Documente Academic

Documente Profesional

Documente Cultură

Belgravia Supreme IOM Guide

Încărcat de

Paul KwongTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Belgravia Supreme IOM Guide

Încărcat de

Paul KwongDrepturi de autor:

Formate disponibile

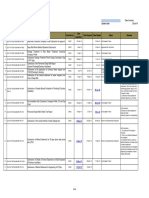

QA/IOM/55 Issue 4 - Belgravia Supreme

BELGRAVIA SUPREME

I N S TA L L AT I O N, O P E R AT I O N &

MAINTENANCE INSTRUCTIONS

Contents:

Page

1. General

1.1. General Description

1.2. Receipt and Preparation

2. Installation

2.1. Removal of Access Panel

2.2. Removal of Casgin

2.3. Removing Motor Plate

2.4. Change of Handing

2.4.1. Standard Airflow Unit

2.4.2. Reversal of Airflow

2.5.Coil Pipework Connections

2.6. Wiring

2.7. Electric Motor Protection

2.8. Recommended Connection / Installation Details

3. Electrical Data

3.1. Control Wiring

3.2. Motor Wiring

3.3. Common Control Options

3.4.Wiring Sequence

3.5. Live Wiring

3.6. Thermostatic Operation

4. Maintenance

10

4.1. General

10

4.2. Filter

10

4.3. Coil

10

4.4. Fan Set

10

4.5. Fusing

10

4.6. Spares

10

5. Fault Finding

11

5.1. No Fan Operation

11

5.2. No Heating

11

6. Contact Information

12

QA/IOM/55 Issue 4 - Belgravia Supreme

1.

GENERAL

1.1

GENERAL DESCRIPTION

This manual covers the Belgravia Supreme Fan Convector range. These are cabinet type units

intended for either vertical or horizontal mounting. Controls can be contained within the casing to

give a clean outline or be installed remotely (on-site by the contractor) for easy customer control.

1.2

RECEIPT AND PREPARATION

The units are wrapped and display the SPC works order number, model reference, site reference

(where appropriate), handing and site details. Installation, operation and maintenance

instructions, together with wiring and any special instructions, are supplied with the unit.

On receipt, check that all details are correct to the Customer Schedules prior to opening

packaging. Damage should be reported to the Carrier and to SPC Office immediately.

It is recommended that packaging is kept in place and the units stored in a safe area until the

necessary services are completed, in order to avoid the possibility of damage on site.

2.

INSTALLATION

2.1

REMOVAL OF ACCESS PANEL

Two methods of fixing access panels are employed:

?

Tamper-proof Fixings (TAP on order paperwork). Where supplied, these are released

with a quarter turn using the Allen Key provided.

?

Lock Fixings (LAP on order paperwork). Where supplied, these are released with a

quarter turn using the key supplied.

2.2.

REMOVAL OF CASING

WARNING! ELECTRICALLY ISOLATE THE UNIT PRIOR TO WORK COMMENCING

?

Remove front access panel as above.

?

Undo the two or four off M6 screws that are located internally, top and bottom in the

back plate side faces.

?

Un-hook casing at top of the unit and pull clear of the back-plate assembly.

QA/IOM/55 Issue 4 - Belgravia Supreme

Page 3.

Back plate assembly

Casing

Access panel

2.3.

REMOVING MOTOR PLATE

WARNING! ELECTRICALLY ISOLATE THE UNIT PRIOR TO WORK COMMENCING

?

Remove front access panel (see above).

?

Remove the two transit bolts that pass through the motor-plate at the front corners.

?

Disconnect plug / socket connections from the motor plate.

?

For normal airflow units, lift the motor plate up and clear of the casing as it is drawn out

of the front opening. For RAF (Reverse Airflow) units, the motor plate bracket needs to

be released at the front and swung down such that the motor plate can drop out

through the front opening. In both instances take care not to damage the fan impellers

in any way during this procedure.

?

On ceiling mounted units, ensure that the motor plate is adequately supported before

releasing the transit bolts.

