Documente Academic

Documente Profesional

Documente Cultură

Top Tips For Passing ST

Încărcat de

tuna61Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Top Tips For Passing ST

Încărcat de

tuna61Drepturi de autor:

Formate disponibile

Tips for Passing Structural Welding Test

Heres a list of 9 top tips that will help you pass your 3G Structural Welding Test (using a 7018 rod)

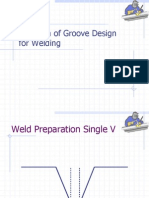

1. Most structural welding tests require a 22.5 degree bevel (also known as a 45 degree including angle)

on the two plates you will be joining together, with a 1/4 inch gap between the two pieces, and 1/4 inch

backing plate. 1/4 inch gap is pretty wide, but this is so youre able to lay the 1/8 inch rod into the bevel

section between the two pieces. You need to make sure your gap is wide

enough to avoid excessive burn into the side walls of the bevel, or down into the backing plate.

2. Use a grinder to remove the mill scale from the welding area of subject materials, grinding down to

clean shiny metal on both sides of weld bevels and the backing plate. This is not technically a test

requirement, but a good idea because its the ideal field practice, and evaluators are looking for that kind

of behavior and attention to detail.

3. Plan ahead for placing your tie-ins. You dont want to put your tie-ins on your root bend. Ideally, you

want to place them just a touch off-center.

4. The angle and height of the plate when youre welding is important. Make sure you dont put the plate

up to high relative to your physical height, it just makes the process that much harder. Evaluators expect

you to position the test plate straight up-and-down, but you can usually get away with up to a 5 degrees

angle. You dont, however, want to angle the plate toward you (thats almost like welding overhead), but

you should be able to get away with angling the plate about 5 degrees away from you, which will make

the rising angle a touch easier to handle as your weld travels upward.

5. Body position is important, because the more confortable you feel, the easier the process. The

consumable rod will become shorter as you weld, and you need to be comfortable with the body motion

necessary to adapt to this shrinking action. Its best to use something to prop up the rod as you weld. If

dont have any suitable object handy, you can prop up the rod with your finger as your weld travels

upward. Take a few dry runs to make sure youre comfortable with the movements necessary to execute

the weld.

6. Expose the tip of your 7018 rod, especially if youre going to restart a rod thats already been used.

7018 rods dont restart well, as they tend to form a slag cover over the end of the rod. With a file, you can

remove the slag coating and create a better starting surface.

7. You want your root pass makes contact with each side of the beveled edge, to ensure the weld

adequately penetrates the side walls and backing plate, and creates solid weld.

8. When you clean the weld with a file or slag hammer, you dont want to peck at the weld bead, because

youll end up with divots, dents and dings. Instead, use the file and slag hammer to rake down each side

the of the weld bead to clean up the weld and remove slag.

9. If allowed (you may not be), use a grinder to clean up the weld bead, especially at start points and tieins.

S-ar putea să vă placă și

- Family Handyman Ultimate Weekend ImprovementsDe la EverandFamily Handyman Ultimate Weekend ImprovementsÎncă nu există evaluări

- Ez Engine Build InstructionsDocument24 paginiEz Engine Build InstructionsAnonymous T7zEN6iLHÎncă nu există evaluări

- 4 Handy Table Saw JigsDocument11 pagini4 Handy Table Saw Jigsmargalaz100% (1)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsDe la EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsEvaluare: 5 din 5 stele5/5 (1)

- Family Handyman Ultimate 1 Day ProjectsDe la EverandFamily Handyman Ultimate 1 Day ProjectsEvaluare: 5 din 5 stele5/5 (1)

- Basic Cornhole Instructions PDFDocument8 paginiBasic Cornhole Instructions PDFpappy1865Încă nu există evaluări

- Chainmail Made Easy: Learn to Chainmail in 24 Hours or Less!: Chainmail Made EasyDe la EverandChainmail Made Easy: Learn to Chainmail in 24 Hours or Less!: Chainmail Made EasyEvaluare: 5 din 5 stele5/5 (4)

- A Rotary Sine Bar For The LatheDocument2 paginiA Rotary Sine Bar For The LatheTheodor EikeÎncă nu există evaluări

- Saw HandleDocument7 paginiSaw Handleانغي رحمنيÎncă nu există evaluări

- Building Firearms - HoffmanDocument81 paginiBuilding Firearms - HoffmanWilliam Owers100% (3)

- AR 15 80 Tutorial Drill PressDocument11 paginiAR 15 80 Tutorial Drill PressBrian Bauman100% (2)

