Documente Academic

Documente Profesional

Documente Cultură

Var 3

Încărcat de

Pop PollyTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Var 3

Încărcat de

Pop PollyDrepturi de autor:

Formate disponibile

(v3.

14)

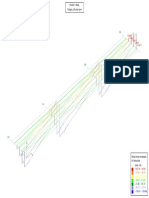

ArcelorMittal Composite Bridge Predesign

Preliminary design software for composite bridges

PRELIMINARY DESIGN REPORT

Company : Universitatea Tehnica Cluj-Napoca

User name : Petrut Mirela

Project name : Structuri compuse otel-beton

Project reference :

Comment :

Date : 31.01.2014

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v3.14)

Project reference :

Comment :

BRIEF DESCRIPTION OF SOFTWARE

Purpose of software

The ACOBRI software is used for preliminary design of the rolled-steel main beams of a composite steel and concrete bridge

superstructure. It is intended as a means of checking the feasibility of a design solution, optimizing a preliminary design through

appropriate choice of parameters, and estimating the main quantities involved. It is not intended to produce a construction design

calculation report

Scope of application

The kinds of bridges handled are road bridges, railway bridges, and footbridges with superstructures made up of steel beams supporting

a participating reinforced concrete slab or with filler-beam decks. Beams may be simply supported or continuous in the case of multi-span

bridges. Calculations are performed in accordance with the following design codes: French codes (2004), Eurocodes ENV, Eurocodes

ENV + French NAD and DIN Fachberichte (2003).

Method of analysis and design checks

On the basis of a definition of bridge geometry, materials, and loads, the program calculates internal forces and moments in the main

beams under the effect of: dead load, superimposed dead load and live load; concrete shrinkage; temperature differential; any support

height adjustment. The analysis is performed with a finite element solver, using a grid model. The structure is discretized by bar elements

corresponding to segments of the main beams, longitudinal and transverse strips of slab, and any crossbeams. For calculating flexural

and torsional stiffnesses, account is taken of creep and any concrete cracking, depending on the type of internal forces or moments.

Longitudinal and transverse influence lines are used to determine the position of mobile loads producing extreme effects at the different

cross-sections considered.

To establish preliminary design of beams, the program calculates the main load combinations for the bridge in the in-service phase. The

design checks for the serviceability limit state and ultimate limit state concern stresses in the beams and in the longitudinal

reinforcement, compressive stresses in the concrete, the ultimate moment resistance, crack control and the vertical deformation and

stress variation in beams at the fatigue limit state. The software also calculates reactions at supports and the number of connectors

required to transfer shear forces between the beams and the slab. For filler-beam decks, the calculations include a number of special

features in accordance with the specifications of the design codes.

Detailed information on the scope of application of the software, on the assumptions, methods, and approximations used and on the

calculations performed are provided in the users manual and in the on-line help module.

Comments :

The program can deal with straight, unskewed bridges with a horizontal slab of constant thickness. If the bridge to be analyzed does not

match these assumptions but does not vary substantively from them, the software can be used for an approximate calculation. In this

case the user will have to use engineering judgment both to determine the adaptations to be made to the data entered and to assess the

representativity of results given and, as required, adjust or complete the calculations and checks.

The software establishes a preliminary design for the main beams of the bridge under in-service conditions. It does not carry out any

checks for construction phases. Lateral-torsional buckling of beams is not analyzed for the construction phase. Diaphragms and/or

bracing may have to be implemented for the construction phase as well as the in-service phase.

ACOBRI is a preliminary design software tool which does not analyze all situations or perform in an exhaustive manner all the verification

calculations required for construction design.

ACOBRI was developed by CTICM, Centre Technique Industriel de la Construction Mtallique, France.

Copyright : ArcelorMittal - Long Carbon Europe - Research Center.

