Documente Academic

Documente Profesional

Documente Cultură

Medium Capacity Air Separation Plants for Oxygen Nitrogen and Argon Production

Încărcat de

kalyanm203515Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Medium Capacity Air Separation Plants for Oxygen Nitrogen and Argon Production

Încărcat de

kalyanm203515Drepturi de autor:

Formate disponibile

IMPIANTI LIQUEFAZION E PRODUZIONE GAS TECNICI

23 years of Excellence

OXYGEN NITROGEN ARGON

AIR SEPARATION PLANTS

LOW OPERATING PRESSURE(5-7 BAR)

MEDIUM CAPACITY PLANTS

1,000m3/h To 10,000m3/h GOX & GAN

Www.oxygenplants.com

IMPIANTI LIQUEFAZION E PRODUZIONE GAS TECNICI

23 years of Excellence

SCOPE OF SUPPLY

1.Air Compressor:

Rotary air compressor screw type can be used for smaller size plants

upto 500m3/hr & 1000m3/hr. Upto 40000m3/hr. Centrifugal

compressor can be used for higher size plants.

Air Compressor

2.Air pre cooling system:

Air separation plants adopts chilling system in all air pre- Cooling

systems.

3.Air purification system:

This system beds of molecular sieve are used in the air purification

system ,it remove the Co2 & moisture for the process air at lowPressure.

4.Rectification column:

The unit in cold box are all low pressure technology.This unit employs the

latest state of the art plate and fin exchanger,condenser and sub-coolers.The

Column is supplied as a packed unit complete with all the control systems

including digital flow meters,temperature,pressure available with high purity

upto 2-3 ppm nitrogen as a second product without loss in oxygen production.

Rectification

Column

U

N

I

V

E

R

S

A

L

Air Purification

System

5.Turbo-expander:

Turbo - expander is used for giving cooling to the air for the

liqefication process and braked by booster, so as to reduce the

expanded air volume,stablize the upper columns working

condition and reduce power consumption. The turbine expanders

have complete trouble free working and long life and reliability.

6.Computer control:

All the plants can be configured for automatic operation through a pc

this will use a out switching valves of German or Japanese and

motorized cryogenic valves on cold box.

Air Pre-Cooling

System

Purifier

Turbo-Expander

IMPIANTI LIQUEFAZION E PRODUZIONE GAS TECNICI

23 years of Excellence

U

N

I

V

E

R

S

A

L

AIR COMPRESSOR

U

N

I

V

E

R

S

A

L

U

N

I

V

E

R

S

A

L

PURIFICATION UNIT

AIR SEPARATION UNIT

CONTROL PANEL

TURBO-EXPANDER

TECHNICAL SPECIFICATION AIR SEPARATION PLANTS

OXYGEN--NITROGEN--ARGON GAS

MEDIUM CAPACITY(1000Nm3/hr To 2500Nm3/hr/32 TPD TO 80 TPD)

MODEL (O2/N2*/Ar)

Oxygen Capacity

Nm3/hr

Oxygen Capacity

Tons Per Day

Oxygen Purity

% O2

Nitrogen Capacity

Nm3/hr

Nitrogen Capacity

Tons Per Day

Nitrogen Purity

Air Pressure

(BAR)

No of O2 cylinder

per day (150 BAR*)

Power Consumption

(KW)