2.4.

CHANGE OF HANDING

Unless otherwise specified, all units will be supplied with heat exchangers having connections at

the right-hand end. It is possible to reverse this handing on-site (see instructions overleaf).

QA/IOM/55 Issue 4 - Belgravia Supreme

Page 4.

2.4.1. STANDARD AIRFLOW UNIT

WARNING! ELECTRICALLY ISOLATE THE UNIT PRIOR TO WORK COMMENCING

?

Remove the casing (as above)

?

Remove the coil by undoing two M6 bolts.

?

Disconnect the in-line wiring plugs that are situated between the motor plate and the

coil and remove the motor plate (as above).

?

Remove the control plate by undoing the two M5 bolts that hold it in place.

?

Unscrew the connection blanking plate to allow the plugs to pass through the void

bracket.

?

Replace the connection blanking plate in closed position.

?

On other void bracket unscrew the connection blanking plate and pass the plugs back

through.

?

Attach the control plate to the other side of the unit. Re-fit the motor plate and re-

connect plugs on top of the motor plate (any internal thermostats will need to be moved

to the other side as well).

?

Rotate the coil and re-fix in required position (this must be on the opposite end to the

control plate) with M6 bolts.

2.4.2. REVERSAL OF AIRFLOW

WARNING! ELECTRICALLY ISOLATE THE UNIT PRIOR TO WORK COMMENCING

?

Place the unit on its back.

?

Remove casing (see above).

?

Remove the coil by undoing four M6 bolts and sliding it out between the void plates.

?

Disconnect the in-line wiring plugs that are situated on the motor plate and then

remove the motor plate (see above).

?

Remove the control plate by undoing the two M5 bolts which hold it in place.

?

Unscrew the connection blanking plate to allow the plugs to pass through the void

bracket.

?

Replace the connection blanking plate in closed position.

?

On other the void bracket, unscrew the connection blanking plate and pass the plugs

back through.

?

Attach the control plate to the other side. Rre-fit the motor plate and reconnect plugs

on top of the motor plate (any internal thermostats will need to be moved to the other

side as well).

?

Rotate the coil and refix in required position (this must be on the opposite end to control

plate) with M6 bolts.

QA/IOM/55 Issue 4 - Belgravia Supreme

Page 5.

2.5.

COIL PIPEWORK CONNECTIONS

It is recommended that pipework connections should be run through a plinth where possible. If this

is not possible, or if the unit has not been supplied with a plinth, then the unit should have modified

case side panels where the knock-outs can be removed to make the coil connections.

Should these panels not have been specified, or pipe connections need to enter the unit from the

top or bottom, then holes will need to be cut through the case metalwork or aluminium extrusions

such that the external casing will still lift on and off after installation.

For ceiling mounted units connections should be made through the back panel with appropriate

sized holes being made to accommodate the connection pipes.

2.6.

WIRING

All electrical work should be carried out in accordance with current I.E.E. regulations.

All motors are fitted with internal self-resetting thermal overload protection (see note below). All

units are equipped with a motor plate mounted 20mm x 5mm antisurge fuse (see spares list). All

units are equipped with 2 metre length of 2 core cable as a flying lead. This is normally coiled within

the unit.

The customer should drill and gland through the back plate (or plinth if fitted) to suit the installation.

The supply should be wired through a suitable means of isolation such as a fused spur box or

similar. Recommended fuse is not more than 3A.

2.7.

ELECTRIC MOTOR PROTECTION

On ceiling mounted and reverse airflow applications where the fan motor is switched off for long

oC

oF

periods, with hot water still circulating through the heat exchangers in excess of 82 (180 ), it is

recommended that a system be employed which automatically closed the hot water supply valve to

prevent damage to the electric motor due to overheating.

QA/IOM/55 Issue 4 - Belgravia Supreme

Page 6.

2.8

RECOMMENDED CONNECTION / INSTALLATION DETAILS

A or BS Style (normal or RAF):

Connections through plinth or

through knock-outs in bottom panel.

