Documente Academic

Documente Profesional

Documente Cultură

032-Procedure For Shop and Field Painting Work On Site PDF

Încărcat de

Köksal PatanDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

032-Procedure For Shop and Field Painting Work On Site PDF

Încărcat de

Köksal PatanDrepturi de autor:

Formate disponibile

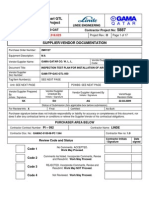

Pearl GTL

Project

Shell Project No: HP-3000-QAT

Project Document Number: T- 4.250.916

Purchase Order Number:

2MH127

Tag/Item Number(s):

N/A

Unit(s):

ASU

PCWBS:

LINDE ENGINEERING

Contractor Project No:

Project Rev.: B

Page 2 of 22

5887

QATAR SHELL GTL PROJECT (PEARL)

C2 AIR SEPARATION UNITS CONSTRUCTION

05.10.08

Ready For Construction

SK

EO

AG

RFC

24.04.08

Ready For Construction

BR

UA

ZG

RFC

04.12.07

Issued for Company comments

BR

AU/MC

ZG

ICC

24.11.07

Issued for Review

BR

AU/MC

ZG

IFR

18.11.07

Issued for Internal Review

BR

AU/MC

ZG

IIR

Date

Description

GAMA

Rev.

No.

Project

Rev

No.

Prepared Checked Approved

By

By

By

ORIGINATOR

Status

Document Title:

LINDEGINEERING AG

QUALITY CONTROL PROCEDURE FOR SHOP AND

FIELD PAINTING WORK ON SITE

Document No.

Contractor

Gama Qatar Co. W. L. L.

LOC470

GAM

PRO

QAC

GTL

032

Org.

Code

Doc.

Type

Disc.

Code

Geogr.

Area

Seq.

No

Rev.

No

Project Document Number: T-4.250. 916

Vendor Code

Rev No: B

Q A T A R

Doc. Title

PROCEDURE FOR SHOP AND FIELD PAINTING WORK ON SITE

Doc No

GAM-QCP-QAC-GTL-032, REV-E

DATE:

06.10.08

TABLE OF CONTENTS

1.

SCOPE _____________________________________________________________________________ 5

2.

PURPOSE __________________________________________________________________________ 5

3.

HSSE ______________________________________________________________________________ 5

4.

REFERENCE _______________________________________________________________________ 5

5.

DEFINITIONS ______________________________________________________________________ 6

6.

RESPONSIBILITIES _________________________________________________________________ 6

7.

PROCEDURE _______________________________________________________________________ 7

7.1.

Safety _________________________________________________________________________________ 7

7.2.

Qualification ___________________________________________________________________________ 7

7.3.

Pre blast ( shop and field ) ______________________________________________________________ 7

7.4.

Surface preparation ( shop and field ) above ground __________________________________________ 7

7.5.

Surface preparation ( shop and field ) underground __________________________________________ 8

7.6.

Paint storage ___________________________________________________________________________ 9

7.7.

Painting mixing _________________________________________________________________________ 9

7.8.

Weather conditions _____________________________________________________________________ 10

7.9.

Masking ______________________________________________________________________________ 11

7.10.

Pre coating cleaning ________________________________________________________________ 11

7.11.

Priming (shop and field) ______________________________________________________________ 12

7.12.

Painting ____________________________________________________________________________ 12

7.13.

Repair of damage coating _____________________________________________________________ 13

7.14.

Identification marking job stencil _____________________________________________________ 14

8.

QUALITY CONTROL ________________________________________________________________ 14

9.

INSPECTION RECORD ______________________________________________________________ 15

9.1.

SHOP BLASTING AND PRIMING _______________________________________________________ 15

9.2.

SHOP PAINTING _____________________________________________________________________ 15

9.3.

FIELD PAINTING OF ABOVE GROUND PIPING _________________________________________ 16

9.4.

FIELD PAINTING OF UNDERGROUND PIPING__________________________________________ 16

10.

STORAGE AND TRANSPORTATION OF PAINTED PIPES / SPOOLS ____________________ 16

11.

ATTACHMENTS __________________________________________________________________ 17

T-4.250.916 Rev. B

Page 4 of 22

Q A T A R

Doc. Title

PROCEDURE FOR SHOP AND FIELD PAINTING WORK ON SITE

Doc No

GAM-QCP-QAC-GTL-032, REV-E

DATE:

06.10.08

1. SCOPE

This procedure covers the Quality Control activity for Painting work by either GAMA Qatar

and/or GAMA Qatars subcontractor and is applicable to underground and above ground

shop and field painting at C2 ASU PEARL GTL PROJECT.

2. PURPOSE

The purpose of this procedure is to define the painting application methods, inspection and

documentation of underground and above ground shop and field painting. This procedure

provides general guidelines. The painting application is governed by specifications and paint

manufacture recommendations.

3. HSSE

All works shall be in compliance with the State of Qatar laws and regulations, Ras Laffan

Industrial City and International standards, codes, LINDE ENGINEERING AG and QSGTL and/or

its PMC requirements and instructions.

In addition all employees and GAMA subcontractor employees on site will have through LINDE

ENGINEERING AG Site Safety Induction and GAMA Qatar Safety induction for site safety,

health, environmental and security prior to work activities. Other training courses will be attended

as required by LINDE ENGINEERING AG or QSGTL and/or its PMC as required.

4. REFERENCE

T-13.376.799: Rev.L; Amendments and supplements to DEP 30.48.00.31 Gen (December

1995) incorporating DEP circular 80/03, painting and coating of new equipments.

DEP 30.48.00.31: Gen December 1995; Painting & Coating of new Equipment

T.4.096.672: Specification for corrosion protection painting

T.4.250 .919: ITP Painting & coating

T-4.250.900 Method Statement for Painting and repair works

SSPC-SP1: Surface Preparation Specification No.1 Solvent Cleaning

SSPC-PA2: Paint Application Specification No.2

ISO 8502-6: Bresle Test Method

ISO 8501-1: Sa 1 - Light blast-cleaning

Sa 2 - Thorough blast-cleaning

T-4.250.916 Rev. B

Page 5 of 22

Q A T A R

Doc. Title

PROCEDURE FOR SHOP AND FIELD PAINTING WORK ON SITE

Doc No

GAM-QCP-QAC-GTL-032, REV-E

DATE:

06.10.08

Sa 2 -Very thorough blast-cleaning

Sa 3 - Blast cleaning to visually clean steel

5. DEFINITIONS

Company

: QSGTL/or its PMC

Contractor

: LINDE ENGINEERING AG

Sub Contractor

: GAMA QATAR

Contract

: QSGTL Pearl Plant - C2 ASU Project

QA/QC

: Quality Assurance / Quality Control

TPI

: Third Party Inspection

DFT

Dry Film Thickness

WFT

Wet Film Thickness

MSDS

: Material Safety Data Sheet

MDS

: Manufacturing Data Sheet

DBT

: Dry Bulb Temperature

WBT

: Wet Bulb Temperature

6. RESPONSIBILITIES

The Painting Engineer is responsible for application of paint in accordance with the Project

Specifications T.13.376.799-Painting & coating of New Equipment (Amendments)

30.48.00.31-Painting & coating of New Equipment and this procedure, appropriate method

statements (T-4.250.900) and the Paint manufacturer's recommendations.

