Documente Academic

Documente Profesional

Documente Cultură

Inyector Bomba MB900 PDF

Încărcat de

Pamela FieldsDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Inyector Bomba MB900 PDF

Încărcat de

Pamela FieldsDrepturi de autor:

Formate disponibile

Power Service Literature

Pgina 1 de 6

Section 2.1

Injector Unit Pump

All MBE 900 engines are water-cooled, four-stroke, direct-injection diesel engines. The cylinders are

arranged in line on both the 6-cylinder and 4-cylinder models. Each has a separate fuel injection pump

(unit pump) with a short injection line to the injection nozzle, which is located in the center of the

combustion chamber. The unit pumps are attached to the engine block and are driven from the camshaft.

Each cylinder has two intake valves and one exhaust valve.

Section 2.1.1

Injector Unit Pump Removal

Remove injector unit pump as follows:

1. Remove the engine trim panel. See Figure "Engine Trim Panel Removal" .

1. Engine Trim Panel

2. Injection Lines

Figure 1. Engine Trim Panel Removal

2. Remove the end cover from the lower right side of the flywheel housing, then attach the engine

barring tool J 46392.

3. Remove the fuel injection line. Refer to "2.2.1 Removal Of High Pressure Fuel Lines And

Transfer Tubes" .

4. Disconnect the engine wiring harness from each injector unit pump to be removed. See Figure

"Injector Unit Pump Removal/Installation" .

https://extranet-ddc.freightliner.com/power_service/literature/Content/09/090301.xml

04/01/2014

Power Service Literature

Pgina 2 de 6

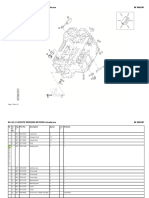

1. Injector Unit Pump

5. Mounting Bolt

2. Black O-ring (large O-ring on shaft)

6. Injection Line

3. Green O-ring (small O-ring on shaft)

7. Engine Wiring Harness

4. O-ring (on head)

Figure 2. Injector Unit Pump Removal/Installation

PERSONAL INJURY

To avoid injury from an ejected injector unit pump, do not completely loosen the mounting

bolts until you have tested the spring tension. If the spring tension is at maximum and you

remove the mounting cap screws, the pump will be ejected from the engine crankcase.

5. Carefully loosen the injector unit pump mounting bolts.

6. Check the spring tension on the injector unit pump by pushing down on it. If you cannot push

down on the injector pump manually, the spring tension is at the maximum. You must decrease

the spring tension on the injector pump before removing it.

7. If the spring tension on the injector pump is at the maximum, go to the next step to reduce it;

https://extranet-ddc.freightliner.com/power_service/literature/Content/09/090301.xml

04/01/2014

Power Service Literature

Pgina 3 de 6

otherwise, go to step 9 for removing the mounting bolts.

8. Using the barring tool, rotate the crankshaft until the spring tension decreases enough to push the

injector pump down manually.

9. Remove the mounting bolts from the injector unit pump.

10. Using the barring tool, rotate the crankshaft until the camshaft lifts the injector unit pump. See

Figure "Injector Unit Pump Removal" .

1. Injector Unit Pump

3. Camshaft

2. Mounting Bolts

4. Fuel Line Connection

Figure 3. Injector Unit Pump Removal

NOTICE:

If the injector unit pump doesn't come out easily, do not try to pry it out. This will damage it. Use the

special impact extractor to remove it.

11. If the injector unit pump doesn't come out easily, use the injector/unit pump puller J 46375 to

remove it.

a. Thread the impact extractor onto the top of the injector unit pump, where the injection line

was installed.

b. Pull the injector unit pump out by using the slide hammer on the impact extractor. Do not

use excessive force that could damage the threads on the injector unit pump fuel line

connection.

12. Check the injector unit pump for wear or damage. If any is found, replace the entire component.

The injector unit pump is not serviceable, except for the O-rings.

Note: Replace all three O-rings.