QS or VS Style (normal or RAF):

Drill through back panel to make

connections.

Inverted BS Style (normal or RAF) and HS Style:

Connection Options:

1. Drill through side panel casework and case becomes fixed after installation (maintenance

can still be achieved through front panel).

2. Request slotted knock-out side panels on units when placing order with SPC.

QA/IOM/55 Issue 4 - Belgravia Supreme

Page 7.

3.

ELECTRICAL INFORMATION

3.1.

CONTROL WIRING

The wiring for internal control options is sited on the motor plate. Wiring from the motor plate to

casing control options is via split connector break plugs.

Customer wiring should be made to the customer connection box for other than the flying lead.

Wiring to other than this point may result in voiding of the warranty.

A wiring diagram showing customer connections is included with each unit. For wiring other than that

specified on the customers order acknowledgement, the SPC Office should be contacted.

3.2.

MOTOR WIRING

For other than variable speed units (VSP), the motor is single tap wound with a multi-tap transformer

controlling low, normal and high speed options. If only one speed is specified, this will be the normal,

unless otherwise indicated.

The motors are 4-pole permanent split capacitor type, with main and auxiliary windings. The auxiliary

is supplied via a capacitor. Variable speed units are single tap with a controlled voltage supply related

to temperature.

3.3.

COMMON CONTROL OPTIONS

Thermostat

Switches

REFERENCE**

FUNCTION

T-1

On-off

T-2

Change speed

LTC

Low water temperature fan cutout

T1 - T2

Combined On/Off/Change Speed

RS-1

On-off

RS-2

Summer-winter

RS-3

Change speed (3speeds)

KOS

Key operated switch (on-off unless specified

**Additional References: Motor plate mounted = B, Case mounted = C, Remote = R

QA/IOM/55 Issue 4 - Belgravia Supreme

Page 8.

3.4.

WIRING SEQUENCE

This is provided as a general guide for checking purposes only. See the supplied wiring diagram

for recommended customer wiring.

3.5.

LIVE WIRING

Colour within the unit follows the arrangement below, change colour at switching points.

Brown

Black

Pink

White

Purple

Yellow - Low (3 speed)

Orange - Normal

Red - High

... Final Wire Run ( Yellow - Normal (Single Speed)

3.6.

...

THERMOSTATIC OPERATION

The T1 and T2 thermostats both have graduated scales to cover their range of operation. Since

the thermostatic bulb is frequently unit mounted it may be offset by various amounts from the

measured room temperature. Set the knob at mid-range and adjust to suit comfort conditions

oC

within the room. The range corresponds to a sensed temperature range of 10 to 30 .

T1 and T2 are adjustable and determine the comfort room temperature range. Set T2 for the low

and T1 for the high point. Exmaple, T2 = 16oC, T1 = 20oC.

oC

The Low Temperature Cutout (LTC) is not adjustable, it is set to 45 , and provides a fan cut-off for

the situation when the water temperature is not sufficiently high to provide warm blown air from the

fan convector. The LTC is mounted at the non-void end of the unit and is clipped on to a return

bend of the coil.

QA/IOM/55 Issue 4 - Belgravia Supreme

Page 9.

MAINTENANCE

4.1

GENERAL

WARNING! ELECTRICALLY ISOLATE THE UNIT PRIOR TO WORK COMMENCING

4.2

FILTER

The AF3 air filter is motor plate mounted as standard. The filter is held in place between 2 brackets

and is removed by sliding it out.

Filters should be gently tapped to remove most of the accumulated dust and either vacuumed clean

or washed in lukewarm water with detergent. Rinse in clean water and allow to dry naturally before

replacement.

4.3

COIL

Remove access panel and clean the coil with a brush or by vacuuming, taking care not to damage

the coil surfaces.

