Documente Academic

Documente Profesional

Documente Cultură

The Transport Disengagement Height (TDH) in A Bubbling Fluidized

Încărcat de

Azharuddin_kfupmDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

The Transport Disengagement Height (TDH) in A Bubbling Fluidized

Încărcat de

Azharuddin_kfupmDrepturi de autor:

Formate disponibile

Refereed Proceedings

The 13th International Conference on

Fluidization - New Paradigm in Fluidization

Engineering

Engineering Conferences International

Year 2010

THE TRANSPORT

DISENGAGEMENT HEIGHT (TDH)

IN A BUBBLING FLUIDIZED BED

(BFB)

Chian Chan

Jonathan P.K. Seville

Jan Baeyens

University

of Warwick, chian.chan@warwick.ac.uk

of Warwick

University of Warwick

This paper is posted at ECI Digital Archives.

University

http://dc.engconfintl.org/fluidization xiii/34

Chan et al.: THE TRANSPORT DISENGAGEMENT HEIGHT (TDH) IN A BUBBLING FLUIDIZED

THE TRANSPORT DISENGAGEMENT HEIGHT (TDH) IN

A BUBBLING FLUIDIZED BED (BFB)

CHIAN W. CHAN, JONATHAN P.K. SEVILLE AND JAN BAEYENS

University of Warwick, School of Engineering, Coventry CV4 7AL (UK)

T: +44(0)7865076612 F: +44(0)2476418922

E: Chian.Chan@warwick.ac.uk

ABSTRACT

Bubbles bursting at the surface of a BFB project particles into the freeboard. Coarser

particles fall back, the solids loading declines with height in the freeboard, and fines

are ultimately carried over. The height of declining solids loading is the TDH,

measured in this research by Positron Emission Particle Tracking, and modeled

from a balance of forces on ejected particles. Model predictions and PEPT-data are

in good agreement. Empirical equations overestimate the TDH.

INTRODUCTION

Bubbles bursting at the surface of the BFB bed project particles into the freeboard.

Depending on their terminal velocities (Ut) and the gas velocity (U), particles are

carried up the freeboard to various heights. The solids loading (kg solids/m gas) will

decline with height. The region within which the solids loading falls is called TDH.

Coarse particles, even with Ut > U, are flung upwards by the bursting bubbles and

then fall back. Above the height they reach, only fines, i.e. particles with Ut < U, are

found. The concentration of fines further decreases with height and eventually

reaches a constant value. The projection height of the coarse particles is called the

splash height or TDH(C). The height above which the fines concentration remains

nearly constant is called TDH(F). The definition of a coarse or fine particle will

depend upon its Ut and upon U. Ut can be calculated according to Geldart [1].

The TDH and the solids loading in the freeboard influence the entrainment rate and

the rate of internal circulation of solids (Geldart et al. [2]), the heat transfer to

surfaces in splash zone and freeboard (George and Grace, [3]), and the progress of

reactions in the freeboard (Baeyens and Van Puyvelde [4]). The TDH has been

studied by measuring the entrainment rate in batch or semi-continuous experiments

at various velocities for different positions of the gas off take (e.g. Chan and

Knowlton [5], Schuurmans [6]); by visually observing the height above which no

downward moving coarse particles are observed (Sciazko et al. [7]); by particle

sampling (Fournol et al. [8]); or from the curve of the pressure drop profile versus

height in the freeboard (Geldart et al.[9], Smolders and Baeyens [10]).

Published by ECI Digital Archives, 2010

The 13th International Conference on Fluidization - New Paradigm in Fluidization Engineering, Art. 34 [2010]

The present paper reports results of real time particle trajectories as measured by

Positron Emission Particle Tracking (PEPT).

EMPIRICAL TDH EQUATIONS

Several empirical equations to predict TDH have been presented in literature and are

cited in Table 1 with their dominant parameters.

Authors

Soroko et al. [11]

Dominant parameters

Settled bed height (Hs)

Particle Re and Ar numbers

Amitin et al. [12]

Superficial gas velocity (U)

Fournol et al. [8]

Superficial gas velocity (U)

Horio et al. [13]

Diameter of bubble at bed

surface (dBo)

Wen et al. [14]

From entrainment rates

Pemberton et al. [15] Bubble velocity (UB) and dBo;

U, g and ; dp and p

Hamdullahpur et al. Bubble diameter (dBo)

[16]

Zenz [17]

Graph as function of (U Umb)

and dBo

Baron et al. [18]

Bubble velocity (UB)

Comments

Only valid for TDH(C)

Hs < 0.5 m, dp 0.7-2.5 mm

TDH(F)

TDH(F), for FCC powder

TDH(F)

TDH(F), for D < 0.6 m

TDH(F)

TDH(F)

TDH

TDH(F), UB calculated

from Werther [19]

Smolders

and Bubble diameter (dBo) and TDH(F)

Baeyens [10]

excess gas velocity (U Umf)

Table 1: Empirical correlations to predict the TDH

The TDH can thus be predicted when calculating dBo using e.g. Dartons equation

[20], and UB according to e.g. Werther [19]. For a 90 m sand in a 0.5m deep bed of

1m I.D at U = 0.4 m/s, predictions vary from 0.55 m [10], to 0.7 m [17, 18], to

approx. 1.8 m [13, 14, 15, 16], and 2.2 m [12]. The predicted TDH-values differ

significantly. Similar differences are predicted for different bed materials and

operating conditions. There is an obvious need to better predict TDH-values.