The Painting Supervisor shall complete the painting forms and ensure that they are endorsed

by the responsible party / QC Paint Inspector at the appropriate of the in process paint

inspection activity.

T-4.250.916 Rev. B

Page 6 of 22

Q A T A R

Doc. Title

PROCEDURE FOR SHOP AND FIELD PAINTING WORK ON SITE

Doc No

GAM-QCP-QAC-GTL-032, REV-E

DATE:

06.10.08

GAMA Qatar shall make sure that painting works have been inspected and painting works are

executed in accordance with the Project specifications and approved Inspection Test Plan.

7. PROCEDURE

7.1.

SAFETY

All works shall be carried out in accordance with manufacturer(s) recommendations site

requirements.

Personal Protective Equipment (PPE) shall be worn all the time and in accordance

with site safety regulations.

All construction activities shall follow Project Safety Procedure.

Discarded paint, empty paint buckets, thinners, or any rags, cloths etc., shall be

discarded into containers and hauled off to an approved dumping site.

7.2.

QUALIFICATION

Painting personnel must have previous experience in the use of the specified surface

preparation and coating systems or similar systems. Only skilled painters shall be used.

For underground coating, the manufacturers technical representative shall witness

the demonstration application of each coating system at the start of the production.

7.3.

PRE BLAST ( SHOP AND FIELD )

The Painting Supervisor shall ensure that pre-blast cleaning is carried out according to

Paint Manufacturer's recommendation and Project Specifications . The surface

of steelwork for new construction shall be blast-cleaned to the visual standard of Sa 2

in accordance with ISO 8501-1, and shall retain this standard of cleanliness at the time

of coating.

Abrasive material Shall be approved By LINDE using GAM-QCR-QAC-GTL-051

7.4.

SURFACE PREPARATION ( SHOP AND FIELD ) ABOVE GROUND

Prior to start blasting, the GAMA shall demonstrate to the satisfaction of LINDE and

SHELL/PMC that the selected abrasive provides the specified anchor profile and

surface cleanliness. This shall be done by blasting representative piece of steel and

measuring the anchor profile, in accordance with ISO 8504-3 and/or comparing the

surface cleanliness to the appropriate visual standard. Any changes in the abrasives or

mesh size shall qualify in the same way prior to be used.

T-4.250.916 Rev. B

Page 7 of 22

Q A T A R

Doc. Title

PROCEDURE FOR SHOP AND FIELD PAINTING WORK ON SITE

Doc No

GAM-QCP-QAC-GTL-032, REV-E

DATE:

06.10.08

Visible oil, grease and soil shall be removed by solvent cleaning, area shall be washed in

clean fresh water and allowed to dry before conventional (air blast) cleaning, automatic

(wheel blast) or hand/power cleaning. GAMA Qatar Quality Department shall perform

surveillance to ensure cleaning is performed adequately, where applicable.

The surface shall be prepared prior to application of primer or paint by abrasive blasting

(paint shop application) or by hand tool/abrasive blasting (field application).The

method of surface preparation shall be recorded on form GAM-QCR-QAC-GTL-055.

Only blasting material that is approved and that conforms to the requirements of project

specification may be used for surface preparation. Test results shall be obtained by the

Painting Supervisor and handed over to GAMA Qatar Quality Department.

The type of abrasive is determined in compliance with the Project Specification

requirements by the profile required and the type of material to be blasted. The use of

steel shot or steel grit is not permitted for blasting of stainless steel. The type of

blasting abrasive used, and the required profile shall be recorded on GAM-QCR-QACGTL-055 by the Painting Supervisor for the Paint Shop and field application.

All blasting materials shall be kept dry. With the exception of expendable abrasives,

blasting abrasives may be reclaimed and used as per the manufacturer procedure.

The GAMA Qatar Quality Department shall perform surveillance of pre-blast blasting

operations. Once the blasting is complete for one batch QCI, shall use testex tape and

measure the profile and shall be witness by LINDE and SHELL/PMC. The result and

testex tape shall be recorded and taped to form GAM-QCR-QAC-GTL-055.

After cleaning, the surfaces shall be kept free from oil, grease, dirt, etc. until the coating

has been applied. Surfaces shall be coated within 4 hours or before any visible

deterioration of the blasted surface has occurred and this will be recorded in GAMQCR-QAC-GTL-055. Surfaces not meeting the blasting profile shall be re-blasted prior

to coating.

Used abrasive shall be removed from external surfaces using a dry brush and blowing

down with clean dry compressed air.

Steel defects revealed during abrasive blasting (silvers, laminations, cracks, pitting etc.,)

shall be reported to the LINDE /SHELL/PMC for evaluation. Defects will be

repaired as directed by the LINDE /SHELL/PMC Representative.

7.5.

SURFACE PREPARATION ( SHOP AND FIELD ) UNDERGROUND

Identification Marking shall be transferred to inside the pipes before commencing the

blasting and painting operation. Transfer of markings shall be witness by the LINDE

T-4.250.916 Rev. B

Page 8 of 22

Q A T A R

Doc. Title

PROCEDURE FOR SHOP AND FIELD PAINTING WORK ON SITE

Doc No

GAM-QCP-QAC-GTL-032, REV-E

DATE:

06.10.08

authorized inspectors as per T-13.377.437-specification for certification and marking

of materials.

Proper surface preparation shall be maintained and checked prior to applying any primer in

accordance with the applicable sections of this procedure and Project specifications.

Pipe ends and fitting ends shall be left uncoated for a distance of 50mm at shop

.

Field welds and damaged coating shall be made ready for painting application using

hand or power tools and then fully coated as applicable.

All blast cleaned surfaces shall be inspected for proper cleaning and anchor profile in

accordance with SSPC Specification and as per Project specification.

7.6.

PAINT STORAGE

The date of manufacture shall be clearly marked on each paint container, and paints that

have exceeded their shelf life shall be discarded. The same will be monitored on a

regular basis by GAMA Qatar, in conjunction with the paint manufacturer.

Paints and thinners shall be stored in areas that are well ventilated, and as specified by

the paint manufacturer (or) MSDS.

Coating materials shall be used on "First in-First out Basis"; no coating materials shall be

used beyond shelf life of 12 months. The maximum shelf life for zinc silicates shall be

6 months

Paints that show signs of leakage or have gelled shall be discarded and any skins that

have formed shall be cut and removed prior to application

Each batch of paint or thinner used shall be accompanied by a MDS from the respective

manufacturer. Any paint or thinner arriving on site without MDS shall not be used until

such time certification has been obtained.