User name : Petrut Mirela

Date : 31.01.2014

Page 1 / 11

E:\FACULTATE\MASTER ECO\ANUL II\ACOBRI\VAR1.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v3.14)

Project reference :

Comment :

DATA

ROAD BRIDGE - Conventional beam and slab superstructure

Eurocodes (EN)

2 spans

Span length 1 = 15.000 m

Span length 2 = 15.000 m

Slab dimensions

Width = 10.000 m

Thickness = 30.0 cm

Haunch = 15.0 cm

4 beam lines (Distance to left-hand edge of deck slab)

Line 1 : 1.500 m

Centre distance = 2.333 m

Line 2 : 3.833 m

Centre distance = 2.333 m

Line 3 : 6.167 m

Centre distance = 2.333 m

Line 4 : 8.500 m

Shear studs : 19x175

Reinforcement ratio = 3.0 %

Top layer : 70 %

Distance to top of slab = 4.0 cm

Bottom layer : 30 %

Distance between bottom of slab = 4.0 cm

Propping :

No propping of main beams during deck slab concreting.

Overhang :

Overhang formwork suspended from the two outermost beams only.

An equivalent superimposed dead load is taken into account in the calculation of the slab weight

Reinforcing steel

fy = 500.00 N/mm

Structural steel S275 (WITH reduction of yield strength with thickness)

Density = 7850 kg/m

Density = 2650 kg/m

Concrete Class C35/45

-6

Shrinkage strain = 200.10

Temperature difference between slab and beams = 10 C

User name : Petrut Mirela

Date : 31.01.2014

Page 2 / 11

E:\FACULTATE\MASTER ECO\ANUL II\ACOBRI\VAR1.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v3.14)

Project reference :

Comment :

Material properties used in calculations

Yield strength of the steel of girders fy = 265.0 MPa

Yield strength of the reinforcing steel fy = 500.0 MPa

Modulus of elasticity

Ecm = 34077 MPa

Limit compressive strenght of concretefck = 35 MPa

User name : Petrut Mirela

Date : 31.01.2014

Page 3 / 11

E:\FACULTATE\MASTER ECO\ANUL II\ACOBRI\VAR1.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v3.14)

Project reference :

Comment :

Steel sections

span 1

span 2

Left-hand edge beam

HE 700 B

Intermediate beams

HE 700 B

Right-hand edge beam

HE 700 B

Left-hand edge beam

HE 700 B

Intermediate beams

HE 700 B

Right-hand edge beam

HE 700 B

Cracked regions

Support lines

LH side (m)

RH side (m)

C0

P1

2.250 (15 %)

2.250 (15 %)

C2

Footways and restraint systems

LH footway width: 1.500 m

RH footway, width: 1.500 m

LH restraint system, distance to LH edge of deck slab 1.500 m

RH restraint system, distance to RH edge of deck slab 1.500 m

Bridge class : 1

Superimposed dead loads of deck surfacing or ballast, footways or maintenance walkways etc - SDL1

Footways

Thickness = 20.0 cm

LH footway width = 1.50 m

RH footway width = 1.50 m

Density = 2000.0 kg/m

Waterproofing

Thickness = 3.0 cm

Density = 2400.0 kg/m

Surfacing

Thickness = 8.0 cm

Density = 2400.0 kg/m

Parapets

left-hand side

right-hand side

x = 0.10 m

x = 0.10 m

q = 1.00 kN/m

q = 1.00 kN/m

Restraint system

left-hand side

right-hand side

x = 1.50 m

x = 1.50 m

q = 1.00 kN/m

q = 1.00 kN/m

Live loads on footways

Distributed load = 5.00 kN/m

Left-hand footway

Width of loaded area = 1.50 m

Distance to slab edge = 0.00 m

Right-hand footway

Width of loaded area = 1.50 m

Distance to slab edge = 0.00 m

User name : Petrut Mirela

Date : 31.01.2014

Page 4 / 11

E:\FACULTATE\MASTER ECO\ANUL II\ACOBRI\VAR1.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v3.14)

Project reference :

Comment :

Definition of truck load models

Abnormal load :

None

Fatigue load model :

