Documente Academic

Documente Profesional

Documente Cultură

RCC Bund Wall Without Shear Key

Încărcat de

nhulugallaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

RCC Bund Wall Without Shear Key

Încărcat de

nhulugallaDrepturi de autor:

Formate disponibile

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

JI-180-000-ECV-CAL-050

0

Mr Dipak

Mr Girish Kurnool

4.3 Design of Concrete Bund Wall for

Main Crude Oil Tank TK - 1526.

SR NO

TABLE OF CONTENTS

4.3.1

Design Data

4.3.2

Design Philosophy

4.3.3

Design of Wall

4.3.4

Design of Base Slab

APPENDIX - I

Typical Detail of Cantilever Wall

PAGE NO

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

JI-180-000-ECV-CAL-050

0

Mr Dipak

Mr Girish Kurnool

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

1.0

JI-180-000-ECV-CAL-050

0

Mr Dipak

Mr Girish Kurnool

INTRODUCTION

RCC retaining walls are provided around the liquid storaeg tanks wherever necessary

to retain the liquid in the event of any possible oil leakages or tank burst conditions.

The various types of retaining walls are cantilever wall, counterfort wall,

butress wall etc.

The type of RCC retaining wall to be adopted depends on the economy and

construction feasibility.

2.0

SCOPE OF WORK

Scope of this document is to furnish design calculation for Cantilever Bund Wall.

Refer Appendix -1 for typical details of RC detail of wall.

Reference codes, books and documents

12-

BS : 8110 - Structural use of concrete.

Civil and structural design philosophy JI-180-000-ECV-SPE-001

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

JI-180-000-ECV-CAL-050

0

Mr Dipak

Mr Girish Kurnool

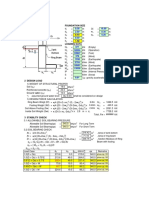

4.3.1 DESIGN DATA :

4.3.1.1 Geometrical Data :

Height of soil filling ( H2 )

Thickness of base slab ( W b )

U/s of base slab from GL of out side of

bunded area ( H )

Free Board ( F )

Total Height of retaining wall ( H1 )

U/s of base slab from tank side GL ( D )

Top of raft from EGL of tank ( D1)

Width of heel slab ( Bh )

Thickness of wall at bottom, ( B )

Width of toe slab ( Bt )

1.6

=

=

0.4

0.3

=

=

5

2

m

m

1.6

=

=

2.7

0.4

m

m

0.5

Thickness of wall at top, ( B1 )

0.3

Thickness of wall at H2 from raft top(Bc)

0.3652

4.3.1.2 Soil Data : ( As Per JI-180-000-ECV-SPE-001 )

Unit weight of soil,( )

kN/m3

=

18

Coefficient of soil pressure, ( Ko )

=

0.5

( considered at rest condition as per geotechnical report)

Net Allowable Bearing capacity of soil

=

150

KN/m2

Angle of internal friction, (

=

32

Coefficient of active earth pre. ( Ka )

( 1-SIN ) / ( 1+SIN )

=

Coefficient of passive earth pre. ( KP )

( 1+SIN ) / ( 1-SIN )

=

Factor of safety against sliding

Factor of safety against overturning

=

=

Tank

Farm

area

H1

H

H2

D1

D

Bh

Bt

Wb

0.308

3.253

N/mm2

Yield Strength of reinforcement ( Fy )

414

N/mm2

Dia of Reinforcement in wall ( dwall )

20

mm

Dia of Reinforcement in base ( dbase )

=

=

20

75

Density of retained liquid, ( w )

Bc

1.75

1.75

4.3.1.3 Material Data: ( As Per JI-180-000-ECV-SPE-001 )

Grade of Concrete ( Fcu )

=

30

Clear Cover to Reinforcement ( c )

Unit Weight of Concrete ( c )

B1

F

24

mm

mm

KN/m3

8.77

KN/m3

4.3.2 DESIGN PHILOSOPHY :

Here, Bund wall has been desinged as a cantilever retaining wall for 1 m length and for that following critical

cases has been considered

Case 1 ) Empty on tank side & soil pressure and wind on other side of retaining wall.

In this case cantilever wall has been analyzed for the active earth pressure from one side only,

while checking for the stability, wt of earth from both the side has been considered.

Case 2 )

Hydrostatic pressure due to stored liquid during spillages or tank burst conditions.

In this case cantilever wall has been analyzed for the submerged liquid pressure from tank side

only passive earth pressure on the other side of retaining wall to the possible extent of 2/3

height of overburden soil. While checking for the stability, wt of earth from both the side & wt of

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

liquid form tank side has been considered.

JI-180-000-ECV-CAL-050

0

Mr Dipak

Mr Girish Kurnool

The stability and base pressure check for the retaining wall have been carried out to decide the

size and other details of the assumed retaining wall. The structural calculations are carried out later.

4.3.3 DESIGN OF WALL :

4.3.3.1 BM Calculation For Case 1 :

a)

Active earth pressure ( Pa )

=

=

Shear at base of stem due to active

earth pressure ( Va )

Moment at base of stem due active

earth pressure ( Ma )

*Ka*H2

Qw

8.870 KN/m2

P a * H2 / 2

7.096 kN

Pa * H2 / 2 * H2 / 3

3.785

kNm

0.76

KN/m2

Shear at base of stem due to wind

pressure ( Vw )

Qw * (H1-H)

Moment at base of stem due to Wind

pressure ( Mw )

2.28

kN

Qw * (H1-H) * ((H1-H)/2+H2)

b)

Wind pressure ( Qw )

Pa

( Refer Civil & Structural design

philosophy JI-180-000-ECV-SPE-001)

c)

Passive earth pressure, ( Pp )

=

=

Shear at base of stem due to passive

earth pressure ( Vp )

Moment at base of stem due to

passive earth pressure ( Mp )

d)

Additional Shear ( Vadd )

=

=

7.068

kNm

*Kp*D1

0.00

KN/m2

P p * D1 / 2

( Passive pressure for moment

calculation has been ignored so

as to be on conservative side )

0.000 kN

Pp * D1 / 2 * D1 / 3

0.000

Additional Moment ( Madd )

0.53

Total shear at base ( V1 )

=

=

Total moment at base ( M1 )

=

=

kNm

kN

( Due to Walkway at top )

kNm

( Due to Walkway at top )

Va + Vw + Vadd - Vp

9.38

kN

Ma + Mw + Madd - Mp

11.38

kNm

Qw

4.3.3.2 BM Calculation For Case 2 :

a)