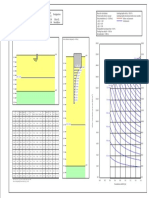

EXPERIMENTAL SET-UP, PROCEDURE AND ILLUSTRATION OF RESULTS

PEPT is a technique to track a fast moving particle in opaque vessels. It has been

extensively applied for obtaining dynamic information of powder flow in a very wide

variety of processes. 18F is prepared and is incorporated into the tracer by an anionsubstitution surface adsorption procedure (Fan et al. [21, 22]). The tracer is located

by triangulation of a number of detected annihilation events, and this ~ every 4 ms,

thus providing trajectory and velocity information. The bulk bed material was

rounded sand (120 m, 2260 kg/m) and rounded sand particles of 150, 250, 330,

390, 460 and 550 m were labelled, as well as alumina (135 m) and coal (390

m), each having a density of 1600 kg/m. A fluidized bed of 0.16 m I.D. with porous

plate distributor (high P) was used, for static bed heights of 0.25, 0.35 and 0.45 m.

http://dc.engconfintl.org/fluidization_xiii/34

Chan et al.: THE TRANSPORT DISENGAGEMENT HEIGHT (TDH) IN A BUBBLING FLUIDIZED

The superficial gas velocity was varied between 0.029 and 0.352 m/s, mostly in the

freely bubbling regime.

The detectors, each 0.47 m wide and 0.59 m high,

were positioned between 5 to 65 cm above the

static bed height, thus allowing for bed expansion.

The principle of the experimental layout is shown in

Fig. 1. The tracer particles were introduced with

the bed material. The exhaust of the rig was

connected to a bag filter. The obtained data, an

extensive list of consecutive particle locations in

three dimensions, determined the instantaneous

velocity as well as the location of the particle in the

freeboard. Since the PEPT-experiments lasted for

several hours at each combined operating

condition, tracer motions were seen in large

numbers, each time with an upward and a

downward movement. Occasionally, tracer was

seen to be re-entrained during its movement by a

second erupting bubble.

dp 135 m

dp 390 m

Fig. 1. Experimental set-up with

TDH50 TDH99 TDH50 TDH99

(1) BFB; (2) -ray cameras; (3)

Operating

air

velocity

and 0.125 0.241 0.037 0.071

vent, to (4) filter and (5)

particle

size 0.166 0.304 0.084 0.154

atmosphere; (6) tracer.

play important 0.255 0.477 0.254 0.416

roles. The height of projection increases with 0.375 0.609 0.306 0.576

increasing superficial air flow rate, with decreasing 0.394 0.646 0.34

OR

particle size. The TDH-values within given operating

0.515 OR

0.382 OR

conditions show a wide range of values due to the

0.024

distribution of bubble sizes and velocities and the TDHo 0.035

possible coalescence of 2 bubbles prior to erupting at

o: minimum TDH measured at

the surface. Data were hence analysed statistically, *TDH

lowest velocity

and given below with a value obtained at 50 % and 99 *OR: Outside range of camera

% of the cumulative TDH curve respectively. Some of Table 1a: TDH (in meters)

the data are illustrated in Tables 1a and 1b.

of alumina and coal

U,

dp 150m

dp of 320m

dp of 460m

dp of 550m

(m/s)

TDH50

TDH99

TDH50

TDH99

TDH50

TDH99

TDH50

TDH99

0.023

0.091

0.156

0.127

0.186

0.131

0.167

0.146

0.223

0.069

0.152

0.278

0.145

0.24

0.139

0.291

0.194

0.275

0.105

0.185

0.369

0.158

0.312

0.145

0.312

0.162

0.308

0.182

0.364

0.582

0.206

0.44

0.185

0.462

0.185

0.375

0.242

0.382

0.642

0.235

0.515

0.226

0.526

0.224

0.452

0.351

TDHo

0.455 OR

0.027

0.307

0.612

0.046

0.295 0.611

0.034

0.266 OR

0.041

*TDHo: minimum TDH measured at lowest velocity

*OR: Outside range of camera

Table 1b: TDH (in metres) of sand particles

Published by ECI Digital Archives, 2010

The 13th International Conference on Fluidization - New Paradigm in Fluidization Engineering, Art. 34 [2010]

MODELING APPROACH TO PREDICT TDH

The fundamental model equations were adapted from Do et al. [23] and transformed

to make a distinction between fine and coarse particles. Consider an individual

particle of size dp and density p, projected into the freeboard by a bursting bubble

rising with velocity UB. The superficial gas velocity in the freeboard is U. The

instantaneous particle velocity is v. In a dilute particle flow, without collisions and

associated momentum transfer, a balance of forces yields:

d 3p dv

6 dt

d 3p

6

CD

d 2p 1

4 2

(1)

The - -sign applies to the region where v > U; the + -sign to the zone where U > v.