13. Remove and discard all three O-rings: two on the injector unit pump shaft, and one on the injector

pump head. See Figure "Injector Unit Pump Removal/Installation" .

14. Repeat this procedure for each injector unit pump that needs to be removed.

Section 2.1.2

https://extranet-ddc.freightliner.com/power_service/literature/Content/09/090301.xml

04/01/2014

Power Service Literature

Pgina 4 de 6

Injector Unit Pump Installation

Install the injector unit pump as follows:

1.

2.

3.

4.

Install a new pump head O-ring on the injector unit pump head, as removed.

Lubricate the injector unit pump bore in the cylinder block with grease.

Lubricate the new pump shaft O-rings with grease.

Install the black O-ring on the injector unit pump shaft. See Figure "Black O-ring Installation" .

1. Black O-ring

3. Head of Injector Unit Pump

2. Seat for Black O-ring

Figure 4. Black O-ring Installation

a. Insert the O-Ring installer J 46382 over the injector pump shaft, leaving only the first

groove in the shaft exposed.

b. Slide the black O-ring (it is the larger of the two) over the installer and onto the first groove

in the injector pump shaft.

5. Install the green O-ring on the injector unit pump shaft. See Figure "Green O-ring Installation " .

https://extranet-ddc.freightliner.com/power_service/literature/Content/09/090301.xml

04/01/2014

Power Service Literature

Pgina 5 de 6

1. Green O-ring

3. Black O-ring (installed)

2. Seat for Green O-ring

4. Head of Injector Unit Pump

Figure 5. Green O-ring Installation

6.

7.

8.

9.

10.

11.

12.

13.

a. Back the O-ring installer out over the injector pump shaft, leaving the second groove in the

shaft exposed.

b. Slide the green O-ring (it is the smaller of the two) over the installer and onto the second

groove in the injector pump shaft.

Insert the injector unit pump into the mounting hole on the crankcase. Use the bolt mounting holes

on the engine as a guide for positioning the injector pump. Push the injector pump in by hand. If it

won't go in easily, rotate the crankshaft until the pump goes in easily.

Install the mounting bolts, and tighten 65 Nm (48 lbft).

Connect the fuel injection line. Refer to "2.2.2 Installation of High Pressure Fuel Line" .

Repeat this procedure for each injector unit pump, as removed.

Connect the engine wiring harness to each injector unit pump.

Prime the fuel system.

Start the engine and check for leaks. Tighten connections as needed.

Install the engine trim panel. See Figure "Engine Trim Panel Installation" .

https://extranet-ddc.freightliner.com/power_service/literature/Content/09/090301.xml

04/01/2014

Power Service Literature

Pgina 6 de 6

1. Engine Trim Panel

2. Injection Lines

Figure 6. Engine Trim Panel Installation

EPA04 MBE 900 Workshop Manual (DDC-SVC-MAN0024)

Printed Sat Jan 04 22:20:22 2014

Copyright 2015 by Detroit Diesel Corporation. All rights reserved.

Generated on 05-04-2015

https://extranet-ddc.freightliner.com/power_service/literature/Content/09/090301.xml

04/01/2014

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 604 I.c.engine (Me-604) Exp. ManualDocument35 pagini604 I.c.engine (Me-604) Exp. Manualnavaneet gupta100% (1)

- MGB Competition Preparation ManualDocument39 paginiMGB Competition Preparation ManualYarg NitramÎncă nu există evaluări

- Engine Performance and ModelingDocument20 paginiEngine Performance and ModelingsathishskymechÎncă nu există evaluări

- SHPbrochure (Rev-01,2014 2 16)Document8 paginiSHPbrochure (Rev-01,2014 2 16)Epure GabrielÎncă nu există evaluări

- Parts Manuals: Enter Your Location HereDocument4 paginiParts Manuals: Enter Your Location HereIván Meza Bastidas100% (2)

- Oil w4015 PDFDocument4 paginiOil w4015 PDFarman chowdhuryÎncă nu există evaluări