Specific Power per

M3 of gox+gan

Specific Power

Kwh/m3 O2

Argon**Capacity

M3/hr

UBT-1000/1200/30 UBT-1500/1500

UBT-2000/2000

UBT-2500/2200/70

1000

1500

2000

2500

32 TPD

48 TPD

64 TPD

80 TPD

99.6

99.6

99.6

99.6

1200

1500

2000

2200

33 TPD

42 TPD

56 TPD

60 TPD

99.9%-99.99%

3PPM

99.9%-99.99%

3PPM

99.9%-99.99%

3PPM

99.9%-99.99%

3PPM

4000

N/A

N/A

N/A

550

825

1000

1250

0.25

0.27

0.25

0.27

0.55

0.55

0.5

0.5

30

N/A

N/A

70

IMPIANTI LIQUEFAZION E PRODUZIONE GAS TECNICI

23 years of Excellence

U

N

I

V

E

R

S

A

L

AIR COMPRESSOR

U

N

I

V

E

R

S

A

L

U

N

I

V

E

R

S

A

L

AIR SEPARATION UNIT

PURIFICATION UNIT

CONTROL PANEL

TURBO-EXPANDER

TECHNICAL SPECIFICATION AIR SEPARATION PLANTS

OXYGEN--NITROGEN--ARGON GAS

MEDIUM CAPACITY(1500Nm3/hr To 10000Nm3/hr/50 TPD TO 320 TPD)

MODEL (O2/N2*/Ar)

Oxygen

Go2

Capacity

Capacity

Nm3/hr

Go2 Capacity

Oxygen

Capacity

TonnePer

Tons

PerDay

Day

Go2 Purity

Oxygen

Purity

% O2

Gn2 Capacity

Nirogen

Capacity

Nm3/hr

Gn2 Capacity

Nitrogen

Capacity

TonnePer

Tons

PerDay

Day

Gn2 PurityPurity

Nitrogen

Air Pressure

(BAR)

No of O2 cylinder

per day (150 BAR*)

Power Consumption

(KW)

Specific Power per

M3 of gox+gan

Specific Power

Kwh/m3 O2

Argon**Capacity

M3/hr

UBT-1500/1500/45 UBT-3600/3600/100 UBT-6000/6000/200 UBT-10000/18000/380

1500

3600

6000

10000

50 TPD

115 TPD

190 TPD

320 TPD

99.6

99.6

99.6

99.6

1500

3600

6000

18000

42 TPD

101 TPD

100

170 TPD

500 TPD

505

99.9%-99.99%

3PPM

99.9%-99.99%

3PPM

99.9%-99.99%

3PPM

99.9%-99.99%

3PPM

N/A

N/A

N/A

N/A

825

1800

2700

4800

0.27

0.25

0.26

0.17

0.5

0.5

0.45

0.48

45

100

100

380

IMPIANTI LIQUEFAZION E PRODUZIONE GAS TECNICI

23 years of Excellence

U

N

I

V

E

R

S

A

L

AIR COMPRESSOR

U

N

I

V

E

R

S

A

L

PURIFICATION UNIT AIR SEPARATION UNIT

CONTROL PANEL

OPT.Optional (as required by buyer Argon attachment can be provided extra)

* CYLINDER CAPACITY FOR CALCULATION PROSES IS 6 TO7CU METER OR 40-47 LITERS WATER

CAPACITY

** Argon gas purity 99.9 & above upto 99.999% or ppm quality

NOTES:

1. All the above data is only indicative to enable the buyers to select the model and detailed offer shall be given

with the order.

2. The oxygen booster/ LO pump depending on model is added for filling oxygen gas in cylinders at 150 /200 bar.

3. Argon can be produced in all plants above 500m3/hr.

4. Pure nitrogen gas upto 3ppm is avail able as a second product with out loss of oxygen, production.

All capacities are as per design suction conditions.

Nitrogen gas Pure output can be taken as optional along with liquid oxygen as per requirement.

Plants for Oxygen/ Nitrogen/Argon output of any desires/specific requirement of the buyer of 20,000 m3/hr upto

40,000m3/hr.

VOLTAGE 380-415 AND 50/60 HZ AS SPECIFICED.ALSO VOLTAGE AND FREQUENCY COUNTRY

SPECIFIC AS ORDERED.HT MOTORS ABOVE 400 KW OF 10/11 KV.