Introducing the slip velocity, vr,, and group-constants a and b:

vr = U v ; a = (p g)g/ p and b = 3 g CD /( 4 p dp)

dv r

dt

Where,

b vr vr

dv r

dt

(2)

b v 2r

vr

0 (3a)

or,

dv r

dt

b v 2r

vr

(3b)

The equation was solved for an initial boundary condition corresponds with vr(t=0)=UUB. Therefore, the height that a particle reaches can be calculated from:

dh

dt

U vr

(4)

CD, the drag coefficient is itself a function of the instantaneous velocity and can be

calculated over the whole velocity range by equation (5a) below (Do et al. [23]):

CD

24

1 0.15 Re 0.687

Re

With Re

dp U v

0.42

1 42500 Re

1.16

(5a)

(5b)

Smolders et al. [10] previously demonstrated that only particles with Ut UB will be

ejected, thus fixing the maximum particle size, dp,max ejected by the bubbles:

http://dc.engconfintl.org/fluidization_xiii/34

Chan et al.: THE TRANSPORT DISENGAGEMENT HEIGHT (TDH) IN A BUBBLING FLUIDIZED

For U t

UB

and U t

4

3

g

g

d p,max g

CD

(6)

For reasons of simplicity it is assumed that the freeboard is not tapered i.e. that a

single value of the superficial gas velocity U can be used throughout the freeboard

height and is equal to the superficial velocity in the fluidised bed itself ( B= FB).

The bulk bed sand being a Geldart-B powder, the bubble diameter dB is calculated

from Darton et al. [20], whereas the bubble velocity is calculated by the procedure of

Werther [19].The operation was mostly freely bubbling (according to the Yagi and

Muchi criterion [24]), except at high air velocities in the 45 cm deep bed.

The solution of differential equations (3a) and (3b) with conditions of t=0 at vr = vr0

and t=ti at vr = vri is as follows:

vr

vr

ti

ti

1

Arctg

ab

1

ln

2 ab

b

v ri

a

a

b

a

b

Arctg

b

v r0

a

v ri

a

b

v r0

v ri

a

b

v r0

(7a)

(7b)

Since the drag coefficient CD is a function of vr, a stepwise calculation needs to be

used whereby v is calculated in steps of e.g. 0.01 m/s. The corresponding C D and

each corresponding value of t i are calculated. The path length is calculated by:

hi

vi t i

U v ri t i

(8)

When the particle reaches its final velocity, all h i are summed to calculate the total

path covered by the particles. According to the difference between their terminal

velocity and respective bubble or superficial gas velocity, we can classify the

particles in three groups:

Ut>UB: these particles are not ejected and need not be considered in TDH.

As shown in Figure 2(a), when U<Ut<UB, particles leave the bed at the bubble

velocity UB. At first the particle velocity exceeds the gas velocity (v r<0), and the

particle is decelerated by gravity and drag. When its velocity becomes smaller than

the gas velocity (vr>0), it is still decelerated by gravity, whilst the gas now tries to

accelerate it. Finally, the particle velocity becomes zero (vr=U) and its direction of

motion is reversed: the particle falls back into the bed. It is evident that in the

deceleration zone, both regimes of vr will occur since initially v will exceed U, but

after deceleration, U will exceed v. Hence both formulae (7a) and (7b) will be used to

calculate the total value of time t.

Published by ECI Digital Archives, 2010

The 13th International Conference on Fluidization - New Paradigm in Fluidization Engineering, Art. 34 [2010]

Fig 2(b) applies to the case when U>Ut. These particles are also projected at the

bubble velocity UB. The particle velocity exceeds the gas velocity (vr<0) and the

particle is decelerated by gravity and drag. When its velocity becomes smaller than

the gas velocity (vr>0), it is still decelerated by gravity, whilst the gas tries to

accelerate it. When vr equals the terminal velocity Ut of the particle, the system is in

equilibrium and the particle will be carried through the freeboard at this constant

velocity (U-Ut).

According to the definition of TDH(C), one can reasonably assume that this TDH(C)

corresponds with the maximum height reached by those coarse particles with Ut=Ub.

Similarly, the height at which a particle with Ut=U reaches its final velocity (vr=Ut or

v=0) is called the TDH(F).

Fig.2. The fate of particle movements in the freeboard: balance of forces acting on

an ejected particle where: (a) coarse particle (Ut>U) and (b) fine particle (Ut U)

DISCUSSION

http://dc.engconfintl.org/fluidization_xiii/34

Chan et al.: THE TRANSPORT DISENGAGEMENT HEIGHT (TDH) IN A BUBBLING FLUIDIZED

The TDH50-values of Tables 1 are in fair agreement with empirical predictions of

Smolders and Baeyens [10] and Zenz [17]. Other empirical equations considerably

overestimate TDH.

Figure

3

summarises

all

experimental

TDH50-data

in

comparison

with

model

predictions. A good agreement is

obtained, provided the air

velocity throughout the particle

jetting zone is taken as UB.

Fig.3. Comparing TDH model with TDH

experimental

Since TDH99 is about twice

TDH50, probably due to the effect

of coalescing bubbles near the

bed surface, the TDH99-value is

only predicted by the model

when using a bubble eruption

diameter

(and

associated

velocity) corresponding to about

1.5 dBo

CONCLUSIONS

PEPT gives a clear picture of the TDH for coarse and fine particles. Model

predictions improve understanding the fundamentals of particle projections and the

TDH, with a different behavior of coarse and light particles. The use of the model

predictions for industrial applications will be dealt with during the presentation.