7.7.

PAINTING MIXING

Paint shall be mixed thoroughly immediately prior to application.

Paint shall be properly mixed with recommended mixers such as, mechanical stirrers,

paddle mixers and can vibrators or shakers.

T-4.250.916 Rev. B

Page 9 of 22

Q A T A R

Doc. Title

PROCEDURE FOR SHOP AND FIELD PAINTING WORK ON SITE

Doc No

GAM-QCP-QAC-GTL-032, REV-E

DATE:

06.10.08

Metallic zinc or other dense pigment filled coatings shall be mechanically mixed

thoroughly prior to and during paint application. In field application, applicators must

constantly agitate the paint to obtain homogeneous mix.

Multi-component material shall be mixed in the volumes pro vided by the coating

manufacturer as "kits". Kits will not be "broken or split" without the written approval of

LINDE and SHELL/PMC.

Approved coating thinners shall be used as directed by the paint manufacturer.

Mixing shall be performed using mechanical mixers, designed to mix paint materials, in

clean containers. Containers shall be kept covered at all times except during

opening/closing and mixing operations.

Manufacturer's pot life, as stated in product data sheets, shall not be exceeded. When

the pot life limit is reached, the equipment must be emptied, material properly disposed of

and new material mixed.

If the paint cannot be mixed uniformly (thick sediments at the bottom etc.), it shall not be

used.

7.8.

WEATHER CONDITIONS

The Painting Supervisor shall monitor the weather conditions and take measurements

for wet bulb temperature, surface temperature, dew point temperature (For Dew Point

Calculation Chart). These, including weather conditions (windy, wet, dry, and cloudy)

shall be recorded on form GAM-QCR-QAC-GTL-055 by the Painting Supervisor at the

start, during and at end of work. Where applicable, all measuring devices shall be

calibrated and shall bear valid calibration stickers.

Any significant changes to weather conditions which may adversely affect the quality of

the paint warrants additional readings as per above.

Blasting operations shall not take place when the metal surface temperature is less

than 3C above the ambient dew point temperature (or) the Relative humidity is

greater than 85%. Priming / Painting shall not be applied when the surface

temperature is greater than 40C (unless higher temperature is agreed by the paint

manufacturer). An ELCOMETER disc type calculator or equivalent means should be used

to determine the relative humidity and dew point.

The GAMA Qatar Quality Department shall perform surveillance inspection to ensure the

data is collected and recorded and to ensure blasting and painting operations are

only performed within the requirements of the project specifications.

T-4.250.916 Rev. B

Page 10 of 22

Q A T A R

7.9.

Doc. Title

PROCEDURE FOR SHOP AND FIELD PAINTING WORK ON SITE

Doc No

GAM-QCP-QAC-GTL-032, REV-E

DATE:

06.10.08

MASKING

The bevel of each spool shall be masked to a distance of 50 mm from the bevel prior to

painting. This also applies to bevels in the field where the piping is painted prior to

completion of the welding. The masking of stainless steel requires special chloride free

tape which will be approved by Linde/PMC.

The Painting Supervisor shall also ensure that the piping identification is maintained

prior to and after painting. This also applies to the straight run pipes.

The Painting Supervisor shall ensure that there is no overspray onto previously painted

surfaces or beyond the application area. If there is danger of inorganic zinc primer

overspray contaminating stainless steel then the stainless steel shall be protected

by suitable means i.e. masking, covering with polythene etc.

After completion of painting all masking shall be removed and any overspray, dry spray

etc.

The GAMA Qatar Quality department shall perform surveillance inspection to ensure

proper masking protection is applied.

Masking shall be applied before blasting and coating operations to protect the gasket

surfaces (except plain face) and the pipe or nozzle interior. Surfaces that will be

inaccessible after assembly including the surfaces of lap joint, flanges, nozzle necks,

bolt holes shall receive the complete painting system before being assembled, steel

structure bolted connections shall be primed only unless otherwise noted.

The outer edge of ring groove flanges and raised face flanges will be blasted and coated

to the upper (outer) edge of the ring groove or the outside edge of the raised portion of

the flange. The entire groove area shall be protected.

In addition to the above, areas to be masked not blasted and painted are nameplates, valve spindles, level gauge glasses, small instruments, etc.

7.10. PRE COATING CLEANING

After the surface has been blasted and prior to application of any coating, the surface shall

be cleaned either by brushing or by air blowing. Used blasting material shall be removed

from external surfaces using a dry brush or by air blowing. Under no circumstances shall

surfaces that have been contaminated be coated before the surface has been adequately

cleaned.

T-4.250.916 Rev. B

Page 11 of 22

Q A T A R

Doc. Title

PROCEDURE FOR SHOP AND FIELD PAINTING WORK ON SITE

Doc No

GAM-QCP-QAC-GTL-032, REV-E

DATE:

06.10.08

All visible oil, grease and soil shall be removed with an approved solvent prior to

coating. Solvent, cleaning solutions, acid washes, inhibitors must be approved by

Material Approval Request (MAR) prior to use. The cleaned area shall then be washed in

clean, potable water and allowed to dry.

The compressed air supply shall be checked by the Painting Supervisor to ensure the air

is moisture and oil free. These checks are to be carried out at the start of each shift and

again after lunch. If necessary, a cooler shall be installed in the compressed air line to

ensure that compressed air is supplied at a temperature less than 110C. A Digital

thermometer also may be used to check the air temperature at the hose tip and will be

recorded in GAM-QCR-QAC-GTL-055.

7.11.

PRIMING (SHOP AND FIELD)

Primers, Intermediate coats and Topcoats shall be as per Project specification and

manufacturers product recommendation /MDS

Prior to application of primer, all difficult to coat areas such as corners edges, and welds

shall be stripe coated with the specified primer.

When inorganic zinc primer is used, checks for surface zinc oxide formation shall be

made immediately prior to applying an epoxy topcoat. Any oxide formation shall be

removed either by high pressure cleaning with potable water, or hosing with potable water

and then scrubbing with a soft brush to remove all the zinc salts. The surface shall be

thoroughly dried before applying the top coat.

Dry film thickness readings will be taken and calculated as per Project specification,

T-13.376.799 and ISO 2808 shall be recorded on GAM-QCR-QAC-GTL-055 by the

Painting inspector. This applies to each individual coat .DFT gauges Shall be calibrated in

accordance with section 2 of SSPC-PA-2

To control the final thickness of the coats the painting Inspector may use WFT (Wet Film

Thickness) measurements as an indicator for final thickness.

7.12. PAINTING

The representative of the paint manufacturer shall visit the site at regular intervals to

provide technical support and he shall submit a periodic report to GAMA Qatar and

LINDE confirming that painting is being carried out in accordance with the requirements

and quality of work is acceptable.

