Documente Academic

Documente Profesional

Documente Cultură

029-Itp Paving and Roads PDF

Încărcat de

Köksal PatanDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

029-Itp Paving and Roads PDF

Încărcat de

Köksal PatanDrepturi de autor:

Formate disponibile

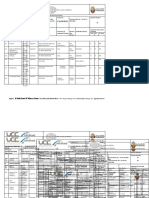

Pearl GTL

Project

Shell Project No: HP-3000-QAT

Project Document Number: T- 4.234.580

Purchase Order Number:

2MH127

Tag/Item Number(s):

N/A

Unit(s):

ASU

PCWBS:

LINDE ENGINEERING

Contractor Project No:

Project Rev.: B

Page 2 of 6

5887

QATAR SHELL GTL PROJECT (PEARL)

C2 AIR SEPARATION UNITS CONSTRUCTION

16.03.2008

Ready For Construction

SB

UA

ZG

RFC

26.01.2008

Ready For Construction

SB

UA

MC/ZG

RFC

27.11.2007

Issued for Review

IU

UA/IO

MC/ZG

IFR

25.11.2007

Issued for Internal Review

IU

UA/IO

MC/ZG

IIR

Date

Description

A

GAMA

Rev.

No.

Project

Rev

No.

Prepared Checked Approved

By

By

By

ORIGINATOR

Status

Document Title:

ITP FOR PAVING AND ROAD WORKS

LINDE ENGINEERING AG

Document No.

Contractor

Gama Qatar Co. W. L. L.

LOC470

GAM

ITP

QAC

GTL

029

Org.

Code

Doc.

Type

Disc.

Code

Geogr.

Area

Seq.

No

Rev.

No

Project Document Number: T-4.234.580

Vendor Code

Rev No: B

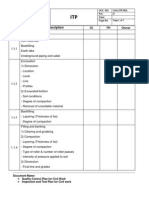

QSGTL PEARL PROJECT

C2 ASU Construction Works

INSPECTION AND TEST PLAN

ROADS & PAVING WORKS(FSI)

S. GAMA QATAR

I: INSPECTION / TEST

Item

Activity

Fill Material

a) Classification of Soil

b) Particle Size

Distribution

c) Optimum Moisture

Content

Water

a) Chlorides

b) Sulphates

c) Ph

d)Total Solids

Excavation (FSI)

Fill (In situ)

(FSI)

Soil density (compaction)

and layer thickness

CBR

(optional)

Final Elevation Checks

T-4.234.580 Rev. B

E. Not used

Characteristic to be Verified

Every 1000 m3 /MT

Date / REV.

X. CONTRACTOR QC

R: DOCUMENT REVIEW

C. COMPANY

S: SURVEILANCE

Control Procedure

Reference

Responsible

Party

a) Soil condition of excavated

bottom

b) Excavation completed and

approved for next activity

a) Visual inspection prior

backfilling and scarifying the top

150 mm of sub grade

b) Area free of deleterious

material prior to backfilling

c) Adjacent below ground

structure correctly coated and

protected in accordance with

project specification

A. FUGRO (TPI)

H: HOLD POINT. W:

Lab Reports

BS 6068 and BS3148

Source Approval

Site Engineer

Latest Project drawings

for required bottom levels

and condition

Lab Reports

Surveyor Report

GAM-QCR-QACGTL001/006/008

Site Engineer

Area Free from

Deleterious Material & as

Specification

Checklist No

GAM-QCR-QACGTL-007

Lab report

GAM-QCR-QACGTL-003

Lab Report

GAM-QCR-QACGTL-006

S

/

R

T-13.376.490

Acceptance Criteria

As per ASTM: D422 and

BS 1377

As per ASTM:

D 1557

T-13.376.490;T.13.377.360

Type (A): Every 300 m2

Type (B): Every750 m2

Type (c): Every400 m3

T-13.376.490

LAB

As per Project

Specification and ASTM

D2922, D3017, D556 and

D216

CBR to be performed when

compaction/in situ Density not

Carried.