ACKNOWLEDGEMENT

The authors wish to thank Prof.D.J.Parker (University of Birmingham) and Dr. X.Fan

(University of Edinburgh) for their assistance during the PEPT experimentation.

NOTATIONS

dBo

h, Hs

Re

TDH(C)

TDH(F)

t

Umf, Ut

Diameter of bubbles at the bed surface [m]

Height and settled bed height, respectively [m]

Reynolds number, as defined by Eqn. 5(b) [-]

Transport disengagement height for coarse particles, [m]

Transport disengagement height for fine particles, [m]

Time, [s]

Minimum fluidization velocity and terminal velocity of particles,

respectively [m s -1]

Published by ECI Digital Archives, 2010

The 13th International Conference on Fluidization - New Paradigm in Fluidization Engineering, Art. 34 [2010]

U

UB

Ufb

vr

v

g, p

dp

Superficial air velocity, [m s-1]

Velocity of erupting bubbles, [m s-1]

Velocity of air in the freeboard, [m s-1]

Slip velocity, [m s-1]

Velocity of particles, [m s-1]

Density of air and of particles, respectively [kg m -3]

Diameter of particles, [m]

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

[22]

[23]

[24]

Geldart, D (1986) Gas Fluidization Technology, John Wiley & Sons Ltd.,

N.Y., chapter 6

Geldart, D.; Broodryk, N. and Kerdoncuff, A. (1993), Powder Technol., 76,

175

George, S.E. and Grace, J.R. (1982) AIChE J, 28, 759-765

Baeyens, J. and Van Puyvelde, F. (1994), Jnl. Hazard. Mat., 37, 179-190

Chan, I.H. and Knowlton, T.M. (1984), Ann. Meeting of AIChE

Schuurmans, H.J.A. (1984), 8th Int. Symp. on Chem. React. Eng., I. Chem.

E. Symp. Ser., no. 87, 495

Sciazko, M.; Bandrowski, J. and Raczek, J. (1991) Powder Technol., 66, 33

Fournol, AB; Bergougnou, M.A. and Baker, C.G.J. (1973) Can. J. Chem.

Eng., 51, 401

Geldart, D; Xue, Y. and Xie, H.-Y. (1995), AIChE Symp. Ser., 91, 308, 93101

Smolders, K. and Baeyens, J., (1997) Powder Handling and Processing, 9,

no. 2, 123

Soroko, V.; Mikhalev, M. and Muklenov, I. (1969) Int. Chem. Eng., 9, 280

Amitin, A.V.; Martyushin, I.G. and Gurevich, D.A. (1986) Khim. Tk. Top.

Mas., 3, 20

Horio, M.; Taki, A.; Hsieh, Y.S. and Muchi, I. (1980) in Fluidization (Eds. JR

Grace and JM Matsen), Plenum Press, 509

Wen, C.Y. and Chen, L.H. (1982) AIChE J., 28, 117

Pemberton, S.J. and Davidson, J.F. (1986) Chem. Eng. Sci., 41, 253

Hamdullahpur, F. and MacKay, G.D.M., (1986) AIChE J., 32, 12, 2047

Zenz, F.A. (1983) Chem. Eng., nov, 28

Baron, T.; Briens, C.L. and Bergougnou, M.A. (1988) Can. J. Chem. Eng.,

66, 749

Werther, J. (1983) Fluidization IV, Japan, paper 1-12

Darton, R.C. (1979) Trans. Inst. Chem. Engrs., 57, 134

Fan, X., Parker, D.J., Smith, M.D., (2006) Nucl. Instr. and Meth. A 558, pp.

542-546

Fan, X., Parker,D.J., Smith,M.D., (2006) Nucl. Instr. and Meth. A 562

pp.345-350

Do, H.T.; Grace, J.R. and Clift, R. (1972), Powder Technology, 6, 195

Yagi, S. and Muchi, I. (1952), Chem. Eng. (Japan), 16, 307

http://dc.engconfintl.org/fluidization_xiii/34

S-ar putea să vă placă și

- Fluid Dynamics in Complex Fractured-Porous SystemsDe la EverandFluid Dynamics in Complex Fractured-Porous SystemsBoris FaybishenkoÎncă nu există evaluări

- Xuan 2004Document7 paginiXuan 2004Swastik RathÎncă nu există evaluări

- Zizheng Gong Et Al - High-Pressure Sound Velocity of Perovskite-Enstatite and The Possible Composition of The Earth's Lower MantleDocument5 paginiZizheng Gong Et Al - High-Pressure Sound Velocity of Perovskite-Enstatite and The Possible Composition of The Earth's Lower MantleDrebuioÎncă nu există evaluări

- Gas Hydrates 2: Geoscience Issues and Potential Industrial ApplicationsDe la EverandGas Hydrates 2: Geoscience Issues and Potential Industrial ApplicationsLivio RuffineÎncă nu există evaluări

- Eames 2003Document19 paginiEames 2003Kayvan SadeghyÎncă nu există evaluări

- Trajectory Characteristics of Inclined Turbulent Dense Jets: Environ. ProcessDocument16 paginiTrajectory Characteristics of Inclined Turbulent Dense Jets: Environ. Processjean miguel oscorima celisÎncă nu există evaluări