- AK-47 Souptonuts 5Document7 paginiAK-47 Souptonuts 5tshirley47100% (3)

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderDe la EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderEvaluare: 5 din 5 stele5/5 (2)

- BHManual Fuselage46 79rev1Document34 paginiBHManual Fuselage46 79rev1viorelu99Încă nu există evaluări

- Arup Scheme Design GuideDocument139 paginiArup Scheme Design GuideDean TyrrellÎncă nu există evaluări

- Slim Ballpoint Pen Hardware Kit: Preparing The Material BlanksDocument4 paginiSlim Ballpoint Pen Hardware Kit: Preparing The Material BlanksLachaud YvonÎncă nu există evaluări

- Dovetail Guide User ManualDocument9 paginiDovetail Guide User ManualAnonymous 9zL9MblM3HÎncă nu există evaluări

- Bladesmithing: Bladesmithing for Beginners: Make Your First Knife in 7 StepsDe la EverandBladesmithing: Bladesmithing for Beginners: Make Your First Knife in 7 StepsEvaluare: 5 din 5 stele5/5 (1)

- Tail-Vise InstructionsDocument22 paginiTail-Vise InstructionsIulian MihaiÎncă nu există evaluări

- Sharpening Drill BitsDocument12 paginiSharpening Drill Bitsaabb_1my3724100% (2)

- Chainmail Made Easy: 8 Wicked Weaves with 8 Practical Projects: Chainmail Made Easy, #2De la EverandChainmail Made Easy: 8 Wicked Weaves with 8 Practical Projects: Chainmail Made Easy, #2Evaluare: 4.5 din 5 stele4.5/5 (11)

- Bowl Basics 1Document5 paginiBowl Basics 1api-522254901Încă nu există evaluări

- Basic Fly Tying: All the Skills and Tools You Need to Get StartedDe la EverandBasic Fly Tying: All the Skills and Tools You Need to Get StartedEvaluare: 3 din 5 stele3/5 (3)

- Dead Drop DeviceDocument7 paginiDead Drop DeviceAgino MottoÎncă nu există evaluări

- Envisionlabs Wood ClocksDocument22 paginiEnvisionlabs Wood ClocksAlfonso100% (1)

- Testing Lathe For AccuracyDocument4 paginiTesting Lathe For AccuracyArnieT100% (1)

- Welding SymbolsDocument21 paginiWelding Symbolstuna61Încă nu există evaluări

- Low-Angle and Standard Block PlanesDocument8 paginiLow-Angle and Standard Block Planesrao1307100% (1)

- DIY Bolt GuideDocument48 paginiDIY Bolt Guidelmkkilo3Încă nu există evaluări

- Angle Grinder Tube Pipe Sander Polishing AttachmenDocument14 paginiAngle Grinder Tube Pipe Sander Polishing AttachmenEdmar DL100% (1)

- Kohler 14 20 RES Parts Manual TP 6806 2016 06Document76 paginiKohler 14 20 RES Parts Manual TP 6806 2016 06peleniusÎncă nu există evaluări

- DIY Fidget Spinners How to Make Fidget Spinner ButtonsDe la EverandDIY Fidget Spinners How to Make Fidget Spinner ButtonsÎncă nu există evaluări

- AK Builder Rivet Tool InstructionsDocument4 paginiAK Builder Rivet Tool InstructionsDale WadeÎncă nu există evaluări

- Navsea S9074 - 278 Part1Document80 paginiNavsea S9074 - 278 Part1tuna61Încă nu există evaluări

- Benchcrafted Moxon ViseDocument12 paginiBenchcrafted Moxon VisexlotoxÎncă nu există evaluări

- ASHRAE Fundamentals 2005 - SI Units - Extract of Tables PDFDocument40 paginiASHRAE Fundamentals 2005 - SI Units - Extract of Tables PDFSufian SarwarÎncă nu există evaluări

- MD Profiler Instruction ManualDocument11 paginiMD Profiler Instruction ManualTatiana Trenogina100% (1)

- ALC 10029C AlcoTec Technical GuideDocument20 paginiALC 10029C AlcoTec Technical Guidetuna61Încă nu există evaluări

- Advance Concrete PDFDocument33 paginiAdvance Concrete PDFUdom RithÎncă nu există evaluări

- Ascent Plan ManualDocument48 paginiAscent Plan Manualkaka_0246878% (9)

- Threading Operations of Lathe SystemDocument37 paginiThreading Operations of Lathe SystemResshille Ann T. SalleyÎncă nu există evaluări