IMPIANTI LIQUEFAZION E PRODUZIONE GAS TECNICI

23 years of Excellence

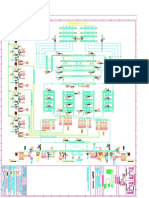

AIR SEPARATION PLANT FLOW CHART WITH MOLECULAR SIEVE PURIFIER AND BOOSTER AIR EXPANSION

N2

PN

O2

WE 2

EX

AT

TE 1

AC

P1

H1

P2

C2

PU

CR

TE 2

RU

C1

E2

LO2

AI

AIR FILTER

AC AIR COMPRESSOR

PC PRE-COOLING UNIT

PU PURIFICATION UNIT

P1/2 TOWER1/TOWER 2

H

HEATER

EX

MAIN HEAT EXCHANGER

TE1/2 TURBO EXPANDER

E2

SUB COOLER

C1

COLUMN

LIN

CR CONDENSOR REBOILER

C2 LOW PRESSURE COLUMN

Technical Data

Production

Purity

Air Pressure

Normal operating pressure of plant

Power Consumption for oxygen

Oxygen

99.6%

Nitrogen

99.9%-99.99% or 3ppm

Argon

99.5% or 5ppm

0.7Mpa/7Bar

0.6 To 0.7Mpa

0.6 To 0.7Mpa

0.5 To 0.8 KWh/m

Nil

0.6 To 0.7Mpa

Negligible

IMPIANTI LIQUEFAZION E PRODUZIONE GAS TECNICI

23 years of Excellence

CRYOGENIC

RE COOLER

LIQUID ARGON

STORAGE

NITROGEN

OXYGEN

FILLING

PROCESS FLOW DIAGRAM

Basic Principle

The air separation plant is a plant recovering oxygen and nitrogen from air simultaeously.

It advance low pressure technology process of Boschi Italy using Rotary screw compressor

(or low oil free piston compressor)and turbo expanders.

The feed air entering the Molecular Sieve purification system employed to remove the

moisture and Co2 from the process air.The air is liquefied by cryogenic cooling using latest

plate and fin high efficiency heat exchangers and turbo expanders.The liquid air separates

into oxygen nitrogen and inert gases in the air separation column.

IMPIANTI LIQUEFAZION E PRODUZIONE GAS TECNICI

23 years of Excellence

PROCESS DESCRIPTION

1 .A IR C O M P R E S S O R-LO W PRESSURE

A ir is c o m p re s s e d a t a lo w p re ss u re o f 5 -7 b a r (0 .5 -0 . 7 m p a ). A ir c a n b e

co m p re s s e d a t su c h lo w p re ssu re b y t ro u b le fre e ro ta ry c o m p re sso r (S c re w /

C e n t rifu g a l T yp e a d v a n c e d t e c h n o lo g y is e m p lo ye d in lie u o f o ld b u lk y p ist o n

co m p re s so r).

2 . P R E C O O L IN G S Y S T E M

T h e se co n d sta g e o f t h e p ro c e ss u se s a lo w p re ssu re re fr ig e ra n t fo r p re co o lin g t h e p ro c e sse d a ir to te m p e rat u re a ro u n d 1 2 d e g C b e fo re it e nt e rs t h e

p u rifie r.

3 . P U R IF IC A T IO N O F A IR B Y P U R IF I E R

T h e a ir e n t e rs a p u rifie r c o n s istin g o f t w in M o le c u la r S ie v e d rie r s, w o rk in g

a lt e rn a t iv e ly. T h e M o le c u la r S iev e s re m o v e t h e C a rb o n d io x id e &

m o ist u re fro m t h e p ro c e ss a ir b e fo re t h e a ir e n t e rs A ir S e p a rat io n U n it .

4 . C R Y O G E N I C C O O L IN G O F A IR B Y T U R B O (E X P A N D E R )

T h e a ir h a s to b e co o led to su b z ero te m p e ratu re s fo r liq u ific a t io n & t h e

c r yo g e n ic re fr ig e ra t io n & t h e c o o lin g is p ro vid e d b y h ig h ly e ffic ie n t tu rb o

e x p a n d e r, w h ic h c o o ls t h e a ir to te m p e rat u re a lm o st b e lo w -1 6 5 to -1 7 0

deg C .

