Documente Academic

Documente Profesional

Documente Cultură

Techical Delivery Conditions PDF

Încărcat de

Goran DjuricDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Techical Delivery Conditions PDF

Încărcat de

Goran DjuricDrepturi de autor:

Formate disponibile

TECHNICAL DELIVERY

CONDITIONS

JSC DNEPROSPETSSTAL

For Metal Products of Structural

Carburizing and Heat treatable Steel

Registered document number:

U DSS 004-2007

(supersedes TU DSS 004-2002)

Reasons for revision:

Extension of the document with standard requirements of DIN EN 10083 -1, 2, 3, Revision 2006.

Diversifying of steel grade and product range.

Supplement with references to EN 10308, EN 10228-3.

List of revised supplements:

Preface supplemented with reference to DIN EN 10083 -1, 2, 3.

Section 1: supplemented with product range of Landgraf line.

Section 2: supplemented with detailed way of special surface conditioning.

Section 3: C25E, C25R, C30E,C30R, 38CrS2, 46CrS2, 36CrNiMo4 steel grades deleted and

35NiCr6, 39NiCrMo3, 30NiCrMo16-6 included; chemical analysis requirements

specified.

Section 4: supplemented with product range of Landgraf line.

Section 5: requirements specified due to diversifying of steel grade and product range and

reference introduction to EN10308, EN10228-3.

Sections 6, 9: requirements specified due to diversifying of steel grade and product range and

introduction of new US-test requirements.

Section 10: Reference Documents is supplemented.

APPROVED:

Deputy Director General for Technology

I.N. Logozinsky

___ __________ 2007

This document is confidential and is supplied on condition that it must only be used for the purpose for which it

has been supplied and must not be copied, exhibited nor communicated to third parties without the consent of JSC

Dneprospetsstal whose property it remains.

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 2

TECHNICAL DELIVERY CONDITIONS DSS 004-2007

Metal products of structural carburizing and heat treatable steel

(revised 2010 amendment 1 included)

The present technical delivery conditions are harmonized with the requirements

specified in DIN EN 10083-1, 2, 3, DIN EN 10084 and cover technical requirements

for metal products exported by JSC Dneprospetsstal.

The present technical delivery conditions shall constitute an integral part of the

contract with customers abroad.

1. SCOPE

1.1 Hot-rolled round bars 20-280 mm in diameter with turned surface.

1.2 Hot-rolled round bars 8-130 mm in diameter without turning.

1.3 Hot-rolled billet 45-250 mm in square side after spot grinding or complete surface

conditioning.

1.4 Blooms 190-280 mm in side with ground surface.

1.5 Hot-rolled square bars 8-100 mm in square side with spot ground surface.

1.6 Hot-rolled flat bars 6-12 x 40-50 mm and 40 x 150 mm in cross section with spot

ground surface.

1.7 Forged round bars 80-550 mm in diameter with turned surface.

1.8 Forged square bars 80-450 mm in square side with ground, planed or milled surface.

1.9 Forged flat bars 30-300 mm in thickness and 80-800 mm in width with ground,

planed or milled surface.

1.10 Cold-drawn round bars 2,0-50,0 mm in diameter.

1.11 Round bars 2,00-50,00 mm in diameter with ground and polished surface.

1.12 Hot rolled round bars 12,00-200,00 mm in diameter with ground and polished

surface processed on Landgraf automatic line.

1.13 Wire 2,0-12,5 mm in diameter.

2. MANUFACTURE

Steel is melted in electric arc furnaces with further vacuum degassing or produced by

ESR-method. Ingots are subjected to hot working on rolling mills, presses, hammers or

GFM-forging machines.

Semi-product is subjected to cold drawing.

Ground and polished surface of bars 2,00-50,00mm in diameter can be achieved in any

process of rolling skin removing.

Ground and polished surface of hot rolled bars 12,00-200,00 mm in diameter is

provided on Landgraf automatic line.

On agreement between sides stated in the specification it is permitted to produce steel

in electric arc furnaces without vacuum degassing.

3. STEEL GRADES

Steel grades and chemical composition of carburizing steel in accordance with

DIN EN 10084, structural non-alloy steel (special steel) in accordance with

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

JSC Dneprospetsstal

Page 3

DIN EN 10083-2, structural alloy steel (without Boron) in accordance with

DIN EN 10083-3 shall meet the requirements specified in Tables 1-3:

Table 1. Steel grades and chemical composition of carburizing steel to

DIN EN 10084

(revision 2010 acc. to the amendment 1)

Steel grade

DIN EN 10084

C10E

(1.1121)

C10R

(1.1207)

C15E

(1.1141)

C15R

(1.1140)

C16E

(1.1148)

C16R

(1.1208)

17r3

(1.7016)

17CrS3

(1.7014)

28r4

(1.7030)

28CrS4

(1.7036)

16MnCr5

(1.7131)

16MnCrS5

(1.7139)

16MnCrB5

(1.7160)

20MnCr5

(1.7147)

20MnCrS5

(1.7149)

18rMo4

(1.7243)

18CrMoS4

(1.7244)

22CrMoS3-5

(1.7333)

20MoCr3

(1.7320)

20MoCrS3

(1.7319)

20MoCr4

(1.7321)

20MoCrS4

(1.7323)

Weight percent by elements, %

GOST

10

10-

15

15-

15

15-

17

17-

28

28-

16

16-

16

20

20-

18

18-

22-

20

20-

20

20-

Si

Mn

0,07

0,13

max

0,40

0,30

0,60

max

0,035

0,12

0,18

max

0,40

0,30

0,60

max

0,035

0,12

0,18

max

0,40

0,60

0,90

max

0,035

0,14

0,20

max

0,40

0,60

0,90

max

0,025

0,24

0,31

max

0,40

0,60

0,90

max

0,025

0,14

0,19

max

0,40

1,00

1,30

max

0,025

0,14

0,19

max

0,40

1,00

1,30

max

0,025

0,17

0,22

max

0,40

1,10

1,40

max

0,025

0,15

0,21

max

0,40

0,60

0,90

max

0,025

0,19

0,24

max

0,40

0,70

1,00

max

0,025

0,17

0,23

max

0,40

0,60

0,90

max

0,025

0,17

0,23

max

0,40

0,70

1,00

max

0,025

S

max

0,035

0,020

0,040

max

0,035

0,020

0,040

max

0,035

0,020

0,040

max

0,035

0,020

0,040

max

0,035

0,020

0,040

max

0,035

0,020

0,040

max

0,035

max

0,035

0,020

0,040

max

0,035

0,020

0,040

0,020

0,040

max

0,035

0,020

0,040

max

0,035

0,020

0,040

Cr

Mo

Ni

Other

elements

0,70

1,00

0,90

1,20

0,80

1,10

0,80

1,10

0,0008

0,005

1,00

1,30

0,90 0,15

1,20 0,25

0,70 0,40

1,00 0,50

0,40 0,30

0,70 0,40

0,30 0,40

0,60 0,50

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

JSC Dneprospetsstal

Page 4

Table 1 (continued)

Steel grade

Weight percent by elements, %

DIN EN

Other

GOST

C

Si

Mn

P

S

Cr

Mo

Ni

elements

10084

16Nir4

max

16

(1.5714)

0,035

0,13 max 0,70

max

0,60

0,80

0,19

0,40

1,00

0,025

1,00

1,10

16NiCrS4

0,020

16-

(1.5715)

0,040

10NiCr5-4

0,07 max 0,60

max

max

0,90

1,20

101

(1.5805)

0,12 0,40 0,90 0,025

0,035

1,20

1,50

18NiCr5-4

0,16 max 0,60

max

max

0,90

1,20

181

(1.5810)

0,21 0,40 0,90 0,025

0,035

1,20

1,50

17CrNi6-6

0,14 max 0,50

max

max

1,40

1,40

1722

(1.5918)

0,20 0,40 0,90 0,025

0,035

1,70

1,70

15NiCr13

0,14 max 0,40

max

max

0,60

3,00

173

(1.5752)

0,20 0,40 0,70 0,025

0,035

0,90

3,50

20NirMo2-2

max

20

(1.6523)

0,035

0,17 max 0,65

max

0,35

0,15

0,40

0,23 0,40 0,95 0,025

0,70

0,25

0,70

20NirMoS2-2

0,020

20-

(1.6526)