Load model on LH track / lane

Mean gross weight of truck : 600. kN

Number of trucks : 2.00 millions per year and slow lane

Service life (years) : 100

Support height ajustments and settlements

Height adjustments

Settlements

Support line No. 0

0 mm

0 mm

Support line No. 1

0 mm

0 mm

Support line No. 2

0 mm

0 mm

User name : Petrut Mirela

Date : 31.01.2014

Page 5 / 11

E:\FACULTATE\MASTER ECO\ANUL II\ACOBRI\VAR1.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v3.14)

Project reference :

Comment :

Assumptions for calculation and checks

Calculation coefficients

Diaphragms

Coefficient for inertia = 0.10

Coefficient for mass = 0.10

Slab elements

Coefficient for inertia - longitudinal = 1.00

Coefficient for inertia - transverse = 1.00

Serviceability Limit States

Deflection due to live loads limited to 1/ 500 of span length

Partial safety factor for the structural steel

Partial safety factor for shear resistance of studs

M,ser = 1.00

v = 1.25

Ultimate Limit States

Partial safety factors :

for sections resistance

for buckling resistance

for slab concrete strength

for shear resistance of studs

M0 = 1.00

M1 = 1.10

c = 1.50

M = 1.15

Fatigue Limit States

Partial safety factors for fatigue loading

Top flange :

Partial safety factor for fatigue strength

Detail category

Bottom flange :

Partial safety factor for fatigue strength

Detail category

Ff = 1.00

Mf = 1.15

80 MPa

Mf = 1.15

160 MPa

User name : Petrut Mirela

Date : 31.01.2014

Page 6 / 11

E:\FACULTATE\MASTER ECO\ANUL II\ACOBRI\VAR1.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v3.14)

Project reference :

Comment :

Weighting factors for SDL1 :

Increase

Reduction

Waterproofing

1.20

0.80

Surfacing

1.40

0.80

Footways

1.00

1.00

Adjustment factors applied to load model 1 (UDL + TS) :

Q1

Qi (i>1)

q1

qi(i>1)

qr

Class 1

1.0

1.0

1.0

1.0

1.0

Class 2

1.0

1.0

1.0

1.0

1.0

Class 3

1.0

1.0

1.0

1.0

1.0

The class of the bridge is : Class 1

Partial factors for loads - Combination factors :

Partial factors for loads (ULS) :

G = 1.35

Q = 1.35

Q = 1.50

P = 1.00

G,set = 1.20

S = 1.00

Permanent loads

Traffic loads

Other variable loads

Height adjustments

Settlements

Shrinkage

Combination factors :

0

'1

gr1a TS

0.75

0.75

0.00

0.80

gr1a UDL

0.40

0.40

0.00

0.80

gr5

0.00

0.00

0.00

1.00

TK

0.60

0.60

0.50

User name : Petrut Mirela

Date : 31.01.2014

Page 7 / 11

E:\FACULTATE\MASTER ECO\ANUL II\ACOBRI\VAR1.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v3.14)

Project reference :

Comment :

SUMMARY OF RESULTS

Summary for bridge

Criterion : Normal stress / shear interaction (Serviceability Limit State)

Max. ratio = 0.88

< 1.00

SATISFACTORY

Combination No.11

Beam line No.1 - Cross-section No.6 : Position = 15.00 m (intermediate support)

_________________________________

Summary for span No. 1

Criterion : Normal stress / shear interaction (Serviceability Limit State)

Max. ratio = 0.88

< 1.00

SATISFACTORY

Combination No.11

Beam line No.1 - Cross-section No.6 : Position = 15.00 m (intermediate support)

Summary for span No. 2

Criterion : Stress in bottom fibre of steel section (Serviceability Limit State)

Max. ratio = 0.86

< 1.00

SATISFACTORY

Combination No.11

Beam line No.1 - Cross-section No.6 : Position = 15.00 m (intermediate support)

Checking minimum reinforcement criterion

Reference : EN 1994-2:2005 7.4.2

Slab reinforcement ratio : 3.00 %

The criterion is satisfied for all design cross-sections, for 20 mm diameter bars.

