Documente Academic

Documente Profesional

Documente Cultură

Oil Immersed Transformer Catalog English March2011

Încărcat de

thibinDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Oil Immersed Transformer Catalog English March2011

Încărcat de

thibinDrepturi de autor:

Formate disponibile

2011.

03

www.hyosungpni.com

HEAD OFFICE 450, Gongdeok-Dong, Mapo-Gu, Seoul, Korea 121-720 TEL : 82-2-707-6008

R&D CENTER 183, Hogye-Dong, Dongan-Gu, Anyang-Si, Gyeonggi-Do, Korea 431-080 TEL : 82-31-428-1000

CHANGWON PLANT 454-2, Nae-Dong, Changwon-Si, Gyeongsangnam-Do, Korea 641-050 TEL : 82-55-268-9114

Oil Immersed

Transformers

Global Top Energy, Machinery & Plant Solution Provider

About HYOSUNG

02 Sustainability

Our sustainability principles are the backbone of the way

we design and manufacture products

Quality Assurance

Hyosung strives for excellence. We believe excellence can only be achieved through absolute quality and value for customers. In order

to create quality products, we believe that all of the actions of every single employee must be focused in the highest level of quality. In

order to achieve such levels, we have implemented a quality assurance policy and programs that make our philosophy into a reality.

Our Quality Assurance Policy was founded based on the management policy of the president and meets the demands of ISO 9001.

As a globally active company, we are committed to comprehensive and quality management through three quality strategies: quality

management system, customer-focused management system, and concentration on core competencies.

The comprehensive quality management system ensures that we completely comply with all compliances and applicable legislation,

codes, and standards in addition to implementing efficient operation of our management resources to eliminate unnecessary waste.

Our customer-focused management system clarifies and simplifies our first priority which is customer satisfaction. All of our work is

aimed to exceed customer needs and provide exceptional value through quality standards, flexibility, and innovation.

Finally, we concentrate on our core competencies for strict quality control and continual improvement which provides quality products

and cost-saving to our clients via advancement in technical capacity and technological innovation.

We implement our policy via a Quality Management Team manages research laboratories, including the Measurement Standard

Laboratory, the Chemical Analysis Laboratory and the Material Analysis Laboratory to maintain a strict control over quality.

Hyosung Power & Industrial Systems PG is a division under Hyosung which consists of

seven performance groups (PGs). In addition to establishing itself as a world-class

manufacturer of electrical equipments, green technology and industrial machineries,

Hyosung is also the largest producer of tire cords and spandex in the global market and

the second largest supplier of ATMs in the USA.

Environment Protection Policy

01 Our Business

Brief introduction of Hyosung Power & Industrial Systems

Hyosung Power & Industrial Systems

Performance Group

Hyosung Power & Industrial Systems Performance Group, a comprehensive energy solution provider, boasts world-leading technology

in the global power industry and has secured a competitive capability on par with that of top competitors in transformers, switchgears,

motors, decelerators, industrial pumps, and wind energy business.

With globalization as one of our top priorities, we have achieved outstanding increase in sales over the past few years thanks to the

enhancement in Hyosungs quality, technology, and brand recognition among overseas clients, which include North America, Europe,

the Middle East, and Asia. We expect such robust performance, marked by an increasing number of orders from the overseas market,

to continue in the future.

At the heart of our capability to grow as a comprehensive energy solution provider is our global organization structure. Hyosung Power

& Industrial Systems Performance Group is divided into four business areas or performance units, depending on the types of flagship

products: Power Systems Performance Unit, Industrial Machinery Performance Unit, Hyosung GoodSprings Performance Unit, and the

Wind Energy Business Division.

Power Systems Performance Unit

Hyosungs Power Systems Performance Unit provides a full spectrum of power generation, transmission, and distribution services,

from design and engineering to the maintenance of equipment and has been building up on cutting-edge information technology

resources and developing substation automation systems, such as power monitor and control systems, and early detection and

prevention systems.

Such vast product assortment and technical know-how is based on our product development history. In 1992, Hyosung was the first

in Korea, and the sixth in the world, to develop a 765kV ultra-high voltage (UHV) transformer, and, in 1999, was the first in the world to

manufacture the 800kV gas insulated switchgear (GIS), which has put Hyosung on an equal technological ground as its top global

competitors.