0,040

17NirMo6-4

max

171

(1.6566)

0,035

0,14 max 0,60

max

0,80

0,15

1,20

0,20 0,40 0,90 0,025

1,10

0,25

1,50

17NirMoS6-4

0,020

171-

(1.6569)

0,040

20NirMoS6-4

0,16 max 0,50

max

0,020

0,60

0,25

1,40

202-

(1.6571)

0,23 0,40 0,90 0,025

0,040

0,90

0,35

1,70

18CrNiMo7-6

0,15 max 0,50

max

max

1,50

0,25

1,40

1822

(1.6587)

0,21 0,40 0,90 0,025

0,035

1,80

0,35

1,70

14NiCrMo13-4

0,11 max 0,30

max

max

0,80

0,20

3,00

143

(1.6657)

0,17 0,40 0,60 0,025

0,035

1,10

0,30

3,50

20NirMo13-4

0,17 max 0,30

max

max

0,80

0,30

3,00

203

(1.6660)

0,22 0,40 0,60 0,025

0,035

1,20

0,50

3,50

Notes:

1. On agreement between the parties stated in the specification, all steel grades shall have sulfur weight

percent of 0.020-0.035 %. In this case, GOST grade designations will have suffix 1.

2. Weight percent of residual elements not stated in Table 1 shall be maximum as follows:

Cu 0.30 %, Ni 0.30 %, W 0.15%, Mo 0.10%, V 0.10% Al 0.06%, Ti 0.03%, Cr 0.30%.

3. For ESR-steel, DIN EN grade designation will have the suffix ESR, and GOST grade designation

will have the suffix . Sulfur weight percent for ESR-steel shall not exceed 0.015%, and phosphorus weight

percent is to be max 0.025%.

4. Melting process shall be stated in the Specification.

5. On customer request stated in the Specification, DIN EN grade name and designation shall have

suffixed heat treatment designation + or +N , i.e. 17NiCrMo6-4+A (1.6566+A, 10E+N (1.1121+N)).

Table 2. Steel grades and chemical composition of structural non-alloy steel

(special steels) according to DIN EN 10083-2

Steel grades

DIN EN

GOST

10083-2

C22E

20

(1.1151)

C22R

20-

(1.1149)

Weight percent by elements, %

C

Si

Mn

Cr

Mo

Ni

0,17

0,24

max

0,40

0,40

0,70

max

0,030

max

0,035

0,020

0,040

max

0,40

max

0,10

max

0,40

Other

elements

Cr+Mo+Ni

max

0,63

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

JSC Dneprospetsstal

Page 5

Table 2 continued

Steel grades

DIN EN

GOST

10083-2

C35E

35

(1.1181)

C35R

35-

(1.1180)

C40E

40

(1.1186)

C40R

40-

(1.1189)

C45E

45

(1.1191)

C45R

45-

(1.1201)

C50E

50

(1.1206)

C50R

50-

(1.1241)

C55E

55

(1.1203)

C55R

55-

(1.1209)

C60E

60

(1.1221)

C60R

60-

(1.1223)

28Mn6

(1.1170)

28

Weight percent by elements, %

C

Si

Mn

0,32

0,39

max

0,40

0,50

0,80

max

0,030

0,37

0,44

max

0,40

0,50

0,80

max

0,030

0,42

0,50

max

0,40

0,50

0,80

max

0,030

0,47

0,55

max

0,40

0,60

0,90

max

0,030

0,52

0,60

max.

0,40

0,60

0,90

max.

0,030

0,57

0,65

max

0,40

0,60

0,90

max

0,030

0,25

0,32

max

0,40

1,30

1,65

max

0,030

S

max

0,035

0,020

0,040

max

0,035

0,020

0,040

max

0,035

0,020

0,040

max

0,035

0,020

0,040

max.

0,035

0,020

0,040

max

0,035

0,020

0,040

max

0,035

Cr

Mo

Ni

max

0,40

max

0,10

max

0,40

max

0,40

max

0,10

max

0,40

max

0,40

max

0,10

max.

0,40

max

0,40

max.

0,10

max

0,40

max

0,40

max

0,10

max.

0,40

max

0,40

max.

0,10

max.

0,40

max.

0,40

max

0,10

max

0,40

Other

elements

Cr+Mo+Ni

max

0,63

Cr+Mo+Ni

max

0,63

Cr+Mo+Ni

max

0,63

Cr+Mo+Ni

max

0,63

Cr+Mo+Ni

max.

0,63

Cr+Mo+Ni

max.

0,63

Cr+Mo+Ni

max

0,63

Notes:

1. On agreement between sides stated in the specifications all steel grades shall be produced with Sulfur

content 0,020 -0,035%. In this case in the steel grade designation according to GOST the index 1 to be

added in hyphen.

2. Residual element content (for elements not shown in Table 2) shall not exceed the following:

Cu 0.30%, W 0.15%, V 0.10%, Al 0,06%, Ti 0,03%.

3. For steel produced by ESR-method in the steel grade designations according to GOST the letter to be

added in hyphen. For grade designations according to DIN EN ESR is to be added. In electro slag remelted

steels Sulfur content shall not exceed 0,015% and Phosphor shall not exceed 0,025%.

4. Melting practice shall be stated in the specification.

5. On customer request stated in the specification at the end of steel grade name and steel grade

number according to DIN EN a heat treatment symbol +A or +N shall be added (e.g. C45E +A

(1.1191+A), C45E +N (1.1191 + N)).

Table 3. Steel grades and chemical composition of structural alloy steel

(without Boron) according to DIN EN 10083-3

Steel grades

DIN EN

GOST

10083-3

38r2

38

(1.7003)

Weight percent by elements, %

C

Si

Mn

Cr

Mo

Ni

Other

elements

0,35

0,42

max.

0,40

0,50

0,80

max

0,025

max

0,035

0,40

0,60

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 6

Table 3 continued

Steel grades

Weight percent by elements, %

DIN EN

Other

GOST

C

Si

Mn

P

S

Cr

Mo

Ni

elements

10083-3

46r2

0,42

max

0,50

max

max

0,40

46

(1.7006)

0,50

0,40

0,80 0,025 0,035 0,60

34r4

max

34

(1.7033)

0,30

max

0,60

max 0,035 0,90

0,37

0,40

0,90 0,025 0,020 1,20

34rS4

34-

(1.7037)

0,040

37r4

..

37

(1.7034)

0,34

..

0,60

.. 0,035 0,90

0,41

0,40

0,90 0,025 0,020 1,20

37rS4

37-

(1.7038)

0,040

41r4

max.

41

(1.7035)

0,38

max

0,60

max 0,035 0,90

0,45

0,40

0,90 0,025 0,020 1,20

41rS4

41-

(1.7039)

0,040

25rMo4

max

25

(1.7218)

0,22

max

0,60

max 0,035 0,90

0,15

0,29

0,40

0,90 0,025 0,020 1,20

0,30

25rMoS4

25-

(1.7213)

0,040

34rMo4

max

34

(1.7220)

0,30

max

0,60

max 0,035 0,90

0,15

0,37

0,40

0,90 0,025 0,020 1,20

0,30

34rMoS4

34-

(1.7226)

0,040

42rMo4

max

42

(1.7225)

0,38

max

0,60

max 0,035 0,90

0,15

0,45

0,40

0,90 0,025 0,020 1,20

0,30

42rMoS4

42-

(1.7227)

0,040

50rMo4

0,46

max

0,50

max max. 0,90

0,15

50

(1.7228)

0,54

0,40

0,80 0,025 0,035 1,20

0,30

34rNiMo6

0,30

max

0,50

max

max

1,30

0,15

1,30

3422

(1.6582)

0,38

0,40

0,80 0,025 0,035 1,70

0,30

1,70

30rNiMo8

0,26

max

0,50

max

max

1,80

0,30

1,80

3022

(1.6580)

0,34

0,40

0,80 0,025 0,035 2,20

0,50

2,20

35NiCr6

0,30

max

0,60

max

max

0,80

1,20

351

(1.5815)

0,37

0,40

0,90 0,025 0,025 1,10

1,60

36NiCrMo16

0,32

max

0,50 max. max

1,60

0,25

3,60

3624

(1.6773)

0,39

0,40

0,80 0,025 0,025 2,00

0,45

4,10

39NiCrMo3

0,35

max

0,50

max

max

0,60

0,15

0,70

39

(1.6510)

0,43

0,40

0,80 0,025 0,035 1,00

0,25

1,10

30NiCrMo16-6

0,26 max. 0,50

max max. 1,20

0,30

3,30

3014

(1.6747)

0,33

0,40

0,80 0,025 0,025 1,50

0,60

4,30

51CrV4

0,47

max

0,70

max

max

0,90

0,10V

50

(1.8159)

0,55

0,40

1,10 0,025 0,025 1,20

0,25

Notes:

1. On agreement between sides stated in the specifications all steel grades (except of 35NiCr6 (1.5815),

36NiCrMo16(1.6773), 30NiCrMo16-6(1.6747), 51CrV4( 1.8159) steel grades may be produced with Sulfur

content 0,020 -0,035%. In this case in the steel grade designation according to GOST the index 1 to be

added in hyphen.