- Figure #2: The Parts For The Drilling Jig After Cutting To SizeDocument7 paginiFigure #2: The Parts For The Drilling Jig After Cutting To SizejacquesmayolÎncă nu există evaluări

- WC5 Parts Fabrication: Author: J. RandleDocument48 paginiWC5 Parts Fabrication: Author: J. RandleCristian Silva100% (1)

- Pivot Replacement: ChecklistDocument7 paginiPivot Replacement: Checklistottershaw57Încă nu există evaluări

- AÇO - DIN17100 St52-3Document1 paginăAÇO - DIN17100 St52-3Paulo Henrique NascimentoÎncă nu există evaluări

- Tips-For-D1 - 1 TestingDocument1 paginăTips-For-D1 - 1 TestingCharlie MillerÎncă nu există evaluări

- Mashop Theory and PracticeDocument38 paginiMashop Theory and PracticeCel Caren MakidatoÎncă nu există evaluări

- Workshop Hints Pivot Replacement: ChecklistDocument8 paginiWorkshop Hints Pivot Replacement: Checklistottershaw57Încă nu există evaluări

- Haide EeeeeeDocument32 paginiHaide Eeeeeeusmaniqbal15Încă nu există evaluări

- Tipt Grp3 Metal Turning and SolderingDocument41 paginiTipt Grp3 Metal Turning and Solderingメルヴリッ クズルエタÎncă nu există evaluări

- BandsawDocument11 paginiBandsawTrung Quoc LeÎncă nu există evaluări

- Riveting Basics: Rivet Gun and Flaring RivetsDocument17 paginiRiveting Basics: Rivet Gun and Flaring RivetsTanu RdÎncă nu există evaluări

- Drilling of A Work Piece Held in A ViseDocument8 paginiDrilling of A Work Piece Held in A ViseFaisal RafiqueÎncă nu există evaluări

- Comon Hand ToolsDocument15 paginiComon Hand Toolsचौकीदार गोपाल भार्गवÎncă nu există evaluări

- 4 Foot PVC Propeller: (Including New Blade Revisions)Document14 pagini4 Foot PVC Propeller: (Including New Blade Revisions)eu1mister6002Încă nu există evaluări

- RodSmith Build-It! KitsDocument1 paginăRodSmith Build-It! KitsCamil BwoyÎncă nu există evaluări

- Construction of A Longworth ChuckDocument10 paginiConstruction of A Longworth ChuckshopsmithmodÎncă nu există evaluări

- Guia VeritasDocument10 paginiGuia VeritasNatalia DiazÎncă nu există evaluări

- BandsawDocument11 paginiBandsawVincent jaramillaÎncă nu există evaluări

- Bending ShapesDocument4 paginiBending ShapesramjoceÎncă nu există evaluări

- AssemblyDocument5 paginiAssemblyAdrian MacayaÎncă nu există evaluări

- Lesson 2 - Maintenance of ToolsDocument27 paginiLesson 2 - Maintenance of ToolsMallory Alva CastanedaÎncă nu există evaluări

- General DrillingDocument3 paginiGeneral DrillingAndrew GoslingÎncă nu există evaluări

- LatheDocument1 paginăLatheMohit SinghÎncă nu există evaluări

- Appendix ADocument4 paginiAppendix AAnonymous SAuK4CÎncă nu există evaluări

- How To CutDocument23 paginiHow To CutAnxi NurhudaÎncă nu există evaluări

- Pushstick Template PDFDocument2 paginiPushstick Template PDFtuna61Încă nu există evaluări

- Using Welding Inspection ToolsDocument9 paginiUsing Welding Inspection Toolstuna61Încă nu există evaluări

- Nuance Power PDF Trial: Corner CupboardDocument26 paginiNuance Power PDF Trial: Corner Cupboardtuna61Încă nu există evaluări

- Hastelloy C-2000 Welding Data: General InformationDocument1 paginăHastelloy C-2000 Welding Data: General Informationtuna61Încă nu există evaluări

- GMAW Transfer ModesDocument3 paginiGMAW Transfer Modestuna61Încă nu există evaluări

- Welding Symbols: Understanding Welding Symbols Terms and Definitions by Mohammed Haroon JaveedDocument21 paginiWelding Symbols: Understanding Welding Symbols Terms and Definitions by Mohammed Haroon Javeedtuna61Încă nu există evaluări

