Documente Academic

Documente Profesional

Documente Cultură

Dresser Rand-MOS - 12

Încărcat de

bavarian_sheepTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Dresser Rand-MOS - 12

Încărcat de

bavarian_sheepDrepturi de autor:

Formate disponibile

Bringing energy and the environment into harmony.

MOS compressors

MOS

TM

compressors

The medium oilfield separable

compressor for common jobs.

Dresser-Rand brings more than

60 years of separable compressor

operating experience to the

medium-duty MOS compressor

line.

These rugged compressors

are engineered for high speed

and high horsepower gas field

applications, including gas lift, gas

gathering, pipeline boosting, gas

transmission, underground gas

storage (injection and withdrawal),

fuel gas boosting, landfill gas

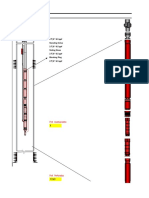

MOS compressor frame.

recovery, enhanced oil recovery,

and many other applications.

They are suited not only for sweet

natural gas services, but can be

built to handle sour natural gas,

propane, carbon dioxide, air,

nitrogen, and most other gases.

As an alternative to more industry

standard type units, the MOS

compressor establishes itself by

taking the best of previous

Dresser-Rand designs, competing

units and "voice of client" input.

The lower cost, compact design

and rapid delivery of packaged

MOS compressors make it an ideal

choice for the most common of

gas field applications such as gas

gathering and gas processing.

With more than 30 years of

experience in our closed-loop

test facility using a variety of field

gases, Dresser-Rand ensures the

integrity of the MOS compressor

design and performance.

Rated to 4,440 hp (3,310 kW) and

1,500 rpm with design pressures

up to and exceeding 10,000 psig

(690 bar), MOS compressors

provide long life because of their

heavy-duty construction. They are

available in two-, four- or six-throw

configurations and in cylinder sizes

ranging from 3.75 (95.3 mm) to

20.50 (520.7 mm). The rigid,

cast iron compressor frame is

heavily ribbed and reinforced, with

integrally cast crosshead extensions

to handle almost any gas field

requirement.

A SINGLE SOURCE FOR ALL

YOUR COMPRESSION NEEDS

MOS compressors offer many

benefits to gas compressor users,

whether used in a standard or

customized package, in rental

service or purchased outright.

Dresser-Rand and its authorized

distributors can provide singlesource responsibility, including

engineering, manufacturing,

packaging, installation, parts,

and service.

With MOS compressors

on the job, you

can expect less

maintenance and

less fuel consumption.

Dresser-Rand and its

distributors support the

MOS compressor line with a

network of computerized parts

warehouses, and overhaul/revamp

facilities located throughout the

U.S. and Canada.

Rugged design for smooth operation, lon

Every MOS compressor includes components designed to enhance

performance. The compressor frame and cylinders are matched to provide

years of smooth, reliable, efficient compression service when operated within

OEM recommendations.

Cylinder Basics

MOS compressor cylinders are gas-cooled for most applications. For special applications, the MOS compressor is available

with water-cooled cylinders that provide additional protection in higher temperature and higher pressure services. Each

system is designed and engineered to match your operating needs.

Cylinder performa

of valves which

PF valve (porte

(mini-Po

Dres

ma

an

rel

pre

opera

provide c

Gas-cooled MOS cylinders use a solid bore cylinder barrel cast in nodular iron. Water-cooled MOS cylinders are HOS

cylinders adapted to the MOS frame and are jacketed for circulating coolant.

A full line-up of higher pressure, forged steel cylinders are available in sizes 3.75 (95.3 mm) to 6.5 (165.1 mm).

The line-up also includes a pipeline cylinder for gas transmission and a storage cylinder for gas injection and withdrawal

applications.

Frame Basics

The open top frame construction ensures rigidity while

providing easy access to major running gear components from

the top. Multiple covers and large access areas are provided

for easy maintenance and inspection. Two-piece precision trimetal bronze main bearings ensure better heat dissipation,

higher reliability and increased life. Thrust shoes are bronze.