- Jet Scour - Hoffmans and Verheij - Maritime Engineering Vol 164 Issue MA4Document12 paginiJet Scour - Hoffmans and Verheij - Maritime Engineering Vol 164 Issue MA4Chris StolkerÎncă nu există evaluări

- Dense Jet Modelling Applied To The Design of Dense Effluent DiffusersDocument10 paginiDense Jet Modelling Applied To The Design of Dense Effluent Diffusersjean miguel oscorima celisÎncă nu există evaluări

- Lab Manual For Various Experiments in Chemical EngineeringDocument151 paginiLab Manual For Various Experiments in Chemical EngineeringAmey Pathak75% (4)

- B.A. Voronin Et Al - HDO Absorption Spectrum Above 11500 CM - 1: Assignment and DynamicsDocument15 paginiB.A. Voronin Et Al - HDO Absorption Spectrum Above 11500 CM - 1: Assignment and Dynamics4534567Încă nu există evaluări

- Hoque 2005Document16 paginiHoque 2005Cecilia GalvezÎncă nu există evaluări

- A Study of Two-Dimensional Flow Past An Oscillating CylinderDocument32 paginiA Study of Two-Dimensional Flow Past An Oscillating CylinderAntonio Martín AlcántaraÎncă nu există evaluări

- Ellipsoidal Model of The Rise of A Taylor Bubble in A Round TubeDocument19 paginiEllipsoidal Model of The Rise of A Taylor Bubble in A Round TubeWagner SorianoÎncă nu există evaluări

- 2005 Theoretical and Experimental Study On Wave Muttray Et AlDocument26 pagini2005 Theoretical and Experimental Study On Wave Muttray Et AlRaed Naim KhammashÎncă nu există evaluări

- 1 s2.0 S0167564802800971 MainDocument8 pagini1 s2.0 S0167564802800971 MainRicardo SilvaÎncă nu există evaluări

- 國內填海造陸背填料防漏設計案例探討Document14 pagini國內填海造陸背填料防漏設計案例探討喬誌江Încă nu există evaluări

- Gas Dispersion and De-Inking in Flotation ColumnDocument6 paginiGas Dispersion and De-Inking in Flotation ColumnAlonso Patricio Herrera GuzmanÎncă nu există evaluări

- Entrainment and Maximum Vapour Flow Rate of Trays: Arnold H. Van Sinderen, E. Frank Wijn and R.W. Jeroen ZantingDocument28 paginiEntrainment and Maximum Vapour Flow Rate of Trays: Arnold H. Van Sinderen, E. Frank Wijn and R.W. Jeroen ZantingdonyaÎncă nu există evaluări

- Numerical Simulation of Toluene Vapor Diffusion in Lim - 2014 - Procedia EngineeDocument6 paginiNumerical Simulation of Toluene Vapor Diffusion in Lim - 2014 - Procedia EngineejanainaÎncă nu există evaluări

- International Journal of Thermal Sciences: F.J. AriasDocument4 paginiInternational Journal of Thermal Sciences: F.J. AriasPrashant IngaleÎncă nu există evaluări

- A Spreadsheet Approach To Diverter Design Calculations: LouisianaDocument12 paginiA Spreadsheet Approach To Diverter Design Calculations: LouisianaMRizwanSadiq313Încă nu există evaluări

- Difusi Kasus Naftalena 110ch0079-8Document62 paginiDifusi Kasus Naftalena 110ch0079-8Tom Tomblowk Cliquers CliqÎncă nu există evaluări

- Absolute and Convective Instabilities of Two-Dimensional Bluff Body Wakes in Ground EffectDocument13 paginiAbsolute and Convective Instabilities of Two-Dimensional Bluff Body Wakes in Ground Effectsamik4uÎncă nu există evaluări

- Axial Dispersion of Particles in A Slugging Column-The Role of The Laminar Wake of The BubblesDocument14 paginiAxial Dispersion of Particles in A Slugging Column-The Role of The Laminar Wake of The BubblesGiuliano TpaÎncă nu există evaluări

- BPF Noise of A FanDocument15 paginiBPF Noise of A Fanrabea matoukÎncă nu există evaluări

- Simulation and Analysis of Noise Associated With Muzzle FlowDocument32 paginiSimulation and Analysis of Noise Associated With Muzzle Flowdiana nistoranÎncă nu există evaluări

- And In: Relative Contributions of Molecular Diffusion Anastomosis Gas Chromatographic ColumnsDocument6 paginiAnd In: Relative Contributions of Molecular Diffusion Anastomosis Gas Chromatographic Columnsnbson217Încă nu există evaluări

- 22 Entraiment A 2004Document34 pagini22 Entraiment A 2004neverwolfÎncă nu există evaluări

- UEME 3112 Free Turbulent JetDocument5 paginiUEME 3112 Free Turbulent Jet蒲俊雄Încă nu există evaluări

- A Literature Review: Structure of Flow in Hydraulic Jumps in Horizontal Rectangular ChannelsDocument14 paginiA Literature Review: Structure of Flow in Hydraulic Jumps in Horizontal Rectangular ChannelsMohamed AmmarÎncă nu există evaluări

- Baniamerian Aghanajafi SREDocument25 paginiBaniamerian Aghanajafi SRESeyedÎncă nu există evaluări