4.4

FAN SET

The motor has sealed for life bearings, which under normal circumstances require no user

maintenance. The motor deck is accessed by means of the access panel and is readily removed if

required. Occasional vacuuming or cleaning of the motor plate is recommended.

4.5

FUSING

Fan motor - Anti-surge 20mm x 5mm 2A to BS4265/IEC127

4.6

SPARES

Fuses

- as above

Filters

- quote model number (SPR 40/60 etc) or unit width

- quote motor plate mounted (AF3) or coil mounted (AF1) or grille mounted (AF2).

Controls

- as specification

- quote wiring diagram number or marked number if possible.

Motor

- quote model number on motor plate

QA/IOM/55 Issue 4 - Belgravia Supreme

Page 10.

5.

FAULT FINDING

5.1

NO FAN OPERATION

5.2

Check fuse on motor plate.

Check power supply to unit.

Check loose wiring and breaker plugs or damage to wiring.

Check switches

Check impellers run freely.

NO HEATING

!

Check thermostat operation (change set point to maximum) where fitted.

Check integrity of wiring.

Check coil vented.

Check hot water to unit.

Check thermostat bulb in airstream.

Check LTC contact on pipe-work or return bend.

QA/IOM/55 Issue 4 - Belgravia Supreme

Page 11.

S & P Coil Products Ltd

SPC House, Evington Valley Road, Leicester, LE5 5LU

Tel: (0116) 249 0044 Fax: (0116) 249 0033

e-mail: spc@spcoils.co.uk Web: www.spcoils.co.uk

QA/IOM/55 Issue 4 - Belgravia Supreme

S-ar putea să vă placă și

- Frigidaire Affinity Dryer Service ManualDocument84 paginiFrigidaire Affinity Dryer Service Manuali0leg3393% (14)

- EP500 English Technical Manual From Serial No 266 With E100 InterfaceDocument29 paginiEP500 English Technical Manual From Serial No 266 With E100 InterfaceYenireé Medina100% (1)

- BiffiDocument32 paginiBiffimattaulhaq0% (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDe la Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsEvaluare: 4 din 5 stele4/5 (1)

- Architectural Material Specification for SC Auto Bus FactoryDocument4 paginiArchitectural Material Specification for SC Auto Bus FactoryPaul Kwong100% (1)

- Antrieb Actuators O & M CatalogueDocument12 paginiAntrieb Actuators O & M Catalogueysr3ee6926100% (3)

- ACS800 - 304 - Suppl - User Manual PDFDocument82 paginiACS800 - 304 - Suppl - User Manual PDFAlamgir Robin0% (1)

- Manual Markon NAC160 NAC190Document23 paginiManual Markon NAC160 NAC190Sajjad HussainÎncă nu există evaluări

- Instrument Cluster VW 90-92Document7 paginiInstrument Cluster VW 90-92pito100% (1)

- Bolens Lawn Tractor RepairDocument46 paginiBolens Lawn Tractor Repairdakehi1188342157% (7)

- Ariston Fault Codes All Models 1Document11 paginiAriston Fault Codes All Models 1Zoran ProkicÎncă nu există evaluări

- Hitachi RAS-10KH2 - Manual Service - Lb. Engleza PDFDocument68 paginiHitachi RAS-10KH2 - Manual Service - Lb. Engleza PDFnoidforall100% (2)

- Addendum For 208-230/460 Volt - 3 Phase Units: Specifications and PerformanceDocument1 paginăAddendum For 208-230/460 Volt - 3 Phase Units: Specifications and PerformanceRuben MoralesÎncă nu există evaluări

- Iom - 1-250Document250 paginiIom - 1-250Eduardo JoseÎncă nu există evaluări

- VaraDocument8 paginiVaraCesar Alfonso Saldivar MontoyaÎncă nu există evaluări

- Al Tronic 1-6 In-Line Engines, Cylinders Installation Instructions Form Al-6111-94Document12 paginiAl Tronic 1-6 In-Line Engines, Cylinders Installation Instructions Form Al-6111-94SMcÎncă nu există evaluări