5 . S E P A R A T IO N IF L IQ U ID A IR IN T O O X Y G E N A N D N I T R O G E N B Y

A IR S E P A R A T IO N C O L U M N

O il fre e , m o ist u re fre e a n d C a rb o n D io x id e fre e a ir e n t ers in t o lo w p re ssu re

p l a t e fin t yp e H eat exchanger w h e re t h e a ir is co o le d b e lo w su b z e ro

te m p e rat u re s b y a ir e x p a n s io n p ro c e ss in th e tu rb o e x p a n d e r. Due to the excellent

thermal efficiency we can achieve a temperature difference delta t as low as 2 deg c at the

warm end of these exchangers.

A ir g e t s liq u e fie d w h e n it e n t e rs th e a ir se p a rat io n co lu m n & g e t s s e p a rate d

in to o x yg e n & n it ro g e n b y t h e p ro ce ss o f re ct ific a t io n .

O x yg e n is a v a ila b le a t t h e o u t le t o f t h e A S U a t a p u rit y o f 9 9 .6 % .

N it ro g e n is a lso a v a ila b le t t h e o u t le t a s a se co n d p ro d u ct at p u rit y o f 9 9 .9 9 %

u p to 3 p p m s im u lt a n e o u s ly w it h o u t lo ss o f o x yg e n p ro d u ct .

6 . C O M P R E S S IO N O F O X Y G E N F I L L IN G IN T H E C Y L IN D E R

T h e fin a l p ro d u ct in t h e fo rm c o m p re sse d O x yg e n /N it ro g e n g o e s to t h e

h ig h p re ssu re o x yg e n c ylin d e rs at 1 5 0 b a r o r u p to h ig h e r a s re q u ire d ..

O r fo r p ip e lin e su p p ly o r c a p t iv e c o n su m p t io n

O r fo r liq u id p la n t s to fill in c r yo g e n ic liq u id t an k s.

S-ar putea să vă placă și

- Understanding Ambient Air Vaporizer Made Easier Now - INOXCVADocument11 paginiUnderstanding Ambient Air Vaporizer Made Easier Now - INOXCVAGilberto YoshidaÎncă nu există evaluări

- IND-22-10-QUE Filling Cylinders With Medical Oxygen (Quebec City)Document28 paginiIND-22-10-QUE Filling Cylinders With Medical Oxygen (Quebec City)Janet Tinio VelardeÎncă nu există evaluări

- Oisd 159Document37 paginiOisd 159Ritika VermaÎncă nu există evaluări

- Handling HydrogenDocument51 paginiHandling HydrogenShabin Shabi100% (1)

- Centrifugal Pump Types (API-610)Document4 paginiCentrifugal Pump Types (API-610)Иван РадевÎncă nu există evaluări

- Temperature Sensors CAT1667Document36 paginiTemperature Sensors CAT1667damienwckÎncă nu există evaluări

- Diesel Power PlantsDocument35 paginiDiesel Power PlantsRagarcÎncă nu există evaluări

- Converting Mass Flow RateDocument3 paginiConverting Mass Flow RateAgung PriambodhoÎncă nu există evaluări

- Free Physical Chemistry Books PDFDocument2 paginiFree Physical Chemistry Books PDFJessieÎncă nu există evaluări

- THERMODYNAMICS AND LIQUEFACTION OF GASESDocument22 paginiTHERMODYNAMICS AND LIQUEFACTION OF GASESkoushik94Încă nu există evaluări

- PEM Electrolysers Systems' Modular DesignDocument10 paginiPEM Electrolysers Systems' Modular Designmsantosu000Încă nu există evaluări

- Cryogenic Vaporisation SystemsDocument30 paginiCryogenic Vaporisation SystemsAnonymous 1XHScfCI100% (1)

- Municipal Solid Waste Project SKTGDocument3 paginiMunicipal Solid Waste Project SKTGDevanSandrasakerenÎncă nu există evaluări

- Cryogenic Liquid Cylinder ManualDocument25 paginiCryogenic Liquid Cylinder Manualshan757Încă nu există evaluări

- Asme B16.47 - 2011Document120 paginiAsme B16.47 - 2011Guido KünstlerÎncă nu există evaluări