DEP 34.13.20.31 Class 2.42

LAB

BS 1377 Chapter -7

T-13.376.490

Site Engineer

Level of Final Grade Elevation

WITNESS

S

T-13.376.490

T-13.376.490;T.13.377.360

16.03.2008 Rev- D

Verifying

Documents

Laboratory

Once a day/any source change

GAM-ITP-QAC-GTL-029

ITP NO:

Latest Project RFC

Drawings for final grade

levels

Page 4 of 6

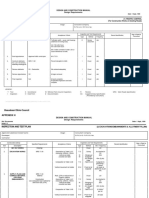

QSGTL PEARL PROJECT

C2 ASU Construction Works

ITP NO:

INSPECTION AND TEST PLAN

ROADS & PAVING WORKS (FSI)

S. GAMA QATAR

I: INSPECTION / TEST

Item

Activity

Concrete Paving

E. Not used

R: DOCUMENT REVIEW

Characteristic to be Verified

Road width & alignment

16.03.2008 Rev-D

Date / REV.

C. COMPANY

S: SURVEILANCE

Control Procedure

Reference

H: HOLD POINT. W:

WITNESS

Verifying

Documents

As per drawing and

standard specification

34.19.20.31

As per drawings

As per drawings

Level

As per drawings

Survey Report

GAM-QCR-QACGTL-006

Form work and Rebar

(FSI)

As per

drawings;T.13.377.360

As per drawing

As per drawing

Cleaning (FSI)

specification34.19.20.31;

T.13.377.360

Free from debris

Visual

Concrete Laying

As per drawings

As per Pour card GAMQCR-QAC-GTL-009

GAM-QCR-QACGTL-009

S

/

R

S/

R

S

/

R

Flow Test

Frequency 1 Test for 1 mix

T-13.376.358

DEP-34.19.20.31;

ASTM C 1611

T-13.376.358

DEP-34.19.20.31

Responsible

Party

A. FUGRO (TPI)

Acceptance Criteria

Compressive strength @7 & 28

days (cube sample as per BS

1881)Testing Frequency as per

T-13.376.358 Section 3.33

T.4.234.580 Rev-B

X. CONTRACTOR QC

GAM-ITP-QAC-GTL-029

Site Engineer /

QCI

Laboratory/

Supplier

Laboratory

Testing Fresh

Concrete.

Flow = 650 Max

BS EN 12390-3 Testing

of Hardened concretestrength of test specimens

Contraction & Expansion joints

(FSI)

34.13.20.31&34.19.20.31;

T.13.377.360

As per Drawing &

Company Specifications

Surface Brushed Finishing

34.13.20.31&34.19.20.31

Visual

Curing (FSI)

Standard specification

34.19.20.31;T.13.377.360

As per Specification

Lab Report

GAM-QCR-QACGTL-017

Laboratory

Report/Supplier

GAM-QCR-QACGTL-020

Drawing &

Company

Specification

Company

Specification

As per

Specification

Page 5 of 6

QSGTL PEARL PROJECT

C2 ASU Construction Works

ITP NO:

INSPECTION AND TEST PLAN

ROADS & PAVING WORKS (FSI)

S. GAMA QATAR

I: INSPECTION / TEST

Item

Activity

E. Not used

Characteristic to be Verified

16.03.2008 Rev-D

Date / REV.

X. CONTRACTOR QC

R: DOCUMENT REVIEW

GAM-ITP-QAC-GTL-029

C. COMPANY

S: SURVEILANCE

Control Procedure

Reference

Responsible

Party

As per drawing and

standard specification

34.19.20.31

Site Engineer

A. FUGRO (TPI)

H: HOLD POINT. W:

WITNESS

Verifying

Documents

As per Drawing &

Company Specifications

Visual & GAMQCR-QAC-GTL006

As per Drawing &

Company Specifications

GAM-QCR-QACGTL-051 & 052

As per Spec. &

Drawings

Acceptance Criteria

For Shoulder

a) Level & Alignments

9

a)Curb Stone Fixing

b)Prime Coat & Tack Coat

b)Coating

10

Asphalting to Shoulders

Level , Alignments & finishing

As per drawing and

standard specification

34.19.20.31

Site Engineer

11

Final Inspection

Finished Elevation Levels &

Documentations

34.13.20.31 &

34.19.20.31

Site Engr /

QCI

T.4.234.580 Rev-B

As per drawing

Page 6 of 6

S-ar putea să vă placă și

- ITP - Concrete Works PDFDocument2 paginiITP - Concrete Works PDFntah8483% (35)