2. Residual element content (for elements not shown in Table 3) shall not exceed the following: Cu 0.30%,

Ni -0,30%, Mo-0,10%, W 0.15%, V 0.10%, Al 0,06%, Ti 0,03%.

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 7

3. For steel produced by ESR-method in the steel grade designations according to GOST the letter to be

added in hyphen. For grade designations according to DIN EN ESR is to be added. In electro slag re-melted

steels Sulfur content shall not exceed 0,015% and Phosphor shall not exceed 0,020%.

4. Melting practice shall be stated in the specification.

5. On customer request stated in the specification at the end of steel grade name and steel grade number

according to DIN EN a heat treatment symbol +A or +N shall be added (e.g. 42CrMo4 +A (1.7225 +A).

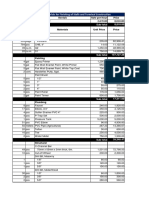

In finished product chemical composition variations shall not exceed the values shown

in Tables 4 - 6.

Table 4. Permissible composition variations in finished product of

carburizing steel according to DIN EN 10084

(revision 2010 acc. to the amendment 1)

Element

Carbon

Silicon

Manganese

Phosphor

Sulfur

Chromium

Molybdenum

Nickel

Boron

Weight percent by elements in

steel, %

0,31

0,40

1,00

1,00 1,40

0,035

0,035

0,020-0,040

1,80

0,30

0,30 0,50

2,00

2,00 3,50

0,0050

Permissible variations, %

0,02

+0,03

0,04

0,05

+0,005

+0,005

0,005

0,05

0,03

0,04

0,05

0,07

0,0005

Table 5. Permissible chemical composition variations in finished product

of structural non-alloy steel ( special steel) according to DIN EN 10083-2

Element

Carbon

Silicon

Manganese

Phosphor

Sulfur

Chromium

Molybdenum

Nickel

Weight percent by elements in

steel, %

0,55

0,55 0,65

0,40

1,00

1,00 1,65

0,030

0,035

0,020-0,040

0,40

0,10

0,40

Permissible variations, %

0,02

0,03

+0,03

0,04

0,05

+0,005

+0,005

0,005

+0,05

+0,03

+0,05

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 8

Table 6. Permissible variations in chemical composition in finished product

of structural alloy steel (without boron) according to DIN EN 10083-3

Element

Carbon

Silicon

Manganese

Phosphor

Sulfur

Chromium

Molybdenum

Nickel

Vanadium

Weight percent by elements in

steel, %

0,55

0,40

1,00

1,00 1,10

0,025

0,035

0,020-0,040

2,00

2,00 2,20

0,30

0,30 0,60

2,00

2,00 4,30

0,25

Permissible variations, %

0,02

+0,03

0,04

0,05

+0,005

+0,005

0,005

0,05

0,10

0,03

0,04

0,05

0,07

0,02

4. PRODUCT RANGE

4.1 Hot-rolled round bars 20-280 mm in diameter with turned surface

Bar diameter and utmost deviations from the diameter shall meet the requirements of

Table 7.

Table 7. Diameter and utmost deviations from it for hot-rolled round bars with turned surface

Utmost deviations, mm

Utmost deviations, mm

Diameter, mm

Diameter, mm

Lot 1

Lot 2

Lot 1

Lot 2

20-28

+0,5/-0,0

98-115

+1,4/-0,0

0,25

0,70

29-48

+0,6/-0,0

116-155

+2,0/-0,0

0,30

1,00

49-58

+0,8/-0,0

156-180

+2,5/-0,0

0,40

1,25

59-79

+1,0/-0,0

181-280

+3,0/-0,0

0,50

1,50

80-97

+1,2/-0,0

0,60

Notes:

1. The lot number shall be stated in the specification.

2. Hot-rolled round bars with turned surface of Ni-alloyed steel are furnished up to 230 mm in

diameter. If agreed upon by the purchaser and manufacturer and stated in specifications, hot rolled bars up to 260 mm in diameter of Ni-alloyed steel may be delivered.

Out-of-round shall not exceed 50% of the sum of utmost deviations from the diameter.

Straightness deviations shall be 2,0 mm max per 1 m of length.

Bar ends shall be straight cut. Burrs and centering holes are not allowed.

Bars processed on a straightening machine with hyperboloid rolls are not subject to

rejection on bar end meniscus.

Inclination from the straight cut shall not exceed 0,1 of bar diameter.

Bars shall be 3,0-6,0 m in length with the utmost deviation from the length 100 mm.

Actual bar length shall be stated in the specification.

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 9

4.2 Hot-rolled round bars 8-130 mm in diameter, without turning

Bar diameter and utmost deviations from it shall be as shown in Table 8.

Table 8. Diameter and utmost deviations from it for hot-rolled round bars without turning

Utmost deviations, mm

Diameter, mm

lot 1

lot 2

8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19

+0,3/-0,5

+0,6/-0,0

20, 21, 22, 23, 24, 25

+0,4/-0,5

+0,8/-0,0

26, 27, 28, 29, 30

+0,3/-0,7

+0,9/-0,0

31, 32, 33, 34, 35, 36, 37, 38, 39, 40, 41, 42, 45, 48

+0,4/-0,7

+1,1/-0,0

50, 52, 55, 56

+0,4/-1,0

+1,4/-0,0

58

+0,4/-1,0

60, 63, 65, 70, 73, 75

+0,5/-1,1

+1,6/-0,0

62, 68, 78

+0,5/-1,1

80, 85, 90, 95

+0,5/-1,3

+1,8/-0,0

83, 88, 93, 98

+0,5/-1,3

100, 105, 110, 115

+0,6/-1,7

+2,3/-0,0

103,5; 108,5; 113,5; 118,5

+0,6/-1,7

120, 125, 130

+0,8/-2,0

+2,8/-0,0

123,5; 128,5

+0,8/-2,0

Note: a lot number shall be stated in the specification.

Out-of-round shall not exceed 50% of the total tolerance on diameter.

Straightness deviations of annealed bars shall be max 2,0 mm per 1 m of length.

For not annealed bars up to 80 mm in diameter straightness deviations shall be max

4,0 mm/m; for bars 80 mm (and over) in diameter straightness deviations shall be max

2,5 mm per 1m of length.

Bar ends shall be straight cut and deburred.

Squeezed ends not exceeding the utmost plus deviations from the diameter are

permitted.

For bars from 8 up to19 mm in diameter inclination from the cut shall not exceed

2 mm; for bars from 20 up to 130 mm in diameter inclination from the cut shall not

exceed 0,1 of diameter.

The diameter and out-of-round of bars shall be measured at a distance not less than

150 mm from the bar end.

Bars shall be 2,0-6,0 m 100 mm in length. Actual length is to be stated in the

specification.

4.3 Hot-rolled billets 45-250 mm in square side

Dimensions of square billets and utmost deviations from them shall meet the

requirements of Table 9.

Convexity, concavity and the difference between any two billet sides shall not exceed

the total tolerance on square side.

The difference between the diagonals at the same cross section shall not exceed 0,7 of

the total tolerance on the side.

Convexity, concavity and the difference between any two billet sides shall not exceed

the total tolerance on square side.