- Solid Gas FlowDocument9 paginiSolid Gas FlowAnu MittalÎncă nu există evaluări

- Axial Development of The Mean Flow in The Entrance Region of Turbulent Pipe and Duct FlowsDocument12 paginiAxial Development of The Mean Flow in The Entrance Region of Turbulent Pipe and Duct FlowsIrfan RimpisÎncă nu există evaluări

- Shuto RoturaDocument5 paginiShuto RoturaDaniel Rojas IturraÎncă nu există evaluări

- Expt B - Particle-Fluid Systems 2016WDocument20 paginiExpt B - Particle-Fluid Systems 2016WJamie SamuelÎncă nu există evaluări

- Drop Characteristics of Free Falling Nappe For Aerated Straight Drop SpillwayDocument6 paginiDrop Characteristics of Free Falling Nappe For Aerated Straight Drop SpillwayAÎncă nu există evaluări

- bf00616809 PDFDocument17 paginibf00616809 PDFSrinivas JangiliÎncă nu există evaluări

- Explosive Volcanic Eruptions - II The Atmospheric Trajectories of PyroclastsDocument12 paginiExplosive Volcanic Eruptions - II The Atmospheric Trajectories of PyroclastsSalma SherbazÎncă nu există evaluări

- Anti Vortex MeasuresDocument7 paginiAnti Vortex MeasuressunnytouchÎncă nu există evaluări

- Pickup and Saltation Velocitiesin Pneumatic ConveyingDocument12 paginiPickup and Saltation Velocitiesin Pneumatic ConveyingMichael J. BaneÎncă nu există evaluări

- 2D Jet Experiment: AE - 611 Laboratory ReportDocument13 pagini2D Jet Experiment: AE - 611 Laboratory ReportAbhishek KanthedÎncă nu există evaluări

- Experimental Thermal and Fluid Science: Serhat Kucukali, Hubert ChansonDocument13 paginiExperimental Thermal and Fluid Science: Serhat Kucukali, Hubert ChansonBrandon LevineÎncă nu există evaluări

- Experimental and Computational Fluid Dynamics Study of Dense-Phase, Transition Region, and Dilute-Phase SpoutingDocument8 paginiExperimental and Computational Fluid Dynamics Study of Dense-Phase, Transition Region, and Dilute-Phase SpoutingHicham HichamÎncă nu există evaluări

- Diffusion PDFDocument6 paginiDiffusion PDFAdeniyi AleseÎncă nu există evaluări

- Turbulence IntensityDocument15 paginiTurbulence IntensityWenbo TANÎncă nu există evaluări

- The Velocity Field Around A Taylor Bubble Rising in A Stagnant Viscous Uid: Numerical and Experimental ResultsDocument13 paginiThe Velocity Field Around A Taylor Bubble Rising in A Stagnant Viscous Uid: Numerical and Experimental Resultsvasumalhotra2001Încă nu există evaluări

- Air Sea ExchangeDocument10 paginiAir Sea Exchangedist2235Încă nu există evaluări

- 24 Ijecsmay PDFDocument11 pagini24 Ijecsmay PDFHarshaÎncă nu există evaluări

- Flow in Pipes and Closed ConduitsDocument31 paginiFlow in Pipes and Closed ConduitsRafael E. Becemberg LÎncă nu există evaluări

- Y2010V6N5P80C55291385Document19 paginiY2010V6N5P80C55291385Anonymous OrhjVLXO5sÎncă nu există evaluări

- Articol 1-2Document15 paginiArticol 1-2Angelescu FilipÎncă nu există evaluări

- Gravity Wave Methodology With Explanations and DerivationsDocument15 paginiGravity Wave Methodology With Explanations and Derivationsnebp.educationÎncă nu există evaluări

- (Journal of Hydrology and Hydromechanics) Discharge Coefficient of A Rectangular Sharp-Edged Broad-Crested WeirDocument5 pagini(Journal of Hydrology and Hydromechanics) Discharge Coefficient of A Rectangular Sharp-Edged Broad-Crested WeirThunder EagleÎncă nu există evaluări

- Helium-Filled Soap Bubbles Tracing Fidelity in Wall-Bounded TurbulenceDocument13 paginiHelium-Filled Soap Bubbles Tracing Fidelity in Wall-Bounded Turbulence1245141448Încă nu există evaluări

- Fluid Flow Through Packed BedDocument9 paginiFluid Flow Through Packed BedAmartya MitraÎncă nu există evaluări

- Liang1996 PDFDocument15 paginiLiang1996 PDFbaja2014Încă nu există evaluări

- Steam Hammer - TheoryDocument6 paginiSteam Hammer - TheoryktsnlÎncă nu există evaluări

- Two-Phase Flow Behavior and Spinner Data Analysis in Geothermal WellsDocument8 paginiTwo-Phase Flow Behavior and Spinner Data Analysis in Geothermal WellsIrwan JanuarÎncă nu există evaluări

- Co-Production of Upgraded Bio-Oils and H - Rich Gas From Microalgae Via Chemical Looping PyrolysisDocument14 paginiCo-Production of Upgraded Bio-Oils and H - Rich Gas From Microalgae Via Chemical Looping PyrolysisAzharuddin_kfupmÎncă nu există evaluări

