Documente Academic

Documente Profesional

Documente Cultură

TRA-Street Light Foundation Installation Work

Încărcat de

binunalukandamDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

TRA-Street Light Foundation Installation Work

Încărcat de

binunalukandamDrepturi de autor:

Formate disponibile

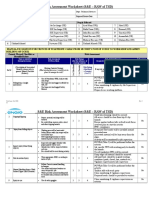

RISK ASSESSMENT

Activity

Street light foundation works

Method Statement No:

DOC NO:EXW P015-0000-SE-LNT-MT-00101,REV CB

Risk Assessment No:013/PP

Date of Assessment

07 Feb 15

Review Date

Revision 0

Act

No.

Activity

Survey,

Marking

layer/level

Potential Hazards

Consequence

Working near plant Injury from

Being hit by a moving

and vehicle

vehicle/plant

Dust

Working near live

road/traffic

06 Feb 2016

Risk Level

Control Measures

P S R

Personal injury

/property damage

from

Excavation

Underground utilities

Working with moving

plants

Noise

Dust

Collusion with

moving plants

and vehicle

Striking

underground

services

Slip, trip and fall

15

L&T/HSE/27

Rev 00 Page 1 of 5

Marking out areas near plant vehicle movement area shall be isolated via

physical barriers or controlled by banks man

PPE such as safety shoe, reflective jacket and helmet must be worn by all

those involved in the activities

The project engineer shall make sure that all required NOCs from

concerned authorities are obtained and available with him prior to start

removal of trees.

Obtain excavation work permit from HSE department before commencing

the work and site supervisor shall make sure the permit, Method statement

and TBT on method statement/risk assessments are available at site.

Competent supervision must be available during work

Identify and mark the underground utilities before starting the excavation

and protect the utilities (If any) during work

Provide adequate protection for open pits such as hard barrier, adequate

hazard warning signs (Danger Deep Excavation), mini flash lights if the

trench is near to live road.

Only manual excavation to be done in areas where there is presence of

underground utilities.

Equipment operation shall only be under the guidance of a competent banks

man.

PPE such as safety shoe, reflective jacket, dust mask. goggles and helmet

must be worn by all those involved in the activities

Resid

ual

Risk

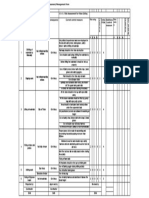

RISK ASSESSMENT

Moving traffic

Operatives and

plants/vehicle close

to the live traffic

Working close to Dust

Live Traffic/Road Foreign object

particles

Material falling from

moving vehicles.

Personal injury,

Fatality, Property

damage from traffic

accident

20

Construction of

precast

Foundation

Unsafe working

platform

Use of hand tools

and power tools

Manual Handling

protruding nails, sharp

edges

Ladder use

Contact with wet

concrete

Personal injuries from

Fall from height

Manual handling

Use of power tools

Health hazard from

contact with wet

concrete

L&T/HSE/27

Rev 00 Page 2 of 5

All Road diversions, Detour and working close to live road shall be carried out

as per approved detour plan and permit

All activity shall be carried out under competent supervision only.

A competent banks man must be present in the vehicle/plant movement area

Pedestrian and vehicle routes shall be segregated so far as reasonably

practical and shall be clearly marked with signs and barriers

All work shall be carried out within the work zone (hard barrier) no one will be

allowed to go to live road.

All employees shall follow instruction and attend training on site traffic

management and logistics

Avoid reverse movement

All employees should wear high visibility jacket at all times

No workers shall be allowed to cross live roads, always be away from live road

and adjacent barriers

Do not move any barrier or signs from its locations

Ensure adequate lighting provided during night activities

Do not store or keep any loose materials close to live road, Do not throw any

materials on live road

Heavy equipment such as cranes, boom loaders, excavators, back hoes should

not swing/extend their booms/arms towards live road direction at any time.

Banks man must control/guide the operators

Safe and suitable working platform with suitable access/egress shall be

provided for all work at height

Good housekeeping shall be maintained to minimise trip hazards and contact

with sharp objects such as protruding nails, sharp steel and tools....etc.

Only competent operatives will use the power tools such as angle grinder,

jack hammer...etc.

The operator/supervisor will check the tools for its inspection tag/colour

coding; guards are in place, cable...etc. while collecting the tool from store

and before starting the work.

The foreman must make sure that no one uses loose clothing when working

with grinder or any rotating machinery.

Trailing cables should not be in the path of other workers.