The specific paint systems to be used are identified in Project

Specifications T-4.096.672/0100 W-SP 2301, T.13.376.799-Painting & coating of New

Equipment (Amendments) and DEP 30.48.00.31-Painting & coating of New Equipment.

T-4.250.916 Rev. B

Page 12 of 22

Q A T A R

Doc. Title

PROCEDURE FOR SHOP AND FIELD PAINTING WORK ON SITE

Doc No

GAM-QCP-QAC-GTL-032, REV-E

DATE:

06.10.08

The paint coats shall be applied in the limits specified by Project specification

T-4.096.672/0100 W-SP 2301, DEP 30.48.00.31-Painting & coating of New Equipment

and MDS.

Each coat shall be checked for correct average DFT by GAMA Qatar QCI or Painting

Subcontractor QCI prior to application of subsequent coat.

The Painting Supervisor shall apply all coats in the paint shop or in the field including

final coat as specified in Project specification,

DEP 30.48.00.31-Painting & coating of New Equipment

All paint shall be applied either by air spray or airless spray as specified by paint

manufacturers. The use of brushes is only allowed in the case of repairs or in difficult

areas where spray technique is not practical.

After the completion of painting in the shop, all spools shall be cleaned to ensure that

spent abrasives are not present inside the pipe. Both ends shall be covered to avoid

ingress of sand after cleaning.

All welds, edges, etc. shall be stripe coated to ensure full DFT in those areas. This

includes nuts and bolts heads.

7.13. REPAIR OF DAMAGE COATING

The damaged area shall be re-cleaned as originally specified for that item and the full

coating system re-applied in accordance with the manufacturers application datas.

Any repair of damaged coating shall be cleaned by hand tools or power tools in

accordance with ISO 8501-1 grade st 3 and documented on form GAM-QCR-QAC-GTL056

Any repair areas shall be feathered into the undamaged coating a minimum of 50 mm.

Repair shall be performed prior to the subsequent coat.

Any damage or repair shall be performed prior to the next coat application. Coating of

weld joints shall be in accordance with original paint application as specified in Project

specification.

For item such as equipment already painted by a supplier, GAMA Qatar shall use the

same paint or an equivalent and compatible paint approved by the supplier.

Repair of damaged surfaces of zinc silicate primer shall be performed as detailed in the

Project specification.

T-4.250.916 Rev. B

Page 13 of 22

Q A T A R

Doc. Title

PROCEDURE FOR SHOP AND FIELD PAINTING WORK ON SITE

Doc No

GAM-QCP-QAC-GTL-032, REV-E

DATE:

06.10.08

Any holidays, defects and unacceptable work shall be repaired in accordance with

manufacturer's recommendations. Holidays should be generally ground to bare metal

feathering the adjacent sound coating back a minimum of 25mm.

7.14. IDENTIFICATION MARKING JOB STENCIL

All spools and straight run pipe shall be identified clearly as per T-4.250.928 Material

Traceability & Marking.

A job stencil shall be applied in the field in letters in a color which is in accordance with

Project specification, T-.13.377.437-certification ad marking of materials. This shall only be

applied on the final coat.

The job stencil shall contain information as per T-4.250.928 Material Traceability &

Marking. and Project specification T-.13.377.437-certification ad marking of materials

8. QUALITY CONTROL

The GAMA Qatar QCI shall perform inspection as per DEP -30.48.00.31 and relevant ITP

on all painting activities, in addition to profile measurements and DFT checks carried out

by the Painting Subcontractor's QCI as perform GAM-QCR-QAC-GTL-055.The Painting

subcontractor's QCI shall perform inspections on each batch and each coat and the

checks shall include but not limited to the following:

Pinholes

Blisters

Bubbling

Fisheyes

Unmatched colors

Uniformity

Curing properties

Dry Film Thickness

Orange peel

Mud cracking

Dry Spray

Runs and sags

Mechanical damage

Holidays, missed areas

The inspection shall be witnessed and signed off by the GAMA Qatar QC Inspector,

LINDE and SHELL/PMC as per relevant ITP on the painting activity on form GAM-QCRQAC-GTL-055

When a painting manufacturer is different between shop coating and field coating,

adhesion testing shall be done at randomly selected areas by grinding (Crosshatch),

following the procedures of ASTM D4541 & ISO 2409. Adhesion testing shall be carried

out at least once per equipment item or 100 m of coated surface, and on properly cured

coating.

T-4.250.916 Rev. B

Page 14 of 22

Q A T A R

Doc. Title

PROCEDURE FOR SHOP AND FIELD PAINTING WORK ON SITE

Doc No

GAM-QCP-QAC-GTL-032, REV-E

DATE:

06.10.08

Adhesion of inorganic zinc coatings shall be tested by firmly scraping the coated surfaces

with the edge of a coin. A zinc film, which is properly dried and hard, will polish to bright

metal without powdering or loss of material.

For underground piping, the inspection on site shall be done by Holiday detector in

accordance with 30.48.00.31-Painting & coating of New Equipment and Project

Specification ASTM D 5162. Form No. GAM-QCR-QAC-GTL-053 shall be used for the

Inspection of underground piping.

9. INSPECTION RECORD

9.1.

SHOP BLASTING AND PRIMING

The shop blasting and priming shall be documented on form GAM-QCR-QAC-GTL-055.

This form shall be completed by the Painting Supervisor and QCI as indicated. The form

shall list all the items which were blasted and primed in one batch. If one batch contains

more than one priming system then separate forms shall be generated for each primer

type.

Should there be items that are not released for further painting these items shall be listed in

the section on the form specified as "Items on hold and release after repair". These items

shall be signed off by GAMA Qatar QCI upon repair. The final signature on this form,

releases all items for next coat application with the exceptions as listed.

9.2.

SHOP PAINTING

The shop painting shall be documented on form GAM-QCR-QAC-GTL-055 this form shall

be completed by the Painting Supervisor and QCI as indicated. This form shall list all the

items which were painted in one batch and these shall reference the report numbers for the

blasting and priming. If one batch contains more than one painting system then separate

forms shall be generated for each paint type.

Should there be items that are not released for further painting these items shall be listed in

the section on the form specified as "Items on hold and release after repair. These items

shall be signed off by GAMA Qatar QCI upon repair. The final signature on this form,

releases all items for next coat application with the exceptions as listed. Signature by GAMA

Qatar QCI / LINDE on form GAM-QCR-QAC-GTL-055 signifies that the painting is complete

and the items are released for transport or storage.