- Section 5 - Repair/Replacement Procedures: Part Number/ Nomenclature DescriptionDocument4 paginiSection 5 - Repair/Replacement Procedures: Part Number/ Nomenclature DescriptionGregorio1927Încă nu există evaluări

- J02798Document6 paginiJ02798Ron CordesÎncă nu există evaluări

- Turbovac Mag 2200 C-2Document132 paginiTurbovac Mag 2200 C-2Giles HarperÎncă nu există evaluări

- Manuals Repair Manual CompactdriveDocument5 paginiManuals Repair Manual Compactdrivegues90Încă nu există evaluări

- GBC 2230s 2250x Parts ListDocument33 paginiGBC 2230s 2250x Parts ListJohn AldenÎncă nu există evaluări

- Alt I Installation GuideDocument10 paginiAlt I Installation GuidegustavoespinosamÎncă nu există evaluări

- Installation Guide: Dellorto Induction Kit for 1984-85 Mazda RX-7Document7 paginiInstallation Guide: Dellorto Induction Kit for 1984-85 Mazda RX-7Brent Z. BaileyÎncă nu există evaluări

- VC Series: Installation Instruction - EinbauanleitungDocument12 paginiVC Series: Installation Instruction - EinbauanleitungIon VasileÎncă nu există evaluări

- Altronics A2-CPU IOM 06-1988 PDFDocument19 paginiAltronics A2-CPU IOM 06-1988 PDFSMcÎncă nu există evaluări

- 143T-449T TECO Welding House GeneralDocument9 pagini143T-449T TECO Welding House GeneralChristian TorresÎncă nu există evaluări

- 18 GJ04D1 6Document40 pagini18 GJ04D1 6sil_muahdibÎncă nu există evaluări

- FM774 1Document24 paginiFM774 1scribd2002Încă nu există evaluări

- Inversor Abb 2 5kwDocument2 paginiInversor Abb 2 5kwapi-290643326Încă nu există evaluări

- Brake Unit Instruction ManualDocument13 paginiBrake Unit Instruction Manuals_barriosÎncă nu există evaluări

- Reflector de Busqueda de Control Remoto de 7''Document4 paginiReflector de Busqueda de Control Remoto de 7''luisgebÎncă nu există evaluări

- Installation Instructions For Motor Operator For 3 - and 4-Pole ND, NBDocument8 paginiInstallation Instructions For Motor Operator For 3 - and 4-Pole ND, NBpayolin77Încă nu există evaluări

- Ounting & Maintenance Instructions For Threephase Induction Motors - Types Dm1 / Dma1 / Dma2Document9 paginiOunting & Maintenance Instructions For Threephase Induction Motors - Types Dm1 / Dma1 / Dma2Chad HuntÎncă nu există evaluări

- KCU401-C Keeler Cryomatic Service ManualDocument25 paginiKCU401-C Keeler Cryomatic Service ManualFrancisco GomezÎncă nu există evaluări

- Cadillac blower motor installDocument2 paginiCadillac blower motor installMohammad PiraniÎncă nu există evaluări

- Hitachi Manual RAS - RAC-18-25YH6Document95 paginiHitachi Manual RAS - RAC-18-25YH6Yashika Arora100% (3)

- ACS550 U1 Quick Start GuideDocument2 paginiACS550 U1 Quick Start GuideIvonne Mayela DiazÎncă nu există evaluări

- Ras-25 - 35FH5 Rac25-35yh5Document95 paginiRas-25 - 35FH5 Rac25-35yh5masinemaÎncă nu există evaluări

- 9479 Inst ManualDocument8 pagini9479 Inst ManualfdkaÎncă nu există evaluări

- GMLAN Communication Issues, No Crank, Warning Lamps & More FixedDocument12 paginiGMLAN Communication Issues, No Crank, Warning Lamps & More Fixedأمجد راضي هادي /A1Încă nu există evaluări

- Service Manual: Room Air ConditionerDocument96 paginiService Manual: Room Air ConditionerMalay K GhoshÎncă nu există evaluări