- Inspection and Test Plan ConcreteDocument2 paginiInspection and Test Plan ConcreteStephen Vivek100% (10)

- ITP 001 Fencing, CurbingDocument19 paginiITP 001 Fencing, CurbingMikiRoniWijaya50% (2)

- Inspection and Test Plan For HVAC Cladding Works: 0-WD860-CA250-00312 0Document3 paginiInspection and Test Plan For HVAC Cladding Works: 0-WD860-CA250-00312 0ResearcherÎncă nu există evaluări

- ITP For Asphalt WorksDocument3 paginiITP For Asphalt WorksBleep News100% (1)

- ITP-01 - BackfillingDocument1 paginăITP-01 - BackfillingMaddala Srinivasa Rao50% (2)

- Inspection and Test Plan: ACTIVITY: ITP For Inspection of Piling WorkDocument4 paginiInspection and Test Plan: ACTIVITY: ITP For Inspection of Piling Workjitendra100% (1)

- Inspection and Test Plan Fro RoadDocument81 paginiInspection and Test Plan Fro RoadJay Alvin Dagpin Denoyo87% (30)

- ITP For Earthworks of Onshore HighwayDocument6 paginiITP For Earthworks of Onshore HighwayYay B. Gico100% (1)

- 027-ITP For Pre - Cast Concrete PDFDocument11 pagini027-ITP For Pre - Cast Concrete PDFKöksal Patan75% (4)

- ITP For Civil WorksDocument15 paginiITP For Civil WorksNoor A Qasim100% (8)

- ITP-FW For Civil & Building WorksDocument17 paginiITP-FW For Civil & Building WorksRajnath Rajbhar Pancham86% (7)

- Preparation of Inspection & Test Plans For Civil & Steelworks, Rev.0 Foster Wheeler Energy LTD Work Practice Construction OperationsDocument5 paginiPreparation of Inspection & Test Plans For Civil & Steelworks, Rev.0 Foster Wheeler Energy LTD Work Practice Construction Operationssateeshsingh100% (2)

- Itp - EarthworkDocument16 paginiItp - Earthworksaharui50% (2)

- 048-Itp For Installation of Hvac Unit PDFDocument8 pagini048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- 048-Itp For Installation of Hvac Unit PDFDocument8 pagini048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- TRONXY P802EA Installation Guide v.03Document29 paginiTRONXY P802EA Installation Guide v.03Jessica Ross100% (1)

- 028-Itp For Building Works PDFDocument10 pagini028-Itp For Building Works PDFKöksal Patan100% (3)

- 023-Itp Concrete Works PDFDocument32 pagini023-Itp Concrete Works PDFKöksal Patan100% (5)

- 043-ITP FOR Water Proofing (Buildings) PDFDocument13 pagini043-ITP FOR Water Proofing (Buildings) PDFKöksal Patan100% (3)

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFDocument10 pagini045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- 044-ITP For Installation of Gypsum Board (Buildings) PDFDocument10 pagini044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- ITP For Sub-Base and Road Base WorksDocument3 paginiITP For Sub-Base and Road Base WorksBleep News0% (1)

- 9686-6130-ITP - 000-1002 - Inspection and Test Plan For General Civil Works Rev A1Document34 pagini9686-6130-ITP - 000-1002 - Inspection and Test Plan For General Civil Works Rev A1anil pk100% (8)

- Concrete Method StatementDocument14 paginiConcrete Method StatementWufei Chang95% (21)

- 5.ITP For Excavation and Back FillingDocument19 pagini5.ITP For Excavation and Back FillingDaniel Sinaga100% (5)

- ITP For CivilDocument85 paginiITP For CivilBilibili weekly TOP 10 videos100% (6)

- ITP For PilingDocument9 paginiITP For PilingAntonio Tomas Gonzalez Losa100% (2)

- ITP-CI-026a-02 (Building Finishing Works)Document4 paginiITP-CI-026a-02 (Building Finishing Works)Delta akathehuskyÎncă nu există evaluări