As an option, a full-length distance piece with oversized

access doors are available. The unique thru-bolt distance

piece is designed for improved load carrying ability.

High-strength, nodular iron crossheads

feature a Babbitt overlay for enhanced

lubrication. Surface-hardened crosshead

pins are full floating for optimum

reliability, and there are no crosshead pin

bushings to contend with.

long life and efficiency.

The MOS compressor uses either solid or two-piece cast iron or

aluminum pistons depending upon service conditions, balance

and inertia forces. Integral steel pistons and rods may be used in

high-pressure applications.

er performance is optimized through the use of two types

alves which are available on the MOS compressor, the

valve (ported plate type) and the D-R Magnum valve

(mini-Poppet element). Both valves use exclusive

Dresser-Rand Hi-Temp nonmetallic wear parts

material. Each valve offers different advantages

and is sized to optimize performance and

reliability for a given application or client

preference. Optional high-volume, manually

operated variable volume clearance pockets

provide clearance for greater capacity control.

Each piston rod is made from a high-strength alloy steel and is

wet-magnetic-particle inspected. Every piston rod thread form is

inspected using Johnson gauging. Piston rods for a given stroke

are identical, regardless of cylinder size.

One packing case design is used,

regardless of cylinder size or stroke.

Packing cases use the emission

control ring design to minimize

leakage.

Crankpin and main bearings are

two-piece precision tri-metal

bronze and are identical, which

reduces spare parts stocking. They

are provided with a micro-babbitt

overlay plate for added start-up

protection and corrosion resistance.

Forged steel connecting rods are

rifle-drilled for pressure lubrication of

crossheads and feature high-strength

bolts with rolled threads. Connecting

rod pin bushings are centrifugally cast

bronze with nickel plate barrier and

topped with lead tin copper overlay

on bore for reliable break-in.

The heavy-duty forged alloy crankshaft is rifle-drill balanced

for connecting rod lubrication. The crankshaft is equipped

with integral counterweights on the two- and four-throw

units to reduce horizontal moments.

Short panel 8.375 x 11

Ratings

Model

Stroke

in. (mm)

Number of

Cylinders

Nominal Rated

Power

hp (kW)

Max. Allowable

Operating Rod Load

lbs. (kN)

Rated

rpm

5MOS2

5 (127)

1,950 (1,454)

45,000 (200)

1,500

5MOS4

5 (127)

3,900 (2,908)

45,000 (200)

1,500

5MOS6

5 (127)

4,200 (3,132)

45,000 (200)

1,500

6MOS2

6 (152.4)

1,800 (1,342)

45,000 (200)

1,200

6MOS4

6 (152.4)

3,600 (2,685)

45,000 (200)

1,200

6MOS6

6 (152.4)

4,320 (3,221)

45,000 (200)

1,200

7MOS2

7 (177.8)

1,700 (1,268)

45,000 (200)

1,000

7MOS4

7 (177.8)

3,400 (2,535)

45,000 (200)

1,000

7MOS6

7 (177.8)

4,440 (3,311)

45,000 (200)

1,000

Standard Features

Optional Features

VVCP (Variable Volume Clearance Pocket)

A chain-drive, positive displacement gear-type frame lube oil

pump, with ship loose cooler and frame-mounted full-flow oil filter

Drilled, tapped and plugged indicator holes on all cylinders

Vented, full-floating, filled Teflon packing rings with cast iron

back-up rings

Filled Teflon, multi-piece combination rings perform double

duty as both compression and rider rings

Frame-fed block distribution system

External frame oil relief valve

Dresser-Rand TC3 (HVOF) coated

piston rods

17-4 PH stainless steel piston rods

Purged packing and purged wiper case

Single- or two-compartment distance

piece

Crankcase and lubricator oil heaters

Crankcase explosion relief devices

Main bearing RTDs

Torsional studies

Flywheel (if required)