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 10

Table 9. Dimensions of hot-rolled square billets and utmost deviations

Utmost deviations from the

Billet side, mm

Corner radius, mm

square side, mm

45, 50

7

1,2

60, 65, 70

9

1,6

75, 80, 90

12

2,0

100, 105

15

2,4

110,120, 125

18

2,7

130, 135, 140, 150

21

3,2

160, 170, 180

25

3,9

230, 240, 250

35

5,2

Note: corner radius is given for shaping pass setting only and is not measured on billet.

The difference between the diagonals at the same cross section shall not exceed 0,7 of

the total tolerance on the side.

Straightness deviation shall not exceed 5 mm per 1m of length. Overall bow shall not

exceed the product of permissible straightness deviation value multiplied by the total

length value in meters.

Twisting around the longitudinal axle shall not exceed 3 degree/m multiplied by billet

length (in meters), but this value shall be 15 degree max.

Billet ends shall be cut and deburred. The inclination from the cut shall be 8 mm.

Squeezed ends after shearing are acceptable.

Billets shall be 2,0-6,0 m in length with utmost deviations from the length 100 mm.

Actual length shall be stated in the specifications.

When agreed upon by the parties and stated in the specification, it is permitted to

supply billets up to 9,0 m in length.

4.4 Blooms 190-280 mm in side size

Bloom dimensions and utmost deviations from them

Table 10.

shall meet the requirements of

Table 10. Dimensions of blooms and utmost deviations from them

Utmost deviation from bloom

side, mm

190

25

6,0

200, 210

30

6,0

220, 230

35

6,0

240, 250

35

7,0

260

40

7,0

270, 280

40

8,0

Note: corner radius is given for shaping pass setting only and is not measured on a bloom.

Bloom side, mm

Corner radius, mm

Bloom sides are to be straight or concave.

Blooms with convexity of two opposite sides not exceeding permissible deviations

from the bloom side are acceptable. The central part of the bloom with the width min

1/3 of bloom side shall be straight or concave.

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 11

Straightness deviation shall not exceed 10mm per 1m of length. Overall bow shall not

exceed permissible straightness deviation value multiplied by the total length value in

meters.

Twisting around the longitudinal axle shall not exceed 3 degree/m multiplied by the

bloom length (in meters).

Bloom ends shall be straight cut and without burrs. The inclination from the cut shall

not exceed 0,1 of bloom side.

Squeezed ends after cutting are acceptable.

Blooms shall be 2,0-6,0 m in length with utmost deviations from the length 100 mm.

Actual lengths shall be stated in the specifications.

4.5 Hot-rolled square bars 8-100 mm in square side

Square side and utmost deviations from it shall meet the requirements of Table 11.

The difference between the diagonals at the same cross section shall not exceed the

double sum of utmost deviations from the square side for bars up to 20 mm in square

side; for bars over 20 mm in square side it shall not exceed the sum of utmost

deviations from the square side.

Edge chamfering shall not exceed 0,15 of square side.

Table 11. Dimensions of hot-rolled square bars and utmost deviation from them

Utmost deviations from the square side, mm

Square side, mm

Lot 1

Lot 2

8, 9, 10, 12, 13, 14, 15, 16, 17, 18

+0,3/-0,5

+0,6/-0,0

22, 25

+0,4/-0,5

+0,8/-0,0

28, 30

+0,3/-0,7

+0,9/-0,0

32, 35

+0,4/-0,7

+1,1/-0,0

45, 50

+0,4/-1,0

+1,4/-0,0

60, 65, 70, 75

+0,5/-1,1

+1,6/-0,0

80, 90

+0,5/-1,3

+1,8/-0,0

100

+0,6/-1,7

+2,3/-0,0

Note: a lot number shall be stated in the specification

Straightness deviations shall not exceed 0,5% of length for bars up to 25 mm (incl.) in

square side; for bars over 25 mm in square side the deviations shall not exceed 0,4% of

the length.

Twisting around longitudinal axle of square bars shall not exceed 4 degree/m

multiplied by bar length (in meters), but it is to be 24 degrees max for bars up to

14 mm in square side. For bars over 14 up to 50mm in square side twisting shall not

exceed 3 degree per meter multiplied by the bar length (in meters), but it is to be max

18 degrees; for bars over 50 mm in square side twisting shall not exceed 3 degree per

meter multiplied by the bar length (in meters) but it is to be 15 degrees max.

Bar ends shall be straight cut. The inclination from the cut shall not exceed 2 mm for

bars 8-18 mm in square side; for bars 22-100mm in square side the inclination from the

cut shall not exceed 0,1 of square side.

Squeezed ends and burrs not exceeding the utmost plus deviation from the square side

are acceptable.

Bar sides and difference between the diagonals shall be measured at a distance

150 mm min from the bar end.

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 12

Bars are to be 3,0-6,0 m in length with utmost deviations from the length 100mm.

Actual length shall be stated in the specification.

On agreement between sides stated in the specification it is permitted to supply bars up

to 9,0 m in length.

4.6 Hot-rolled flat bars 6-12 x 40-50 mm and 40 x 150 mm in size with spot ground

surface

Flat bar dimensions (S x B, where S = thickness, B = width) and utmost deviations

from them shall be in accordance with requirements of Table12.

Table 12. Dimensions of hot-rolled rectangular bars and utmost deviations from them

Utmost deviations, mm

Section size

Lot 1

Lot 2

(S x B), mm

From thickness

From width

From thickness

From width

6 40

+0,3/-0,5

+0,5/-1,0

+0,5/-0,0

+1,8/-0,0

8 45

+0,2/-0,5

+0,5/-1,0

+0,5/-0,0

+1,8/-0,0

10 45

+0,2/-0,5

+0,5/-1,0

+0,6/-0,0

+1,8/-0,0

12 45

+0,2/-0,5

+0,5/-1,0

+0,6/-0,0

+2,0/-0,0

6 50

+0,3/-0,5

+0,5/-1,0

+0,5/-0,0

+2,0/-0,0

8 50

+0,2/-0,5

+0,5/-1,0

+0,5/-0,0

+2,0/-0,0

40 150

+0,2/-1,6

+1,2/-2,8

Note: a lot number is stated in the specification.

Convexity or concavity of narrow sides is acceptable.

Convexity shall not exceed the utmost deviation from the width and concavity shall not

reduce the minimal size limits.

The difference between the diagonals shall not exceed the total utmost deviation from

the width.

Flat bars are to be supplied with sharp edges. Edge chamfering not exceeding 0,20 of

the thickness is permitted. Corner radius is given only for shaping pass setting and is

not measured on the bar.

Overall bow shall not exceed 0,5% of the length.

Non- flatness shall be max 0,5% of the length.

Bar ends shall be straight cut. The inclination from the cut shall not exceed 0,1 of the

thickness.

The thickness and the width shall be measured at a distance 150 mm min from the bar

end.

Flat bars are to be 2,0 - 4,0 m in length with utmost deviations from the length 100 mm.

4.7 Forged round bars 80-550 mm in diameter with turned surface

Bar diameter and utmost deviations from the diameter shall be in accordance with

Table 13.

Table 13. Diameter and utmost deviations from it for forged round bars with turned surface

Diameter, mm

80-97

98-115

116-155 156-180 181-500 501-530

531-550

Utmost

+1,2

+1,4

+2,0

+2,5

+3,0

+4,0

+5,0

deviations, mm

-0,0

-0,0

-0,0

-0,0

-0,0

-0,0

-0,0

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 13

Out-of-round shall not exceed the total tolerance on diameter.

Straightness deviation shall be 2,0mm max per 1m of length.

Bar ends shall be straight cut, without burrs and centering holes.

Inclination from the cut shall not exceed 0,1 of bar diameter.

Bar length shall be 2,0-6,0 m with utmost deviations from the length 100 mm. Actual

length shall be stated in the specification.

4.8 Forged square bars 80-450 mm in square side with ground, planed or milled

surface

Square side sizes and utmost deviations from them shall be in accordance with

Table 14.