Having such world-class technology, we established Baoding Hyosung Tianwei Transformer Co., Ltd., a joint venture with the Baoding

Tianwei Organization, to hold the largest share of the market in Baoding City, China. This venture was established in 2003, and by the

end of 2004, we established a production plant producing 11,000 transformers per year. In 2006 we acquired one of the top five

companies in quality terms as certified by the Chinese government, Nantong Hyosung Transformer Co., Ltd. in Jiangsu.

The Power systems Performance Unit is continuously striving to secure competitiveness in every aspect of quality, technology, sales,

services, and management, in order to satisfy customer needs globally and become a top-tire company in the world by providing

customers with the best quality products and services in the power systems sector.

Hyosung understands the impact of Hyosungs activities in the environment and works to protect the environment from pollution,

manages the environmental impacts of Hyosungs products and technologies, and prevents future pollution and harmful effects in the

environment by investing in environmentally-friendly products and solutions.

Based on this eco-philosophy of shared responsibility, Hyosung has implemented a comprehensive environmental protection program

that aims to minimize our impact on the environment and conserve resources. Our environmental policy fulfils all requirements of the

ISO 14001.

03 R&D

Inspiring innovation, creation and expertise

Hyosung R&D Center identifies innovation, creation, and expertise as core value, and concentrates on world class R&D activities in the

21st century with a philosophy aspiring after customer satisfaction, quality priority, and performance orientation. Hyosung pursues to

be the worlds best company in the field of heavy electrical machinery, industrial & electrical electronics engineering, and energy

system. Ever since establishment in 1978, R&D Center had led the development of domestic technology. Along with the Anyang and

Changwon labs, the group has endeavored to produce core technology and world-class products in the areas of heavy electrical

machinery, energy system, electrical electronics engineering, and industrial automation system.

Research Areas

Hyosung R&D Center engages in the activities in the field of energy system, solution & service, applied electrical and electronic

technology, basic core technology, technology of improved reliability, core components, and new materials.

Energy System

Basic Core Technology

Renewable energy

(wind system, wind turbine, wind PCS, solar system, PV PCS,

fuel cell, co-generation)

Electric Vehicle (EV charger, EV motor)

Fortified technology in structural dynamics,

electromagnetics, heat transfer analysis, etc.

Skills for system simulation, analysis and evaluation

Business support technology

Solution & Service

Technology with Improved Reliability

Power facility diagnosis algorithm and system

Power facility lifecycle evaluation system

Service solution for remote diagnosis for prevention

Test data analysis and testing facility

Analysis of lifecycle and cause of error

Reliability assessment (environment-friendliness, durability,

long-term degradation, and more)

Applied Electrical & Electronic Technology

Oil Immersed Transformers

CONTENTS

02 Our Business 03 Sustainability / R&D 04 General 05 Technology 06 Design Concept

07 Construction 08 Products & Details 14 Total Quality Assurance 15 Global Network

Power conversion system

Flexible AC transmission system and high voltage direct current

Power quality solution

Core Components and New Materials

Organic and inorganic insulation materials

Silicon forming technology

Intelligent sensor

(facility diagnosis, CT, PT, VT, LA, and more)

Oil Immersed

Transformers

04 05

Oil Immersed Transformers

Technology

Hyosung is the leading supplier of the power transformer industry.

Starting with the development of the 154kV high-voltage transformer in 1969, Hyosung introduced the

345kV and the 765kV transformers subsequently for the first time in the country, and only the sixth in the world.

Hyosungs oil immersed transformers are designed to withstand all environmental hazards.

In the rated power range up to 60MVA and operating voltage up to 66kV, these transformers have off-load

or on-load tap changers to adapt it to various network conditions.

Hyosung manufactures transformers under IEC, JEC, ANSI, BS and every required national standard.

We offer individual solutions for satisfying requirements related to types of operation, low noise and low

losses, connection technology, type of cooling, transportation, installation and so on.