Dynamic valve analysis

Pump-to-point cylinder lubrication

Electric drive lubricator

Dual oil filter

Automatic unloading devices

Manual frame pre-lube pump

118.4" (3,008 mm) (6 throw)

114.4" (2,906 mm) (4 throw)

Frame Specifications and Dimensions

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . One piece, cast iron, high-strength

Crosshead pins . . . . . . . . . . . . . . . . . . . . Alloy-steel, hardened, super-finished

Main bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tri-metal

Crosshead pin bushings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bronze

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Forged steel

Piston rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Alloy steel, rolled threads

Crankpin bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tri-metal

Connecting rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Forged steel

Oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gear-type, chain-drive

Connecting rod bolts . . . . . . . . . . . . . . . . . . . . . . . . Alloy steel, rolled threads

Oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Full-flow, 10 micron

Connecting rod bushings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tri-metal

Oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Shell-and-tube

Crossheads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nodular iron, babbit

Lubricator . . . . . . . . . . . . . . . . . . . . . . . . . . . . Flange mounted, chain-drive

42"

1,067 mm

42"

1,067 mm

67.25"

1,708 mm

26.375"

670 mm

26.375"

670 mm

B

C

42"

1,067 mm

33.38"

848 mm

Note: E dimension

is the piston and rod

removal distance.

E

33.38"

848 mm

Standard Cylinder offering and dimensions

Cylinder

Size

in. (mm)

20.50 (520.7)

19.00 (482.6)

17.50 (444.5)

16.25 (412.7)

15.00 (381.0)

14.00 (355.6)

13.00 (330.2)

12.25 (311.1)

11.50 (292.1)

10.50 (266.7)

9.50 (241.3)

9.00 (228.6)

8.50 (215.9)

8.00 (203.2)

7.50 (190.5)

7.00 (177.8)

6.50 (165.1)

6.00 (152.4)

5.75 (146.0)

4.75 (120.7)

3.75 to 7.00

(95.3 to 177.8)

MAWP

psig

(kg/cm2)

No Jacket

265 (18.6)

265 (18.6)

385 (27.1)

385 (27.1)

385 (27.1)

385 (27.1)

550 (38.7)

550 (38.7)

660 (46.6)

660 (46.6)

750 (52.7)

750 (52.7)

1,150 (80.8)

1,150 (80.8)

1,650 (116.0)

1,650 (116.0)

1,925 (135.3)

1,925 (135.3)

1,925 (135.3)

1,925 (135.3)

6,000 (421.8)

42"

1,067 mm

A

in. (mm)

B

in. (mm)

C

in. (mm)

43.5 (1,105)

43.5 (1,105)

43.5 (1,105)

43.5 (1,105)

43.5 (1,105)

43.5 (1,105)

43.5 (1,105)

43.5 (1,105)

43.5 (1,105)

43.5 (1,105)

43.5 (1,105)

43.5 (1,105)

43.5 (1,105)

43.5 (1,105)

43.5 (1,105)

43.5 (1,105)

43.5 (1,105)

43.5 (1,105)

43.5 (1,105)

43.5 (1,105)

15.0 (381)

15.0 (381)

15.0 (381)

15.0 (381)

15.0 (381)

15.0 (381)

15.0 (381)

15.0 (381)

15.0 (381)

15.0 (381)

15.0 (381)

15.0 (381)

15.0 (381)

15.0 (381)

15.0 (381)

15.0 (381)

15.0 (381)

15.0 (381)

15.0 (381)

15.0 (381)

58.5 (1,486)

58.5 (1,486)

58.5 (1,486)

58.5 (1,486)

58.5 (1,486)

58.5 (1,486)

58.5 (1,486)

58.5 (1,486)

58.5 (1,486)

58.5 (1,486)

58.5 (1,486)

58.5 (1,486)

58.5 (1,486)

58.5 (1,486)