Table 14. Dimensions of forged square bars and utmost deviations from them

Square side, mm

Utmost deviations, mm

80, 85

+3,0 / -0,0

90

+3,5 / -0,0

100, 105

+3,5 (+3,5) / -0,0

110, 115

+4,0 (+4,0) / -0,0

120, 125, 130, 135, 140, 145

+4,5 (+4,5) / -0,0

150

+5,0 (+5,0) / -0,0

180

+7,0 (+5,0) / -0,0

185-200

+8,0 (+5,0) / -0,0

205-450

+10,0 (+5,0) / -0,0

Note: values in brackets are given for bars with planed or milled surface; values without brackets are

for bars with ground surface.

The difference between the diagonals at the same cross section shall not exceed 5% of

square side.

Forged square bars shall have sharp edges. Edge chamfering not exceeding 3% of

square side is permitted.

On agreement between sides stated in the specification for bars up to 200 mm in square

side permissible chamfering of longitudinal edges is to be 8-15 mm in width; for bars

over 200 mm in square side permissible chamfering of longitudinal edges is to be 1020 mm in width.

Straightness deviation shall not exceed 10 mm on the whole length.

Bar ends shall be straight cut. The inclination from the cut shall not exceed 0,1 of

square side. Burrs and squeezed ends are not acceptable.

Bars shall be 2,0-4,0 m in length with utmost deviations from the length 100mm.

4.9 Forged flat bars 30-300 mm in thickness and 80-800 mm in width, with

ground, planed or milled surface

Section sizes for bars 30-150 mm in thickness and 80-350 mm in width, as well as

utmost deviations from them shall be in accordance with Table 15.

The dimensions of bars 100-300 mm in thickness and 300-800 mm in width, as well as

utmost deviations from them shall be in accordance with Table 16.

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 14

The difference between the diagonals at the same cross section shall not exceed the

utmost deviations from the width.

Flat bars shall have sharp edges. Edge chamfering not exceeding 0,030 of the bar width

is permitted.

On agreement between sides stated in the specification, for bars up to 200 mm in

square side permissible chamfering of longitudinal edges is to be 8-15 mm in width;

for bars over 200 mm in square side permissible chamfering of longitudinal edges is to

be 10-20 mm in width.

Table 15. Dimensions of forged flat bars 30-150 x 80-350 mm and utmost deviations from them

Utmost deviations, mm

Thickness, mm

Width, mm

From thickness

From width

80 119

+4,0/-0,0

30 64

120 179

+2,5/-0,0

+5,0/-0,0

180 200

+7,0/-0,0

80 119

+4,0/-0,0

120 179

+5,0/-0,0

180 214

+7,0/-0,0

65 89

+4,5/-0,0

215 249

+8,0/-0,0

250 284

+9,0/-0,0

285 300

+10,0/-0,0

90 119

+4,0/-0,0

120 179

+5,0/-0,0

180 214

+7,0/-0,0

90 150

215 249

+5,0/-0,0

+8,0/-0,0

250 284

+9,0/-0,0

285 344

+10,0/-0,0

345 350

+12,0/-0,0

Table 16. Dimensions of forged flat bars 100-300 x 300 -800 mm and tolerances on them

Plus tolerance on

Plus tolerance on

Thickness, mm

Width, mm

thickness, mm

width, mm

100

+5,0 (+5,0)

300

+10,0 (+5,0)

over 100 to 250

+7,0 (+5,0)

over 300 to 600

+15,0 (+10,0)

over 250 to 300

+10,0 (+5,0)

over 600 to 800

+20,0 (+15,0)

Note: For flat bars with planed and milled surface tolerances are shown in brackets, for flat bars after

complete surface conditioning tolerances are given without brackets.

Convexity or concavity of narrow sides is acceptable for the flat bars furnished with

complete surface conditioning that have dimensions given in Table 16.

The convexity shall not exceed utmost deviation from the width and the concavity shall

not reduce nominal size limits.

Non- flatness and overall bow of as-ground flat bars shall not exceed the following:

- 0,25% of the length for flat bar sizes given in Table 15;

- 0,4% of the length - for flat bar sizes given in Table 16.

Non -flatness and overall bow of flat bars with planed and milled surface shall be 0,2%

max of length.

Twisting shall not exceed 0,3% of the length.

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 15

Bar ends shall be straight cut and deburred. Inclination from the cut shall not exceed

0,10 of thickness.

Flat bars shall be 2,0-4,0 m in length with utmost deviations from the length

100mm.

4.10 Cold drawn round bars 2,0-50,0 mm in diameter

Bar diameter and utmost deviations from it shall be in accordance with Table 17.

Out-of-round shall not exceed one half of utmost deviation from diameter.

Bar ends shall be straight cut. Bending and burrs at the ends are not acceptable.

Table 17. Diameter of cold-drawn bars and utmost deviations from it.

2,00

3,00

6,00

10,00

Diameter, mm

3,00

6,00

10,00

18,00

Utmost deviations, mm:

For size tolerance h 11

-0,060

-0,075

-0,090

-0,110

For size tolerance h 12

-0,120

-0,150

-0,180

Note: Size tolerances shall be stated in the specification.

18,00

30,00

30,00

50,00

-0,130

-0,210

-0,160

-0,250

Squeezed ends and burrs are permitted if they do not exceed the nominal size limits.

For bars up to 30 mm in diameter inclination from the cut shall not exceed 0,1 of

diameter; for bars over 30 mm in diameter it shall not exceed 5,0 mm.

Straightness deviation shall be max 0,2% of length.

Depending on the diameter bar length and utmost deviations from the length shall

conform to the values given in Table 18.

Table 18. Length and tolerances on it for cold-drawn round bars depending on their diameter

Tolerance on length, mm

Diameter, mm

Length, m

from 2,00 to 3,00

2.0

+50/-0

over 3,00 to 6,00

2,5

+50/-0

over 6,00 to 10,00

3,0

+50/-0

over 10,00 to13,00

3,0 4,5

+50/-0

over 13,00 to 50,00

up to 6,0

+50/-0

4.11 Round bars 2,00-50,00 mm in diameter with ground and polished surface

Bar diameter and tolerances on diameter shall meet the requirements of Table 19.

Table 19. Diameter and tolerances on it for round bars with ground and polished surface

2,00- ov. 3,00 ov. 6,00 ov.10,00 ov.15,00 ov.18,00 ov.30,00 ov.34,00

Diameter,mm

3,00 to 6,00 to 10,00 to 15,00 to 18,00 to 30,00 to 34,00 to 50,00

Tolerance on diameter,

mm:

for size tolerance h9

-0,025 -0,030 -0,036 -0,043

for size tolerance k9

+0,025 +0,030 +0,036 +0,043

for size tolerance h10

-0,040 -0,048 -0,058 -0,070 -0,070 -0,084 -0,100

for size tolerance k10

+0,040 +0,048 +0,058 +0,070 +0,070 +0,084 +0,100

for size tolerance h11

-0,060 -0,075 -0,090 -0,110 -0,110 -0,130 -0,160 -0,160

for size tolerance k11

+0,060 +0,075 +0,090 +0,110 +0,110 +0,130 +0,160 +0,160

for size tolerance h12

-0,120 -0,150 -0,180 -0,180 -0,210 -0,250 -0,250

for size tolerance k12

+0,120 +0,150 +0,180 +0,180 +0,210 +0,250 +0,250

Note: Size tolerances shall be stated in the specification.

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 16

For bars 2,00-15,00 mm in diameter with size tolerance h9(k9), bars over 15,00 up to

34,00 mm in diameter with size tolerance h10 (k10), bars over 34,00 to 50,00 mm in

diameter with size tolerance h11 (k11) it is permitted to deliver 20% of each item with

size tolerance h10, h11, h12 correspondingly separately bundled. (See Table 20)

Out-of-round shall not exceed one half of the utmost deviation from diameter.

For bars up to 30,00 mm in diameter straightness deviations shall not exceed 0,5 mm/m;

for bars over 30,00 mm in diameter straightness deviations shall not exceed 1,0 mm/m.

Bar ends shall be straight cut without bending and burrs. Inclination from the cut shall

be max 0,1 of diameter. Meniscus at the bar end after straightening/polishing is not

subject to rejection.