- 980a1003 PDFDocument48 pagini980a1003 PDFMichael DavenportÎncă nu există evaluări

- Installation, Operation and Service Manual for T40000RT Pool/Spa Equipment Control PanelDocument4 paginiInstallation, Operation and Service Manual for T40000RT Pool/Spa Equipment Control PanelOlga Joy Labajo GerastaÎncă nu există evaluări

- Maintenanceboth Q and ADocument46 paginiMaintenanceboth Q and AMMS SÎncă nu există evaluări

- Kaukan Oil Cooler Instruction HandbookDocument14 paginiKaukan Oil Cooler Instruction HandbooksunhuynhÎncă nu există evaluări

- Gen Set Replacement Control Panel MODEL 540: Installation - Operation ManualDocument13 paginiGen Set Replacement Control Panel MODEL 540: Installation - Operation ManualBrianHaze100% (1)

- RAS-14EH1/RAC-14EH1 Service ManualDocument93 paginiRAS-14EH1/RAC-14EH1 Service Manualpeterdodov100% (1)

- Fuel System: SectionDocument13 paginiFuel System: Sectiontomallor101Încă nu există evaluări

- Carrier 2trDocument15 paginiCarrier 2trfernandoreyes893Încă nu există evaluări

- R 22Document22 paginiR 22Luis MartinezÎncă nu există evaluări

- Multigraphics 1450/1650 Heavy-Duty Drive Motor Conversion KitDocument8 paginiMultigraphics 1450/1650 Heavy-Duty Drive Motor Conversion KitporqÎncă nu există evaluări

- Cummins ECM Connector Repair KitDocument10 paginiCummins ECM Connector Repair KitvmrvdnvÎncă nu există evaluări

- Fitting Instructions Fsit ValveDocument2 paginiFitting Instructions Fsit ValveNolan PillayÎncă nu există evaluări

- 08T - Power Mirror SystemsDocument6 pagini08T - Power Mirror SystemsjohnqevilÎncă nu există evaluări

- Globe Valve Type Flow Switch: DescriptionDocument4 paginiGlobe Valve Type Flow Switch: DescriptiongoparsucoÎncă nu există evaluări

- Parking Brake System: SectionDocument8 paginiParking Brake System: Sectionfrank1220uÎncă nu există evaluări

- MK RepairsDocument141 paginiMK RepairsAnonymous SJyuwb0DÎncă nu există evaluări

- Hitachi Ras Rac-7!9!14gh4Document68 paginiHitachi Ras Rac-7!9!14gh4cristiangodeanuÎncă nu există evaluări

- Anexo 1Document110 paginiAnexo 1rhusseinpos4765Încă nu există evaluări

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDe la EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementÎncă nu există evaluări

- Conopy & Passge WayDocument5 paginiConopy & Passge WayPaul KwongÎncă nu există evaluări

- 5.2.2 Excavation & FillingDocument6 pagini5.2.2 Excavation & FillingPaul KwongÎncă nu există evaluări

- Vetting Sheet SampleDocument4 paginiVetting Sheet SamplePaul KwongÎncă nu există evaluări

- Analysis of Myanmar's Foreign Investment Law - Part 1Document3 paginiAnalysis of Myanmar's Foreign Investment Law - Part 1Paul KwongÎncă nu există evaluări

- 5.2.1 Concrete WorksDocument23 pagini5.2.1 Concrete WorksPaul KwongÎncă nu există evaluări

- YCDC Notification No 9 1999Document16 paginiYCDC Notification No 9 1999Paul KwongÎncă nu există evaluări

- 5.2.3 Piling WorksDocument12 pagini5.2.3 Piling WorksPaul KwongÎncă nu există evaluări

- 5.2.4 Structural SteelworksDocument9 pagini5.2.4 Structural SteelworksPaul KwongÎncă nu există evaluări