- User Inputs Cost Outputs: Fillet Weld Cost Analysis ToolDocument2 paginiUser Inputs Cost Outputs: Fillet Weld Cost Analysis Tooltuna61Încă nu există evaluări

- Test PlateDocument1 paginăTest Platetuna61Încă nu există evaluări

- Variation of Groove Design For WeldingDocument10 paginiVariation of Groove Design For Weldingtuna61Încă nu există evaluări

- Export Dataset To PDF in ASP NetDocument2 paginiExport Dataset To PDF in ASP NetWilliamÎncă nu există evaluări

- Flabeg Solar enDocument11 paginiFlabeg Solar enZeec NoorÎncă nu există evaluări

- Da10 Air Cooled Engine (Appn Code D3.2007 & D3Document26 paginiDa10 Air Cooled Engine (Appn Code D3.2007 & D3Sandeep NikhilÎncă nu există evaluări

- Getting Started With Java: Atul PrakashDocument20 paginiGetting Started With Java: Atul PrakashOwsozeroÎncă nu există evaluări

- E3 - 5.5.3 - PTAct Troubleshooting Spanning Tree ProtocolDocument2 paginiE3 - 5.5.3 - PTAct Troubleshooting Spanning Tree ProtocolIvandiÎncă nu există evaluări

- Op Manual Roi-18-01Document16 paginiOp Manual Roi-18-01William BondÎncă nu există evaluări

- Exception Handling Notes For Vtu StudentsDocument42 paginiException Handling Notes For Vtu StudentshelloÎncă nu există evaluări

- MMTI Literature ReviewDocument39 paginiMMTI Literature ReviewGargee GhoshÎncă nu există evaluări

- WinDNC - V05 - 02 English PDFDocument2 paginiWinDNC - V05 - 02 English PDFAnonymous XXKCjKnc0Încă nu există evaluări

- Smart Obj. Kiss and SwotDocument5 paginiSmart Obj. Kiss and SwotjtopuÎncă nu există evaluări

- GMSYS Release NotesDocument2 paginiGMSYS Release NotesrenzoquimÎncă nu există evaluări

- Dimitrios Iliadelis - Effect of Deep Excavation On An Adjacent Pile FoundationDocument77 paginiDimitrios Iliadelis - Effect of Deep Excavation On An Adjacent Pile Foundationmateus456Încă nu există evaluări

- Customizing The ADFS Sign-In PagesDocument4 paginiCustomizing The ADFS Sign-In Pagesmicu0% (1)

- Combustion System Repairs - Industrial Gas Turbines: Industrial Frame Engines - GE, Siemens, Alstom - Including "F" ClassDocument2 paginiCombustion System Repairs - Industrial Gas Turbines: Industrial Frame Engines - GE, Siemens, Alstom - Including "F" ClassfrdnÎncă nu există evaluări

- Data SheetDocument2 paginiData SheetAsalamEilujÎncă nu există evaluări

- Dataproducts - LZR 1260 Laser Printer (1989)Document6 paginiDataproducts - LZR 1260 Laser Printer (1989)Bobby ChippingÎncă nu există evaluări

- Punjab Bye Laws For Commercial BuildingsDocument11 paginiPunjab Bye Laws For Commercial BuildingsAshween ManchandaÎncă nu există evaluări

- TK-C Transmitter PDFDocument4 paginiTK-C Transmitter PDFGopal HegdeÎncă nu există evaluări

- Oracle Inventory Consigned Inventory From Supplier Process GuideDocument60 paginiOracle Inventory Consigned Inventory From Supplier Process GuideJenny RochaÎncă nu există evaluări

- Environmental Engineering Jobs in Bangladesh - Careerjet - Com.bdDocument4 paginiEnvironmental Engineering Jobs in Bangladesh - Careerjet - Com.bdamrin jannatÎncă nu există evaluări

- 02 - Student Lesson 2 Pile Driving SystemDocument91 pagini02 - Student Lesson 2 Pile Driving SystemdannyzuanÎncă nu există evaluări

- Kalzip - Vapour Layer FR 0822 PDFDocument2 paginiKalzip - Vapour Layer FR 0822 PDFBerat CakmakliÎncă nu există evaluări

- Forming ProcessesDocument8 paginiForming ProcessesKishor PatilÎncă nu există evaluări

- TDS Tixatrol STDocument2 paginiTDS Tixatrol STJose E BatistaÎncă nu există evaluări

- CENG6206 Soil Dynamics ExerciseProblemDocument4 paginiCENG6206 Soil Dynamics ExerciseProblemFekadu Wub100% (1)