Table 20. Diameter and tolerances on it for round bars with ground and polished surface

Diameter, mm

Tolerance on diameter, mm

from 2,00 to 3,00

over 3,00 to 6,00

over 6,00 t 10,00

over 10,00 t 15,00

over 15,00 t 18,00

over 18,00 t 30,00

over 30,00 t 34,00

over 34,00 t 50,00

-0,040 (h10), +0,040 (k10)

-0,048 (h10), +0,048 (k10)

-0,058 (h10), +0,058 (k10)

-0,070 (h10), +0,070 (k10)

-0,110 (h11), +0,110 (k11)

-0,130 (h11), +0,130 (k11)

-0,160 (h11), +0,160 (k11)

-0,250 (h12), +0,250 (k12)

Bars 2,00-13,00 mm in diameter shall be 2,0-3,2 m in length; bars over 13,00 mm up

to 17,00 mm in diameter shall be 4,0-5,5 m in length and bars over 17,00 to 50,00mm

mm in diameter shall be up to 6,0 m in length with utmost deviations from the length

50 mm.

4.12 Hot rolled round bars 12,00 200,00 mm in diameter with ground and

polished surface processed on Landgraf automatic line.

Bar diameter and tolerances on diameter shall conform to the requirements specified

in Table 21.

Outofround of bars (the difference between the largest and the smallest diameter in

the same cross section) shall not exceed one half of utmost deviation from diameter.

Straightness deviation of bars up to 30 mm inclusive in diameter shall not exceed

0,5 mm per 1 m of length , for bars over 30 mm it shall not exceed 1,0 mm per 1 m of

length.

Bar ends shall be straight cut and after that turned or milled. Inclination from the

straight cut shall not exceed 0,1 of bar diameter.

Bars up to 70,00 mm in diameter shall be one end chamfered. It is permitted to supply

bars both ends chamfered.

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

JSC Dneprospetsstal

Page 17

Table 21. Diameter and tolerances on it for hot-rolled bars with ground and polished surface

processed on Landgraf automatic line.

Tolerance on diameter for size tolerance, mm

Diameter, mm

h9

k9

h10

k10

h11

k11

From 12,00 to18,00

-0,043

+0,043

-0,070

+0,070

-0,110

+0,110

Over 18,00 to 30,00

-0,052

+0,052

-0,084

+0,084

-0,130

+0,130

Over 30,00to 50,00

-0,062

+0,062

-0,100

+0,100

-0,160

+0,160

Over 50,00 to 80,00

-0,074

+0,074

-0,120

+0,120

-0,190

+0,190

Over 80,00 to 120,00

-0,087

+0,087

-0,140

+0,140

-0,220

+0,220

Over 120,00 to 160,00

-0,100

+0,100

-0,160

+0,160

-0,250

+0,250

Over 160,00 to 180,00

-0,160

+0,160

-0,250

+0,250

Over 180,00 to 200,00

-0,185

+0,185

-0,290

+0,290

Notes:

1. Size tolerance shall be stated in the specification.

2. On agreement between sides stated in the specification it is permitted to supply 10% of bars

with size tolerance h9(k9), h10(k10) of each item with size tolerance h10 (k10) and h11(k11)

correspondingly, separately bundled. Bundle tag with indicated utmost deviations shall have

additional round mark 4 -5 mm in diameter in the right upper corner.

Bars shall be 3,0 -6,0 m in length with utmost deviation from the length +50 /-0,0 mm.

Actual bar lengths may be agreed in the specification.

4.13 Wire 2,0-12,5 mm in diameter

Wire diameter and utmost deviations from the diameter shall conform to the

requirements specified in Table 22.

Table 22. Wire diameter and tolerances on it.

Diameter, mm

2,00-3,00

3,00-6,00

6,00-10,00

10,00-12,50

Tolerance on diameter, mm

(size tolerance h11)

-0,060

-0,075

-0,090

-0,110

Out-of-round shall not exceed one half of the utmost deviation from the diameter.

Coil ends shall be cut or broken without burrs.

Coil inner diameter shall be 500 mm min.

Coil weight may vary from 40 to 135 kg.

5. TECHNICAL REQUIREMENTS

5.1 Products shall be supplied in annealed, normalized condition or without heat

treatment that should be agreed upon by the purchaser and the manufacturer and stated

in the specification.

All annealed products (annealing according to practice +A, EN 10083-1 and

EN 10084) shall have hardness conforming to the values specified in Table 23.

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 18

Table 23. Hardness of metal products in annealed condition

(revision 2010 acc. to the amendment 1)

Grade designation

EN 10084

GOST

C10E

C10R

C15E

C15R

C16E

C16R

17r3

17CrS3

28r4

28CrS4

16MnCr5

16MnCrS5

16MnCrB5

20MnCr5

20MnCrS5

18rMo4

18CrMoS4

22CrMoS3-5

20MoCr3

20MoCrS3

20MoCr4

20MoCrS4

16Nir4

16NiCrS4

10NiCr5-4

18NiCr5-4

17CrNi6-6

15NiCr13

20NirMo2-2

20NirMoS2-2

17NirMo6-4

17NirMoS6-4

20NirMoS6-4

18CrNiMo7-6

14NiCrMo13-4

20NiCrMo13-4

10

10-

15

15-

15

15-

17

17-

28

28-

16

16-

16

20

20-

18

18-

22-

20

20-

20

20-

16

16-

101

181

1722

173

20

20-

171

171-

202-

1822

143

203

Hardness ,

max

131

143

156

174

217

207

207

217

207

217

217

207

217

192

223

229

229

212

229

229

229

241

255

Grade designation

EN 10083-2,3

GOST

C22E

C22R

C35E

C35R

C40E

C40R

C45E

C45R

C50E

C50R

C55E

C55R

C60E

C60R

28Mn6

38Cr2

46Cr2

34CR4

34CrS4

37Cr4

37rS4

41r4

41rS4

25rMo4

25rMoS4

34rMo4

34rMoS4

42rMo4

42rMoS4

50rMo4

34rNiMo6

30rNiMo8

35Nir6

36NirMo16

39NirMo3

30NirMo16-6

51CrV4

20

20-

35

35-

40

40-

45

45-

50

50-

55

55-

60

60-

28

38X

46X

34X

34X-

37

37-

41

41-

25M

25M-

34M

34M-

42M

42M-

50

342H2

302H2

35H1

36X2H4MA

39H

30X1H4M

50X

Hardness ,

max

156

183

197

183

207

229

241

223

207

223

223

235

241

212

223

241

248

248

223

269

240

270

248

Note: Bars with ground and polished surface, cold-drawn bars and wire up to 5 mm (incl.) in diameter

shall be delivered after tensile strength testing (without hardness testing). Tensile strength values shall

be stated in the specification.

5.1 (added acc. to the amendment 1) On agreement between the parties stated in the

Specification, metal products of steel grades C10E(1.1121), C10R(1.1207),

C15E(1.1141), C15R(1.1140), C16E(1.1148), C16R(1.1208), 16MnCr5(1.7131),

16MnCrS5(1.7139), 16MnCrB5(1.7160), 20MnCr5(1.7147), and 20MnCrS5(1.7149)

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 19

shall be shipped as-normalized, after hardness test of finished product. Hardness of

normalized products shall comply with requirements of Table 23.

Table 23. Hardness of normalized products

Steel grade

Hardness,

DIN EN 10084

GOST

C10E(1.1121)

10

85-140

C10R(1.1207)

10-

C15E(1.1141)

15

95-150

C15R(1.1140)

15-

C16E(1.1148)

15

100-155

C16R(1.1208)

15-

16MnCr5(1.7131)

16

138-187

16MnCrS5(1.7139)

16-

16MnCrB5(1.7160)

16

138-187

20MnCr5(1.7147)

20

140-201

20MnCrS5(1.7149)

20-

5.2 Surface condition of round and square bars, square billets, blooms, flat bars and

wire shall conform to the following requirements.

5.2.1 Round bars 20-40 mm in diameter shall be delivered in turned or ground

condition and bars over 40 to 550 mm in diameter shall be supplied in turned condition

with surface roughness Rz 80 m max. On agreement between sides stated in the

specification round bars 8-130mm in diameter may be delivered without turning, but

after spot grinding of surface defects.

Cracks, laps (forging folds), scabs, rolled/forged impurities, seams, rolled/forged crust,

blisters are not allowed on the surface of round bars that are with or without turning.

Local surface imperfections shall be removed by flat grinding. The width of grind-outs

shall be minimum 5 times the depth.