58.5 (1,486)

58.5 (1,486)

58.5 (1,486)

58.5 (1,486)

58.5 (1,486)

58.5 (1,486)

D

in. (mm)

102.0 (2,591)

102.0 (2,591)

102.0 (2,591)

102.0 (2,591)

102.0 (2,591)

102.0 (2,591)

102.0 (2,591)

102.0 (2,591)

102.0 (2,591)

102.0 (2,591)

102.0 (2,591)

102.0 (2,591)

102.0 (2,591)

102.0 (2,591)

102.0 (2,591)

102.0 (2,591)

102.0 (2,591)

102.0 (2,591)

102.0 (2,591)

102.0 (2,591)

E

in. (mm)

26.0 (660)

26.0 (660)

26.0 (660)

26.0 (660)

26.0 (660)

26.0 (660)

26.0 (660)

26.0 (660)

26.0 (660)

26.0 (660)

26.0 (660)

26.0 (660)

26.0 (660)

26.0 (660)

26.0 (660)

26.0 (660)

26.0 (660)

27.0 (686)

27.0 (686)

27.0 (686)

VA RY D E P E N D IN G ON P IP IN G N E E D S

HOS (higher pressure and/or water cooled) cylinders are available for the MOS compressor as well as cylinder liners.

Additionally, specialty cylinders for storage or pipeline applications can be applied to the MOS compressor.

For more information on the MOS Compressor, visit www.dresser-rand.com/gfc or contact us at:

Dresser-Rand

Gas Field Compressors

1354 South Sheridan Road

Tulsa, Oklahoma 74112-5416 USA

Tel: (Intl +1) 918-254-4099

Fax: (Intl +1) 918-252-9055

E-mail: GFC@dresser-rand.com

Dresser-Rand

Reciprocating Operations

100 Chemung Street

Painted Post, NY 14870 USA

Tel: (Intl +1) 607-937-2011

Fax: (Intl +1) 607-937-2905

For a complete list of products and services, visit www.dresser-rand.com or contact the following:

CORPORATE Headquarters

Regional Headquarters

Dresser-Rand

West8 Tower, Suite 1000

10205 Westheimer Road

Houston, Texas 77042

Tel: (Int'l +1) 713-354-6100

Fax: (Int'l +1) 713-354-6110

The Americas

West8 Tower, Suite 1000

10205 Westheimer Road

Houston, Texas 77042

Tel: (Intl +1) 713-354-6100

Fax: (Intl +1) 713-354-6110

Dresser-Rand

112, Avenue Kleber

Cedex 16

Paris 75784 France

Tel: (Intl +33) 156 26 71 71

Fax: (Intl +33) 156 26 71 72

Email: info@dresser-rand.com

EMEA

(Europe, Middle East & Africa)

Dresser-Rand S.A.

31 Boulevard Winston Churchill

Cedex 7013

Le Havre 76080, France

Tel: (Int'l +33) 2-35-25-5225

Fax: (Int'l +33) 2-35-25-5366/5367

Asia-Pacific

Dresser-Rand Asia Pacific Sdn Bhd

Unit 9-4, 9th Floor

Bangunan Malaysian Re

17 Lorong Dungun

Damansara Heights

50490 Kuala Lumpur, Malaysia

Tel: (Int'l +60) 3-2093-6633

Fax: (Int'l +60) 3-2093-2622

2012 Dresser-Rand. DRESSER-RAND is a registered trademark of Dresser-Rand Company. Printed in U.S.A.

This brochure comprises a general overview of the Dresser-Rand products described herein. It is solely for informational purposes, does not

represent a warranty or guarantee of the information contained herein, and is not to be construed as an offer to sell or solicitation to buy.

Contact Dresser-Rand for detailed design and engineering information suitable to your specific applications. Dresser-Rand reserves the right

to modify its products and related product information at any time without prior notice.

Form 85246

Bringing energy and the environment into harmony.