- Economic Analysis of Improved Alkaline Water Electrolysis: Wilhelm Kuckshinrichs, Thomas Ketelaer and Jan Christian KojDocument13 paginiEconomic Analysis of Improved Alkaline Water Electrolysis: Wilhelm Kuckshinrichs, Thomas Ketelaer and Jan Christian KojAzharuddin_kfupmÎncă nu există evaluări

- Energies 16 02102Document20 paginiEnergies 16 02102Azharuddin_kfupmÎncă nu există evaluări

- Thermodynamic Assessment of Membrane-Assisted Premixed and Non-Premixed Oxy-Fuel Combustion Power CyclesDocument8 paginiThermodynamic Assessment of Membrane-Assisted Premixed and Non-Premixed Oxy-Fuel Combustion Power CyclesAzharuddin_kfupmÎncă nu există evaluări

- Ente201600095 Sup 0001 Misc - InformationDocument9 paginiEnte201600095 Sup 0001 Misc - InformationAzharuddin_kfupmÎncă nu există evaluări

- Gao 2016Document33 paginiGao 2016Azharuddin_kfupmÎncă nu există evaluări

- International Journal of Heat and Mass TransferDocument8 paginiInternational Journal of Heat and Mass TransferAzharuddin_kfupmÎncă nu există evaluări

- MMC 1Document2 paginiMMC 1Azharuddin_kfupmÎncă nu există evaluări

- Ceia Tin TopingDocument13 paginiCeia Tin TopingAzharuddin_kfupmÎncă nu există evaluări

- Concept Analysis of An Indirect Particle-Based Redox Process For Solar-Driven H O/Co SplittingDocument13 paginiConcept Analysis of An Indirect Particle-Based Redox Process For Solar-Driven H O/Co SplittingAzharuddin_kfupmÎncă nu există evaluări

- Thermal Performance Analysis of Porous Medium Solar Receiver With Quartz Window To Minimize Heat Ux GradientDocument12 paginiThermal Performance Analysis of Porous Medium Solar Receiver With Quartz Window To Minimize Heat Ux GradientAzharuddin_kfupmÎncă nu există evaluări

- CO Production From CO2 Via Reverse Water-Gas Shift Reaction Performed in A Chemical Looping Mode: Kinetics On Modified Iron..Document10 paginiCO Production From CO2 Via Reverse Water-Gas Shift Reaction Performed in A Chemical Looping Mode: Kinetics On Modified Iron..Azharuddin_kfupmÎncă nu există evaluări

- Thermodynamic Analysis of Beam Down Solar Gas Turbine Power Plant Equipped With Concentrating Receiver..Document10 paginiThermodynamic Analysis of Beam Down Solar Gas Turbine Power Plant Equipped With Concentrating Receiver..Azharuddin_kfupmÎncă nu există evaluări

- Aspen Plus Model For Moving Bed Coal GasifierDocument30 paginiAspen Plus Model For Moving Bed Coal GasifierAzharuddin_kfupm100% (2)

- Characterization and Evaluation of Prepared Fe O /al O Oxygen Carriers For Chemical Looping ProcessDocument10 paginiCharacterization and Evaluation of Prepared Fe O /al O Oxygen Carriers For Chemical Looping ProcessAzharuddin_kfupmÎncă nu există evaluări

- Jiang2014 PDFDocument13 paginiJiang2014 PDFAzharuddin_kfupmÎncă nu există evaluări

- Computational Fluid Dynamics For Microreactors Used in Catalytic Oxidation of PropaneDocument8 paginiComputational Fluid Dynamics For Microreactors Used in Catalytic Oxidation of PropaneAzharuddin_kfupmÎncă nu există evaluări

- (NATO ASI Series 110) Alirio Rodrigues, Carlos Costa, Rosa Ferreira (Auth.), Hugo I. de Lasa (Eds.)-Chemical Reactor Design and Technology_ Overview of the New Developments of Energy and PetrochemicalDocument838 pagini(NATO ASI Series 110) Alirio Rodrigues, Carlos Costa, Rosa Ferreira (Auth.), Hugo I. de Lasa (Eds.)-Chemical Reactor Design and Technology_ Overview of the New Developments of Energy and PetrochemicalAzharuddin_kfupmÎncă nu există evaluări

- Experimental Modeling of Vertical Dynamics of Vehicles With Controlled SuspensionsDocument23 paginiExperimental Modeling of Vertical Dynamics of Vehicles With Controlled SuspensionsAzharuddin_kfupmÎncă nu există evaluări

- (Nanostructure Science and Technology 174) Balasubramanian Viswanathan, Vaidyanathan (Ravi) Subramanian, Jae Sung Lee (Eds.)-Materials and Processes for Solar Fuel Production-Springer-Verlag New YorkDocument246 pagini(Nanostructure Science and Technology 174) Balasubramanian Viswanathan, Vaidyanathan (Ravi) Subramanian, Jae Sung Lee (Eds.)-Materials and Processes for Solar Fuel Production-Springer-Verlag New YorkAzharuddin_kfupmÎncă nu există evaluări

- The University of Nottingham: Answer ALL QuestionsDocument15 paginiThe University of Nottingham: Answer ALL QuestionsusgsusgsÎncă nu există evaluări

