Documente Academic

Documente Profesional

Documente Cultură

2nd Part

Încărcat de

Yoven NadaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

2nd Part

Încărcat de

Yoven NadaDrepturi de autor:

Formate disponibile

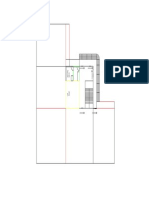

Design of the rafter

5

5.1

Design of the Rafter

Introduction

Portal frame design is usually governed by the verification of members at ultimate limit

service (ULS). Although serviceability limit state (SLS) checks are important, orthodox

frames are generally sufficiently stiff to satisfy the SLS deflection limits. Economy in

the overall frame can usually be achieved by the use of plastic analysis; this requires

Class 1 or 2 sections throughout and Class 1 where there is a hinge which is predicted to

rotate.

Rafters are subject to high bending moments in the plane of the frame, that vary from a

maximum hogging moment at the junction with the column to a minimum sagging

moment close to the apex. They are also subject to overall compression from the frame

action. They are not subject to any minor axis moments. Although member resistance is

important, stiffness of the frame is also necessary to limit the effects of deformed

geometry and to limit the SLS deflections. For these reasons, high strength members are

generally not used in portal frames, but lower steel grades with higher inertias.

Optimum design of portal frame rafters is generally achieved by use of:

1. A cross-section with a high ratio of Iyy to Izz that complies with the

requirements of Class 1 or Class 2 under combined major axis bending and axial

compression.

2. A haunch that extends from the column for approximately 10% of the frame

span. This will generally mean that the maximum hogging and sagging moments

in the plain rafter length are similar.

5.2

Rafter strength

The resistances of all critical cross-sections of the rafter must be verified in accordance

with Section 6 of EN 1993-1-1.

5.3

Rafter Stability

Both in-plane and out-of-plane checks are required. Initially, the out-of-plane checks

are completed to ensure that the restraints are located at appropriate positions and

spacing. In addition to the out-of-plane checks, in-plane checks must be satisfied using

Expression 6.61 of EN 1993-1-1.

33

Analysis of selected scheme

5.4

Design Summary

Below is the summary of the design carried out for the rafter. Detailed calculations are

attached after the design summary.

Table 3 - Design summary for the rafter

Description

Remarks

Section used

457 191 82 UB

Rafter classification

Class 1

Shear resistance of rafter

Ok

Bending and shear interaction

May be neglected

Compression resistance

Ok

Combined bending and axial force

May be neglected

Bending resistance

Ok

Axial verification

Ok

Lateral torsional buckling

Ok but purlin distance limited to 1.5 m

Spacing requirements of rafter

1.4 m

Flexural buckling resistance about minor

Ok

axis

Lateral torsional buckling resistance

Ok

34

Analysis of selected scheme

Interaction of axial force and bending

Ok

moment

Resistance to buckling and bending

Ok

Interaction of axial force and bending

Ok

moment (Second check)

35

S-ar putea să vă placă și

- Project Template Schedule 3 Week Look AheadDocument2 paginiProject Template Schedule 3 Week Look AheadYoven NadaÎncă nu există evaluări

- Fast Track Contracting (Mauritius) Limited: Request For Information (Rfi)Document1 paginăFast Track Contracting (Mauritius) Limited: Request For Information (Rfi)Yoven NadaÎncă nu există evaluări

- Detail ADocument1 paginăDetail AYoven NadaÎncă nu există evaluări

- CB - Ir - TemplateDocument1 paginăCB - Ir - TemplateYoven NadaÎncă nu există evaluări

- Upgrading of Cinq Arpents Bridge: September OctoberDocument2 paginiUpgrading of Cinq Arpents Bridge: September OctoberYoven NadaÎncă nu există evaluări

- Concrete Planning 05.06.2020Document28 paginiConcrete Planning 05.06.2020Yoven NadaÎncă nu există evaluări

- What Is Project ManagementDocument1 paginăWhat Is Project ManagementYoven NadaÎncă nu există evaluări

- Method Statement For Demolition WorksDocument1 paginăMethod Statement For Demolition WorksYoven NadaÎncă nu există evaluări

- I Don't Know What To Do. I Don't Know What To DoDocument1 paginăI Don't Know What To Do. I Don't Know What To DoYoven NadaÎncă nu există evaluări

- I DNT Know About ThisDocument8 paginiI DNT Know About ThisYoven NadaÎncă nu există evaluări

- Ladies and GentlemanDocument2 paginiLadies and GentlemanYoven NadaÎncă nu există evaluări

- Yoven Proposal ModelDocument1 paginăYoven Proposal ModelYoven NadaÎncă nu există evaluări

- Site Requirement (Version 1)Document3 paginiSite Requirement (Version 1)Yoven NadaÎncă nu există evaluări

- Study Timetable: Monday Tuesday Wednesday Thursday Friday Saturday SundayDocument2 paginiStudy Timetable: Monday Tuesday Wednesday Thursday Friday Saturday SundayYoven NadaÎncă nu există evaluări

- I See FireDocument1 paginăI See FireYoven NadaÎncă nu există evaluări

- TeamworkDocument3 paginiTeamworkYoven NadaÎncă nu există evaluări

- Research Proposal: Problem StatementDocument1 paginăResearch Proposal: Problem StatementYoven NadaÎncă nu există evaluări

- FrameDocument2 paginiFrameYoven NadaÎncă nu există evaluări

- Material SelectionDocument2 paginiMaterial SelectionYoven NadaÎncă nu există evaluări