- Tax Flow ChartDocument1 paginăTax Flow ChartPaul KwongÎncă nu există evaluări

- Colliers International Yangon Condominium Report 4Q 2014Document4 paginiColliers International Yangon Condominium Report 4Q 2014Paul KwongÎncă nu există evaluări

- Tender Presentation: Qingjian International (Myanmar) Group Development Co., LTDDocument1 paginăTender Presentation: Qingjian International (Myanmar) Group Development Co., LTDPaul KwongÎncă nu există evaluări

- YCDC Notification No 9 1999Document16 paginiYCDC Notification No 9 1999Paul KwongÎncă nu există evaluări

- Analysis of Myanmar Foreign Investment Law - Part 2Document5 paginiAnalysis of Myanmar Foreign Investment Law - Part 2Paul KwongÎncă nu există evaluări

- Doing Business in BurmaDocument2 paginiDoing Business in BurmaPaul KwongÎncă nu există evaluări

- Doing Business in Burma - Commercial Guide 2014 (US)Document68 paginiDoing Business in Burma - Commercial Guide 2014 (US)Paul KwongÎncă nu există evaluări

- Food and Beverage To Myanmar (Australia)Document5 paginiFood and Beverage To Myanmar (Australia)Paul KwongÎncă nu există evaluări

- Construction and Infrastructure Developments in Myanmar Feb 2014Document3 paginiConstruction and Infrastructure Developments in Myanmar Feb 2014Paul KwongÎncă nu există evaluări

- How To Develop Underdeveloped Countries Through Proper PlanningDocument3 paginiHow To Develop Underdeveloped Countries Through Proper PlanningPaul KwongÎncă nu există evaluări

- How To Develop Underdeveloped Countries Through Proper PlanningDocument3 paginiHow To Develop Underdeveloped Countries Through Proper PlanningPaul KwongÎncă nu există evaluări

- Myanmar New Tax LawDocument4 paginiMyanmar New Tax LawKo NgeÎncă nu există evaluări

- Myanmar - A Nation in CrisisDocument19 paginiMyanmar - A Nation in CrisisPaul KwongÎncă nu există evaluări

- Material Catalogue Submission List (6-Aug-15)Document2 paginiMaterial Catalogue Submission List (6-Aug-15)Paul KwongÎncă nu există evaluări

- Myanmar Capital Gains Tax Rates, and Property Income TaxDocument8 paginiMyanmar Capital Gains Tax Rates, and Property Income TaxPaul KwongÎncă nu există evaluări

- Trade Policy Reform-Myanmar - As of 23 Sept 14Document21 paginiTrade Policy Reform-Myanmar - As of 23 Sept 14Paul KwongÎncă nu există evaluări

- Date Over-Due Don't Need To Submit Revise & Resubmit M&E Shop Drawing Register Combine Service Drawing & Structural Electrical and Mechanical Drawing (CSD & SEM) Updated Date: 25-Jul-15Document36 paginiDate Over-Due Don't Need To Submit Revise & Resubmit M&E Shop Drawing Register Combine Service Drawing & Structural Electrical and Mechanical Drawing (CSD & SEM) Updated Date: 25-Jul-15Paul KwongÎncă nu există evaluări

- Myanmar Government Reverses Prohibition On Foreign WinesDocument2 paginiMyanmar Government Reverses Prohibition On Foreign WinesPaul KwongÎncă nu există evaluări

- Material Catalogue Submission List (19-Aug-15)Document1 paginăMaterial Catalogue Submission List (19-Aug-15)Paul KwongÎncă nu există evaluări

- Shop Drawings Submission List (6-Aug-15)Document3 paginiShop Drawings Submission List (6-Aug-15)Paul KwongÎncă nu există evaluări

- Tech SubDocument10 paginiTech SubPaul KwongÎncă nu există evaluări

- Manual Microtremor SARA SL-07Document2 paginiManual Microtremor SARA SL-07Afif HamzahÎncă nu există evaluări