Contained Liquid pressure ( Pw )

=

=

w*(H1-W b-F)

37.711 KN/m2

Pw * (H1-W b-F)/2

Shear at base of stem due to liquid

pressure ( Vl )

Moment at base of stem due to liquid

pressure ( Ml )

81.079 kN

Pw * (H1-W b-F)2/6

116.213 kNm

Pa

Pw

Pp

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

b)

Active earth pressure ( Pa )

=

=

Shear at base of stem due to active

earth pressure ( Va )

Moment at base of stem due to active

earth pressure ( Ma )

c)

Passive earth pressure ( Pp )

=

=

=

=

Shear at base of stem due to passive

earth pressure ( Vp )

Moment at base of stem due to

passive earth pressure ( Mp )

d)

Wind pressure ( Qw )

3.639 kN

Ka*D13/6

1.941

0.000 KN/m2

P p * H2 / 2

( Passive pressure for moment

calculation has been ignored so

as to be on conservative side )

0.000 kN

Pp * H2 / 2 * H2 / 3

0.76

Qw * F

kNm

*Kp*H2

Moment at base of stem due to wind

pressure ( Mw )

e)

Additional Shear ( Vadd )

4.549 KN/m2

Ka*D12/2

0.000

0

Mr Dipak

Mr Girish Kurnool

Ka * D1

Shear at base of stem due to wind

pressure ( Vw )

JI-180-000-ECV-CAL-050

kNm

KN/m2

0.228 kN

Qw * F * (F/2 + (H1-F-W b))

1.0146

kNm

0.00

kN

( Due to Walkway at top )

Additional Moment ( Madd )

0.53

kNm

( Due to Walkway at top )

Total shear at base ( V2 )

=

=

Total moment at base ( M2 )

=

=

Vl + Va + Vw + Vadd - Vp

84.95 kN

Ml + Ma + Mw + Madd - Mp

119.70 kNm

4.3.3.3 Rebar Calculation :

Design factored bending

moment ( Mu )

Effective depth ( d )

=

=

1.4 * ( Maximum of M1 & M2 )

167.58

kNm

( Load factor for soil pressure is

1.4, as per BS:8110-Part I )

( B * 1000 ) - (dwall/2) - c

315

mm

Now as per clause 3.4.4.4 of BS 8110 ( Part - I )

k

=

=

=

=

=

=

Mu / fcu bd2

30

0.056

167.58

x 1000

<

x 106

x 315

0.156

d* [ 0.5 + sqrt ( 0.25 - k/0.9 )]

315 x [ 0.5 + sqrt( 0.25 293.88 mm

&

x 315

0.056

/0.9)]

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

z

=

0.95 x d

=

299.25 mm

Take z

=

=

Minimum Of Above two values

293.88 mm

Required Ast1

=

=

M / [0.95*fy*z]

=

=

=

0.13 % of Area of concrete

0.13

x 1000

x 400

mm2

520

As per table 3.25 of BS : 8110 ( Part - I )

Min reinforcement for flexure ten Ast2

JI-180-000-ECV-CAL-050

0

Mr Dipak

Mr Girish Kurnool

1449.84 mm2/m

/ 100

As per table 3.25 of BS : 8110 ( Part - I ) clause 3.9.4.19

Min reinforcement for crack control Ast3

=

0.25 % of Area of concrete

=

=

=

From the above required Astreq1

Required 20 mm bar at a spacing of 217 mm c/c

Provide 20 mm bar at a spacing of

150

Area of steel provided Astprov1

=

pt provided

0.25

1000

500

x 1000

mm2

mm2

1449.84 mm2

x 400

/ 100

on both face

on each face

Max of Ast1, Ast2 & Ast3

mm c/c

2093

0.52 %

mm2

4.3.3.4 Distribution Steel :

Provide Min Reinforcement As Dist. Steel, As per table 3.25 of BS : 8110 ( Part - I )

Distribution steel, Adist

=

0.13 % of Area of concrete

=

=

Dia of distribution rebar

Provide 12 mm bar at a spacing of

Area of steel provided Astprov1

4.3.3.5 Check For Shear :

Maximum design shear at face ( Vf )

Shear V at face of the support ( Vu1 )

=

200

=

=

=

=

=

0.13

520

12

mm c/c

565

x 1000

mm2

x 400

/ 100

mm

mm2

Maximum Of V1 & V2

84.95

1.4 * Vf

kN

118.92

kN

Shear stress at face of support, ( v1 )

=

=

Vu1/bd

0.38

N/mm

Maximum allowed shear stress ( vmax )

4.38

N/mm2

Max( 0.8fcu , 5 )

( Load factor for soil pressure is

1.4, as per BS:8110-Part I )

or

5 N/mm2

v1 < vmax, O.K. (Clause 3.7.7.2)

100Ast / bd

From BS 8110, Part 1 Table 3.8, ( vc )

Revise value of ( vc )

=

=

0.66

0.51

N/mm

vc*( fcu /25 )1/3

For fcu = 25 N/mm2

For fcu = 30 N/mm2

0.54

N/mm

Since vc > v1, Hence section is SAFE in shear

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

JI-180-000-ECV-CAL-050

0

Mr Dipak

Mr Girish Kurnool

4.3.3.6 Calculation Of Crack Width

Maximum allowable crack width

0.3

mm (Per BS 8110-2 : 1985 clause 3.2.4)

1 ) Crack width for drying shrinkage / thermal movement :

fcu

=

=

Characteristic strength of reinforced concrete

30

N/mm2

fy

Characteristic strength of reinforcing steel as per table 3.1 of BS 8110

( As per design philosophy 0.9fy )

414

N/mm2

=

Thermal strain r

R

=

=

=

=

=

0.8*t**R ( Refer equation 14 of clause 3.8.4.2 of BS 8110-2)

0.6

( Per Table 3.3 of BS 8110-2)

Coefficient of thermal expansion of mature concrete

0.000012 Table 7.3 of BS 8110 ( Part 2 )

Fall in temperatue between hydration peak and ambient

20

( per Table 3.2 of BS 8110-2)

Thermal strain r

Design surface crack width, W 1

Where,

acr

0.0001152

=

3*acr*r/(1+2*((acr-cmin)/(h-x)))

=

=

=

=

=

=

=

=

=

Dist from point considered to the surface of the nearest long bar

Sqrt( S/22+ (c+/2)2 ) - (/2)

acr

113.31 mm

Size of each reinforcing bar

20

Depth of wall = B

400

Spacing of reinforcement

150

As

=

=

Area of steel

2093.333

W1

D

S

0.03

mm

<

0.30

mm

2 ) Crack width in flexure :