The depth of spot ground areas on turned bars shall not reduce the bar size under the

minimally permissible.

The depth of spot ground areas on round bars without turning shall not exceed 0,5 of

the total utmost deviations from diameter for bars up to 80 mm in diameter; for bars

80-130 mm in diameter the depth shall not exceed the total utmost deviation from the

diameter counting from actual size. Not more than 2 grind-outs of maximal depth are

acceptable at the same cross section.

Single marks, scratches, indentations and other surface defects of mechanical origin are

acceptable on the surface of round bars without grinding if their depth does not exceed

0,5 of the total utmost deviations from the diameter counting from actual size.

Welding repair or flash welding of surface imperfections is not permitted.

5.2.2 Flat and square bars and billets up to 100 mm (incl.) in square side or in thickness

are delivered after spot grinding of surface defects.

Flats, square bars and billets over 100 mm in square side or thickness are delivered

after complete surface conditioning or in as-planed (milled) condition with surface

roughness Rz not exceeding 100 m.

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 20

On agreement between sides stated in the specifications flat or square bars and billets

over 100 mm in square side or thickness may be supplied after spot grinding of surface

defects.

Blooms shall be after complete surface conditioning with surface roughness Rz max 100 m.

Surface conditioning practice shall be stated in the specification.

Surface of flat and square bars, billets and blooms shall be free from cracks, laps,

scabs, rolled/forged impurities, seams, rolled/forged crust, rolled/forged blisters.

Local surface imperfections shall be removed by flat grinding; the width of flat

grinding shall be at least 5 times the depth.

For flat bars, square billets and bars up to 80 mm in square side or thickness the depth

of grinding shall not exceed of the total utmost deviations from the thickness or

square side. For flat bars, square billets and bars 80-100 mm in square side or thickness

this depth shall not exceed the total utmost deviation from the square side or thickness.

For flat bars, blooms, square billets and bars with ground surface over 100 mm in

square (bloom) side or thickness the depth of grinding shall not exceed 5% of thickness

or square (bloom) side counting from actual size. For planed and milled bars and flat

bars the depth of grinding shall not reduce the size under minimally permissible one.

Single marks, scratches and other defects of mechanical origin are permitted without

flat grinding if their depth is:

- 1,0 mm max - for flat bars, square bars and billets up to 100 mm in thickness or

square side;

- 2,0 mm max for flat bars, square bars and billets 100-180 mm in thickness or

square side;

- 2,5 mm max for flat bars, blooms, square bars and billets over 180 mm in

thickness or square (bloom) side.

Welding of surface imperfections or repair by flash welding is not permitted.

5.2.3 Surface defects of mechanical origin are permitted on the surface of cold-drawn

bars and wire if their depth does not exceed the utmost deviation from diameter.

5.2.4 Surface defects of mechanical origin are permitted on the surface of ground and

polished bars if their depth does not exceed of utmost deviation from diameter.

Bar surface roughness Ra shall be 2,5 m max.

5.2.5 Surface defects of mechanical origin are permitted on the surface of hot-rolled

bars with ground and polished surface 12 -200mm in diameter, processed on Landgraf

automatic line, if their depth does not exceed the following:

- 0,040 mm max for bars 12,00 -80,00 mm in diameter with size tolerance

h9(k9) and bars 12,00 -18,00 mm in diameter with size tolerance h10(k10);

- one half of utmost deviation - for bars over 18,00 to 80, 00 mm in diameter with

size tolerance h10(k10) and bars 12,00 -80,00 mm in diameter with size

tolerance h11(k11), as well as bars over 80 to 200 mm in diameter with size

tolerance h-9 h11( k9 k11).

Surface roughness Ra shall be 1,4m max for bars to 130 mm and 4,0 m max for bars

130 mm and above.

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 21

5.3 Steel macrostructure determined on etched specimens (templates) shall be free

from visible pipe cavity, porosity, blisters, cracks, slag inclusions, laminations, crust

and flakes.

5.4 Austenitic grain size shall be 5-8 to ASTM E 112 or 2 numbers finer.

5.5 Non-metallic inclusions in steel shall be tested in accordance with DIN 50602,

Method K. On agreement between sides stated in specification non-metallic inclusions

may be evaluated in accordance with ASTM E 45, Method A.

5.5.1 The results of non-metallic inclusion evaluation performed in accordance with

DIN 50602 (Method K) shall conform to the requirements stated in Table 24.

Table 24.Total K-value (oxides) for each heat when tested to DIN 50602

Total parameter K (oxides) for each heat

Melting process

Diameter or thickness,

Electric arc furnace

mm

Electric arc furnace

without vacuum

ESR

+vacuum degassing

degassing

to 8

2 15

2 35

2 10

over 8 to 17

3 15

3 30

3 10

over 17 to 35

3 20

3 40

3 15

over 35 to 70

4 15

4 35

4 10

over 70 to 100

4 15

4 40

4 10

over 100 to 140

4 20

4 45

4 15

over 140 to 200

4 20

4 50

4 15

Note: for metal products over 200 mm in diameter or thickness non-metallic inclusion testing shall be

performed on samples re-forged into round or square 90-100 mm in size.

5.5.2 The results of non-metallic inclusion evaluation performed in accordance with

ASTM E 45 (Method A) shall conform to the requirements stated in Table 25.

Table 25. Average rating of non-metallic inclusions to ASTM E45

Average rating of inclusion content, max

Melting process

Inclusion type

Inclusion series

A

B

C

Electric arc furnace

thin

2,5

2,5

2,5

with vacuum degassing

heavy

2,0

2,0

2,0

Electric arc furnace

thin

3,0

3,0

3,0

without vacuum

heavy

2,0

2,0

2,0

degassing

ESR

thin

heavy

2,5

1,5

2,0

0,5

0,5

0,5

D

2,5

2,0

3,0

2,0

1,0

0,5

Note: for steel grades with specified inferior sulfur limit, non-metallic inclusions of A-type are not

subject to rejection.

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 22

5.6 Mechanical properties of heat treatable steel delivered as-annealed or without heat

treatment when determined at room temperature on longitudinal heat-treated specimens or

specimens made of heat-treated test pieces shall conform to the requirements of Table 26.

Table 26. Mechanical properties of steel tested on heat-treated specimens or heat-treated test pieces.

Grade designation

DIN EN

10083-2, 3

GOST

C22E

20

C22R

20-

C35E

35

C35R

35-

C40E

40

C40R

40-

C45E

45

C45R

45-

C50E

50

C50R

50-

C55E

55

C55R

55-

C60E

60

C60R

60-

28Mn6

28

38r2

38

46r2

46

34r4

34

34rS4

34-

Heat treatment of

specimens or test

pieces

Water quenching

at 860-900C,

tempering at 550660C

Water or oil

quenching at 840880C, tempering

at 550-660C

Water or oil

quenching at 830870C, tempering

at 550-660C

Water or oil

quenching at 820860, tempering

at 550-660

Water or oil

quenching at 810850, tempering

at 550-660

Water or oil

quenching at 810850, tempering

at 550-660

Water or oil

quenching at 810850, tempering

at 550-660

Water or oil

quenching at 840880, tempering

at 540-680

Water or oil

quenching at 830870, tempering

at 540-680

Water or oil

quenching at 820860, tempering

at 540-680

Water or oil

quenching at 830870, tempering at

540-680

Reduction

of area, Z,

%

Impact

energy

KV, J

Yield

strength Re

(R0,2),

N/mm2

(min)

Tensile

strength

Rm,

N/mm2

Elongation

5, %

290

470-620

22

50

50

380

600-750

19

45

35

400

630-780

18

40

30

430

650-800

16

40

25

460

700-850

15

35

490

750-900

14

35

520

800-950

13

30

490

700-850

15

45

40

450

700-850

15

40

35

550

800-950

14

40

35

590

800-950

14

40

40

min

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 23

Table 26 (continued)