- 050-Itp For Installation of Air Intake Filter PDFDocument17 pagini050-Itp For Installation of Air Intake Filter PDFKöksal PatanÎncă nu există evaluări

- 030-Itp For Ug GRP Piping PDFDocument22 pagini030-Itp For Ug GRP Piping PDFKöksal Patan89% (9)

- 015-MS For Night Works PDFDocument16 pagini015-MS For Night Works PDFKöksal Patan80% (5)

- 015-Method Statement For Painting Works (Building) PDFDocument21 pagini015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- 050-Itp For Installation of Air Intake Filter PDFDocument17 pagini050-Itp For Installation of Air Intake Filter PDFKöksal PatanÎncă nu există evaluări

- 044-ITP For Installation of Gypsum Board (Buildings) PDFDocument10 pagini044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- Materials Select Torsionally Stressed ShaftDocument7 paginiMaterials Select Torsionally Stressed ShaftJuan Diego Garcia EsquenÎncă nu există evaluări

- 021-Itp For Site Preparation and Earth Works PDFDocument6 pagini021-Itp For Site Preparation and Earth Works PDFKöksal Patan100% (2)

- 041 - ITP For Painting (Building) PDFDocument12 pagini041 - ITP For Painting (Building) PDFKöksal Patan78% (9)

- 022-Itp For Fence & Gate PDFDocument5 pagini022-Itp For Fence & Gate PDFKöksal Patan83% (6)

- 026-Itp For Structural Steel PDFDocument18 pagini026-Itp For Structural Steel PDFKöksal Patan100% (11)

- 024-Itp For Grouting Works PDFDocument8 pagini024-Itp For Grouting Works PDFKöksal Patan100% (1)

- 027 ITP For Pre Cast Concrete PDFDocument27 pagini027 ITP For Pre Cast Concrete PDFlinga2014Încă nu există evaluări

- 039-Itp For Embedded Plate PDFDocument7 pagini039-Itp For Embedded Plate PDFKöksal PatanÎncă nu există evaluări

- 025-ITP For Sewer & Drainage PDFDocument6 pagini025-ITP For Sewer & Drainage PDFKöksal PatanÎncă nu există evaluări

- ItpDocument7 paginiItpJose Sherin100% (1)

- ITP For Concrete Paving WorkDocument15 paginiITP For Concrete Paving WorkShewale Pravin100% (1)

- 029-QCP For Roads & Paving PDFDocument22 pagini029-QCP For Roads & Paving PDFKöksal PatanÎncă nu există evaluări

- ITP CIVIL WORK-Rev-1Document6 paginiITP CIVIL WORK-Rev-1Ateeq Rahman100% (1)

- Inspection and Test Plan For Earthworks NSCR-PSC-N05-CRKDPT-PRO-QA-000000Document7 paginiInspection and Test Plan For Earthworks NSCR-PSC-N05-CRKDPT-PRO-QA-000000ResearcherÎncă nu există evaluări

- RLC-AH-QP-91-3001 Inspection Test Plan For Plumbing Works-1Document6 paginiRLC-AH-QP-91-3001 Inspection Test Plan For Plumbing Works-1nighttrasherÎncă nu există evaluări

- Itp For Construction of Precast FoundationDocument7 paginiItp For Construction of Precast Foundationreachpunnya5538100% (2)

- ITP For Civil WorksDocument8 paginiITP For Civil WorksOsama Waheed100% (1)

- Appendix H: Design and Construction Manual Design RequirementsDocument17 paginiAppendix H: Design and Construction Manual Design RequirementsPageduesca RouelÎncă nu există evaluări

- Inspection Plan TemplateDocument1 paginăInspection Plan Templatedennis386100% (1)

- ITP-00010 Pavement Road WorksDocument3 paginiITP-00010 Pavement Road WorksIsmail MydeenÎncă nu există evaluări

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 paginiProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKÎncă nu există evaluări

- ITP Excavation & Backfilling For MCUPDocument9 paginiITP Excavation & Backfilling For MCUPShewale PravinÎncă nu există evaluări

- T-242 - Method Statement For Excavation & BackfillDocument9 paginiT-242 - Method Statement For Excavation & Backfillsindalisindi100% (1)

