDocument8 paginiSCRenzo7259Încă nu există evaluări

- 6-Pin Wire Harness Assembly Installation GuideDocument2 pagini6-Pin Wire Harness Assembly Installation GuideMabelRinaldiÎncă nu există evaluări

- Engine Alternator Repower GiudeDocument64 paginiEngine Alternator Repower Giudedrishk100% (2)

- Manual Dish 12.1lbDocument17 paginiManual Dish 12.1lbMabelRinaldiÎncă nu există evaluări

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- CobraDocument4 paginiCobraMabelRinaldiÎncă nu există evaluări

- Operation of SRS Airbag ComponentsDocument4 paginiOperation of SRS Airbag Componentsenzo7259Încă nu există evaluări

- Carte Tehnica FORD Focus 2001Document296 paginiCarte Tehnica FORD Focus 2001essoxlucius100% (6)

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Allison T270 Series PDFDocument2 paginiAllison T270 Series PDFMabel Graciela LazzariÎncă nu există evaluări

- 30-547841 enDocument168 pagini30-547841 enctorres_505746100% (1)

- D85E-SS-2A-E brake pedal parts listDocument2 paginiD85E-SS-2A-E brake pedal parts listFachrieÎncă nu există evaluări

- 38, 44, 52, 57, 68H and SBS Cone CrushersDocument4 pagini38, 44, 52, 57, 68H and SBS Cone Crushersjuanandres_martinez100% (2)

- Lista de Precios Nexxt InfrastructureDocument15 paginiLista de Precios Nexxt InfrastructureMarco Antonio RubinaÎncă nu există evaluări

- WB LS10Document12 paginiWB LS10Winny Winer DujmićÎncă nu există evaluări

- 2009ChryslerJourneyStudentGuide Transmissions PDFDocument70 pagini2009ChryslerJourneyStudentGuide Transmissions PDFEd Kruse100% (2)

- Massey Ferguson 5435 TRACTOR (TIER 3) Service Parts Catalogue Manual (Part Number 3906177)Document18 paginiMassey Ferguson 5435 TRACTOR (TIER 3) Service Parts Catalogue Manual (Part Number 3906177)bvk2980022Încă nu există evaluări

- Generador Turbina v47Document16 paginiGenerador Turbina v47Jorge Espinoza100% (1)

- Disclosure To Promote The Right To InformationDocument66 paginiDisclosure To Promote The Right To Information2313400% (1)

- Ball PistonDocument15 paginiBall PistonNm5793100% (1)

- Internal Combustion Engines GuideDocument216 paginiInternal Combustion Engines GuideRohit ThoratÎncă nu există evaluări

- NIT Silchar's Semi Floating Suspension System Mini ProjectDocument30 paginiNIT Silchar's Semi Floating Suspension System Mini ProjectFarhanÎncă nu există evaluări

- Ch.1 Solucionario Mechanisms and Dynamics of MachineryDocument54 paginiCh.1 Solucionario Mechanisms and Dynamics of MachineryNico MingoÎncă nu există evaluări

- Catalogue No: Engine Type: Engine NoDocument210 paginiCatalogue No: Engine Type: Engine NoOğuz Kağan ÖkdemÎncă nu există evaluări

- Manual Rav4 2009Document222 paginiManual Rav4 2009Jhimmy ZuritaÎncă nu există evaluări

- Schedule 80 - PVC: Pressure FittingsDocument12 paginiSchedule 80 - PVC: Pressure FittingsCesar PreciadoÎncă nu există evaluări

- Tightening Torques D12DDocument5 paginiTightening Torques D12DAlexÎncă nu există evaluări

- KPI ProcurementDocument33 paginiKPI ProcurementArdy AntÎncă nu există evaluări

- New Holland Spare Replacement PartsDocument39 paginiNew Holland Spare Replacement PartstomÎncă nu există evaluări

- Reciprocating Compressor IIDocument66 paginiReciprocating Compressor IIAli O Dalki100% (1)

- Gear TrainsDocument99 paginiGear TrainskeerthivÎncă nu există evaluări

- P185WJD-T4i-D75 Parts 10-04-11Document138 paginiP185WJD-T4i-D75 Parts 10-04-11Aurora Maria Tejada LondoñoÎncă nu există evaluări

- Removing Reinstalling and Aligning The Main Drive AssemblyDocument4 paginiRemoving Reinstalling and Aligning The Main Drive Assemblykostas sanÎncă nu există evaluări

- Fz150 V-Ixion Rear WheelDocument2 paginiFz150 V-Ixion Rear Wheelajoilham100% (1)

- Manitowoc Cranes Machine Component IndexDocument961 paginiManitowoc Cranes Machine Component Indexpedro northÎncă nu există evaluări

- CRW02 - Spur Gear - Eng VerDocument54 paginiCRW02 - Spur Gear - Eng VerpruthvirajÎncă nu există evaluări

- 2007 Land Rover Defender Workshop ManualDocument1.213 pagini2007 Land Rover Defender Workshop ManualIonut Boczar95% (22)

- Training Kubota 03M Serie 2008 Bomag EnglischDocument64 paginiTraining Kubota 03M Serie 2008 Bomag EnglischJulio Alvarado MoralesÎncă nu există evaluări

- CG938HPartsmanual SpecImport Khabarovsk PDFDocument166 paginiCG938HPartsmanual SpecImport Khabarovsk PDFCharly RamosÎncă nu există evaluări