With Hyosung Oil Immersed Transformers, you obtain

not only the transformer but also an Energy Partner for

your business

- Excellent short-circuit resistance

- Satisfies the various load conditions required by customers

- Low-loss step lap laminated core

- Uses latest insulation material with high short-circuit strength to realize high thermal capacity

- Cold steel sheet is used for radiating pipe to ensure a sufficient cooling effect and aesthetic exterior

- Compact, light, and low-noise transformer with standard efficiency and noise level which can be easily

installed even in a small indoor or outdoor area

General

Based on know-how accumulated over several years, Hyosungs oil-immersed transformers have been supplied to various industries including

semiconductor, steel work, and petrochemical. Further, as an outstanding and comprehensive solution provider, we respond to the demanding

requirements of our customers by developing and manufacturing both eco-friendly and high-efficiency transformers.

Hyosung exports its oil immersed transformers to more than 25 countries all over the world.

06 07

Oil Immersed Transformers

Design Concept

Construction

Minimize Losses

Minimize Hottest-Spot

Max. Withstand Short-Circuit

01

For highest customer value, Hyosung supplies world-class quality transformers at a reasonable price. High

quality starts from the design process. For transformer design, accumulated experience level and computer

technology are the two most important aspects in evaluating transformer engineering. Well-trained engineers

with a high quality training program help to assure high quality design.

With more than 40 years of engineering database network system and optimum design program

experience, Hyosung guarantees customers a trustworthy transformer. Our computerized design system,

including 3D analysis (Electric field, magnetic field and mechanical analysis) reinforces not only the insulation

system but also the dielectric strength. With Hyosungs advanced design program, the actual finish product

can be reviewed in advance. Dedicated and customer-centered engineers always provide defect-free and

optimized products to customers.

02

03

04

01 Windings

Windings are composed of two parts, namely, a conductor and insulation material. For the conductor,

Hyosung uses high grade electrolytic copper or aluminium. Hyosung Oil Immersed Transformers obtain high

thermal capacity with the use of Epoxy coated Insuldur Kraft Paper, which has higher short time overload

capacity than any other Kraft paper type.

02 Core

Core design is essential because it determines the transformers efficiency and noise level. For high

dimensional accuracy, the core cutting processing of Hyosung is controlled by a computerized system. By

Step-Lap core stacking, Hyosung Oil Immersed Transformers attain to optimal characteristics for each customer.

03 Winding Support System

Coils are sized and clamped by being pressed with a special hydraulic fixture after assembly with the core.

With Axial and Radial direction, we reinforce the winding support system. This secure structure helps

withstand harsh short circuit forces.

Magnetic Field Analysis

Mechanical Analysis

Dielectric Analysis

04 Radiator

The transformer will be furnished with panel or corrugated radiators assuring that the temperature rise of the

windings or oil will not exceed their specified limit when the transformer continuously operates at the rated

full load.

08 09

Oil Immersed Transformers

Products and Details

Hyosung Oil Immersed Transformers,

Your Reliable Energy Partner

Product Arrangement

Ratings

- Single or 3 - Phase Unit

- Rated Frequency : 50Hz or 60Hz

- Thermal Insulation Class : A

- Winding Conductor : Copper or Aluminum

- kVA Range : From 100kVA up tp 60MVA

- High Voltage : 3.3kV - 66kV

(with taps, N.L.T.C. or O.L.T.C.)

- Low Voltage : 600V below

- Production Capacity : 12,000MVA/year

Petrochemical and chemical plants are processing industries, and operate continuously 24/7.

If one facility stops, everything else must be gradually stopped.

Moreover once this happens, petrochemical and chemical raw materials become solid and transmute, it

should be burned and purified before the facilities start to operate again,

so the damage is huge.

By thinking from the customers point of view, Hyosung ensures the

Stability of transformers. We have been actively engaged in largescale petrochemical and chemical projects around the

world.