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFDocument53 paginiA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFMOST PASONÎncă nu există evaluări

- 19-09-24 Preparatory Work Method Statement MobilizationDocument2 pagini19-09-24 Preparatory Work Method Statement MobilizationShahab Khan100% (2)

- 022 Itp For Fence Gate PDFDocument5 pagini022 Itp For Fence Gate PDFJithesh.k.sÎncă nu există evaluări

- 18.9 ITP SUB BASE Rev01Document2 pagini18.9 ITP SUB BASE Rev01YEHIA100% (1)

- 040-ITP For Repair of Steam Distribution Manifold PDFDocument11 pagini040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanÎncă nu există evaluări

- 032-Itp For Painting and Coating PDFDocument19 pagini032-Itp For Painting and Coating PDFKöksal Patan80% (20)

- 034-ITP For Air Cooled Steam Condenser PDFDocument41 pagini034-ITP For Air Cooled Steam Condenser PDFKöksal PatanÎncă nu există evaluări

- 013-WPS FOR SS321 (1.5 - 26.6 MM) PDFDocument26 pagini013-WPS FOR SS321 (1.5 - 26.6 MM) PDFKöksal PatanÎncă nu există evaluări

- 014-MS For General Scaffolding PDFDocument33 pagini014-MS For General Scaffolding PDFKöksal Patan100% (2)

- 013-MS For Mass Concrete Works PDFDocument26 pagini013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- 017-CIVIL-MS For Installation of Fence & Gate PDFDocument18 pagini017-CIVIL-MS For Installation of Fence & Gate PDFKöksal Patan100% (6)

- 016-CIVIL - MS Anchor Bolt Installation PDFDocument14 pagini016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- 013-MS Utilization of Hilti DX 76 PDFDocument51 pagini013-MS Utilization of Hilti DX 76 PDFKöksal PatanÎncă nu există evaluări

- 012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFDocument16 pagini012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFKöksal Patan91% (11)

- 014-MS For Bolt Tightening (Piping& Equipments) PDFDocument23 pagini014-MS For Bolt Tightening (Piping& Equipments) PDFKöksal PatanÎncă nu există evaluări

- 011-Method Statement For Repair of Concrete Works PDFDocument25 pagini011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- 047-Itp For Oxygen Lines Fabrication and Installation PDFDocument28 pagini047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanÎncă nu există evaluări

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFDocument18 pagini046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanÎncă nu există evaluări

- 049-Itp For Lighting and Small Power (Building) PDFDocument15 pagini049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- 012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFDocument18 pagini012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFKöksal PatanÎncă nu există evaluări

- 010-MS For Grouting PDFDocument33 pagini010-MS For Grouting PDFKöksal PatanÎncă nu există evaluări

- 010-MS For Welding and Hot Works For General Activities at TSF Area PDFDocument17 pagini010-MS For Welding and Hot Works For General Activities at TSF Area PDFKöksal PatanÎncă nu există evaluări

- 009-Method Statement - Main Erection Sequence For Acc PDFDocument68 pagini009-Method Statement - Main Erection Sequence For Acc PDFKöksal Patan100% (6)

- 009-Civil-Ms Concrete Works PDFDocument27 pagini009-Civil-Ms Concrete Works PDFKöksal PatanÎncă nu există evaluări

- 041 - ITP For Painting (Building) PDFDocument12 pagini041 - ITP For Painting (Building) PDFKöksal Patan78% (9)

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFDocument23 pagini008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanÎncă nu există evaluări

- 040-ITP For Repair of Steam Distribution Manifold PDFDocument11 pagini040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanÎncă nu există evaluări

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFDocument25 pagini007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanÎncă nu există evaluări

- 008-CIVIL-MS Backfilling Works PDFDocument16 pagini008-CIVIL-MS Backfilling Works PDFKöksal Patan100% (1)

- 038-Itp For Coldboxes PDFDocument25 pagini038-Itp For Coldboxes PDFKöksal PatanÎncă nu există evaluări

- 039-Itp For Embedded Plate PDFDocument7 pagini039-Itp For Embedded Plate PDFKöksal PatanÎncă nu există evaluări