- As 4264.5-1999 Coal and Coke - Sampling Guide To The Inspection of Mechanical Sampling SystemsDocument6 paginiAs 4264.5-1999 Coal and Coke - Sampling Guide To The Inspection of Mechanical Sampling SystemsSAI Global - APACÎncă nu există evaluări

- Safe Catalyst Handling in Hyco Plants: European Industrial Gases Association AisblDocument25 paginiSafe Catalyst Handling in Hyco Plants: European Industrial Gases Association AisblDEO SALVACIONÎncă nu există evaluări

- Composite Pressure VesselsDocument22 paginiComposite Pressure VesselsInternational Journal of Research in Engineering and TechnologyÎncă nu există evaluări

- Lab: Introduction to Control Apparatus and PLC Control of Asynchronous MotorDocument11 paginiLab: Introduction to Control Apparatus and PLC Control of Asynchronous MotorMuhammad J SherwaniÎncă nu există evaluări

- Pipeline Safety and Public Awareness - Spectra EnergyDocument2 paginiPipeline Safety and Public Awareness - Spectra EnergyElisa CanoÎncă nu există evaluări

- Mechanical Topics - Skive ProjectsDocument15 paginiMechanical Topics - Skive ProjectsJithin V KÎncă nu există evaluări

- The Definitive Guide To Cryogenic EngineeringDocument21 paginiThe Definitive Guide To Cryogenic EngineeringSamanthaPereraÎncă nu există evaluări

- API Std 618 vs 680 for Critical Nitrogen CompressorDocument3 paginiAPI Std 618 vs 680 for Critical Nitrogen CompressorShantanuÎncă nu există evaluări

- Phases of CO2 PDFDocument4 paginiPhases of CO2 PDFMubin Ashraf SheikhÎncă nu există evaluări

- 147 20 Safe Practices Guide For Cryogenic Air Separation PlantsDocument86 pagini147 20 Safe Practices Guide For Cryogenic Air Separation PlantsJose ChiriÎncă nu există evaluări

- The energy transition creates opportunities for hydrogenDocument40 paginiThe energy transition creates opportunities for hydrogenSebastián RojasÎncă nu există evaluări

- Nioec SP 00 10Document7 paginiNioec SP 00 10Amirhossein DavoodiÎncă nu există evaluări

- Instrumentation Fittings, Valves & Accessories GuideDocument12 paginiInstrumentation Fittings, Valves & Accessories GuideGloria HamiltonÎncă nu există evaluări

- Uses and Applications of AmmoniaDocument5 paginiUses and Applications of AmmoniaSohail Asghar100% (2)

- Vanzetti Cryogenic Pumps & Technology GuideDocument0 paginiVanzetti Cryogenic Pumps & Technology GuidekanchanabalajiÎncă nu există evaluări

- Datasheet 40ft ISO LNG Containers v2Document1 paginăDatasheet 40ft ISO LNG Containers v2jbloggs2007Încă nu există evaluări

- Introduction to LP & MP CompressorsDocument61 paginiIntroduction to LP & MP Compressorschuminh100% (1)

- Project Oxygen DocumentationDocument38 paginiProject Oxygen DocumentationGoda KondapallyÎncă nu există evaluări

- Plate Heat ExchangerDocument12 paginiPlate Heat ExchangerEngSafwanQadousÎncă nu există evaluări

- Dle 75Document3 paginiDle 75Jon PeñafielÎncă nu există evaluări

- FRP VesselsDocument2 paginiFRP VesselsNaveenraj DadaÎncă nu există evaluări

- M13Document54 paginiM13Adrian GuzmanÎncă nu există evaluări

- Health Technical Memorandum 2010: SterilizationDocument166 paginiHealth Technical Memorandum 2010: Sterilizationboborg8792Încă nu există evaluări

- 10 Years PYQs ?toppers Handbook? POLITY EnglishDocument60 pagini10 Years PYQs ?toppers Handbook? POLITY EnglishshubhamÎncă nu există evaluări