S-ar putea să vă placă și

- Profile of the International Pump Industry: Market Prospects to 2010De la EverandProfile of the International Pump Industry: Market Prospects to 2010Evaluare: 1 din 5 stele1/5 (1)

- KCDocument3 paginiKCSandheepKumarÎncă nu există evaluări

- 41000Document36 pagini41000tetiospamÎncă nu există evaluări

- Blackmer Maintenance ScheduleDocument16 paginiBlackmer Maintenance ScheduleAbrar HussainÎncă nu există evaluări

- 3620 10th Lores 2Document8 pagini3620 10th Lores 2Dinh Quang NhamÎncă nu există evaluări

- Assembling Procedure For Framo Pump Sd200Document4 paginiAssembling Procedure For Framo Pump Sd200Gonçalo CruzeiroÎncă nu există evaluări

- Diaphragm Pump NOVADOS - H3Document2 paginiDiaphragm Pump NOVADOS - H3yadavmihir63Încă nu există evaluări

- Bombas MultietapaDocument60 paginiBombas MultietapaManuel Jumbo RamírezÎncă nu există evaluări

- BPCL Training ReportDocument34 paginiBPCL Training ReportVishalVaishÎncă nu există evaluări

- Friction Loss On SuctionDocument2 paginiFriction Loss On SuctionSathish LingamÎncă nu există evaluări

- Hose Hanger Installation Operating Procedures Rev.1Document9 paginiHose Hanger Installation Operating Procedures Rev.1HSE PULAI AÎncă nu există evaluări

- Varat Pump and Machinery Pvt. Ltd.Document59 paginiVarat Pump and Machinery Pvt. Ltd.Kaushik ChakrabortyÎncă nu există evaluări

- UPA Type Series BookletDocument122 paginiUPA Type Series BookletRicardo BarrosÎncă nu există evaluări

- Manual Embudo SidewinderDocument18 paginiManual Embudo SidewinderHugo VillcaÎncă nu există evaluări

- Accelerated Multiplex Plunger Pumps PDFDocument20 paginiAccelerated Multiplex Plunger Pumps PDFJessica montesÎncă nu există evaluări

- 1887 125HP Union TD 120 Triplex Sour Pump PackageDocument11 pagini1887 125HP Union TD 120 Triplex Sour Pump PackageIvan Jojic100% (1)

- Flygt 3153 PDFDocument38 paginiFlygt 3153 PDFMarcelo DelgadoÎncă nu există evaluări

- Gefico Brochure +UFDocument40 paginiGefico Brochure +UF1zorro10% (1)

- ITT Gould PumpsDocument2 paginiITT Gould PumpsBilly ZununÎncă nu există evaluări

- Berkeley Ownwes ManualDocument28 paginiBerkeley Ownwes ManualMoses Alvarado100% (1)

- 20 RR NOV 300Q-5 Technical Data SheetsDocument2 pagini20 RR NOV 300Q-5 Technical Data SheetsJorge SoriaÎncă nu există evaluări

- Vertical PumpsDocument16 paginiVertical PumpsAdel ShatlaÎncă nu există evaluări

- 350q-5 Operation ManualDocument97 pagini350q-5 Operation ManualCesar Mora100% (2)

- 600ws Plunger OmegaDocument37 pagini600ws Plunger Omegaariel feÎncă nu există evaluări

- Effect of Viscosity On PumpsDocument4 paginiEffect of Viscosity On PumpsChemkhiÎncă nu există evaluări

- Data Sheet API 610Document20 paginiData Sheet API 610abisaÎncă nu există evaluări

- Fso pm3 CaaDocument2 paginiFso pm3 CaaskisascribdÎncă nu există evaluări

- Durco Mark 3 71569102 English 03-17Document72 paginiDurco Mark 3 71569102 English 03-17Triod jackson0% (1)

- Grundfosliterature 3366981Document48 paginiGrundfosliterature 3366981Leonardo GarroÎncă nu există evaluări