Plugs and sockets should be water resistant and colour coded. Not domestic

appliances.

Adequate PPE must be used by the operatives using power tools, such as

eye, respiratory protection, hand gloves, face shield while working with

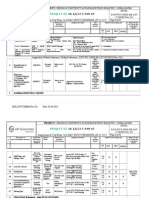

RISK ASSESSMENT

Erection of precast

chambers

Use of crane/

Lifting

operation

L&T/HSE/27

Crane associated

hazards

Structural failure

Erection of lifting

equipment at poor

ground condition,

close to edge of

embankment

Proximity Hazards

such as OH electric

line, Excavation,

mobile

equipments, other

traffic

Underground utilities

Use of damaged

lifting gears

Absent of competent

rigger/supervisor

Manual Handling

Inclement weather

Rev 00 Page 3 of 5

Injury/fatality by crane

failure, dropped load,

load striking other

object/personal

Death or Major Injury/

property damage from

lifting equipment

failure/dropped load

12

15

grinders...etc.

Manual handling technique must be taught to all operatives involved in the

activities

If ladders used as access/egress it must be secured top and bottom

Operatives involved in the concrete activity shall use appropriate PPE such

gumboots, hand gloves, safety glassetc.

Lifting permit must be obtained from HSE Department and implement the

permit requirements

Only competent crane operator will operate the crane

Competent lifting supervisor and rigger will present during lifting

Crane and lifting gears shall be suitable and certified, valid certificates must

be available with crane

Site Engineer shall make sure that the crane, lifting equipment, gears are

suitable for the load and visually inspected by HSE team and Lifting Permit

is obtained from HSE department.

The lifting supervisor and the crane operator must check the ground

condition and the surrounding of operation for any proximity hazard such

as edge of embankment, manholes, overhead electrical line, mobile

equipment etc.

All lifting activities shall be carried out by competent operator under a

competent supervisor and rigger.

The lifting area shall be demarked provide sufficient hazard warning signs

to avoid unauthorized entry of people/vehicle.

Ensure load is secured properly, remove if any loose material.

Use tag line of sufficient length to prevent unwanted swinging of the load.

Provide PPE such as hand gloves, goggles, safety shoes & hard hat to the

workers engaged.

Stop the activity in case of bad weather such as sand storm affecting

visibility, heavy wind 35 KMPH or more and heavy rainetc.

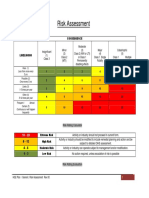

RISK ASSESSMENT

Severity

Risk Matrix

Consequence

Likelihood(probability) of occurrence

Very

Low

Medium

High

Low

1

2

3

4

Very

High

5

Insignificant

FAC

Insignificant

(QR 1 to 500)

Minor impact/ damage

Minor

Impact

Minor

(MTC/ RWC)

Moderate

(LTI/ PPD/ reportable

injuries)

Major

Single Fatality/ PTD

Moderate

(QR 501 to 5000)

Considerable

(QR 5001 to 50000)

Moderate Impact-reportable to

authority

Localized Impact- authority

involvement

Limited Impact

Considerable Impact

12

15

Major

(QR 50001 to 100000)

Major Impact

Country wide impact.

12

16

20

Catastrophic

Multiple PTDs/ Fatalities

Heavy

(above QR 100000)

Massive Impact

Worldwide impact

10

15

20

25

3

4

5

Risk Rating Criteria

Risk= Severity X Likelihood

Low Risk:

Risk Rating from 1 to 3

Medium Risk:

Risk Rating from 4 to9

High Risk:

Risk Rating from 10 to 25

Assessed By

L&T/HSE/27

Rev 00 Page 4 of 5

Designation

Signature

Date

Occurred more

than 5 times in

a year in the

Company/

project

company/ Occurred 5

project times in a year

times in the

R

Reputation

project Occurred in

the company/

E

Environment

knownThe incident is

A

Asset(s)

(Damage or loss of any kind)

Never heard of

the incident

H

Human

(injury)

5

10

RISK ASSESSMENT

1. R Sreenivasan

2. Polaprakasan

3. R Ethirajan

L&T/HSE/27

Rev 00 Page 5 of 5

Construction Manager

HSE Manager

Deputy Project Director

S-ar putea să vă placă și

- SWP Excavation Near Overhead Electrical Live LinesDocument2 paginiSWP Excavation Near Overhead Electrical Live LinesSn AhsanÎncă nu există evaluări