Main Service Areas

- Naphtha Cracking Complexes

- Aromatics Complexes

- Fertilizer & Pesticide Complexes

- Chemical Plants

- Fine Chemical Plants

Temperature Rise : 55C, 55/65C, 65C(Optional :

special temp. Rise)

Basic Insulation Level : 30kV BIL through 350kV BIL

Options and Accessories

- Oil temperature indicator

- Winding temperature indicator

- Oil level indicator

- Buchholz relay

- Pressure relief device

- Sudden pressure relay

- Thermometer pocket

- Skid base or bi-directional rollers

- Cooling fan and fan control panel

- Various oil preservation system

Other accessories are available upon request

Transformer for Special Applications

Hyosung Offers

- For Rectifiers

- For Harmonic Distortion

- For Arc Furnaces

- For Variable Speed Drives

- For Reactors

- For Inverter and Converters

- Earthing Transformers

- Excitation Transformers

- High Efficiency Transformers

- Maintenance and Site testing

- Site assembling and Installation

- Commissioning

- Training

- Spare parts procurement

- Technical solutions

- Retrofit and Upgrading

Hyosung provides customized solution for

individual customers needs

For Petrochemical & Chemical Plants

10 11

Oil Immersed Transformers

Products and Details

For Oil & Gas Plants

For Power Plants & Substations

Different from the past, most oil and gas plants accept electric furnaces for the production process. These

types of facilities uses an immense amount of electricity. Because good quality of electricity is directly

related to good quality of oil and gas, Stability and Lasting Quality are key factors for transformers.

Hyosung has supplied high and secure stability transformers for field of oil and gas facilities, such as oil

production, refinery and gas processing facilities.

Electricity is vital for most everyday activities. Power plants connect to a huge network of people, electric

lines, and generating equipment. Because of this network, transformers in power plants and substations are

very important.

Power plants need to generate high quality power, and very stable loads, so the top element of a transformer

is Efficiency. With Hyosung transformers top-class efficiency, Hyosung has supplied the product to various

power plants, such as nuclear and thermal power plants and substations. With extensive experience

records and accumulated experience, Hyosung offers high quality transformers to the power sectors.

Main Service Areas

- Oil and Gas Production Facilities

- Oil Refinery Facilities

- HOU (Heavy Oil Upgrading) Facilities

- FCC (Fluidized Catalytic Cracking) Facilities

- Gas Processing Facilities

- LNG Facilities

Main Service Areas

- Combined Cycle Power Plants

- Thermal Power Plants

- Cogeneration Power Plants

- Diesel Engine Power Plants

- Geothermal Power Plants

- Hydro, Pumped Storage Power Plants

- Wind Power Plants

- Transmission, Substation & Distribution

- Nuclear Facilities

12 13

Oil Immersed Transformers

Products and Details

For Industrial Plants

For Environmental Plants

If a semi-conductor factory stops for even a few seconds, the damage is enormous because it needs long

time to adjust the optimal manufacturing condition. The secure electric supply is directly connected with

customers benefits in the industrial plant. Hyosung understands the importance of the transformer for

industrial plants, we provide Individual Solutions for satisfying various kinds of requirements : types of operation,

high efficiency, resistance against harmonic distortion, maintenance, installation and so on.

In environmental plants, such as seawater desalination facilities and wastewater treatment facilities, the main

equipment is a pump. Loads of such equipment are very unsteady, and undergo dramatical changes.

Hyosung transformers are designed for environmental plants with Mechanical Strength to bear short-time

overload.

Main Service Areas

- Seawater Desalination Facilities

- Flue Gas Desulphurization / Denitrification

- Wastewater Treatment Facilities

- Solid Waste Management Facilities

- Semiconductor & LCD related Plants

- Steel Mills & Metal Plants

- Automobile Plants

- Cement Plants

- Pulp / Paper Mills

- Material Recycling Plants

Main Service Areas

14 15

Oil Immersed Transformers

Total Quality Assurance

At Hyosung, our goal is not only to meet the needs of

our customers today but also to provide them better

life in the future.

Hyosungs total quality commitment to our customers is demonstrated by providing the highest quality

product at the most competitive prices with on time delivery. We achieve these high quality levels through

our integrated quality assurance program. Our products are used extensively both at home and abroad.

This level of experience allows Hyosungs quality assurance and reliability to exceed those of our

competitors. We share our customers goals with high quality products. From design to assembly, testing

and installation, our customers requirements are our minimum standards.

All tests are based on International standards and our customers requirements. Through additional testing,

Hyosung seeks to exceed established testing criteria, thereby producing more reliable products.