LINDE or SHELL/PMC acceptance of the shop painting work shall be obtained on the

30.48.00.31-Painting & coating of New Equipment .The main function of this Procedure to

compile and handover the completed and signed-off forms GAM-QCR-QAC-GTL-055

pertaining to a certain period of shop production specified under ITP scope. Consequently,

T-4.250.916 Rev. B

Page 15 of 22

Q A T A R

Doc. Title

PROCEDURE FOR SHOP AND FIELD PAINTING WORK ON SITE

Doc No

GAM-QCP-QAC-GTL-032, REV-E

DATE:

06.10.08

this ITP shall include in-process Inspection activities. The acceptance of work shall be the

relevant section of the form GAM-QCR-QAC-GTL-055

9.3.

FIELD PAINTING OF ABOVE GROUND PIPING

Date to date production and QC inspections for field painting shall be documented by GAMQCR-QAC-GTL-055. This form shall be generated for each type of paint, and may include

more than one isometric. The completed GAM-QCR-QAC-GTL-055 shall be filed per unit or

area

LINDE or SHELL/PMC acceptance of the field painting work shall be obtained on the

30.48.00.31-Painting & coating of New Equipment. The main function of this procedure to

compile and handover the completed and signed-off form GAM-QCR-QAC-GTL-055

pertaining to the individual ITP scope. Consequently, this ITP shall include in-process

Inspection activities and there are no sign-off acceptances of the painting works. The

acceptance of work shall be the relevant section of the form GAM-QCR-QAC-GTL-055, as

applicable.

9.4.

FIELD PAINTING OF UNDERGROUND PIPING

Field painting of underground piping inspection shall be carried after tape wrapping of

welded joints by Holiday detection in accordance with 30.48.00.31-Painting & coating of

New Equipment and ASTM D 5162. The inspection report # GAM-QCR-QAC-GTL-056

should be filled and signed by GAMA Qatar, LINDE, and SHELL/PMC before backfilling

operations start.

10. STORAGE AND TRANSPORTATION OF PAINTED PIPES / SPOOLS

All painted pipes/spools should be properly stored, dunned and clear from the ground.

Pipes with end caps are supplied, end caps should be reinstated and wherever end caps

were not provided, pipes shall be protected both ends.

Method of storage shall protect coated pipes/spools from standing water, direct soil

contact, and sharp or hard objects.

Coated / Painted pipes and spools shall be transferred by lifting and placement without

the use of hooks, ropes, cables, or other sharp handling devices.

If coated/painted underground pipes

Handling Procedure.

T-4.250.916 Rev. B

are to

be stored, it should

follow the Material

Page 16 of 22

Q A T A R

Doc. Title

PROCEDURE FOR SHOP AND FIELD PAINTING WORK ON SITE

Doc No

GAM-QCP-QAC-GTL-032, REV-E

DATE:

06.10.08

11. ATTACHMENTS

Dew Point Calculation Chart

GAM-QCR-QAC-GTL-051

GAM-QCR-QAC-GTL-053

GAM-QCR-QAC-GTL-055

GAM-QCR-QAC-GTL-056

T-4.250.916 Rev. B

Page 17 of 22

Q A T A R

Doc. Title

PROCEDURE FOR SHOP AND FIELD PAINTING WORK ON SITE

Doc No

GAM-QCP-QAC-GTL-032, REV-E

DATE:

06.10.08

DEW POINT CALCULATION CHART

Q A T A R

AMBIENT AIR TEMPERATURE

(DEGREES CENTIGRADE)

%

Relative

Temperature

-7 C

-1 C

4 C

10 C

16 C

21 C

27 C

32

38 C 43 C 49 C

90

-8

-2

14

19

25

31

36

42

47

85

-8

-3

13

18

24

29

35

40

45

80

-9

-4

12

17

23

28

34

39

43

75

-9

-4

11

17

22

27

33

38

42

70

-11

-6

-1

10

16

20

26

31

36

41

65

-11

-7

-2

14

19

24

29

34

39

60

-12

-7

-3

13

18

23

28

33

38

55

-13

-8

-4

12

16

21

27

32

37

50

-14

-9

-5

-1

10

15

19

25

30

34

45

-16

-11

-6

-2

13

18

23

28

33

40

-17

-12

-8

-3

11

16

21

26

31

38

-19

-13

-9

-5

-1

14

18

23

28

30

-21

-16

-11

-7

-2

11

16

21

25

humidity

Example: If the air temperature is 21 C and the relative humidity is 70%, the dew point is 16.

T-4.250.916 Rev. B

Page 18 of 22

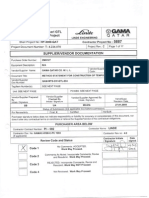

C2 ASU PEARL GTL PROJECT

RAS LAFFAN INUSTRIAL CITY

MAR

(Material Acceptance Report)

Project: QSGTL PEARL GTL PROJECT

MAR No.:

Date:

Manufacturer:

PO/Subcontract

Number :

Description of the Proposed Material:

QTY:

Nos:

Note:

Civil / Buildings

Mech. / Piping

Civil

Involved

Discipline:

Mechanical

Electrical

Instrumental

Welding

Others

..

Location & Usage of the Delivered Material:

Applicable Specifications & Technical Details:

Proposed material complies with applicable project specification

Attachments:

Inspection Report

Release Note

Yes

Mill Certificates

Data Sheets

No

Others

Comments:

Accepted By

Carried out By

GAMA REP.

VENDOR REP.

LINDE REP.

QSGTL REP.

GAM-QCR-QAC-GTL-051

DATE

NAME

SIGNATURE

Q A T A R

C2 ASU PEARL GTL PROJECT

RAS LAFFAN INDUSTRIAL CITY

PINHOLE & HOLIDAY TESTING REPORT

Subcontract Ref.:

Report No.

Item Description:

Inspection Date:

Item Location / Area:

Test Code No.:

System:

ITP No.:

Subsystem:

Ref.Drg./Doc.

Used Measuring and test equipment ref. (if applicable):

HOLIDAY DETECTOR

DETAILS

Make: _________

Date

Identification No.:

Pipe

T.D.F.T

Ident. No.

Dia (inch) Microns

K.V.Range:

KV

Settings

H.D Result

Damages

Pinholes

Remarks:

Accepted By

ORGANIZATIONS

THIRD PARTY

REP.

GAMA REP.

LINDE REP.

QSGTL or its PMC

REP.

GAM-QCR-QAC-GTL-053

DATE

NAME

SIGNATURE

Remarks

C2 ASU PEARL GT PROJECT

RAS LAFFAN INDUSTRIAL CITY

PAINTING INSPECTION REPORT

QATAR

Report No.:

Item Description:

System:

Item Location / Area:

Ref. DWG / Documents:

Used Measuring and test equipment ref. (if applicable):

Working Conditions

Internal / External

Inspection Date:

Test Code No.:

Subsystem:

ITP No.:

Paint Spec:

Compr. Air Temp.

Time (hrs.)