- Risk Assessment For Installation of Diesel Generator111111Document8 paginiRisk Assessment For Installation of Diesel Generator111111Baher Mohamed100% (1)

- Abrasive Wheels Risk AssessmentDocument4 paginiAbrasive Wheels Risk AssessmentAhmed El-sherpiniÎncă nu există evaluări

- 13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLDocument17 pagini13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLkeertiraj09100% (1)

- Activity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilityDocument2 paginiActivity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilityYug DobariyaÎncă nu există evaluări

- Ra of Manual Excavation For Trench of Telephone CableDocument5 paginiRa of Manual Excavation For Trench of Telephone CableRaza Muhammad SoomroÎncă nu există evaluări

- Risk assessment for night shift activitiesDocument16 paginiRisk assessment for night shift activitiesthomson100% (1)

- EMP - Environmental Risk RegisterDocument23 paginiEMP - Environmental Risk RegisterNaveen ChaudharyÎncă nu există evaluări

- GIS-RA-4061E-002 Risk Assessment For Lifting (Rev.00)Document6 paginiGIS-RA-4061E-002 Risk Assessment For Lifting (Rev.00)Ajas AjuÎncă nu există evaluări

- Building Materials Risk AssessmentDocument3 paginiBuilding Materials Risk AssessmentAhmed El-sherpiniÎncă nu există evaluări

- IM-08-B HSE Wall Grinding For Finishing WorkDocument2 paginiIM-08-B HSE Wall Grinding For Finishing WorkAnsari HarisÎncă nu există evaluări

- Hazard Identification & Risk Assessment: Main ActivityDocument3 paginiHazard Identification & Risk Assessment: Main ActivityAnsari Shakeel100% (1)

- Risk Assessment SurveyDocument2 paginiRisk Assessment Surveymohamed ghalyÎncă nu există evaluări

- Job Hazard Analysis (Jha) WorksheetDocument4 paginiJob Hazard Analysis (Jha) WorksheetSamer AlsumaryÎncă nu există evaluări

- Risk-Assessment Ducts & AccessoriesDocument13 paginiRisk-Assessment Ducts & AccessoriesMohammed Amer PashaÎncă nu există evaluări

- Ra02 - Container OffloadingDocument3 paginiRa02 - Container OffloadingSamÎncă nu există evaluări

- Jsa-Rp-001 Site Preparation and General EarthworksDocument20 paginiJsa-Rp-001 Site Preparation and General Earthworksibaig1970Încă nu există evaluări

- Surface Preparation SWMSDocument11 paginiSurface Preparation SWMSAmit SinghÎncă nu există evaluări

- Installation Testing Commisiioning of LPG SYSTEMDocument12 paginiInstallation Testing Commisiioning of LPG SYSTEMYounis KhanÎncă nu există evaluări

- Heavy Lifting Safety ChecklistDocument1 paginăHeavy Lifting Safety ChecklistMock ProjectÎncă nu există evaluări

- Company Task Renew Main Mast Equipment: a) Navigation LightDocument17 paginiCompany Task Renew Main Mast Equipment: a) Navigation LightAbid MujtabaÎncă nu există evaluări

- ARK JSA Manual Excavation A 3Document9 paginiARK JSA Manual Excavation A 3REMYAÎncă nu există evaluări

- RA - 9 - For Slab On Grade ConstructionDocument23 paginiRA - 9 - For Slab On Grade ConstructionIbrahim EsmatÎncă nu există evaluări

- Hazard Task Risk Control MeasuresDocument5 paginiHazard Task Risk Control MeasuresIshan DankharaÎncă nu există evaluări

- RISK ASESSMENT For SKYLIGHTDocument23 paginiRISK ASESSMENT For SKYLIGHTadeoye Adeyemi100% (1)

- Brazing (Oxygen and Acetylene)Document6 paginiBrazing (Oxygen and Acetylene)My Zain100% (1)

- RA - 5 - For Backfilling & CompactionDocument14 paginiRA - 5 - For Backfilling & CompactionIbrahim EsmatÎncă nu există evaluări

- HSE PLAN Generic RA PDFDocument5 paginiHSE PLAN Generic RA PDFテレブリコ ジェファーソン100% (1)

- Risk Assessment For Demolition WorksDocument5 paginiRisk Assessment For Demolition Worksappu pocom3100% (1)

- Work at Height ProcedureDocument36 paginiWork at Height ProcedureShams JogÎncă nu există evaluări

- Safe excavation SOPDocument6 paginiSafe excavation SOPHana Seiadi100% (1)