Our special process operators and technicians are highly trained. Continued professional growth and

advanced training is encouraged through internal training groups and outside courses.

All our products have ISO 9001 and ISO 14001 certifications.

At Hyosung, we endeavor to maintain the highest quality.

Product Development History

Year

Milestones

2009

High Efficiency Certificate for Oil-Immersed Transformers

Year

Milestones

1995

Development of PAD Transformers for KEPCO

Development of Low Loss Pole Transformers for KEPCO

2007

Development of Eco-Friendly Transformers

Short-Circuit Test for 45MVA and 2.5MVA

Oil-Immersed Transformers

1993

Development of Self-Diagnostic Pole Transformers

for KEPCO

2004

Development of Low Loss Oil-Immersed Transformers

for Export to Japan

1990

Development of Amorphous Core Type Pole Transformers

1984

Earthquake-proof Test for 630kVA Mold Transformers

1998

Development of 170kV Gas V/ T for GIS

1981

Development of C.S.P Pole Transformers

1997

Supply of 30MVA Shunt Reactors for KEPCO

1962

Production of Oil Immersed Transformers

and Pole Transformers

Scope

In line with major international standards for quality assurance, the quality assurance program of our plants

includes the following elements.

- Contract review

- Inspection/test control

- Design control

- Measuring and test equipment

- Procurement document control

- Storage, handling and shipping

- Purchased materia

- Nonconforming item

- Identification

- Quality assurance records

- Special Process

Global Network

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Implementation of Brigada EskwelaDocument9 paginiImplementation of Brigada EskwelaJerel John Calanao90% (10)

- Relativity of ContractsDocument7 paginiRelativity of ContractsCristy C. Bangayan100% (1)

- Descartes and The JesuitsDocument5 paginiDescartes and The JesuitsJuan Pablo Roldán0% (3)

- Methodology For Rating General Trading and Investment CompaniesDocument23 paginiMethodology For Rating General Trading and Investment CompaniesAhmad So MadÎncă nu există evaluări

- Computer Engineering Project TopicsDocument5 paginiComputer Engineering Project Topicskelvin carterÎncă nu există evaluări

- Cdg11 16Document10 paginiCdg11 16keith_homeÎncă nu există evaluări

- Electrical SafetyDocument43 paginiElectrical Safetythibin100% (1)

- Bus Bar Voltage Drop Calculation: Bus Bar No SR - No Location Sub Panel No Power Line Length (MT) Line Current (Amp)Document6 paginiBus Bar Voltage Drop Calculation: Bus Bar No SR - No Location Sub Panel No Power Line Length (MT) Line Current (Amp)thibinÎncă nu există evaluări

- Schneider Meher Power Capacitors Catalouge PDFDocument40 paginiSchneider Meher Power Capacitors Catalouge PDFthibin100% (1)

- Detuned ReactorsDocument3 paginiDetuned ReactorsthibinÎncă nu există evaluări

- Gas Insulated SubstationDocument84 paginiGas Insulated SubstationRajmohan96% (23)

- Substation Tender DocumentDocument97 paginiSubstation Tender DocumentthibinÎncă nu există evaluări

- Technical Specifications of SubstationDocument3 paginiTechnical Specifications of SubstationthibinÎncă nu există evaluări

- Code of Practice For Earthing - Railway SpecDocument16 paginiCode of Practice For Earthing - Railway Specsuresh kumarÎncă nu există evaluări

- Testing and Commissioning On TransformerDocument3 paginiTesting and Commissioning On TransformerthibinÎncă nu există evaluări

- CPD/VRF PresentationDocument23 paginiCPD/VRF PresentationthibinÎncă nu există evaluări

- 220V DCDBDocument4 pagini220V DCDBthibinÎncă nu există evaluări

- Aerodrome OperationDocument36 paginiAerodrome Operationthibin100% (1)

- Doksun Make Earthing and Lightning Protection SystemDocument9 paginiDoksun Make Earthing and Lightning Protection SystemthibinÎncă nu există evaluări

- Detection of Earth Fault in LT SystemDocument4 paginiDetection of Earth Fault in LT SystemthibinÎncă nu există evaluări

- Aerodrome Lighting and SignsDocument53 paginiAerodrome Lighting and SignsthibinÎncă nu există evaluări