- Main Combustion ChamberDocument31 paginiMain Combustion Chambershaliq28Încă nu există evaluări

- Asu 12 11 Pap BocDocument30 paginiAsu 12 11 Pap Bocsudhakarrajam2002Încă nu există evaluări

- Firewater Pump PresentationDocument56 paginiFirewater Pump PresentationFredie UnabiaÎncă nu există evaluări

- Process Units: Raw Gas GAS Ethane Propane Butane Condensate Sulfur & Acid GAS DSO Meg + WaterDocument39 paginiProcess Units: Raw Gas GAS Ethane Propane Butane Condensate Sulfur & Acid GAS DSO Meg + WaterLarbi Hammoun100% (1)

- Maximator Gas Boosters 04-2007Document32 paginiMaximator Gas Boosters 04-2007a_abbaspourÎncă nu există evaluări

- Everything You Need to Know About Jockey PumpsDocument4 paginiEverything You Need to Know About Jockey PumpsChemical.AliÎncă nu există evaluări

- Cryogenic Experts Price List for Cryogenic EquipmentDocument6 paginiCryogenic Experts Price List for Cryogenic EquipmentkanchanabalajiÎncă nu există evaluări

- CNG Cylinder and LNG Tank Technology: Number 62 April 2012Document36 paginiCNG Cylinder and LNG Tank Technology: Number 62 April 2012mihailspiridonÎncă nu există evaluări

- Coating Spec 01 PDFDocument5 paginiCoating Spec 01 PDFWINÎncă nu există evaluări

- TBV Cryogenic Ball Valves CAMERONDocument20 paginiTBV Cryogenic Ball Valves CAMERONboudissaÎncă nu există evaluări

- O2 SafetyDocument3 paginiO2 Safetyrajpatil0007Încă nu există evaluări

- Asme Sec XDocument1 paginăAsme Sec XSARSAN NDTÎncă nu există evaluări

- From Fossil-To Bio-Based Refineries: Case Study Biorefinery LeunaDocument15 paginiFrom Fossil-To Bio-Based Refineries: Case Study Biorefinery Leunasslome@nexant.comÎncă nu există evaluări

- Ace Maxicem 8000 FY 14-15Document2 paginiAce Maxicem 8000 FY 14-15Abhinay SuratkarÎncă nu există evaluări

- 1200ekw 1500kVA Generator SetDocument1 pagină1200ekw 1500kVA Generator SetWilson PatilangiÎncă nu există evaluări

- Shell Flavex Oil 595: Specifications, Approvals & RecommendationsDocument2 paginiShell Flavex Oil 595: Specifications, Approvals & RecommendationsΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣÎncă nu există evaluări

- Commercial Park Layout and Testing RegimeDocument1 paginăCommercial Park Layout and Testing RegimemawejosephÎncă nu există evaluări

- Fire Fighting EquipmentDocument2 paginiFire Fighting EquipmentuniversalfireprotectionÎncă nu există evaluări

- Maxon 5550 BulletinDocument4 paginiMaxon 5550 BulletindcarunchioÎncă nu există evaluări

- Yamaha AMP GP Pro A Series-Disklavier III-dc3a Dc5a Dc6a Dc7a Ds4a Ds6a Dcf3sa ProDocument116 paginiYamaha AMP GP Pro A Series-Disklavier III-dc3a Dc5a Dc6a Dc7a Ds4a Ds6a Dcf3sa ProDamon Brunger100% (1)

- Control Valves (ABB Kent)Document816 paginiControl Valves (ABB Kent)anhkietvt100% (1)

- CHP SopDocument26 paginiCHP Sopkalyanm20351550% (2)

- TF 005Document4 paginiTF 005Abdul BokhariÎncă nu există evaluări

- TF 005Document4 paginiTF 005Abdul BokhariÎncă nu există evaluări

- Hardgrove Index in CoalDocument6 paginiHardgrove Index in CoalsprotkarÎncă nu există evaluări

- Boiler Efficiency Calculations SheetDocument5 paginiBoiler Efficiency Calculations Sheetkalyanm20351578% (9)