- Ra 02 - Anti-Termite TreatmentDocument4 paginiRa 02 - Anti-Termite TreatmentHafiz M WaqasÎncă nu există evaluări

- Risk Evaluation (Refer To Evaluation Form)Document3 paginiRisk Evaluation (Refer To Evaluation Form)Aftab QadirÎncă nu există evaluări

- Risk Assessment For Installation of Drainage Pipes PDF FreeDocument17 paginiRisk Assessment For Installation of Drainage Pipes PDF FreeMalik RizwanÎncă nu există evaluări

- Construction Risk AssessmentDocument21 paginiConstruction Risk AssessmentMuhammad Shahid Iqbal0% (1)

- Risk Assessment Distribution Board DB Junction Box Junction Box InstallationDocument6 paginiRisk Assessment Distribution Board DB Junction Box Junction Box InstallationAnonymous HeA9HEbtDmÎncă nu există evaluări

- Ref: Section / Dept: Civil Activity: Risk Assessment For False CeilingDocument1 paginăRef: Section / Dept: Civil Activity: Risk Assessment For False CeilingJack P100% (2)

- Risk Assessment for Overhead Line Relocation ProjectDocument5 paginiRisk Assessment for Overhead Line Relocation Projectghada gattouchÎncă nu există evaluări

- SWMS 1 Loading, Unloading & ShiftingDocument8 paginiSWMS 1 Loading, Unloading & ShiftingJ.j.JijoÎncă nu există evaluări

- Excavation Trenching & Pipe Laying R-ADocument18 paginiExcavation Trenching & Pipe Laying R-ANabil Abdelsamea100% (1)

- Risk Assessment For Refurbishment of Civil Assets in Pump Station Rev 00Document12 paginiRisk Assessment For Refurbishment of Civil Assets in Pump Station Rev 00Sachwin SachuÎncă nu există evaluări

- Installation of Under Ground Chilled Water PipingDocument18 paginiInstallation of Under Ground Chilled Water PipingAnandu AshokanÎncă nu există evaluări

- RA - For Precast ChambersDocument5 paginiRA - For Precast ChambersKallem RajashekarÎncă nu există evaluări

- RA - 8 - For WaterproofingDocument13 paginiRA - 8 - For WaterproofingIbrahim EsmatÎncă nu există evaluări

- PPE Risk Assessment DocumentDocument5 paginiPPE Risk Assessment DocumentFarzanaÎncă nu există evaluări

- DSM-FRM-0001-27-0, HDPE PE-100 Pipe InstallationDocument4 paginiDSM-FRM-0001-27-0, HDPE PE-100 Pipe Installationkadir tanzaniaÎncă nu există evaluări

- Job Safe Practices for Overhead Crane Operation (JSP 08Document4 paginiJob Safe Practices for Overhead Crane Operation (JSP 08Farooq MohammadÎncă nu există evaluări

- CRA - Structural Steel Staircase Fabrication Works at Leighton Plant YardDocument4 paginiCRA - Structural Steel Staircase Fabrication Works at Leighton Plant YardRiyas Mangodan100% (1)

- RA Construction For Sub-Base & Road Base WorksDocument17 paginiRA Construction For Sub-Base & Road Base WorksBleep NewsÎncă nu există evaluări

- Excavation Working in Trenches Swms 10281-6Document17 paginiExcavation Working in Trenches Swms 10281-6JamesÎncă nu există evaluări

- RA 02 - Earth WorkDocument38 paginiRA 02 - Earth WorkAnonymous kWfNFb100% (2)

- Fencing Installation Risk AssessmentDocument6 paginiFencing Installation Risk AssessmentVictorÎncă nu există evaluări

- Risk Assessment For Earthing Work-R1Document3 paginiRisk Assessment For Earthing Work-R1Azhar Mushtaq75% (4)

- Brick/Block Work Hazards AssessmentDocument40 paginiBrick/Block Work Hazards AssessmentGyanendra Srivastava0% (1)

- Daily JSA - Fence Post InstallationDocument5 paginiDaily JSA - Fence Post Installationshoaib akhtarÎncă nu există evaluări

- Risk Assessment & Control Register - Grease Trap CleaningDocument7 paginiRisk Assessment & Control Register - Grease Trap CleaningAbdul RahmanÎncă nu există evaluări

- JSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Document11 paginiJSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Jayson EscamillanÎncă nu există evaluări