Air

WB

O

Temp

( C)

DB

Dew Point (O C)

Relative Humidity %

Metal Temp. (O C)

1. Hygrometer

Insp. Equipment Used

Identification #

2. DP / RH Calculator

3. Temperature Gauge

4. Hypodermic Needle

Gauge

5. Surface Profile Gauge

6. WFT Gauge

7. DFT Gauge

Surface Cleaning with fresh water

SURFACE PREPARATION

PROFILE MEASUREMENT TAPE

From: ________________hrs.

To: ________________hrs.

Grit Blasting

Machine Sl.No.

Nozzle Pressure

Grit Type

Wire Brushing

Manual / Power

Grade

mm

PSIG

Surface Finish

Surface Profile

Microns

*PAINT APPLICATION

From: ______________ hrs. To: _______________ hrs.

Manual / Auto

Coating Manufacturer:

Paint:

Product/Coat

Batch No.

Mix

Ratio

A.

B.

Intermediate A.

Coat

B.

A.

Top Coat

B.

Further Inspection Required:

Conducted :

Corrective action if necessary:

Application

Methods

Airless Spray Machine Sl. No.

Total

Colour

WFT DFT

DFT

Overcoat

Time

Primer

Accepted By

ORGANIZATIONS

DATE

NAME

THIRD PARTY REP.

GAMA REP.

LINDE REP.

QSGTL or its PMC REP.

*Priming application will be done within 4 hrs after surface preparation.

GAM-QCR-QAC-GTL-055, Rev-1

SIGNATURE

Q A T A R

C2 ASU PEARL GT PROJECT

RAS LAFFAN INDUSTRIAL CITY

REPAIR & TOUCHUP PAINTING

INSPECTION REPORT

System:

Item Description:

Item Location / Area:

Subsystem:

Ref. DWG / Documents:

Used Measuring and test equipment ref. (if applicable):

Working Conditions

Internal / External

Report No.:

Inspection Date:

Test Code No.:

ITP No.:

Paint Spec:

Insp. Equipment Used

Identification #

1. Whirling Hygrometer

Time (hrs.)

Air

WB

O

Temp

( C)

DB

Dew Point (O C)

Relative Humidity

%

Metal Temp. (O C)

2. DP / RH Calculator

3. Temperature Gauge

4. WFT Gauge

5. DFT Gauge

SURFACE PREPARATION

From: ________________

To: ________________

Method of

Cleaning

PAINT APPLICATION

From: ______________ hrs. To: _______________ hrs.

Application

Methods

Airless Spray Machine Sl. No.

Total

Colour WFT DFT

DFT

DATE

NAME

Coating Manufacturer:

Paint:

Product/Coat

Batch No.

A.

B.

A.

Intermediate

B.

A.

Top coat

B.

Remarks:

Mix

Ratio

Overcoat

Time

Primer

Accepted By

ORGANIZATIONS

THIRD PARTY REP.

GAMA REP.

LINDE REP.

QSGTL or its PMC REP.

GAM-QCR-QAC-GTL-056, Rev-1

SIGNATURE

S-ar putea să vă placă și

- Strategy 13 Presentation - Social Emotional LearningDocument29 paginiStrategy 13 Presentation - Social Emotional Learningapi-588940234Încă nu există evaluări

- 016-CIVIL - MS Anchor Bolt Installation PDFDocument14 pagini016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- 035-Procedure For Material Traceability and Marking PDFDocument16 pagini035-Procedure For Material Traceability and Marking PDFKöksal Patan100% (10)

- 043-ITP FOR Water Proofing (Buildings) PDFDocument13 pagini043-ITP FOR Water Proofing (Buildings) PDFKöksal Patan100% (3)

- Structural Steel ErectionDocument7 paginiStructural Steel Erectionzaki fadlÎncă nu există evaluări

- 005-Ms-Painting and Repair Works PDFDocument24 pagini005-Ms-Painting and Repair Works PDFKöksal Patan100% (1)

- 030-Itp For Ug GRP Piping PDFDocument22 pagini030-Itp For Ug GRP Piping PDFKöksal Patan89% (9)

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFDocument10 pagini045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- 014-MS For General Scaffolding PDFDocument33 pagini014-MS For General Scaffolding PDFKöksal Patan100% (2)

- 013-MS For Mass Concrete Works PDFDocument26 pagini013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- 14 Procedure For Shop and Field PaintingDocument24 pagini14 Procedure For Shop and Field PaintingdnbinhÎncă nu există evaluări

- 015-Method Statement For Painting Works (Building) PDFDocument21 pagini015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- 015-Method Statement For Painting Works (Building) PDFDocument21 pagini015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- Method Statement-Ext Pipe FittingsDocument13 paginiMethod Statement-Ext Pipe FittingsSam JoseÎncă nu există evaluări

- Method StatementDocument4 paginiMethod StatementtayitbatovÎncă nu există evaluări

- RA For Installation & Dismantling of Loading Platform A69Document15 paginiRA For Installation & Dismantling of Loading Platform A69Sajid ShahÎncă nu există evaluări

- Safe Work Method Statement FormDocument7 paginiSafe Work Method Statement FormSokha RunÎncă nu există evaluări

- 001-MS For Structural Steel Assembly and Erection PDFDocument28 pagini001-MS For Structural Steel Assembly and Erection PDFKöksal Patan100% (1)

- 010-MS For Welding and Hot Works For General Activities at TSF Area PDFDocument17 pagini010-MS For Welding and Hot Works For General Activities at TSF Area PDFKöksal PatanÎncă nu există evaluări

- 010-MS For Welding and Hot Works For General Activities at TSF Area PDFDocument17 pagini010-MS For Welding and Hot Works For General Activities at TSF Area PDFKöksal PatanÎncă nu există evaluări

- 041 - ITP For Painting (Building) PDFDocument12 pagini041 - ITP For Painting (Building) PDFKöksal Patan78% (9)

- 050-Itp For Installation of Air Intake Filter PDFDocument17 pagini050-Itp For Installation of Air Intake Filter PDFKöksal PatanÎncă nu există evaluări

- 012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFDocument16 pagini012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFKöksal Patan91% (11)

- 044-ITP For Installation of Gypsum Board (Buildings) PDFDocument10 pagini044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- 004-MS For Erection of Equipment Platforms, Handrails, Gratings, Stairways PDFDocument9 pagini004-MS For Erection of Equipment Platforms, Handrails, Gratings, Stairways PDFKöksal Patan100% (1)

- 015-MS For Night Works PDFDocument16 pagini015-MS For Night Works PDFKöksal Patan80% (5)

- Hse Eil 1Document201 paginiHse Eil 1Manav SharmaÎncă nu există evaluări

- 031-Procedure For Hydro and Pneumatic Testing PDFDocument36 pagini031-Procedure For Hydro and Pneumatic Testing PDFKöksal PatanÎncă nu există evaluări

- 004-Civil - MS Construction of Temporary Roads PDFDocument17 pagini004-Civil - MS Construction of Temporary Roads PDFKöksal Patan100% (2)