- 660mw Adani - Cold Start Up ProcedureDocument11 pagini660mw Adani - Cold Start Up Procedurekalyanm203515100% (1)

- 660mw Sop LancoDocument17 pagini660mw Sop Lancokalyanm203515Încă nu există evaluări

- DM Fill Up PumpsDocument4 paginiDM Fill Up Pumpskalyanm203515Încă nu există evaluări

- DM Fill Up PumpsDocument4 paginiDM Fill Up Pumpskalyanm203515Încă nu există evaluări

- Tubine Bypass SystemDocument12 paginiTubine Bypass Systemkalyanm203515Încă nu există evaluări

- Third Exam for Boiler Inspector RecognitionDocument28 paginiThird Exam for Boiler Inspector Recognitiondada jamdarÎncă nu există evaluări

- ApplicationformDocument1 paginăApplicationformkalyanm203515Încă nu există evaluări

- HPCL recruitment Packaging Quality OfficerDocument8 paginiHPCL recruitment Packaging Quality Officerkalyanm203515Încă nu există evaluări

- BensonDocument5 paginiBensonAditya YallapragadaÎncă nu există evaluări

- Third Exam for Boiler Inspector RecognitionDocument28 paginiThird Exam for Boiler Inspector Recognitiondada jamdarÎncă nu există evaluări

- HPCL recruitment Packaging Quality OfficerDocument8 paginiHPCL recruitment Packaging Quality Officerkalyanm203515Încă nu există evaluări

- Acid Dewpoint MonitoringDocument8 paginiAcid Dewpoint Monitoringkalyanm203515Încă nu există evaluări

- Basic Maintenance AspectDocument194 paginiBasic Maintenance Aspectkalyanm203515100% (1)

- Bank Tubes in BoilerDocument2 paginiBank Tubes in Boilerkalyanm203515100% (1)

- Fqap For Presser PartsDocument5 paginiFqap For Presser Partskalyanm203515Încă nu există evaluări

- Fag CataDocument114 paginiFag Catakalyanm203515Încă nu există evaluări

- Heat ExchangerDocument155 paginiHeat ExchangerSajilal JosephÎncă nu există evaluări

- A4 P&id of Steam & Water - Saturated To SH, 2001b-00-2001, SHT 2 of 3 - R2-ModelDocument1 paginăA4 P&id of Steam & Water - Saturated To SH, 2001b-00-2001, SHT 2 of 3 - R2-Modelkalyanm203515Încă nu există evaluări

- EspDocument21 paginiEspkalyanm203515Încă nu există evaluări

- Stturated SystemDocument1 paginăStturated Systemkalyanm203515Încă nu există evaluări

- Boiler Technology Exam PapersDocument9 paginiBoiler Technology Exam PaperssaurabhshineÎncă nu există evaluări

- Calculating NPSH SampleDocument8 paginiCalculating NPSH SamplejsmargateÎncă nu există evaluări

- Pressure Units ConversionDocument4 paginiPressure Units Conversionkalyanm203515Încă nu există evaluări

- Simulation - Furnace Draft & Drum LevelDocument2 paginiSimulation - Furnace Draft & Drum Levelkalyanm203515Încă nu există evaluări

- GMK5220 Super Pressure AdjustmentsDocument9 paginiGMK5220 Super Pressure AdjustmentsAngel Dlsg100% (2)

- Pipes General - Nominal Pipe Size (NPS) and Schedule (SCH)Document5 paginiPipes General - Nominal Pipe Size (NPS) and Schedule (SCH)PrakashÎncă nu există evaluări

- Pumps That Move Rotating Can Be Classified As FollowsDocument6 paginiPumps That Move Rotating Can Be Classified As FollowsWahyu Muhamad RomadoniÎncă nu există evaluări

- Pump Selection and Design GuideDocument178 paginiPump Selection and Design GuideSudhanshu ShekharÎncă nu există evaluări