Crack width, ( W 2 )

3*acr*m/(1+2*(acr - cmin)/(h-x))

Where,

acr

=

=

=

=

=

113.31

mm

average strain at the level where the cracking is being considered

1 -2

0.001

bt*(h-x)*(a'-x)/3*Es*As*(d-x)

for crack width of 0.3mm

0.0003

OK

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

1

f

/E

*((h-x)/(d-x))

=

s

s

Moment in section, M

Stress in steel, fs

h

=

=

=

=

=

=

0.001

119.698 kNm

M/(As*(d-S'/2))

JI-180-000-ECV-CAL-050

0

Mr Dipak

Mr Girish Kurnool

( Unfactored moment)

194.5708 N/mm2

OK

Overall depth of member

400

mm

= D

bt

=

=

Width of section at the centroid of tensile steel

1000

mm

Es

a

=

=

=

=

=

=

=

=

Modulus of elasticity of reinforcement

200000 N/mm2

Distance from the compression face to the point at which the

crack width is being calculated

effective depth ( d )

315

mm

Effective depth

D - cmin - /2

315

mm

cmin

=

=

Minimum cover to tensile steel

75

mm

=

=

=

=

=

=

=

=

=

=

Mu / fcu bd2

0.056

<

0.156

d* [ 0.5 + sqrt ( 0.25 - k/0.9 )]

293.88 mm

&

293.88 mm

Depth of stress block

42.23868 mm

depth of neutral axis

(d-z)/0.45

46.93186 mm

3*acr*m/(1+2*(acr - cmin)/(h-x))

z

z

S'

x

W2

=

=

0.28

mm

<

&

299.25

0.30

0.95 x d

mm

mm

OK

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

JI-180-000-ECV-CAL-050

0

Mr Dipak

Mr Girish Kurnool

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

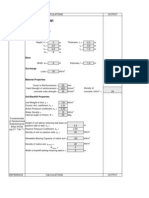

Sign Convention :

Clockwise Moment

Anti clockwie Moment

+Ve

-Ve

JI-180-000-ECV-CAL-050

0

Mr Dipak

Mr Girish Kurnool

Horizontal left to right direction

Horizontal right to left direction

+Ve

-Ve

4.3.4 DESIGN OF BASE SLAB :

4.3.4.1 Stability Analysis For Case 1 :

( Moment has been calculated with respect to A )

a)

Active earth pressure ( Pa )

=

=

Shear at base due to active earth

pressure ( Va )

Moment at base due active

pressure ( Ma )

=

=

*Ka*H

11.088

Pa * H/2

Qw

KN/m2

11.088 kN

Pa * H/2 * H/3

7.392

kNm

A

b)

Wind pressure ( Qw )

Pa

KN/m

=

0.76

( Refer Civil & Structural design philosophy JI-180-000-ECV-SPE-001)

Qw * (H1-H)

Shear at base due to wind

=

2

pressure ( Vw )

Moment at base due to Wind

pressure ( Mw )

c)

Passive earth pressure, ( Pp )

7.980

=

=

Kp*D

Shear at base due to passive earth

pressure ( Vp )

Moment at base due to passive earth

pressure ( Mp )

d)

Additional Shear ( Vadd )

Additional Moment ( Madd )

2.280 kN

Qw * (H1-H) * ((H1-H)/2+H)

=

=

0.000

Pp * D/2

kNm

( Passive pressure

has been neglected )

KN/m2

0.000 kN

Pp * D/2 *D/3

0.000

0.53

kNm

kN

kNm

Check Against Overturning :

Overturning moment ( Mo )

=

=

Mp - Ma - Mw - Madd

-15.90

kNm

W1 =

( 5.00 - 0.40 ) x 0.30 x 24

33.12

kN

W 1' =

1/2 x ( 5.00 - 0.40 ) x ( 0.40 - 0.30 ) x 24

5.52

kN

W2 =

0.50 x 1.60 x 18

14.4

kN

W 2' =

1/2 x ( 0.40 - 0.37 ) x 1.60 x 18

0.50

kN

W3 =

( 2.70 + 0.40 + 0.50) x 0.40 x 24

34.56

kN

77.76

kN

4.30

kN

W4 =

2.70 x 1.60 x 18

Additional Axial Force ( W add )

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

W 1 + W 2 +W 3 + W 1' + W 2' + W 4 + W add

W

=

=

JI-180-000-ECV-CAL-050

0

Mr Dipak

Mr Girish Kurnool

170.16087 kN

B1 = 0.30

Wadd

B1 = 0.37

GL

W2'

W1

H1 = 5.00

W2

GL

D1 = 1.60

W1'

H2 = 1.60

W4

A

W3

Bh = 2.70

Wb = 0.40

B = 0.40

Bt = 0.50

Restoring moment ( Mr )

W 1*(Bh+0.5*B1) + W 2*(Bh+B+0.5*Bt) + W 3*(Bh+Bt+B)/2 + W add*(Bh+0.5*B1)

=

W 1' *(Bh+B1+(B-B1)/3) + W 2' * (Bh+B1+(B-Bc)*2/3) + W 4*Bh/2

=

340.329

F.O.S

kNm

=

=

Mr / Mo

21.402

>

1.75

OK

Check Against Sliding :

Shear at base ( Vb )

Total weight of wall and soil, ( W )

Coeff of friction between soil and

concrete, ( )

Restoring force

F.O.S

=

=

Vp - Va - Vw - Vadd

-13.368

kN

=

=

=

=

=

170.16

tan(2/3)

0.391

*W

66.465

kN

=

=

Restoring force / Shear at base

4.97

>

1.75

kN

Calculation Of Base Pressure :

Length of base slab ( L )

Width of base slab ( B )

Base area ( A )

=

=

=

=

=

=

3.6

1.00

BL

3.6

B L2 / 6

2.16

m

m

W

Mr

170.16

kN

340.33

kNm

Mo

-15.90

kNm

Section modulas of base slab ( Z )

m2

m3

OK

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

x

=

=

=

=

x

0.107

=

=

Wxe

18.207

kNm

Pressure

P1

W /A

55.70

KN/m

P2

Moment due to eccentricity ( Me )

0

Mr Dipak

Mr Girish Kurnool

( Mr - Mo ) / W

1.907

Eccentricity ( e )

JI-180-000-ECV-CAL-050

L/2

<

0.6

(L/6)