- 035-Procedure Structural Steel Repair Works at Site PDFDocument14 pagini035-Procedure Structural Steel Repair Works at Site PDFKöksal Patan100% (1)

- Equipment Nitrogen Purging Procedure PDFDocument13 paginiEquipment Nitrogen Purging Procedure PDFKUMAR100% (2)

- 002-MS Nitrogen Filling, Cyrogenic Vaporizer PDFDocument18 pagini002-MS Nitrogen Filling, Cyrogenic Vaporizer PDFKöksal PatanÎncă nu există evaluări

- Method Statement for Earth WorkDocument8 paginiMethod Statement for Earth WorkOsama AbdulkafiÎncă nu există evaluări

- 014-MS For Bolt Tightening (Piping& Equipments) PDFDocument23 pagini014-MS For Bolt Tightening (Piping& Equipments) PDFKöksal PatanÎncă nu există evaluări

- 049-Itp For Lighting and Small Power (Building) PDFDocument15 pagini049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- Flange Joint Box-UpDocument1 paginăFlange Joint Box-UpJR MohanÎncă nu există evaluări

- Modesto Mabunga Vs PP (GR 142039)Document3 paginiModesto Mabunga Vs PP (GR 142039)Ericha Joy GonadanÎncă nu există evaluări

- Specification For 3 Layer Polyethylene CoatingDocument34 paginiSpecification For 3 Layer Polyethylene CoatingYogesh BaraskarÎncă nu există evaluări

- 009-Civil-Ms Concrete Works PDFDocument27 pagini009-Civil-Ms Concrete Works PDFKöksal PatanÎncă nu există evaluări

- GSMA Moile Money Philippines Case Study V X21 21Document23 paginiGSMA Moile Money Philippines Case Study V X21 21davidcloud99Încă nu există evaluări

- 048-Itp For Installation of Hvac Unit PDFDocument8 pagini048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- 027-PRO For MONITORING OF CONCRETE FOUNDATIONS PDFDocument9 pagini027-PRO For MONITORING OF CONCRETE FOUNDATIONS PDFKöksal PatanÎncă nu există evaluări

- 011-Method Statement For Repair of Concrete Works PDFDocument25 pagini011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- 017-CIVIL-MS For Installation of Fence & Gate PDFDocument18 pagini017-CIVIL-MS For Installation of Fence & Gate PDFKöksal Patan100% (6)

- Method Statement For Hot Tapping Rev 0 PDFDocument9 paginiMethod Statement For Hot Tapping Rev 0 PDFsharif339Încă nu există evaluări

- 09 - Method Statement For Paint WorkDocument6 pagini09 - Method Statement For Paint WorkAnsar WarraichÎncă nu există evaluări

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFDocument23 pagini008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanÎncă nu există evaluări

- Seminar 6 Precision AttachmentsDocument30 paginiSeminar 6 Precision AttachmentsAmit Sadhwani67% (3)

- 038-Itp For Coldboxes PDFDocument25 pagini038-Itp For Coldboxes PDFKöksal PatanÎncă nu există evaluări

- 034-Pro For Building PDFDocument36 pagini034-Pro For Building PDFKöksal Patan0% (1)

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFDocument25 pagini007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanÎncă nu există evaluări

- 047-Itp For Oxygen Lines Fabrication and Installation PDFDocument28 pagini047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanÎncă nu există evaluări

- 040-ITP For Repair of Steam Distribution Manifold PDFDocument11 pagini040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanÎncă nu există evaluări

- Method Statement For For Cable Tray and Conduit Installation With Risk AssesmentDocument9 paginiMethod Statement For For Cable Tray and Conduit Installation With Risk Assesmentobasiigwe8499Încă nu există evaluări

- 250600DBQRD0008 - Exde00 - 22 - Procedure For Handling, Transport and Storage of Pipes From The Stock Pile To TrenchDocument22 pagini250600DBQRD0008 - Exde00 - 22 - Procedure For Handling, Transport and Storage of Pipes From The Stock Pile To TrenchAbdullah AbdullahÎncă nu există evaluări

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFDocument18 pagini046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanÎncă nu există evaluări

- SUBCO-FRM-01 Subcontractor's Prequalification FormDocument16 paginiSUBCO-FRM-01 Subcontractor's Prequalification FormMuhammad Umer100% (1)

- 037-Procedure For Cleanliness PDFDocument21 pagini037-Procedure For Cleanliness PDFKöksal PatanÎncă nu există evaluări

- 008-CIVIL-MS Backfilling Works PDFDocument16 pagini008-CIVIL-MS Backfilling Works PDFKöksal Patan100% (1)

- 010-MS For Grouting PDFDocument33 pagini010-MS For Grouting PDFKöksal PatanÎncă nu există evaluări

- 009-Method Statement - Main Erection Sequence For Acc PDFDocument68 pagini009-Method Statement - Main Erection Sequence For Acc PDFKöksal Patan100% (6)

- 035 Procedure For Material Traceability and Markingpdf PDF FreeDocument16 pagini035 Procedure For Material Traceability and Markingpdf PDF FreeabbasÎncă nu există evaluări

- 002-BOLT TIGHTENING (Structural) PDFDocument22 pagini002-BOLT TIGHTENING (Structural) PDFKöksal Patan82% (11)

- Welding Inspection of Hmu Existing Flare Line Shutdown Tie-In Jobs PDFDocument5 paginiWelding Inspection of Hmu Existing Flare Line Shutdown Tie-In Jobs PDFRakesh RanjanÎncă nu există evaluări

- Painting SpecificationDocument19 paginiPainting SpecificationArunkumar Rackan0% (1)

- RA 5921 and RA 10918Document32 paginiRA 5921 and RA 10918Hani Loveres100% (1)

- PE and Health 12 - Module 7Document19 paginiPE and Health 12 - Module 7Stephen Lorenzo A. DoriaÎncă nu există evaluări

- 013-MS Utilization of Hilti DX 76 PDFDocument51 pagini013-MS Utilization of Hilti DX 76 PDFKöksal PatanÎncă nu există evaluări

- Hsps05 Control of Noise at WorkDocument12 paginiHsps05 Control of Noise at WorkJean HoneyÎncă nu există evaluări

- Punch List For Fire Water Pump & Foam Pump PackageDocument4 paginiPunch List For Fire Water Pump & Foam Pump PackageGomathyselviÎncă nu există evaluări

- Telegra Manual - DatasheetDocument79 paginiTelegra Manual - DatasheetNilanjan Chakravortty100% (1)

- Monthly Quality Report: Akt Oil ServicesDocument4 paginiMonthly Quality Report: Akt Oil ServicesLaith SalmanÎncă nu există evaluări

- Zawtika Project ITP for Electrical, Instrumentation and Telecom InspectionDocument13 paginiZawtika Project ITP for Electrical, Instrumentation and Telecom Inspectionsfd640Încă nu există evaluări