- Viscount Rotational Moulding Iviscount - Rotational - Moulding - Infrastructure - Catalogue - Railnfrastructure Catalogue RailDocument2 paginiViscount Rotational Moulding Iviscount - Rotational - Moulding - Infrastructure - Catalogue - Railnfrastructure Catalogue RailredchaozÎncă nu există evaluări

- Week 4 PRPRAC 1Document26 paginiWeek 4 PRPRAC 1Weero GretÎncă nu există evaluări

- Chapter8 Buckling PDFDocument8 paginiChapter8 Buckling PDFdroessaert_stijnÎncă nu există evaluări

- Case StudyDocument4 paginiCase StudyHarsh Vatsyayen100% (1)

- SCAFFOLDING PROCEDURE Rev.1Document14 paginiSCAFFOLDING PROCEDURE Rev.1คุณพ่อน้อง บิ๊กบอส100% (1)

- Synopsis ShivaniDocument11 paginiSynopsis Shivanisv928957Încă nu există evaluări

- Cmat 11Document4 paginiCmat 11Emmanuel Cafirma RiveraÎncă nu există evaluări

- CA42 Holding Down Bolts To EC2Document4 paginiCA42 Holding Down Bolts To EC2zaidiamna9Încă nu există evaluări

- Corrugated Aluminum Jacketing CladdingDocument3 paginiCorrugated Aluminum Jacketing CladdingGia Minh Tieu TuÎncă nu există evaluări

- Dolphin Capital Investors (DCI LN) Investment ThesisDocument27 paginiDolphin Capital Investors (DCI LN) Investment ThesistennismanacpÎncă nu există evaluări

- Trellidor Premium Rollerstyle E BrochureDocument1 paginăTrellidor Premium Rollerstyle E BrochureKanishka DharÎncă nu există evaluări

- Canopy Estimate 07222019Document7 paginiCanopy Estimate 07222019tony moralesÎncă nu există evaluări

- Flange Coupling Lab PDFDocument25 paginiFlange Coupling Lab PDFAli Raza MalikÎncă nu există evaluări

- Print 1 1 PDFDocument74 paginiPrint 1 1 PDFLhester PresasÎncă nu există evaluări

- ADSSC Standard and Typical Drawings Version 3 0Document5 paginiADSSC Standard and Typical Drawings Version 3 0Brv ManÎncă nu există evaluări

- Living Area: Ground Floor Plan Second Floor PlanDocument4 paginiLiving Area: Ground Floor Plan Second Floor PlanMary Gold FerberÎncă nu există evaluări

- Fire Damper - FDDocument7 paginiFire Damper - FDZaw Moe KhineÎncă nu există evaluări

- Aggregate Comparison Research PaperDocument5 paginiAggregate Comparison Research PaperMuzammal HussainÎncă nu există evaluări

- Low Voltage Range of CablesDocument80 paginiLow Voltage Range of Cablesgj42107Încă nu există evaluări

- Cost Estimating Guide For Road ConstructionDocument118 paginiCost Estimating Guide For Road Constructionscottrileywilson100% (3)

- Asme Section II A Sa-395Document12 paginiAsme Section II A Sa-395Anonymous GhPzn1xÎncă nu există evaluări

- 5-2 Api S 625Document2 pagini5-2 Api S 625ycwangÎncă nu există evaluări

- DPS Standard For Project DocumentationDocument18 paginiDPS Standard For Project DocumentationalwagieÎncă nu există evaluări

- Influence of Cement Ageing and Addition Time On The Performance of Superplastics PDFDocument10 paginiInfluence of Cement Ageing and Addition Time On The Performance of Superplastics PDFTran Huynh NamÎncă nu există evaluări

- PLANDocument14 paginiPLANElmon Ray JuratilÎncă nu există evaluări

- ATS Pristine 2 SpecificationsDocument1 paginăATS Pristine 2 SpecificationsZama KazmiÎncă nu există evaluări

- Tabaco ChurchDocument5 paginiTabaco ChurchMariah Jasmine SebastianÎncă nu există evaluări

- Brochure Under Sleeper Pads For Ballasted Track enDocument16 paginiBrochure Under Sleeper Pads For Ballasted Track ensorinarseneÎncă nu există evaluări