- Boom Lift - Working FromDocument5 paginiBoom Lift - Working Fromwahyu nugrohoÎncă nu există evaluări

- Hse Risk Assessment - 006 Ra - Hdpe Duct LayingDocument7 paginiHse Risk Assessment - 006 Ra - Hdpe Duct Layingbinunalukandam83% (12)

- JOB SAFETY ANALYSIS FOR WATER TREATMENT FACILITIESDocument8 paginiJOB SAFETY ANALYSIS FOR WATER TREATMENT FACILITIESAldrinÎncă nu există evaluări

- NOTE-Spec. For Ductile Iron Pipes1 K9-K12Document32 paginiNOTE-Spec. For Ductile Iron Pipes1 K9-K12binunalukandamÎncă nu există evaluări

- Classic Range Dn60 To 2000Document48 paginiClassic Range Dn60 To 2000binunalukandamÎncă nu există evaluări

- AVM Pipes Fittings CatalogueDocument41 paginiAVM Pipes Fittings CataloguebinunalukandamÎncă nu există evaluări

- Retained Marshall Stability Test ProcedureDocument2 paginiRetained Marshall Stability Test ProcedurebinunalukandamÎncă nu există evaluări

- EXW-P015-0000-QM-LNT-IT-00066 Rev CADocument4 paginiEXW-P015-0000-QM-LNT-IT-00066 Rev CAbinunalukandamÎncă nu există evaluări

- Classic Range Dn60 To 2000Document48 paginiClassic Range Dn60 To 2000binunalukandamÎncă nu există evaluări

- AVM Pipes Fittings CatalogueDocument41 paginiAVM Pipes Fittings CataloguebinunalukandamÎncă nu există evaluări

- Hse Risk Assessment - 006 Ra - Hdpe Duct LayingDocument7 paginiHse Risk Assessment - 006 Ra - Hdpe Duct Layingbinunalukandam83% (12)

- Glass BeadsDocument20 paginiGlass BeadsbinunalukandamÎncă nu există evaluări

- Marshall Immersion Test ProcedureDocument2 paginiMarshall Immersion Test ProcedurebinunalukandamÎncă nu există evaluări

- EXW-P015-0000-QM-LNT-IT-00066 Rev CBDocument5 paginiEXW-P015-0000-QM-LNT-IT-00066 Rev CBbinunalukandamÎncă nu există evaluări

- 5.itp For Construction MaterialsDocument8 pagini5.itp For Construction Materialsbinunalukandam100% (1)

- Volume 2 Cover PagesDocument3 paginiVolume 2 Cover PagesbinunalukandamÎncă nu există evaluări

- Pages From 02b. Specifications-Concrete MixDocument1 paginăPages From 02b. Specifications-Concrete MixbinunalukandamÎncă nu există evaluări

- Almasaoodd Prestige OfficialDocument5 paginiAlmasaoodd Prestige OfficialbinunalukandamÎncă nu există evaluări

- Pages From 02b. Specifications-Concrete MixDocument1 paginăPages From 02b. Specifications-Concrete MixbinunalukandamÎncă nu există evaluări

- 5.itp For Construction MaterialsDocument8 pagini5.itp For Construction Materialsbinunalukandam100% (1)

- Volume 2 Cover PagesDocument3 paginiVolume 2 Cover PagesbinunalukandamÎncă nu există evaluări

- Volume 2 Cover PagesDocument3 paginiVolume 2 Cover PagesbinunalukandamÎncă nu există evaluări

- Volume 2 Cover PagesDocument3 paginiVolume 2 Cover PagesbinunalukandamÎncă nu există evaluări

- AttachementDocument63 paginiAttachementbinunalukandamÎncă nu există evaluări

- AttachementDocument63 paginiAttachementbinunalukandamÎncă nu există evaluări

- Pages From 02b. Specifications-Concrete MixDocument1 paginăPages From 02b. Specifications-Concrete MixbinunalukandamÎncă nu există evaluări

- Performance Based DesignDocument4 paginiPerformance Based DesignMichelle McguinessÎncă nu există evaluări

- SMPS5103 Process Safety Management - Vapr2020Document243 paginiSMPS5103 Process Safety Management - Vapr2020Manjit100% (1)

- SDRRM Manual 1 InsideDocument26 paginiSDRRM Manual 1 InsideNORMAN BREGENTEÎncă nu există evaluări

- Research & Activity Report On Strengthening Disaster Preparedness in IndonesiaDocument59 paginiResearch & Activity Report On Strengthening Disaster Preparedness in IndonesiaAdila ArdissaÎncă nu există evaluări