- ABB Ie2 High EfficiencyDocument4 paginiABB Ie2 High EfficiencyPARBATIÎncă nu există evaluări

- INFA3227 Esquema 01-MAR-2021Document9 paginiINFA3227 Esquema 01-MAR-2021sasgarisÎncă nu există evaluări

- Mud Pump CavitationDocument2 paginiMud Pump CavitationJonathan SumimsaÎncă nu există evaluări

- Wastecorp PlungerDocument18 paginiWastecorp PlungerAlexander MedinaÎncă nu există evaluări

- Flanges PDFDocument9 paginiFlanges PDFDGG2010Încă nu există evaluări

- API 618 Compressors1 PDFDocument0 paginiAPI 618 Compressors1 PDFAnonymous ffje1rpaÎncă nu există evaluări

- Kinney LR PumpsDocument20 paginiKinney LR Pumpsnarupv100% (1)

- Magnum IOM - (Rev H)Document53 paginiMagnum IOM - (Rev H)ibromishÎncă nu există evaluări

- Manual - DDR Pacific Rim Gear BoxDocument40 paginiManual - DDR Pacific Rim Gear BoxJuan Felipe Garza GÎncă nu există evaluări

- Fluid Catalytic CrackingDocument10 paginiFluid Catalytic CrackingImran Hanif LubisÎncă nu există evaluări

- Vacuum DehydratorDocument12 paginiVacuum DehydratorAntonne E. PhillipÎncă nu există evaluări

- Zollern - Plain Bearing - Type ZDocument20 paginiZollern - Plain Bearing - Type ZYuri BachÎncă nu există evaluări

- C Tuthill PDFDocument37 paginiC Tuthill PDFRaulEfrainCharrezCastilloÎncă nu există evaluări

- CatalogueDocument429 paginiCatalogueHarkamal SinghÎncă nu există evaluări

- Manual Cat Pump Model 45Document4 paginiManual Cat Pump Model 45Jhon Jairo Maestre UribeÎncă nu există evaluări

- GOULDS E GS and Z6 Technical Data FINAL 102018 PDFDocument84 paginiGOULDS E GS and Z6 Technical Data FINAL 102018 PDFpt.esasurya arcapadaÎncă nu există evaluări

- Maintenance Manual VCP Upto 80mmDocument16 paginiMaintenance Manual VCP Upto 80mmKaushik Chakraborty0% (1)

- A08012200E D en TPH400Document85 paginiA08012200E D en TPH400Doni Kurniawan100% (1)

- Fan Calculation MooreDocument8 paginiFan Calculation MooreArjun GirishÎncă nu există evaluări

- API Flanges GasketDocument6 paginiAPI Flanges GasketSurya NarayanÎncă nu există evaluări

- D SeriesDocument20 paginiD SeriesJorge A VilalÎncă nu există evaluări

- Bonetti Glass Level Gauge ManuelDocument8 paginiBonetti Glass Level Gauge ManuelZeeshan SajidÎncă nu există evaluări

- HOS (Heavy Oilfield Separable Compressor) BrochureDocument6 paginiHOS (Heavy Oilfield Separable Compressor) BrochureakamalapuriÎncă nu există evaluări

- Aurora 340 DsDocument4 paginiAurora 340 DsdesuyaÎncă nu există evaluări

- Cylinder Catalog HydraulicDocument130 paginiCylinder Catalog HydraulicArmando Alvarado AraujoÎncă nu există evaluări

- MC Series MNDocument33 paginiMC Series MNnvkjayanthÎncă nu există evaluări

- Catalog ParkerDocument230 paginiCatalog Parkeringerash_mic9067% (3)

- Isuzu NKR 4jb1Document62 paginiIsuzu NKR 4jb1Jakes Schmidt79% (14)

- HOS Frame and Running Gear Data Standard Frame and Running Gear AssembliesDocument8 paginiHOS Frame and Running Gear Data Standard Frame and Running Gear AssembliesJose Luis RattiaÎncă nu există evaluări