OK

Me / Z

38.83764 KN/m2

>

<

0

186

Comp

OK

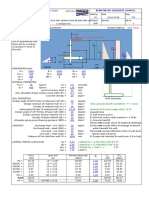

PRESSURE DIAGRAM

Down pressures :

Tank side pressure

( Earth + Base Slab )

=

=

(xD1) + (cxW b)

Other side pressure

( Earth + Base Slab )

=

=

(xH2) + (cxW b)

38.40

38.40

KN/m2

KN/m2

1.907

1.8

Base Pressure :

P2

1.8

2.70

0.40

38.84

51.48

0.50

53.35

P1

55.70

Downward Pressure :

38.40

38.40

Effective Depth d

Tank farm side :

a ) Shear force at wall face

0.315

38.84 x

18.25

2.70

38.40 x

kN

+

2.70

12.64 x

2.70 /2

2.385

38.40 x

kN

+

2.385

11.17 x

2.385 /2

10.43 x

2.228 /2

=

b ) Shear at d distance from

the wall face

i.e. = 2.70 - 0.315 = 2.385

38.84 x

14.36

c ) Shear at 1.5d distance

38.84 x

2.228

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

from the wall face

38.40 x

2.228

i.e. = 2.70 - ( 1.5 x 0.315 ) = 2.228

=

12.60 kN

d ) BM

=

Other side :

a ) Shear force at wall face

38.84 x

12.64 x

38.40 x

16.96

2.70 x

2.70 x

2.70 x

kNm

38.40 x

53.35 x

-8.06

kN

38.40 x

-3.12

0.185

54.83 x

kN

c ) Shear at 1.5d distance

=

from the wall face

i.e. = 0.50 - ( 1.5 x 0.315 ) = 0.027

=

38.40 x

-

0.028

55.57 x

d ) BM

38.40 x

53.35 x

2.34 x

-2.06

=

b ) Shear at d distance from

the wall face

i.e. = 0.50 - 0.315 = 0.185

=

=

-0.47

2.70 /2

2.70 /6

2.70 /2

0.50

0.50

JI-180-000-ECV-CAL-050

0

Mr Dipak

Mr Girish Kurnool

+

-

2.34 x

0.50 /2

0.185

0.87 x

0.185 /2

0.028

0.13 x

0.028 /2

0.50 /2

0.50 /2

0.50 /3

kN

0.50 x

0.50 x

0.50 x

kNm

Design BM & Shear For Case1 :

BM at face of wall, ( Mf1 )

16.96

kNm

Shear at wall face, ( Vf11)

18.25

kN

Shear at d dist. from wall face ( V f12)

14.36

kN

Shear at 1.5d dist. from wall face ( V f13)

12.60

kN

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

Sign Convention :

Clockwise Moment

Anti clockwie Moment

-Ve

+Ve

JI-180-000-ECV-CAL-050

0

Mr Dipak

Mr Girish Kurnool

Horizontal left to right direction

Horizontal right to left direction

-Ve

+Ve

4.3.4.2 Stability Analysis For Case 2 :

( Moment has been calculated with respect to B )

a)

Contained Liquid pressure ( Pw )

Shear at base due to liquid

pressure ( Vl )

Moment at base due to liquid

pressure ( Ml )

Qw

=

=

=

w*(H1-F)

=

=

96.86 kN

Pw * (H1-F)2/6

41.219 KN/m2

Pw * (H1-F)/2

151.75

kNm

Pa

Pw

Pp

B

b)

Active earth pressure ( Pa )

Shear at base due to active earth

pressure ( Va )

Moment at base due to active earth

pressure ( Ma )

c)

Passive earth pressure ( Pp )

Shear at base due to passive earth

pressure ( Vp )

Moment at base due to passive earth

pressure ( Mp )

d)

Wind pressure ( Qw )

Shear at base due to wind

pressure ( Vw )

Moment at base due to wind

pressure ( Mw )

e)

Additional Shear ( Vadd )

Additional Moment ( Madd )

=

=

=

Ka*D

=

=

5.676 kN

Ka*D3/6

5.675781 KN/m2

Ka*D2/2

3.784

kNm

=

=

=

*Kp*H*(2/3)

78.058 KN/m2

Pp * H/2 *(2/3)

=

=

52.039 kN

(4/9)*Pp * H2/6

23.128

( Passive pressure for 2/3 ht

has been considered )

kNm

KN/m2

=

=

0.76

Qw * F

=

=

0.228 kN

Qw * F * (F/2 + (H1-F))

1.106

kNm

0.00

kN

0.53

kNm

Check Against Overturning :

Overturning moment ( Mo )

W1

=

=

Mp - Mw - Ml - Ma - Madd

-134.05 kNm

( 5.00 - 0.40 ) x 0.30 x 24

33.12

kN

W 1' =

1/2 x ( 0.40 - 0.30 ) x ( 5.00 - 0.40 ) x 24

5.52

kN

W2

0.50 x 1.60 x 18

14.4

kN

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

W 2' =

1/2 x ( 0.40 - 0.37 ) x 1.60 x 18

=

0.50

kN

kN

77.76

kN

63.9333

kN

4.30

kN

( 0.40 + 0.50 + 2.70) x 0.40 x 24

W4

2.70 x 1.60 x 18

W5

0

Mr Dipak

Mr Girish Kurnool

34.56

W3

( 5.00 - 2.00 + 0.30) x 2.70 x 8.77

Additional Axial Force ( W add )

JI-180-000-ECV-CAL-050

W 1 + W 2 +W 3 + W 1' + W 2' + W 4 + W 5 + W add

=

=

234.09417 kN

B1 = 0.30

Wadd

F = 0.30

Bc = 0.37

WL

GL

W2'

2.70

W5

W1

H1 = 5.00

W2

GL

D1 = 1.60

H2 = 1.60

W1'

W4

Wb = 0.40

W3

Bh = 2.70

B = 0.40

Bt = 0.50

Restoring moment ( Mr )

W 1*(Bt+(B-B1)+ B1/2) + W 2*Bt/2 + W 3*(Bh+B+Bt)/2 + W add*(Bt+(B-B1)+ B1/2) +

=

W 4*(Bt+B+Bh/2) + W 5*(Bt+B+Bh/2) + W 1' *(Bt+(B-B1)*(2/3)) + W 2' *( Bt+(B-Bc)/3)

=

416.067

kNm

F.O.S

=

=

Mr / Mo

3.103914

>

1.75

OK

Check Against Sliding :

=

Shear at base, ( Vb )