Grade designation

EN 10083-1

GOST

37r4

37

37rS4

37-

41r4

41

41rS4

41-

25rMo4

25

25rMoS4

25-

34rMo4

34

34rMoS4

34-

42rMo4

42

42rMoS4

42-

50rMo4

50

34rNiMo6

3422

30rNiMo8

3022

35NiCr6

35XH1

36NiCrMo16 3624

39CrNiMo3

Heat treatment of

specimens or test

pieces

39XHM

30NiCrMo16-6 30X1H4M

Water or oil

quenching at 825865, tempering

at 540-680

Water or oil

quenching at 820860, tempering

at 540-680

Water or oil

quenching at 840900, tempering

at 540-680

Water or oil

quenching at 830890, tempering

at 540-680

Water or oil

quenching at 820880, tempering

at 540-680

Oil quenching at

820-870,

tempering at 540680

Oil quenching at

830-860,

tempering at 540660

Oil quenching at

830-860,

tempering at 540660

Oil quenching at

840-860,

tempering at 530630

Oil quenching at

865-885,

tempering at

550-650

Oil quenching at

830-850,

tempering at

550-650

Oil quenching at

840-860,

tempering at

540-630

Impact

energy

KV, J

Yield

strength Re

(R0,2),

N/mm2

(min)

Tensile

strength

Rm,

N/mm2

Elongation

5, %

630

850-1000

13

40

35

660

900-1100

12

35

35

600

800-950

14

55

50

650

900-1100

12

50

40

750

10001200

11

45

35

780

10001200

10

45

30

900

11001300

10

45

45

1050

12501450

40

30

740

880-1085

14

40

35

1050

12501450

40

30

735

9301130

11

40

880

1080 1230

10

45

Reduction

of area, Z,

%

min

35

35

JSC Dneprospetsstal

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

Page 24

Table 26 (continued)

Grade designation

EN 10083-1

51rV4

Heat treatment of

specimens or test

pieces

GOST

50

Oil quenching at

820-870,

tempering at 540680

Yield

strength Re

(R0,2),

N/mm2

(min)

Tensile

strength

Rm,

N/mm2

800

10001200

Elongation

5, %

Reduction

of area, Z,

%

Impact

energy

KV, J

min

10

45

30

Notes:

1. For metal products over 100 mm in diameter or thickness it is permitted to determine mechanical

properties on samples re-forged into round or square 90-100 mm.

2. Heat treatment (see 3rd column of Table 26) shall be performed on specimens or test pieces 15-25

mm in diameter or square side. Cooling process after tempering is in the option of the manufacturer.

5.7 Mechanical properties of heat treatable normalized steel when tested at room

temperature on longitudinal specimens in delivery condition shall conform to Table 27.

Table 27. Mechanical properties of normalized steel tested on specimens in delivery condition

Yield strength Re Tensile strength

Elongation 5,

Grade designation

Diameter or

2

2

(R0,2), N/mm

Rm, N/mm

%

thickness, mm

EN 10083-1 GOST

min

16

240

430

24

C22E

20

>16100

210

410

25

>100250

200

400

25

C22R

20-

>250550

190

390

25

16

300

550

18

C35E

35

>16100

270

520

19

>100250

245

500

19

C35R

35-

>250550

235

490

19

16

320

580

16

C40E

40

>16100

290

550

17

>100250

260

530

17

C40R

40-

>250550

250

520

17

16

340

620

14

C45E

45

>16100

305

580

16

>100250

275

560

16

C45R

45-

>250550

265

550

16

16

355

650

13

C50E

50

>16100

320

610

14

>100250

290

590

14

C50R

50-

>250550

280

580

14

16

370

680

11

C55E

55

>16100

330

640

12

>100250

300

620

12

C55R

55-

>250550

290

610

12

16

380

710

10

C60E

60

>16100

340

670

11

>100250

310

650

11

C60R

60-

>250550

300

640

11

16

345

630

17

>16100

310

600

18

28Mn6

28

>100250

290

590

18

>250550

280

580

18

Notes:

1. For bars 16 mm (and less) in diameter yield strength is not tested; it can be estimated by actual

values of tensile strength using the equation R0,2 = 0,55 Rm.

2. On customer request stated in the specification, impact energy KV, J shall be tested additionally on

longitudinal specimens and test results shall be reported in the inspection certificate.

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

JSC Dneprospetsstal

Page 25

On customer require stated in the specification, for C22E, C22R, C35E, C35R, C45E,

C45R, C50E, C50R, C60E, C60R steel grades delivered in normalized condition

mechanical properties shall conform to Table 27a.

Table 27a. Mechanical properties of normalized steel tested on specimens in delivery in condition.

Grade designation

DIN EN

10083-2

C22E

Diameter or

thickness,

mm

GOST

20

C22R

20-

C35E

35

C35R

35-

C45E

45

C45R

45-

C50E

50

C50R

50-

C60E

60

C60R

60-

Yield

strength Re

(R0,2), N/mm2

(min)

Tensile

strength Rm,

N/mm2

225

215

205

275

255

245

325

305

295

345

325

315

375

355

345

410-520

410-520

410-520

490-610

490-610

490-610

590-720

590-720

590-720

620-770

620-770

620-770

680-830

680-830

680-830

250

>250500

>500550

250

>250500

>500550

250

>250500

>500550

250

>250500

>500550

250

>250500

>500550

Impact energy

DVM, J

Elongation 5, %

L

48

41

38

38

34

31

31

27

24

-

34

27

24

24

21

17

17

14

14

-

min

26

25

24

22

21

20

18

16

15

16

15

14

14

13

12

19

17

16

15

14

12

12

11

10

11

10

9

10

9

8

Notes:

1. L and Q are longitudinal and transversal directions of specimen cutting correspondingly.

2. For bars 16 mm (and less) in diameter yield strength is not tested; it can be estimated by actual

values of tensile strength using the equation R0,2 = 0,55 Rm

3. For bars 160 mm (and under) in diameter elongation and impact energy on the transversal

specimens are not tested.

4. For bars less than 16 mm in diameter impact energy on the longitudinal specimens is not tested.

5.8 Metal products of carburizing steel shall be delivered after hardenability testing by

end-quench test (Jominy test). Rockwell hardness limits shall conform to Table 28

Table 28. Rockwell hardness limits (revision 2010 acc. to the amendment 1)

Grade designation

DIN EN

GOST

10084

17r3

17

17CrS3

17-

28r4

28

28CrS4

28-

16MnCr5

16

16MnCrS5

16-

16MnCrB5

16

20MnCr5

20MnCrS5

20

20-

Hardness HRC (max/min) at a distance from the bar end, mm

1,5

11

13

15

20

25

30

35

40

47

39

44

35

40

25

33

20

29

-

27

-

25

-

24

-

23

-

21

-

53

45

52

43

51

39

49

29

45

25

42

22

39

20

36

-

33

-

30

-

29

-

28

-

27

-

47

39

47

39

49

41

46

36

46

36

49

39

44

31

44

31

48

36

41

28

41

28

46

33

39

24

39

24

43

30

37

21

37

21

42

28

35

35

41

26

33

33

39

25

31

31

37

23

30

30

35

21

29

29

34

-

28

28

33

-

27

27

32

-

Technical Delivery Conditions DSS 004-2007 (2010)

Metal products of structural carburizing and heat treatable steel

JSC Dneprospetsstal

Page 26

Table 28 (continued)

Grade designation

DIN EN

GOST

10084

18rMo4

18

18CrMoS4

18-

22CrMoS3-5

22-

20MoCr3

20MoCrS3

20MoCr4

20MoCrS4

16Nir4

16NiCrS4

20

20-

20

20-

16

16-

10NiCr5-4

101

18NiCr5-4

181

17CrNi6-6

1722

15NiCr13

173

20NirMo2-2

20

20NirMoS2-2 20-

17NirMo6-4

171

17NirMoS6-4 171-

20NirMoS6-4 202-

18CrNiMo7-6

1822

14NiCrMo13-4

143

20NiCrMo13-4

203

Hardness HRC (max/min) at a distance from the bar end, mm

1,5

11

13

15

20

25

30

35

40

47

39

50

42

49

41

49

41

47

39

41

32

49

41

47

39

48

41

49

41

48

40

49

41

48

40

47

39

53

43

46

37

49

41

47

38

47

37

46

36

39

27

48

39

47

38

48

41

48

37

48

40

49

40

48

40

47

39

52

42

45

34

48

37

45

34

44

31

44

33

37

24

46

35

46

36

48

41

45

31

47

37

48

39

48

39

46

37

52

42

42

30

47

33

40

28

41

27

42

29

34