- Catálogo Cat Pump 230Document4 paginiCatálogo Cat Pump 230magliopatricioÎncă nu există evaluări

- طلمبات أفقية أحادية المرحلةDocument12 paginiطلمبات أفقية أحادية المرحلةRheoserve Industrial SolutionsÎncă nu există evaluări

- Data Sheet API 610Document20 paginiData Sheet API 610abisaÎncă nu există evaluări

- Data Sheet API 610Document20 paginiData Sheet API 610abisaÎncă nu există evaluări

- Shell Morlina OilDocument2 paginiShell Morlina OilabisaÎncă nu există evaluări

- Gevisa QM eDocument57 paginiGevisa QM eabisaÎncă nu există evaluări

- 2133 Rla RlvaDocument2 pagini2133 Rla RlvaAgung SubangunÎncă nu există evaluări

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsDe la EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsEvaluare: 4.5 din 5 stele4.5/5 (2)

- Introduction to Power System ProtectionDe la EverandIntroduction to Power System ProtectionEvaluare: 5 din 5 stele5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridDe la EverandShorting the Grid: The Hidden Fragility of Our Electric GridEvaluare: 4.5 din 5 stele4.5/5 (2)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDe la EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterÎncă nu există evaluări

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDe la EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialÎncă nu există evaluări

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDe la EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentEvaluare: 4.5 din 5 stele4.5/5 (21)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDe la EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesEvaluare: 4.5 din 5 stele4.5/5 (21)

- A Practical Handbook for Drilling Fluids ProcessingDe la EverandA Practical Handbook for Drilling Fluids ProcessingÎncă nu există evaluări

- Heat Transfer Engineering: Fundamentals and TechniquesDe la EverandHeat Transfer Engineering: Fundamentals and TechniquesEvaluare: 4 din 5 stele4/5 (1)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsDe la EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsÎncă nu există evaluări

- Well Integrity for Workovers and RecompletionsDe la EverandWell Integrity for Workovers and RecompletionsEvaluare: 5 din 5 stele5/5 (3)

- Flow Analysis for Hydrocarbon Pipeline EngineeringDe la EverandFlow Analysis for Hydrocarbon Pipeline EngineeringÎncă nu există evaluări

- Power Electronics Diploma Interview Q&A: Career GuideDe la EverandPower Electronics Diploma Interview Q&A: Career GuideÎncă nu există evaluări

- Electric Motors and Drives: Fundamentals, Types and ApplicationsDe la EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsEvaluare: 4.5 din 5 stele4.5/5 (12)

- Handbook on Battery Energy Storage SystemDe la EverandHandbook on Battery Energy Storage SystemEvaluare: 4.5 din 5 stele4.5/5 (2)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ADe la EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AÎncă nu există evaluări

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDe la EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsÎncă nu există evaluări

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceDe la EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceÎncă nu există evaluări

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsDe la EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsÎncă nu există evaluări

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerDe la EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerÎncă nu există evaluări

- Electric Motor Control: DC, AC, and BLDC MotorsDe la EverandElectric Motor Control: DC, AC, and BLDC MotorsEvaluare: 4.5 din 5 stele4.5/5 (19)

- Smart Power Distribution Systems: Control, Communication, and OptimizationDe la EverandSmart Power Distribution Systems: Control, Communication, and OptimizationÎncă nu există evaluări

- Hybrid Enhanced Oil Recovery Using Smart WaterfloodingDe la EverandHybrid Enhanced Oil Recovery Using Smart WaterfloodingÎncă nu există evaluări

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successDe la EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successEvaluare: 4.5 din 5 stele4.5/5 (3)

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977De la EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Încă nu există evaluări

- A Pathway to Decarbonise the Shipping Sector by 2050De la EverandA Pathway to Decarbonise the Shipping Sector by 2050Încă nu există evaluări