- Mileage FormDocument1 paginăMileage FormYoven NadaÎncă nu există evaluări

- Loading - First FloorDocument8 paginiLoading - First FloorYoven NadaÎncă nu există evaluări

- The LetterDocument1 paginăThe LetterYoven NadaÎncă nu există evaluări

- FrameDocument2 paginiFrameYoven NadaÎncă nu există evaluări

- Items To Be DeliveredDocument1 paginăItems To Be DeliveredYoven NadaÎncă nu există evaluări

- AnacondaDocument1 paginăAnacondaYoven NadaÎncă nu există evaluări

- Design Calculation SheetDocument2 paginiDesign Calculation SheetYoven NadaÎncă nu există evaluări

- ReferencesDocument7 paginiReferencesYoven NadaÎncă nu există evaluări

- ParkingMap14 15Document1 paginăParkingMap14 15Yoven NadaÎncă nu există evaluări

- PHASE I - Project Proposal 16 Days Aug 18 '14 Data Collection 3 Days Aug 20 '14Document2 paginiPHASE I - Project Proposal 16 Days Aug 18 '14 Data Collection 3 Days Aug 20 '14Yoven NadaÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- All The Information You Need On The ENIG Black PadDocument10 paginiAll The Information You Need On The ENIG Black PadjackÎncă nu există evaluări

- ME305 - Advance Strength of Material PDFDocument2 paginiME305 - Advance Strength of Material PDFAnjali ShahÎncă nu există evaluări

- Lecture # 15 (Deformation of Axially Loaded Members)Document19 paginiLecture # 15 (Deformation of Axially Loaded Members)Os ,Încă nu există evaluări

- Syllabus Pap 1 XRDDocument31 paginiSyllabus Pap 1 XRDsriharivelagaÎncă nu există evaluări

- "Phase Transformation in Materials": 2015 FallDocument34 pagini"Phase Transformation in Materials": 2015 Fallmüsait bir yerdeÎncă nu există evaluări

- Analysis of Industrial Sheds Using Different Design PhilosophiesDocument10 paginiAnalysis of Industrial Sheds Using Different Design PhilosophiesChandu CKÎncă nu există evaluări

- EG Tribology Course PDH File5681Document60 paginiEG Tribology Course PDH File5681operationmanagerÎncă nu există evaluări

- Static Load Plate TestDocument11 paginiStatic Load Plate TestGechmcz100% (5)

- Chapter 4. Griffiths-Electric Fields in Matter 4.1Document8 paginiChapter 4. Griffiths-Electric Fields in Matter 4.1frank samndomiÎncă nu există evaluări

- Three Point and Four Point StarterDocument7 paginiThree Point and Four Point Starterkaran nirmala gajanan shindeÎncă nu există evaluări

- 1999 Xu and GoswamiDocument12 pagini1999 Xu and GoswamiimeqingenieriaÎncă nu există evaluări

- Annular RaftDocument8 paginiAnnular RaftMamoudAbdoÎncă nu există evaluări

- Welding DefectsDocument77 paginiWelding DefectsBalakumar100% (1)

- Assignment 5 PDFDocument2 paginiAssignment 5 PDFkiruba karanÎncă nu există evaluări

- Mechanical Systems and Signal ProcessingDocument23 paginiMechanical Systems and Signal ProcessingBeatriz WangÎncă nu există evaluări

- Series Resistors FloydDocument28 paginiSeries Resistors FloydNatalia khanÎncă nu există evaluări

- Charlotte Plastics Tech ManualDocument132 paginiCharlotte Plastics Tech ManualChairul AnwarÎncă nu există evaluări

- PROPERTIES OF MATTER Fill in BlanksDocument7 paginiPROPERTIES OF MATTER Fill in BlanksBalachandar2000Încă nu există evaluări

- Bolt Strength PDFDocument1 paginăBolt Strength PDFhlsimonÎncă nu există evaluări

- Thermo Calc & Dictra Computational Tool For Materials Science PDFDocument40 paginiThermo Calc & Dictra Computational Tool For Materials Science PDFHumberto Garcia CedilloÎncă nu există evaluări

- 20170214160241lecture 2 Skm3013-Virial and GraphicalDocument9 pagini20170214160241lecture 2 Skm3013-Virial and GraphicalAnonymous eGc6IFJc8GÎncă nu există evaluări

- 4 Shear Force and Bending MomentDocument20 pagini4 Shear Force and Bending Momentmuhamadsaidi0% (1)

- Electron Configuration DLP CalatravaDocument13 paginiElectron Configuration DLP CalatravaGwendolyn CalatravaÎncă nu există evaluări

- Experiment 1 FamiliarizationDocument7 paginiExperiment 1 FamiliarizationSeif-El-Islam BayÎncă nu există evaluări

- 34 CR Mo 4Document2 pagini34 CR Mo 4Stefan GhÎncă nu există evaluări

- Belzona 1111ps EnglDocument2 paginiBelzona 1111ps EnglNikolay GuerreroÎncă nu există evaluări

- Mds SM13CRM 110 enDocument5 paginiMds SM13CRM 110 enColinÎncă nu există evaluări

- IOT Practical FileDocument37 paginiIOT Practical FileFiroz AnsariÎncă nu există evaluări

- Module 1 - WSD FlexureDocument19 paginiModule 1 - WSD FlexureMichelle LeeÎncă nu există evaluări

- B32344E4252A080Document10 paginiB32344E4252A080GerardoÎncă nu există evaluări