=

=

Vp - Vw - Vl - Va - Vadd

Total weight of liquid,wall and soil ( W )

Coeff of friction between soil and

concrete, ( )

Restoring force

=

=

=

=

=

234.094 kN

tan(2/3)

0.391

*W

91.437 kN

F.O.S

=

=

Restoring force / Shear at base

1.80

>

1.75

-50.730 kN

Calculation Of Base Pressure :

Length of base slab ( L )

Width of base slab ( B )

Base area ( A )

=

=

=

3.6

1.00

BL

m

m

OK

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

=

3.6

m2

B L2 / 6

Section modulas of base slab ( Z )

=

m3

=

2.16

W

Mr

234.0942 kN

416.0672 kNm

Mo

=

=

Eccentricity ( e )

=

=

-134.05

JI-180-000-ECV-CAL-050

0

Mr Dipak

Mr Girish Kurnool

kNm

( Mr - Mo ) / W

1.205

x

-0.595

L/2

<

0.6 OK

(L/6)

Moment due to eccentricity ( Me )

=

=

Wxe

-139.286

kNm

Pressure

P1

W /A

0.54

KN/m

P2

Me / Z

129.5104 KN/m2

>

<

PRESSURE DIAGRAM

0

186

Comp

OK

Down pressures :

Tank side pressure

( Earth+liquid+ Base Slab)

=

=

(xD1) + (cxW b) + (wx(H1-D1-W b-F))

Other side pressure

( Earth + Base Slab )

=

=

(xH2) + (cxW b)

62.08

38.40

KN/m2

KN/m2

1.205

1.8

1.8

Base Pressure :

P1

2.70

0.54

0.40

97.27

P2

0.50

111.598

129.51

Downward Pressure :

62.08

38.40

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

Effective Depth d

0.315

62.08 x

0.54 x

35.57

kN

62.08 x

44.88

2.385

0.54 x

kN

c ) Shear at 1.5d distance

=

from the wall face

i.e. = 2.70 - ( 1.5 x 0.315 ) = 2.228

=

62.08 x

-

2.228

0.54 x

d ) BM

62.08 x

0.54 x

96.73 x

106.78

Tank farm side :

a ) Shear force at wall face

JI-180-000-ECV-CAL-050

0

Mr Dipak

Mr Girish Kurnool

2.70

2.70

96.73 x

2.70 /2

2.385

85.44 x

2.385 /2

+

2.228

79.80 x

2.228 /2

2.70 /2

2.70 /2

2.70 /6

111.60 x

0.50

38.40 x

41.08 kN

+

0.50

17.91 x

0.50 /2

122.88 x

0.185

38.40 x

16.24 kN

+

0.185

6.63 x

0.185 /2

c ) Shear at 1.5d distance

=

from the wall face

i.e. = 0.50 - ( 1.5 x 0.315 ) = 0.027

=

128.53 x

-

+

0.028

0.99 x

0.028 /2

d ) BM

111.60 x

0.50 x

17.91 x

0.50 x

38.40 x

0.50 x

10.64 kNm

0.50 /2

0.50 /3

0.50 /2

+

-

=

b ) Shear at d distance from

the wall face

i.e. = 2.70 - 0.315 = 2.385

=

Other side :

a ) Shear force at wall face

=

=

b ) Shear at d distance from

the wall face

i.e. = 0.50 - 0.315 = 0.185

48.21

2.49

kN

2.70 x

2.70 x

2.70 x

kNm

0.028

38.40 x

kN

Design BM & Shear For Case2 :

BM at face of wall, ( Mf2 )

106.78

kNm

Shear at wall face, ( Vf21)

41.08

kN

Shear at d dist. from wall face ( V f22)

44.88

kN

Shear at 1.5d dist. from wall face ( V f23)

48.21

kN

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

Sign Convention :

Clockwise Moment

Anti clockwie Moment

-Ve

+Ve

JI-180-000-ECV-CAL-050

0

Mr Dipak

Mr Girish Kurnool

Horizontal left to right direction

Horizontal right to left direction

-Ve

+Ve

4.3.4.3 Rebar Calculation :

Max Design BM & Shear From Case 1 & Case 2 :

BM at face of wall ( Mf )

106.78

kNm

Max Of ( Mf1,Mf2 )

Shear at wall face ( Vf1 )

41.08

kN

Max Of ( Vf11,Vf21 )

Shear at d dist. from wall face ( Vf2 )

44.88

kN

Max Of ( Vf12,Vf22 )

Shear at 1.5d dist. from wall face ( Vf3 )

48.21

kN

Max Of ( Vf13,Vf23 )

Design factored bending

moment ( Mu )

1.4 * ( Mf )

Effective depth ( d )

=

=

149.49 kNm

1.4, as per BS:8110-Part I )

( W b * 1000 ) - (dbase/2) - c

315

( Load factor for soil pressure is

mm

Now as per clause 3.4.4.4 of BS 8110 ( Part - I )

k

=

=

=

Mu / fcu bd2

30

0.050

149.49

x 1000

<

x 106

x 315

0.156

=

=

=

d* [ 0.5 + sqrt ( 0.25 - k/0.9 )]

315 x [ 0.5 + sqrt( 0.25 296.31 mm

&

=

=

0.95 x d

299.25

Take z

=

=

Minimum Of Above two values

296.31 mm

Required Ast1

=

=

M / [0.95*fy*z]

1282.75 mm2

=

=

=

0.13 % of Area of concrete

0.13

x 1000

x 400

520

mm2

As per table 3.25 of BS : 8110 ( Part - I )

Min reinforcement for flexure ten Ast2

x 315

0.050

mm

/ 100

As per table 3.25 of BS : 8110 ( Part - I ) clause 3.9.4.19

Min reinforcement for crack control Ast3

=

0.25 % of Area of concrete

=

=

=

From the above required Astreq1

=

Required 20 mm bar at a spacing of 245 mm c/c

Provide 20 mm bar at a spacing of

Area of steel provided Astprov1

150

=

0.25

1000

500

x 1000

mm2

mm2

1282.75 mm2

mm c/c

2093

mm2

x 400

/ 100

on both face

on each face

Max of Ast1, Ast2 & Ast3

/0.9)]

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Doc No

:

Subject : BUND WALLS DESIGN AND CONTAINMENT

Rev No

:

CAPACITY CALCULATIONS FOR GC-21

Prep. By :