- A 217Document1 paginăA 217AnuranjanÎncă nu există evaluări

- Continuous Flow Measurement Using Differential PressureDocument2 paginiContinuous Flow Measurement Using Differential Pressurebcanilkumar007Încă nu există evaluări

- Toshiba Rotary Compressor Tech Specs PDFDocument1 paginăToshiba Rotary Compressor Tech Specs PDFcalvin.bloodaxe4478100% (2)

- Reciprocating PumpsDocument10 paginiReciprocating PumpsMae Ann Dolor EstrellanaÎncă nu există evaluări

- Mizer No-Bleed Pilot ValveDocument2 paginiMizer No-Bleed Pilot ValveKate FaulhaberÎncă nu există evaluări

- CFM56 Engine Certification DetailsDocument14 paginiCFM56 Engine Certification DetailshamidrezachamaniÎncă nu există evaluări

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument29 paginiWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For Scientistsethiopian art2020Încă nu există evaluări

- Air Tube Product Offering: Osi PN DescriptionDocument5 paginiAir Tube Product Offering: Osi PN DescriptionAmirÎncă nu există evaluări

- Procedure For AGRP Amine DegreasingDocument20 paginiProcedure For AGRP Amine DegreasingRathinavel Perumal100% (4)

- 299h Series Pressure Reducing Regulator Instruction ManualDocument20 pagini299h Series Pressure Reducing Regulator Instruction ManualdonitoticoÎncă nu există evaluări

- 22-DS-R-001 Rev 1 API 617 GTCPsDocument25 pagini22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- Lecture 4 Penstock Alignment Accessories 1Document14 paginiLecture 4 Penstock Alignment Accessories 1Nischal PokharelÎncă nu există evaluări

- Iqwq Ce1091 VPWLD D7 4556 - 0Document7 paginiIqwq Ce1091 VPWLD D7 4556 - 0jacksonbello34Încă nu există evaluări

- Chapter 8 23 PDFDocument1 paginăChapter 8 23 PDFAlwin WanÎncă nu există evaluări

- Hydrotest Pressure Procedure - 2023Document15 paginiHydrotest Pressure Procedure - 2023Amit HasanÎncă nu există evaluări

- Standardization of Steel Pipe SizesDocument4 paginiStandardization of Steel Pipe SizesMuhammed Abo-FandoodÎncă nu există evaluări

- Sharp Edge OrificeDocument2 paginiSharp Edge Orificeleo.caguimbal6433Încă nu există evaluări

- B - Minimum Required Thickness Permanent Blank ASME 304.5.3Document2 paginiB - Minimum Required Thickness Permanent Blank ASME 304.5.3edisjdavÎncă nu există evaluări

- Plano Thomas Numatico169484ADocument3 paginiPlano Thomas Numatico169484ADaniel Alex SánchezÎncă nu există evaluări

- Operation Manual Oil-Free Oxygen Piston Compressor Water-CooledDocument20 paginiOperation Manual Oil-Free Oxygen Piston Compressor Water-CooledPABLOBOBADILLAÎncă nu există evaluări

- Vetus Waste Controll PDFDocument56 paginiVetus Waste Controll PDFBen GrahamÎncă nu există evaluări

- Valvula Limitadora de Presion PrecomandadaDocument4 paginiValvula Limitadora de Presion PrecomandadaGabriela ReyesÎncă nu există evaluări

- Pengolahan Data Pompa SentrifugalDocument7 paginiPengolahan Data Pompa SentrifugalAnnisah MardiyyahÎncă nu există evaluări

- Valve BlockDocument1 paginăValve BlockEdnKristi WilsonÎncă nu există evaluări

- Lecture On Specific Speed 2019Document22 paginiLecture On Specific Speed 2019Ariel GamboaÎncă nu există evaluări

- Valve Section (Auxiliary Valve) - (S - N 232512782 & Below, 232711433 & Below, 232612157 & Below) - 334Document2 paginiValve Section (Auxiliary Valve) - (S - N 232512782 & Below, 232711433 & Below, 232612157 & Below) - 334EUROPARTSÎncă nu există evaluări