User name : Petrut Mirela

Date : 31.01.2014

Page 8 / 11

E:\FACULTATE\MASTER ECO\ANUL II\ACOBRI\VAR1.APM

S-ar putea să vă placă și

- Tasare Stalp MarginalDocument2 paginiTasare Stalp MarginalPop PollyÎncă nu există evaluări

- Tasare Stalp MarginalDocument2 paginiTasare Stalp MarginalPop PollyÎncă nu există evaluări

- 7Document8 pagini7Pop PollyÎncă nu există evaluări

- RezultatDocument17 paginiRezultatPop PollyÎncă nu există evaluări

- Compass Solution User Guide - V1.0.1 - 2016.04.06Document21 paginiCompass Solution User Guide - V1.0.1 - 2016.04.06Pop PollyÎncă nu există evaluări

- Macara Turn Coeficient PaulaDocument2 paginiMacara Turn Coeficient PaulaPop PollyÎncă nu există evaluări

- Sup Med 0 Z Sup Z Med I (M) GZ Sup GZ Med Inf Z Inf GZ InfDocument2 paginiSup Med 0 Z Sup Z Med I (M) GZ Sup GZ Med Inf Z Inf GZ InfPop PollyÎncă nu există evaluări

- Tabel MotorinaDocument2 paginiTabel MotorinaPop PollyÎncă nu există evaluări

- Diagrama 5Document1 paginăDiagrama 5Pop PollyÎncă nu există evaluări

- RezultatDocument17 paginiRezultatPop PollyÎncă nu există evaluări

- Diagram ADocument1 paginăDiagram APop PollyÎncă nu există evaluări

- Diagram ADocument1 paginăDiagram APop PollyÎncă nu există evaluări

- Diagrama 4Document1 paginăDiagrama 4Pop PollyÎncă nu există evaluări

- ArcelorMittal Composite Bridge DesignDocument3 paginiArcelorMittal Composite Bridge DesignPop PollyÎncă nu există evaluări

- Universitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentDocument3 paginiUniversitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentPop PollyÎncă nu există evaluări

- Universitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentDocument3 paginiUniversitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentPop PollyÎncă nu există evaluări

- Universitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentDocument3 paginiUniversitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentPop PollyÎncă nu există evaluări

- Universitatea Tehnica Cluj-Napoca: Summary of Results Summary For BridgeDocument1 paginăUniversitatea Tehnica Cluj-Napoca: Summary of Results Summary For BridgePop PollyÎncă nu există evaluări

- Var 1 ConsolidareDocument1 paginăVar 1 ConsolidarePop PollyÎncă nu există evaluări

- DeseneDocument3 paginiDesenePop PollyÎncă nu există evaluări

- Scan TuneluriDocument19 paginiScan TuneluriPop PollyÎncă nu există evaluări

- Var 1 ConsolidareDocument1 paginăVar 1 ConsolidarePop PollyÎncă nu există evaluări

- Var 1 - Diagrama Oboseala DalaDocument1 paginăVar 1 - Diagrama Oboseala DalaPop PollyÎncă nu există evaluări

- RezultatDocument17 paginiRezultatPop PollyÎncă nu există evaluări

- Auto DeskDocument2 paginiAuto DeskPop PollyÎncă nu există evaluări

- DateDocument165 paginiDatePop PollyÎncă nu există evaluări

- Universitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentDocument3 paginiUniversitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentPop PollyÎncă nu există evaluări

- Universitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentDocument3 paginiUniversitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentPop PollyÎncă nu există evaluări

- Universitatea Tehnica Cluj-Napoca: Summary of Results Summary For BridgeDocument1 paginăUniversitatea Tehnica Cluj-Napoca: Summary of Results Summary For BridgePop PollyÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Goat Shed EstimateeDocument4 paginiGoat Shed EstimateeRam pakhrinÎncă nu există evaluări

- MalhotraDocument98 paginiMalhotraFlorin CarageaÎncă nu există evaluări

- PermaBase BRAND Cement Board Guide Specifications 1457491Document9 paginiPermaBase BRAND Cement Board Guide Specifications 1457491Sky MoonÎncă nu există evaluări