Checkd. By :

pt provided

=

0.52 %

JI-180-000-ECV-CAL-050

0

Mr Dipak

Mr Girish Kurnool

4.3.4.4 Distribution Steel :

Provide Min Reinforcement As Dist. Steel, As per table 3.25 of BS : 8110 ( Part - I )

Distribution steel, Adist

=

0.13 % of Area of concrete

Dia of distribution rebar

Provide 12 mm bar at a spacing of

Area of steel provided Astprov1

4.3.4.5 Check For Shear :

Shear V at face of the support ( Vu1 )

=

=

0.13

520

12

200

565

=

=

1.4 * ( Vf1 )

/ 100

mm

mm2

57.51 kN

1.4 * ( Vf2 )

Shear V at d distance from the

support ( Vu2 )

Shear V at 1.5d distance from the

support ( Vu3 )

=

=

67.49

Shear stress at face of support, ( v1 )

=

=

=

Vu1/bd

Maximum allowed shear stress

( vmax ) = Max( 0.8fck , 5 )

x 400

mm c/c

x 1000

mm2

62.83 kN

1.4 * ( Vf3 )

0.18

4.382

( Load factor for soil pressure is

1.4, as per BS:8110-Part I )

( Load factor for soil pressure is

1.4, as per BS:8110-Part I )

( Load factor for soil pressure is

kN

N/mm

N/mm2

1.4, as per BS:8110-Part I )

or

5 N/mm2

v1 < vmax, O.K. (Clause 3.7.7.2)

Actual shear stress at d dist.

from support ( v2 )

Vu2/bd

=

=

0.20

Vu3/bd

N/mm

Actual shear stress at 1.5d dist.

from support ( v3 )

0.21

N/mm

100Ast / bd

0.665

From BS 8110, Part 1 Table 3.8 ( vc )

Revise value of ( vc )

=

=

0.450 N/mm

vc*( fcu /25 )1/3

For fcu = 25 N/mm2

For fcu = 30 N/mm2

0.478 N/mm

Since vc > v1, v2 & v3, Hence section is SAFE in shear

Client : Kuwait Oil Company

Project : Facility Upgrade and Relocation of Under Ground Process

Job No : JI-180

Subject : BUND WALLS DESIGN AND CONTAINMENT

CAPACITY CALCULATIONS FOR GC-21

Doc No

: JI-180-000-ECV-CAL-050

Rev No

: 0

Prep. By : Mr Dipak

Checkd. By : Mr Girish Kurnool

Appendix - I

EL 100.50

300

EL 100.20

Tank Side

Earth Side

4600

EL 97.50

EL 97.50

1600

1600

400

2700

500

400

Sectional Elevation Of Wall

** All Dimensions Are In MM

( GA Detail Only )

Tank Side

Earth Side

T12 @ 200 mmc/c

T20 @ 150 mmc/c

T12 @ 200 mmc/c

T20 @ 150 mmc/c

Sectional Elevation Of Wall

( RC Detail Only )

S-ar putea să vă placă și

- RCC Bund Wall With Shear KeyDocument27 paginiRCC Bund Wall With Shear Keynhulugalla100% (1)

- 15 Masonry Bearing Design (BS5628Document2 pagini15 Masonry Bearing Design (BS5628NewtonÎncă nu există evaluări

- Fencing Oman With Block Footing - 03072013Document20 paginiFencing Oman With Block Footing - 03072013RAJENDRA PRASADÎncă nu există evaluări

- 20d-Stepped Masonry Retaining Wall-Stability CheckDocument6 pagini20d-Stepped Masonry Retaining Wall-Stability CheckParthiban Arivazhagan100% (1)

- Structure: 1 Dimension Data Foundation Size: Qmax Qa, OK! Qmax Qa, OK! Qmax Qa, OK!Document5 paginiStructure: 1 Dimension Data Foundation Size: Qmax Qa, OK! Qmax Qa, OK! Qmax Qa, OK!dantevariasÎncă nu există evaluări

- Bund Wall Analysis 01Document6 paginiBund Wall Analysis 01orode franklyn100% (3)

- Cable Trench Desiign Report 26.04.2020 PDFDocument50 paginiCable Trench Desiign Report 26.04.2020 PDFkkgcÎncă nu există evaluări

- Manhole Calculation P 113 10Document4 paginiManhole Calculation P 113 10Pradeep BalasubramaniamÎncă nu există evaluări

- 2 Piles Cap Design ExampleDocument3 pagini2 Piles Cap Design ExampleSilvanus ChepkocheiÎncă nu există evaluări

- 10.0m LIGHTING POLES - Concrete Design BS8110Document7 pagini10.0m LIGHTING POLES - Concrete Design BS8110Nicoleta cristianÎncă nu există evaluări

- 3.000 M X 1.200 M Board (CKE 8+430)Document12 pagini3.000 M X 1.200 M Board (CKE 8+430)UmesgÎncă nu există evaluări

- Pratt Type Roof Truss-DesignDocument9 paginiPratt Type Roof Truss-DesignARSE0% (1)

- Pile SpringDocument6 paginiPile Springkaleswara_tellakula100% (2)

- Shoring Depth CalculationDocument11 paginiShoring Depth CalculationUpali KarunarathneÎncă nu există evaluări

- 6.5 Design of Precast Protection Slab 6.5.1 Materials: Job: Made by Sheet No. Total Sh. Set No. Date Rev. No. Job NoDocument47 pagini6.5 Design of Precast Protection Slab 6.5.1 Materials: Job: Made by Sheet No. Total Sh. Set No. Date Rev. No. Job NobalaramÎncă nu există evaluări

- Slab PedestalDocument5 paginiSlab PedestalnhulugallaÎncă nu există evaluări

- Concrete Ring Wall FoundationDocument16 paginiConcrete Ring Wall Foundationrao159951Încă nu există evaluări

- Footing Design According To BS8110 CodeDocument4 paginiFooting Design According To BS8110 CodeMohit VatsÎncă nu există evaluări

- LG001 Csa Cal 026Document89 paginiLG001 Csa Cal 026Iman RahmatullahÎncă nu există evaluări

- Bs 8110 Isolated FootingDocument23 paginiBs 8110 Isolated FootingWilfredoEnghoyÎncă nu există evaluări

- Base Slab Design - RampDocument6 paginiBase Slab Design - RampSuresh Mahalingam100% (1)

- Retaining Wall DesignDocument6 paginiRetaining Wall Designdocument123456789100% (1)

- RCC Mat Foundation 4 PedestalDocument173 paginiRCC Mat Foundation 4 PedestalKutty Mansoor50% (2)