- MAN B&W B1-Operating InstructionsDocument296 paginiMAN B&W B1-Operating InstructionsJACK Backs100% (2)

- MTU 20V4000 DS4000: Diesel Generator SetDocument6 paginiMTU 20V4000 DS4000: Diesel Generator SetMarioyfernanda Guerra Murua100% (1)

- PSR Jet SystemDocument9 paginiPSR Jet SystemMiroslav JebavýÎncă nu există evaluări

- A Performance Combustion and Emission STDocument6 paginiA Performance Combustion and Emission STJogoje AjitÎncă nu există evaluări

- 811.01 11229979 99999999 05702516 CrankcaseDocument24 pagini811.01 11229979 99999999 05702516 Crankcaseeshopmanual EnamÎncă nu există evaluări

- Cummins N855 BigCam Torque ValueDocument4 paginiCummins N855 BigCam Torque ValueCésar Pérez92% (12)

- Car Engine Parts: Cylinder Block of Four Cylinder Engine (Image 01)Document10 paginiCar Engine Parts: Cylinder Block of Four Cylinder Engine (Image 01)Ibrahima DioufÎncă nu există evaluări

- Design and Fabrication of Multi Process Machine Using Scotsh Yoke Mechanism IJERTCONV7IS06031Document2 paginiDesign and Fabrication of Multi Process Machine Using Scotsh Yoke Mechanism IJERTCONV7IS06031Sushant GhurupÎncă nu există evaluări

- EEE 2306 Supp FinalDocument2 paginiEEE 2306 Supp FinalBen KomenÎncă nu există evaluări

- 2 Maintenance BDocument324 pagini2 Maintenance BPranav Shekhar100% (1)

- Demo SM Cat 924H & 924HZ (Ped00001-Up)Document15 paginiDemo SM Cat 924H & 924HZ (Ped00001-Up)Em sulistio80% (5)

- Diesel Generator Set C600D6: 750 kVA Standby - 60HzDocument4 paginiDiesel Generator Set C600D6: 750 kVA Standby - 60HzIgorÎncă nu există evaluări

- L+V32/44CR: Four-Stroke Diesel EngineDocument12 paginiL+V32/44CR: Four-Stroke Diesel Engineoctober monthÎncă nu există evaluări

- Overview CPMADocument18 paginiOverview CPMAaritmeticsÎncă nu există evaluări

- Engine Control (1zz-Fe, 1zz-Fbe, 3zz-Fe)Document15 paginiEngine Control (1zz-Fe, 1zz-Fbe, 3zz-Fe)Mas YadÎncă nu există evaluări

- Ingersoll Rand Compressor - 2545 Engineering DataDocument4 paginiIngersoll Rand Compressor - 2545 Engineering DataJÎncă nu există evaluări

- common rail xe tải PDFDocument12 paginicommon rail xe tải PDFANH LÊÎncă nu există evaluări

- Does A Chevrolet Spark Have A Timing Belt or Timing ChainDocument11 paginiDoes A Chevrolet Spark Have A Timing Belt or Timing ChainUltraJohn95Încă nu există evaluări

- Mobil Delvac MX 15W40 Data SheetDocument4 paginiMobil Delvac MX 15W40 Data SheetJuan EstebanÎncă nu există evaluări

- America Engine Parts Catalogo 2015Document12 paginiAmerica Engine Parts Catalogo 2015Tele FantasmaÎncă nu există evaluări

- Midi Service Manual-091231 PDFDocument203 paginiMidi Service Manual-091231 PDFDario Luis Flores CollasÎncă nu există evaluări

- Hard Question For InstrumentDocument3 paginiHard Question For InstrumentumeshÎncă nu există evaluări

- Caterpillar C18 ACERTDocument2 paginiCaterpillar C18 ACERTMauricio Gomes de Barros60% (5)

- Cds13041 Yamaha PWC Plug-In EcuDocument1 paginăCds13041 Yamaha PWC Plug-In EcuGérôme ZélateurÎncă nu există evaluări