- Lecture 2 Chapter 1 2014 1Document50 paginiLecture 2 Chapter 1 2014 1Asahel NuñezÎncă nu există evaluări

- Historical EssaysDocument908 paginiHistorical EssayssehlebaÎncă nu există evaluări

- ΘΕΜΑΤΑ ΑΓΓΛΙΚΩΝ Α ΛΥΚΕΙΟΥ - ΙΟΥΝΙΟΣ 14Document3 paginiΘΕΜΑΤΑ ΑΓΓΛΙΚΩΝ Α ΛΥΚΕΙΟΥ - ΙΟΥΝΙΟΣ 14gxartÎncă nu există evaluări

- Pagasa Early Warning System - PNCDocument55 paginiPagasa Early Warning System - PNCMyrhen Tolentino100% (1)

- NATO's wide range of crisis management operationsDocument5 paginiNATO's wide range of crisis management operationsTanja E100% (1)

- History of Nonlinear Seismic AnalysisDocument18 paginiHistory of Nonlinear Seismic AnalysisMuhannad AbdulRaoufÎncă nu există evaluări

- BP Case StudyDocument5 paginiBP Case StudyJashvini GunasekaranÎncă nu există evaluări

- E.N.S.O.: (El Nino-Southern Oscillation)Document5 paginiE.N.S.O.: (El Nino-Southern Oscillation)GregBaldelomarÎncă nu există evaluări

- July Wellness Letter..Document3 paginiJuly Wellness Letter..Michael AllenÎncă nu există evaluări

- Iata Delay Sub Code List Ahm731Document1 paginăIata Delay Sub Code List Ahm731Ahmad MuhammadÎncă nu există evaluări

- MSDS PeakDocument2 paginiMSDS PeakPaulus SÎncă nu există evaluări

- Analysis of Buildings For Gravity LoadsDocument10 paginiAnalysis of Buildings For Gravity LoadsPrashant SunagarÎncă nu există evaluări

- Indonesia Counts Islands to Claim RightsDocument28 paginiIndonesia Counts Islands to Claim RightsKrisdayantiHmÎncă nu există evaluări

- The Virtue of Courage: Douglas N. WaltonDocument15 paginiThe Virtue of Courage: Douglas N. WaltonmihaitacheÎncă nu există evaluări

- Disaster Management: Ar. Keshav Kumar SinghDocument17 paginiDisaster Management: Ar. Keshav Kumar SinghAkshit KalaÎncă nu există evaluări

- Disaster Preparedness Minimum Standards for Local GovernmentsDocument24 paginiDisaster Preparedness Minimum Standards for Local GovernmentsJoe Felipe100% (2)

- Shipmate Rs8400Document34 paginiShipmate Rs8400SergeyÎncă nu există evaluări

- Business Continuity Generaly Accepted Practices GAP v2.1 (Disaster Recovery Journal 2015) PDFDocument140 paginiBusiness Continuity Generaly Accepted Practices GAP v2.1 (Disaster Recovery Journal 2015) PDFducuhÎncă nu există evaluări

- Free Sample BCP OutlineDocument8 paginiFree Sample BCP OutlineNabeel IqbalÎncă nu există evaluări

- District Disaster Management Plan-UdupiDocument165 paginiDistrict Disaster Management Plan-UdupiAuna SandoÎncă nu există evaluări

- Earthquake Resistant Design and Construction Practices in IndiaDocument9 paginiEarthquake Resistant Design and Construction Practices in IndiaBiswajit DeyÎncă nu există evaluări

- Analysis of RC Structure With Floating Column in Different Seismic Zones Using ETABSDocument9 paginiAnalysis of RC Structure With Floating Column in Different Seismic Zones Using ETABSIJRASETPublicationsÎncă nu există evaluări

- Expalanation Text About ThunderDocument2 paginiExpalanation Text About ThunderAzmiFarizÎncă nu există evaluări

- Ibm Catastrophy ModelingDocument17 paginiIbm Catastrophy Modelingvladimir_kovacevic_caÎncă nu există evaluări

- Airport Emergency Plans AustraliaDocument93 paginiAirport Emergency Plans AustraliaBryan ChiuÎncă nu există evaluări

- Mapping Disaster Research Ethics Scenarios: The Case StudiesDocument16 paginiMapping Disaster Research Ethics Scenarios: The Case StudiesBence KlusóczkiÎncă nu există evaluări