- Corbel S&TDocument4 paginiCorbel S&TrajivkannanÎncă nu există evaluări

- Basement Wall Rev1Document9 paginiBasement Wall Rev1Tee Bun Pin0% (1)

- Ring Beam Foundation DesignDocument3 paginiRing Beam Foundation DesigndantevariasÎncă nu există evaluări

- Wind CalculationDocument6 paginiWind CalculationKhairul JaggerÎncă nu există evaluări

- Sign Board CalcsDocument34 paginiSign Board CalcsMimi MoragnÎncă nu există evaluări

- Equipment Block Foundation DesignDocument1 paginăEquipment Block Foundation DesigndantevariasÎncă nu există evaluări

- 2.0 Crack Width CheckDocument8 pagini2.0 Crack Width CheckMoses LugtuÎncă nu există evaluări

- Properties of Pile: 4.0 Design Calculation of Pile Foundations Calculation of Pile InputDocument15 paginiProperties of Pile: 4.0 Design Calculation of Pile Foundations Calculation of Pile InputARUN RAWATÎncă nu există evaluări

- Design of SlabDocument3 paginiDesign of SlabKetan Dhameliya100% (2)

- Design - BorepileDocument10 paginiDesign - BorepileSumedha MayadunnaÎncă nu există evaluări

- Pile Set CriteriaDocument3 paginiPile Set CriteriaAnonymous O404LiV4CÎncă nu există evaluări

- Dike Wall and Slab Design Calculation - RevisedDocument84 paginiDike Wall and Slab Design Calculation - RevisedRichard ChavezÎncă nu există evaluări

- 1 Design Philosophy and Design BasisDocument9 pagini1 Design Philosophy and Design BasisFazilat Mohammad ZaidiÎncă nu există evaluări

- Building Inspection ReportDocument8 paginiBuilding Inspection ReportA DubeyÎncă nu există evaluări

- Job Pile Design-450 (R1)Document3 paginiJob Pile Design-450 (R1)Kyle ForemanÎncă nu există evaluări

- CBP Wall - DWGDocument1 paginăCBP Wall - DWGsambasivammeÎncă nu există evaluări

- Retaining WallDocument37 paginiRetaining WallMUTHUKKUMARAMÎncă nu există evaluări

- Sump Tank CalculationDocument4 paginiSump Tank Calculationmustafe100% (1)

- Design Calculation Report Shelter Guebiba BaseDocument35 paginiDesign Calculation Report Shelter Guebiba BaseAkram FerchichiÎncă nu există evaluări

- Pier FootingDocument2 paginiPier FootingMathurathipan Rajendraseelan100% (1)

- Method of Design - SLAB & BEAMDocument19 paginiMethod of Design - SLAB & BEAMসামিউলইসলামÎncă nu există evaluări

- Detail Design and Analysis of Earthquake PDFDocument59 paginiDetail Design and Analysis of Earthquake PDFSabih Hashim Alzuhairy100% (1)

- DOCUMENT NO.: IPPX-6394-8310-TN-050-0001 PROJECT NAME: 1.2 MMTPA PX-PTA Project, IOCL Paradip Refinery Toyo Job No.: 6394Document38 paginiDOCUMENT NO.: IPPX-6394-8310-TN-050-0001 PROJECT NAME: 1.2 MMTPA PX-PTA Project, IOCL Paradip Refinery Toyo Job No.: 6394Gautam AcharyyaÎncă nu există evaluări

- Ground Anchor DesignDocument4 paginiGround Anchor DesignVardhanÎncă nu există evaluări

- Retaining WallDocument11 paginiRetaining Wallardi rahadianÎncă nu există evaluări

- Shoring SystemDocument3 paginiShoring SystemJason RoyÎncă nu există evaluări

- VMS Gantry DesignDocument14 paginiVMS Gantry DesignNIRMAN INFRASTRUCTURESÎncă nu există evaluări

- Isolation Valve Chamber - 900 MM Diameter PipeDocument47 paginiIsolation Valve Chamber - 900 MM Diameter PipeAnonymous 3kDy7e100% (1)

- Beam Aisc LRFDDocument7 paginiBeam Aisc LRFDsocrates00701227100% (1)

- 005 Deck SlabDocument15 pagini005 Deck SlabFerkei UngÎncă nu există evaluări

- Wind LoadDocument1 paginăWind Loadvikramjain66Încă nu există evaluări

- Retaining Walls - Design To BS - CODEDocument11 paginiRetaining Walls - Design To BS - CODEAnonymous xUo6UrÎncă nu există evaluări

- Staad Pro Stainless Steel ReportDocument29 paginiStaad Pro Stainless Steel ReportRaviteja Girijala100% (1)

- Test Tank TK 1527 Equal DepthDocument20 paginiTest Tank TK 1527 Equal DepthnhulugallaÎncă nu există evaluări

- Column Wall DesignDocument42 paginiColumn Wall DesignCivilax.comÎncă nu există evaluări

- RCC Bund Wall Without Shear KeyDocument19 paginiRCC Bund Wall Without Shear Keydubin strukturÎncă nu există evaluări

- Transformer Foundation Along With Blast WallDocument11 paginiTransformer Foundation Along With Blast Wallkrmurali2000Încă nu există evaluări

- Blast CalculationDocument35 paginiBlast CalculationnhulugallaÎncă nu există evaluări

- Test Tank TK 1527 Equal DepthDocument20 paginiTest Tank TK 1527 Equal DepthnhulugallaÎncă nu există evaluări

- Slab PedestalDocument5 paginiSlab PedestalnhulugallaÎncă nu există evaluări

- Effective Length For Moment FrameDocument5 paginiEffective Length For Moment FramenhulugallaÎncă nu există evaluări

- Crack Width BS 8110Document2 paginiCrack Width BS 8110nhulugallaÎncă nu există evaluări

- Anchor BlockDocument12 paginiAnchor BlocknhulugallaÎncă nu există evaluări

- Design Forces Applied To Beams: Table For Beam To Column Moment Connection (Type - MC)Document7 paginiDesign Forces Applied To Beams: Table For Beam To Column Moment Connection (Type - MC)nhulugallaÎncă nu există evaluări

- Change Fix Line260508Document1 paginăChange Fix Line260508nhulugallaÎncă nu există evaluări

- Beam DesignDocument7 paginiBeam DesignAlexs DiazÎncă nu există evaluări

- Design of Shear KeyDocument13 paginiDesign of Shear Keynhulugalla100% (1)

- Slab DesignDocument7 paginiSlab Designnhulugalla0% (1)