- Plastering Work ChecklistDocument1 paginăPlastering Work ChecklistNadira PervinÎncă nu există evaluări

- Ruukki 41323 Accesorii Panou Termoizolant Sp2e PuDocument24 paginiRuukki 41323 Accesorii Panou Termoizolant Sp2e PuMunteanu DanÎncă nu există evaluări

- FYP FinalDocument1 paginăFYP FinalOmar ShahidÎncă nu există evaluări

- Fundamentals of Concrete ADocument174 paginiFundamentals of Concrete AV Venkata Narayana100% (1)

- The Essential Guide To FramingDocument121 paginiThe Essential Guide To Framingpawkom100% (7)

- Structural Analysis Report of Mrs. Pramila Shrestha Residential Building at Kavrepalanchowk, NepalDocument106 paginiStructural Analysis Report of Mrs. Pramila Shrestha Residential Building at Kavrepalanchowk, NepalSopan GochheÎncă nu există evaluări

- Ghana Building Code - Part 9.3Document59 paginiGhana Building Code - Part 9.3vasvukÎncă nu există evaluări

- Carbon Fiber Reinforced Polymers Construction Materials TestingDocument5 paginiCarbon Fiber Reinforced Polymers Construction Materials TestingStarexx JarsÎncă nu există evaluări

- THERMO 4 Aswandi AlamDocument13 paginiTHERMO 4 Aswandi AlamAhmad S AminudinÎncă nu există evaluări

- A&m BSR-2011Document26 paginiA&m BSR-2011Mukesh Jangid100% (1)

- Lecture#2-Introduction of Air Conditioning System - Part IIDocument36 paginiLecture#2-Introduction of Air Conditioning System - Part IIHhhh GehrhhÎncă nu există evaluări

- Holcim Masonry Cement PDDocument2 paginiHolcim Masonry Cement PDTin NguyenÎncă nu există evaluări

- Curing Concrete Methods TradeoffsDocument1 paginăCuring Concrete Methods TradeoffsdavidchansmÎncă nu există evaluări

- Plumbing Max Fajardo PDFDocument175 paginiPlumbing Max Fajardo PDFJoe Luis BalaiboÎncă nu există evaluări

- Concrete BUildings Scheme Design Manual PDFDocument142 paginiConcrete BUildings Scheme Design Manual PDFAnilMohanK67% (3)

- Common Problems (Complete)Document26 paginiCommon Problems (Complete)junreymorales100% (1)

- Elite Software - ChvacDocument10 paginiElite Software - Chvacsyedkaleem550% (1)

- 15 Stout ST Green Room Presentation Jason QuinnDocument10 pagini15 Stout ST Green Room Presentation Jason QuinnJasonÎncă nu există evaluări

- 6.3 Control Joints: June 2018 Section 6.3Document10 pagini6.3 Control Joints: June 2018 Section 6.3Hansen YinÎncă nu există evaluări

- គំរបលូDocument4 paginiគំរបលូChhim RothyÎncă nu există evaluări

- CC100 ListDocument3 paginiCC100 ListlewoodwardÎncă nu există evaluări

- Price List Construction Elements 2016Document12 paginiPrice List Construction Elements 2016Abdurrasheed OlugbadeÎncă nu există evaluări

- Sustainability Minikshi JainDocument4 paginiSustainability Minikshi JainManujit KhuranaÎncă nu există evaluări

- Saving Energy With Cooling TowersDocument7 paginiSaving Energy With Cooling TowersPatrickÎncă nu există evaluări

- Plaster Assemblies Chapter 02 Plaster Substrates LathDocument26 paginiPlaster Assemblies Chapter 02 Plaster Substrates LathFare NienteÎncă nu există evaluări

- Booth Muirie Architectural Cladding Systems - Web PDFDocument60 paginiBooth Muirie Architectural Cladding Systems - Web PDFsathiyanÎncă nu există evaluări

- ROOF INDIA 2013 Exhibitor ListDocument4 paginiROOF INDIA 2013 Exhibitor ListRaju MalhotraÎncă nu există evaluări