- DENSITYDocument9 paginiDENSITYJonaver RebiteÎncă nu există evaluări

- Science8 q1 Mod6 Heat-And-temperature FINAL07282020Document22 paginiScience8 q1 Mod6 Heat-And-temperature FINAL07282020kiannatherese andradaÎncă nu există evaluări

- DistillationDocument103 paginiDistillationKrishnamoorthy VijayalakshmiÎncă nu există evaluări

- Non Destructive Testing of Pipelines State and Methods For Its RepairingDocument19 paginiNon Destructive Testing of Pipelines State and Methods For Its RepairingCarlos MusellaÎncă nu există evaluări

- Polyphenol Oxidase Activity of Bananas 2Document5 paginiPolyphenol Oxidase Activity of Bananas 2Victor Nyarugwe100% (3)

- Boyle'S Law and Charles' Law: Learning Activity Sheets Grade 10 - ScienceDocument4 paginiBoyle'S Law and Charles' Law: Learning Activity Sheets Grade 10 - ScienceCristina Yuson67% (6)

- Acrylic PropertiesDocument2 paginiAcrylic PropertiesMarc AlfredÎncă nu există evaluări

- Tunneling-Like Wave Transmission in Non-Hermitian Lattices With Mirrored NonreciprocityDocument6 paginiTunneling-Like Wave Transmission in Non-Hermitian Lattices With Mirrored Nonreciprocitydonniedarko817Încă nu există evaluări

- Example 4.1: School of Engineering - EN334Document7 paginiExample 4.1: School of Engineering - EN334Ismail DoğanÎncă nu există evaluări

- THE BOUNDARY CONDITIONS IN DIRECT SIMPLE SHEAR TESTS Developments For Peat Testing at Low Normal StressDocument92 paginiTHE BOUNDARY CONDITIONS IN DIRECT SIMPLE SHEAR TESTS Developments For Peat Testing at Low Normal StressTiago SchuckÎncă nu există evaluări

- Form 5 Physics Test On Fluid QuestionsDocument2 paginiForm 5 Physics Test On Fluid QuestionsThapelo JeremiahÎncă nu există evaluări

- 4.0 CM 4.2 CM 4.4 CM 4.6 CMDocument1 pagină4.0 CM 4.2 CM 4.4 CM 4.6 CMisturmanÎncă nu există evaluări

- Hydrosphere Notes GeoDocument8 paginiHydrosphere Notes GeoMary Ingrid BumatayÎncă nu există evaluări

- Parameters For Foundation DesignDocument8 paginiParameters For Foundation DesignMehedi Hasan100% (2)

- Flow Through NozzlesDocument13 paginiFlow Through NozzlesBharat SharmaÎncă nu există evaluări

- Lecture 22 Thermal Engineering II (18.08.2020)Document36 paginiLecture 22 Thermal Engineering II (18.08.2020)Dr. BIBIN CHIDAMBARANATHANÎncă nu există evaluări

- Michelson Interferometer Experiment 1 Michelson InterferometerDocument6 paginiMichelson Interferometer Experiment 1 Michelson InterferometerSuman Dutta100% (1)

- Strain LifeDocument11 paginiStrain LifeChuoiEmÎncă nu există evaluări

- For Finals Practice ProblemsDocument13 paginiFor Finals Practice Problemsengr marcialawÎncă nu există evaluări

- Student Exploration: Limiting ReactantsDocument3 paginiStudent Exploration: Limiting ReactantsJohn BrauswetterÎncă nu există evaluări

- HeatDocument1 paginăHeatCarlo HafallaÎncă nu există evaluări

- Lecture On Diffusion in SolidsDocument31 paginiLecture On Diffusion in SolidsSiva Kumar RajuÎncă nu există evaluări

- Design of Fans Working in Potentially Explosive Atmospheres: British Standard Bs en 14986:2007Document40 paginiDesign of Fans Working in Potentially Explosive Atmospheres: British Standard Bs en 14986:2007Araz CabbarliÎncă nu există evaluări

- QPAMBSC17Document789 paginiQPAMBSC17jonnaÎncă nu există evaluări

- En - 1999 01 07 - T - WL 21507 Ea Srbs in Polysius Vertical Roller Mill QuadropolDocument2 paginiEn - 1999 01 07 - T - WL 21507 Ea Srbs in Polysius Vertical Roller Mill QuadropolmiteshmechÎncă nu există evaluări

- Lecture 11 - Introduction To Distributed Normal LoadsDocument30 paginiLecture 11 - Introduction To Distributed Normal LoadsLantretz LaoÎncă nu există evaluări

- KELOMPOK 6 (Arus Listrik Dan Persamaan Kontinuitas)Document13 paginiKELOMPOK 6 (Arus Listrik Dan Persamaan Kontinuitas)Ema MaharaniÎncă nu există evaluări

- Improved Membrane Absorbers OldfieldDocument208 paginiImproved Membrane Absorbers OldfieldChris WilbyÎncă nu există evaluări

- Final Report 2Document110 paginiFinal Report 2Aftab AliÎncă nu există evaluări

- University of Chicago Press Fall 2009 CatalogueDe la EverandUniversity of Chicago Press Fall 2009 CatalogueEvaluare: 5 din 5 stele5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesDe la EverandUniversity of Chicago Press Fall 2009 Distributed TitlesEvaluare: 1 din 5 stele1/5 (1)