- LP2012 Technical ManualDocument227 paginiLP2012 Technical Manualalicarlos13Încă nu există evaluări

- Design of Piled Raft Foundations For Tall BuildingsDocument7 paginiDesign of Piled Raft Foundations For Tall BuildingsnhulugallaÎncă nu există evaluări

- Steel Design Vol 3 - EL-Sayed Bahaa MachalyDocument474 paginiSteel Design Vol 3 - EL-Sayed Bahaa Machalynhulugalla100% (3)

- Salaries and Tax DEMODocument6 paginiSalaries and Tax DEMOnhulugallaÎncă nu există evaluări

- Various Test On WorkabilityDocument93 paginiVarious Test On WorkabilityParul SinghÎncă nu există evaluări

- Test Tank TK 1527 Equal DepthDocument20 paginiTest Tank TK 1527 Equal DepthnhulugallaÎncă nu există evaluări

- Belajar Menggambar 3d Dengan Autocad 2007Document200 paginiBelajar Menggambar 3d Dengan Autocad 2007Iswant MacanÎncă nu există evaluări

- Pile Foundation DesignDocument82 paginiPile Foundation Designcuongnguyen89% (28)

- Etabs MateDocument14 paginiEtabs MatenhulugallaÎncă nu există evaluări

- Seismic Behavior and Design of Composite Steel Plate Shear Walls PDFDocument73 paginiSeismic Behavior and Design of Composite Steel Plate Shear Walls PDFmanpreetkhanujaÎncă nu există evaluări

- Bridge Design Using STAADDocument38 paginiBridge Design Using STAADpheron200390% (10)

- Retention Pile EmbedmentDocument1 paginăRetention Pile EmbedmentnhulugallaÎncă nu există evaluări

- LMC BrochureDocument1 paginăLMC BrochurenhulugallaÎncă nu există evaluări

- Dss Question Bank 2022Document7 paginiDss Question Bank 2022vcb57xbtd5Încă nu există evaluări

- AISI S913-13 - SDocument18 paginiAISI S913-13 - SEdison BecerraÎncă nu există evaluări

- ECON1203 PASS Week 3Document4 paginiECON1203 PASS Week 3mothermonkÎncă nu există evaluări

- NAVIER Laboratory - UMR 8205 - DUPLA Jean-ClaudeDocument6 paginiNAVIER Laboratory - UMR 8205 - DUPLA Jean-ClaudeSusmita PandaÎncă nu există evaluări

- Physics Form 3Document88 paginiPhysics Form 3caphus mazengera100% (1)

- Unijin Pressure Gauge p258Document2 paginiUnijin Pressure Gauge p258Nguyễn Đăng PhúcÎncă nu există evaluări

- Quality Assurance Plan For Civil4mDocument3 paginiQuality Assurance Plan For Civil4mMohammed Abdul BaseerÎncă nu există evaluări

- Chapter 8 CoordinatesDocument13 paginiChapter 8 CoordinatesWei ZhaoÎncă nu există evaluări

- Evaluating The Dual Porosity of Landfilled Municipal Solid WasteDocument9 paginiEvaluating The Dual Porosity of Landfilled Municipal Solid WasteMary PinÎncă nu există evaluări

- Set Theory For The Working Mathematician - Krzysztof Ciesielski - 1997Document244 paginiSet Theory For The Working Mathematician - Krzysztof Ciesielski - 1997Jack Bullets100% (3)

- Msa Ace Inv 1Document11 paginiMsa Ace Inv 1api-413796204Încă nu există evaluări

- YIN CSE578 Lec1 Lab Tests and Behaviour 2019Document37 paginiYIN CSE578 Lec1 Lab Tests and Behaviour 2019wei zhongÎncă nu există evaluări

- Guyton and Hall Medical PhysiologyDocument34 paginiGuyton and Hall Medical PhysiologyFul VianaÎncă nu există evaluări

- Ee 1002Document108 paginiEe 1002Akhilesh Kumar MishraÎncă nu există evaluări

- Stepper Motors VsServo MotorsDocument2 paginiStepper Motors VsServo MotorsEhab MohamedÎncă nu există evaluări

- Insta Grid Products PamphletDocument2 paginiInsta Grid Products PamphletShawn Paul BoikeÎncă nu există evaluări

- 413 Impurities Testing in MedicalDocument2 pagini413 Impurities Testing in MedicalIsmail MathakiyaÎncă nu există evaluări

- Chapter Four: Fig.12.a. Flow Diagram of Simple Vapour Compression SystemDocument15 paginiChapter Four: Fig.12.a. Flow Diagram of Simple Vapour Compression SystemAnonymous 5HYsyrddpÎncă nu există evaluări

- (19MT18302) Modeling and Analysis of Electrical Machines (Theory)Document3 pagini(19MT18302) Modeling and Analysis of Electrical Machines (Theory)Prabhu MoorthyÎncă nu există evaluări

- BBS10 PPT MTB Ch04 ProbabiltyDocument37 paginiBBS10 PPT MTB Ch04 ProbabiltyAgenttZeeroOutsiderÎncă nu există evaluări

- Research Review of Cement Clinker ChemistryDocument14 paginiResearch Review of Cement Clinker ChemistryAman SahadeoÎncă nu există evaluări

- 3.2 - 3.4 NotesDocument4 pagini3.2 - 3.4 NotesSamih AliÎncă nu există evaluări

- General Solution For U-ShapeDocument12 paginiGeneral Solution For U-ShapeDiana SoareÎncă nu există evaluări

- Fire Resisting Properties of Common Building MterialsDocument2 paginiFire Resisting Properties of Common Building MterialssuryakantameÎncă nu există evaluări

- Is Your Mesh Refined Enough? Estimating Discretization Error Using GCIDocument10 paginiIs Your Mesh Refined Enough? Estimating Discretization Error Using GCIFareena FatimaÎncă nu există evaluări

- Indian Standard: Specificati-OnDocument14 paginiIndian Standard: Specificati-On661982Încă nu există evaluări

- Top 40 Civil Engineer Interview QuestionsDocument18 paginiTop 40 Civil Engineer Interview QuestionsAkhtar Ali100% (2)

- Basics of Mining and Mineral ProcessingDocument179 paginiBasics of Mining and Mineral Processingminerales&materiales100% (6)

- Umass Lowell Computer Science 91.503: Graduate AlgorithmsDocument46 paginiUmass Lowell Computer Science 91.503: Graduate AlgorithmsShivam AtriÎncă nu există evaluări