- Modelos de ColimadoresDocument8 paginiModelos de ColimadoreslauraÎncă nu există evaluări

- VPC WiringDocument13 paginiVPC Wiringpanca nanginÎncă nu există evaluări

- Cat DP150 Forklift Service Manual 1Document209 paginiCat DP150 Forklift Service Manual 1diego100% (1)

- Aircraft Antiskid Brake SystemsDocument38 paginiAircraft Antiskid Brake SystemsAishah HanisÎncă nu există evaluări

- Legal Base MapDocument1 paginăLegal Base MapHenry IlanjianÎncă nu există evaluări

- Adidas Original Ecuador 1Document33 paginiAdidas Original Ecuador 1kelvinmd2009Încă nu există evaluări

- VC Series Zone Valves: Balanced 2-Way and 3-Way Hydronic ValvesDocument8 paginiVC Series Zone Valves: Balanced 2-Way and 3-Way Hydronic ValvesGiovanni Dala PaulaÎncă nu există evaluări

- ABB PowerCubeDocument18 paginiABB PowerCubemixed25465688Încă nu există evaluări

- Triton Wireline ValvesDocument2 paginiTriton Wireline ValvesrezaÎncă nu există evaluări

- Panasonic MINAS A3 SeriesDocument320 paginiPanasonic MINAS A3 SeriesNhật TrầnÎncă nu există evaluări

- Rayovac Workhorse FlashlightDocument2 paginiRayovac Workhorse Flashlightkhiconhomhinh_92Încă nu există evaluări

- Spherical MirrorDocument8 paginiSpherical MirrorAtul VermaÎncă nu există evaluări

- User Manual Binocular Stereo Microscope: Model G223ADocument7 paginiUser Manual Binocular Stereo Microscope: Model G223AMarcelo WillyÎncă nu există evaluări

- BMPT2Document8 paginiBMPT2minthuhtunÎncă nu există evaluări

- Hydr FanDocument22 paginiHydr FanMed EkahÎncă nu există evaluări

- Fairchild Semiconductors Design Solutions 0701 PDFDocument8 paginiFairchild Semiconductors Design Solutions 0701 PDFFernando Vidal100% (1)

- Difference BN MCB, MCCB, Elcb, RCCB, Acb & VCBDocument5 paginiDifference BN MCB, MCCB, Elcb, RCCB, Acb & VCBsrinivasaphanikiranÎncă nu există evaluări

- CCTV kit prices and specsDocument18 paginiCCTV kit prices and specsCB SmartÎncă nu există evaluări

- Dowinco excavator attachment catalogDocument11 paginiDowinco excavator attachment catalogzephyrinÎncă nu există evaluări

- LBSDocument5 paginiLBSPritam SinghÎncă nu există evaluări

- ATSL1-150: Data SheetsDocument3 paginiATSL1-150: Data SheetsCALGERIÎncă nu există evaluări

- UDR MANUFACTURE ManufacturesDocument8 paginiUDR MANUFACTURE ManufacturesQuadri Consultancy ServicesÎncă nu există evaluări

- Bar Cutting Machine Inspection ChecklistDocument1 paginăBar Cutting Machine Inspection ChecklistRicardo Dalisay100% (4)

- 450 857 07 C44CL Memcom Otis REM6 Wiring Loom V02 MLDocument8 pagini450 857 07 C44CL Memcom Otis REM6 Wiring Loom V02 MLsam11Încă nu există evaluări

- Principles of Knitting TechnologyDocument18 paginiPrinciples of Knitting TechnologysaadbinazadÎncă nu există evaluări

- Yaskawa SGDH ManualDocument263 paginiYaskawa SGDH ManualsunhuynhÎncă nu există evaluări

- Book Parts E-WE 1204-55 INGDocument138 paginiBook Parts E-WE 1204-55 INGricardo assaf marchetiÎncă nu există evaluări

- Reducing of Line StopaggesDocument39 paginiReducing of Line StopaggesSuvro ChakrabortyÎncă nu există evaluări