- People Vs MaganaDocument3 paginiPeople Vs MaganacheÎncă nu există evaluări

- Assignment LA 2 M6Document9 paginiAssignment LA 2 M6Desi ReskiÎncă nu există evaluări

- Warhammer Armies: The Army of The NorseDocument39 paginiWarhammer Armies: The Army of The NorseAndy Kirkwood100% (2)

- ConsignmentDocument2 paginiConsignmentKanniha SuryavanshiÎncă nu există evaluări

- ICargo Mobility QantasDocument4 paginiICargo Mobility QantasViswateja KrottapalliÎncă nu există evaluări

- Actividad N°11 Ingles 4° Ii Bim.Document4 paginiActividad N°11 Ingles 4° Ii Bim.jamesÎncă nu există evaluări

- Be It Enacted by The Senate and House of Representatives of The Philippines in Congress AssembledDocument7 paginiBe It Enacted by The Senate and House of Representatives of The Philippines in Congress AssembledYanna ManuelÎncă nu există evaluări

- Role and Responsibilities of Forensic Specialists in Investigating The Missing PersonDocument5 paginiRole and Responsibilities of Forensic Specialists in Investigating The Missing PersonMOHIT MUKULÎncă nu există evaluări

- Southwest CaseDocument13 paginiSouthwest CaseBhuvnesh PrakashÎncă nu există evaluări

- Proposed Food Truck LawDocument4 paginiProposed Food Truck LawAlan BedenkoÎncă nu există evaluări

- About Debenhams Company - Google SearchDocument1 paginăAbout Debenhams Company - Google SearchPratyush AnuragÎncă nu există evaluări

- Memorandum of Inderstanding Ups and GoldcoastDocument3 paginiMemorandum of Inderstanding Ups and Goldcoastred_21Încă nu există evaluări

- Design and Pricing of Deposit ServicesDocument37 paginiDesign and Pricing of Deposit ServicesThe Cultural CommitteeÎncă nu există evaluări

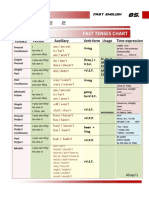

- Table 2: Fast Tenses ChartDocument5 paginiTable 2: Fast Tenses ChartAngel Julian HernandezÎncă nu există evaluări

- BPV Installation Inspection Request Form With Payment AuthorizationDocument2 paginiBPV Installation Inspection Request Form With Payment AuthorizationBoriche DivitisÎncă nu există evaluări

- Solar - Bhanu Solar - Company ProfileDocument9 paginiSolar - Bhanu Solar - Company ProfileRaja Gopal Rao VishnudasÎncă nu există evaluări

- Aradau Security Materiality SDDocument22 paginiAradau Security Materiality SDTalleres NómadaÎncă nu există evaluări

- Module 2 2023Document14 paginiModule 2 2023ubpi eswlÎncă nu există evaluări

- MODULE 7 - Voting SystemDocument19 paginiMODULE 7 - Voting SystemHanz PeñamanteÎncă nu există evaluări

- RA-070602 - REGISTERED MASTER ELECTRICIAN - Manila - 9-2021Document201 paginiRA-070602 - REGISTERED MASTER ELECTRICIAN - Manila - 9-2021jillyyumÎncă nu există evaluări

- Union Africana - 2020 - 31829-Doc-Au - Handbook - 2020 - English - WebDocument262 paginiUnion Africana - 2020 - 31829-Doc-Au - Handbook - 2020 - English - WebCain Contreras ValdesÎncă nu există evaluări

- Hassan I SabbahDocument9 paginiHassan I SabbahfawzarÎncă nu există evaluări

- Climate Change and Mitigation Programs in Davao CityDocument64 paginiClimate Change and Mitigation Programs in Davao CityChona BurgosÎncă nu există evaluări

- Year 1 Homework ToysDocument7 paginiYear 1 Homework Toyscyqczyzod100% (1)

- Utilitarianism Bentham: PPT 6 Hedonic Act UtilitarianismDocument9 paginiUtilitarianism Bentham: PPT 6 Hedonic Act UtilitarianismPepedÎncă nu există evaluări