- 012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFDocument18 pagini012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFKöksal PatanÎncă nu există evaluări

- Compliance Statement for 4 Residential Building ProjectDocument1 paginăCompliance Statement for 4 Residential Building ProjectAhmed HelmyÎncă nu există evaluări

- 039-Itp For Embedded Plate PDFDocument7 pagini039-Itp For Embedded Plate PDFKöksal PatanÎncă nu există evaluări

- Site Specific Procedure (Junction Box)Document120 paginiSite Specific Procedure (Junction Box)Mohd Khairi AhmadÎncă nu există evaluări

- Gas Pipe Fitting InstallationDocument2 paginiGas Pipe Fitting InstallationMcLester Love ElinaÎncă nu există evaluări

- Method Statement For Carbon Steel U G Piping Fabrication ErectionDocument28 paginiMethod Statement For Carbon Steel U G Piping Fabrication ErectionAriel Anasco100% (1)

- ITP Plan - FF PDFDocument7 paginiITP Plan - FF PDFAltaf KhanÎncă nu există evaluări

- SWMS-AssembleWallFramesDocument2 paginiSWMS-AssembleWallFramesHamza NoumanÎncă nu există evaluări

- 2.3 Hot WorkDocument9 pagini2.3 Hot Workvishal bailurÎncă nu există evaluări

- SEO-Optimized Sewer Pipe Installation TitleDocument15 paginiSEO-Optimized Sewer Pipe Installation TitleFrancisco M. RamosÎncă nu există evaluări

- Curriculumvitae: Personal ParticularDocument14 paginiCurriculumvitae: Personal ParticularBakhtiar Afendy ZaabaÎncă nu există evaluări

- Fuel Tank Lifting REV01Document7 paginiFuel Tank Lifting REV01armagan55Încă nu există evaluări

- 022 Itp For Fence Gate PDFDocument5 pagini022 Itp For Fence Gate PDFJithesh.k.sÎncă nu există evaluări

- Petroleum Development Oman Construction/Commissioning Punch ListDocument5 paginiPetroleum Development Oman Construction/Commissioning Punch ListMuthu KumaranÎncă nu există evaluări

- AUDIT Reporting ProcedureDocument25 paginiAUDIT Reporting ProcedureVasilica BarbarasaÎncă nu există evaluări

- Bawana BOQDocument28 paginiBawana BOQSasi Kiran VundamatlaÎncă nu există evaluări

- Brega-Sidra 34Document11 paginiBrega-Sidra 34ahmed08839494Încă nu există evaluări

- BD List of Approved Foundation SystemDocument2 paginiBD List of Approved Foundation SystemGary LoÎncă nu există evaluări

- Project Plan and Actuals TrackerDocument5 paginiProject Plan and Actuals TrackerRiaz MohammedÎncă nu există evaluări

- ITP-FW For Civil & Building WorksDocument17 paginiITP-FW For Civil & Building WorksRizki KresnaÎncă nu există evaluări

- Method StatementDocument4 paginiMethod StatementbecpavanÎncă nu există evaluări

- Description SLP Number Date Location Project Client Prepared by REF Attachments Machine: ConfigurationDocument1 paginăDescription SLP Number Date Location Project Client Prepared by REF Attachments Machine: ConfigurationozchrisÎncă nu există evaluări

- IntuitionDocument10 paginiIntuitionmailsonÎncă nu există evaluări

- Your Results For: "Multiple-Choice Questions: B": DelayDocument4 paginiYour Results For: "Multiple-Choice Questions: B": DelayawairmalikÎncă nu există evaluări

- De Thi HK 2 Tieng Anh 9 de 2Document17 paginiDe Thi HK 2 Tieng Anh 9 de 2Lê Thu HiềnÎncă nu există evaluări

- NewTrendsInLeadershipandManagement ArikkokDocument32 paginiNewTrendsInLeadershipandManagement Arikkoksocofem288Încă nu există evaluări

- Elements of Ayurveda Daily Routine GuideDocument1 paginăElements of Ayurveda Daily Routine GuideShivani GargÎncă nu există evaluări

- Kanavos Pharmaceutical Distribution Chain 2007 PDFDocument121 paginiKanavos Pharmaceutical Distribution Chain 2007 PDFJoao N Da SilvaÎncă nu există evaluări

- Chapter 4. Quality Service and Standards TrainingDocument40 paginiChapter 4. Quality Service and Standards TrainingJia Mae Sapico ApantiÎncă nu există evaluări

- Self Healing Challenge - March 2023 Workshop ThreeDocument16 paginiSelf Healing Challenge - March 2023 Workshop ThreeDeena DSÎncă nu există evaluări

- Andrew Linklater - The Transformation of Political Community - E H Carr, Critical Theory and International RelationsDocument19 paginiAndrew Linklater - The Transformation of Political Community - E H Carr, Critical Theory and International Relationsmaria luizaÎncă nu există evaluări

- Monthly Business ReviewDocument36 paginiMonthly Business Reviewmdipu5_948971128Încă nu există evaluări

- Falling Weight Deflectometer Bowl Parameters As Analysis Tool For Pavement Structural EvaluationsDocument18 paginiFalling Weight Deflectometer Bowl Parameters As Analysis Tool For Pavement Structural EvaluationsEdisson Eduardo Valencia Gomez100% (1)

- Horizontal Vertical MarketDocument4 paginiHorizontal Vertical MarketVikasÎncă nu există evaluări

- Expt 1 Yarn Formation (Sherley Trash Analyser)Document7 paginiExpt 1 Yarn Formation (Sherley Trash Analyser)Yashdeep Sharma0% (1)

- T Cells & Autoimmunity, s3Document21 paginiT Cells & Autoimmunity, s3LiaAriestaÎncă nu există evaluări

- Project Report VajDocument15 paginiProject Report VajTamil SelvanÎncă nu există evaluări

- MF-QA-001 PDIR ReportDocument2 paginiMF-QA-001 PDIR ReportBHUSHAN BAGULÎncă nu există evaluări

- Connection Between Academic and Professional IntegrityDocument3 paginiConnection Between Academic and Professional IntegrityJoshua NyabindaÎncă nu există evaluări

- EINC ChecklistDocument3 paginiEINC ChecklistMARK JEFTE BRIONESÎncă nu există evaluări

- ManuscriptDocument2 paginiManuscriptVanya QuistoÎncă nu există evaluări

- BBRC4103 - Research MethodologyDocument14 paginiBBRC4103 - Research MethodologySimon RajÎncă nu există evaluări

- Silicone Bonding BrochureDocument4 paginiSilicone Bonding BrochureAmir ShahzadÎncă nu există evaluări

- Defining Public RelationsDocument4 paginiDefining Public RelationsKARTAVYA SINGHÎncă nu există evaluări