Documente Academic

Documente Profesional

Documente Cultură

2000 Flyer v2

Încărcat de

Adam SamyDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

2000 Flyer v2

Încărcat de

Adam SamyDrepturi de autor:

Formate disponibile

2000

Pump

The Moyno 2000 gear joint

pump offers best value and application

versatility. The proprietary gear joint design

effectively handles radial and thrust loads for

maximum performance and long life.

Typical Applications

> Sewage lift stations and headworks

> Primary and tertiary sedimentation

> Grit removal

> Nitrification

> Thickening and conditioning

> Dewatering

> Multiphase fluid transfer

> Lease automatic custody transfer

> Adhesives

> Slurries

> Chemical metering

> Polymer

> Food and beverage processing

> Starches, slurries, and coatings

> Leaching / neutralization

> Flocculants

Capacity

> up to 4,500 gal/min

Pressure

> up to 1,500 psi

Temperature

> 14F up to 230F

Features & Benefits

Gear Joint Design

The uniform design of the ring gear

and gear ball components create

greater surface contact leading to less

wear and better overall performance.

Materials of Construction

Available in cast iron or stainless steel,

with a choice of rotor and stator

materials to suit individual applications

e.g. hard chrome plated rotor or

natural rubber stator.

Low Running Speeds

Reduced wear for a longer working

pump life which extends the periods

between routine maintenance. Think

of the savings that could be realized

on abrasive applications.

Viscous Products and Heavy Solids

Minimizes shear and crush damage

to the pumped product, while

maintaining a steady flow when

pumping products with a high solids

content.

Durable Coatings

Rotors can be supplied with specialized

coatings to help extend the life of the

rotors through improved wear and

corrosion resistance.

High Pressure/Long Haul Pumping

Can offer considerable project cost

savings by utilizing small borehole

pipework and eliminating the need

for series of pumps when pumping

over long distances or with high head

requirements.

Additional Features

> Standard flange and close-coupled

models available

> Open inlet configurations in 1, 1.5,

and 2-meter lengths to align with

standard feed areas from centrifuges

> Independently driven bridge breakers

for high viscosity, solids-laden fluids

to eliminate products from bridging

> *Flush gland - Allows packing

leakage to be flushed away from the

pump, preventing potential damage

to the seals and packing

> *Fiber deflector - Prevents ragging

around the connecting rod and rotor

head

> *Shaft sleeve - Protects drive shaft

from wear in highly abrasive

applications

*Options for 2000 G1 models only

2000 WA - Close Coupled Design

2000 WB - Close Coupled Design

> Close coupled bearing

housing design

> Similar to WA, but no

shaft bearings

> Bearings integral to adapter

housing

> Traditional close coupled

design

> Uses standard size/keyed gear reducer shaft

> Does not require a coupling and guard

> Thrust and radial loads supported by the bearings in the

gear reducer thus no coupling or guard needed

2000 G1 - Flanged Design

2000 G2 - Single Auger Feed

> Long-coupled, versatile pump

> Single auger feed mechanism

to stuff product into the

pump elements for

increased fill efficiency

> Features patented joint

seals to effectively protect

the gear joints from

pumpage contamination and a hollow drive shaft

> Optional features include shaft sleeve, fiber deflector,

and flush gland

> Wide, open throat minimizes plugging that could occur

in a standard inlet

> Capable of varying lengths to match wide feed areas

from centrifuges and belt filter presses

2000 G3 - Bridge Breaker

2000 G4 - 45 Inlet Design

> Ideal for handling semi-dry,

high solids content fluids

> 45 Inlet lowers friction loss

and provides for gentler

handling of the product

> Features a series of finger

mechanisms mounted on

two counter-rotating shafts to eliminate accumulation of

material in the throat of the pump

> Bridge breaker is independently driven for flexibility

> Patented auger feed on the

rotor head smoothly transfers

product directly into the cavity

without obstruction

2000 HS System

> Combines the high efficiency of the 2000 G4 pump and an integral

hopper with a twin-screw auger feeder

> Efficiently handles over 50% solids content

> Concentric rotation in a close tolerance pressure tube allows the TSF to

generate positive stuffing pressure to the pump inlet

> Intermeshing augers counter-rotate to create a pull-down effect and provide self-cleaning action

For more information, visit www.moyno.com/2000.

www.moyno.com

U.S.A. +1 937.327.3553

Outside U.S.A. 877.4UMOYNO

2014 by Moyno | Moyno is a brand of NOV

Printed in U.S.A.

2000 R2

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Machine Guarding PDFDocument133 paginiMachine Guarding PDFbrsharmaÎncă nu există evaluări

- Mil e 7016FDocument48 paginiMil e 7016Fgustavojorge12Încă nu există evaluări

- Six Sigma Green Belt Training Statistical Self Assessment ToolDocument5 paginiSix Sigma Green Belt Training Statistical Self Assessment Toolashutoshsingh2302Încă nu există evaluări

- Gitlab CICDDocument15 paginiGitlab CICDdeepak bansal100% (1)

- 953CDocument24 pagini953CVictor M. Mejia Diaz0% (1)

- York Ylcs 725 HaDocument52 paginiYork Ylcs 725 HaDalila Ammar100% (2)

- Code of Practice forThermalOilHeaters PDFDocument56 paginiCode of Practice forThermalOilHeaters PDFarjmandquestÎncă nu există evaluări

- Minor ProjectDocument49 paginiMinor Projectapi-334907813Încă nu există evaluări

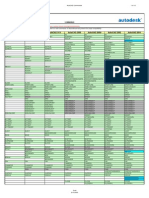

- OZ Racing Rims: Name Method Size Weight (LBS.) Weight (KGS.)Document4 paginiOZ Racing Rims: Name Method Size Weight (LBS.) Weight (KGS.)ilpupÎncă nu există evaluări

- ManualDocument79 paginiManualAdam SamyÎncă nu există evaluări

- 2Document8 pagini2Adam SamyÎncă nu există evaluări

- General CatalogDocument115 paginiGeneral CatalogAdam SamyÎncă nu există evaluări

- GSR High TempratureDocument3 paginiGSR High TempraturestruanÎncă nu există evaluări

- 2/2 Way Solenoid Valve - BC-40Document1 pagină2/2 Way Solenoid Valve - BC-40Adam SamyÎncă nu există evaluări

- TechTalk-Magnetic Flowmeter SizingDocument1 paginăTechTalk-Magnetic Flowmeter SizingAdam SamyÎncă nu există evaluări

- Pressure Switch in Hydraulic or Pneumatic Design For Mining and ChemistryDocument2 paginiPressure Switch in Hydraulic or Pneumatic Design For Mining and ChemistryAdam SamyÎncă nu există evaluări

- S103C E - Magnetici Flowmter CH608 ConverterDocument2 paginiS103C E - Magnetici Flowmter CH608 ConverterAdam SamyÎncă nu există evaluări

- FJN 501 eDocument2 paginiFJN 501 eAdam SamyÎncă nu există evaluări

- S103C E - Magnetici Flowmter CH2200 - 2500 Flanged PipeDocument7 paginiS103C E - Magnetici Flowmter CH2200 - 2500 Flanged PipeAdam SamyÎncă nu există evaluări

- PressureDocument2 paginiPressureAdam SamyÎncă nu există evaluări

- 4204 Livello Ad Ultrasuoni ENGDocument2 pagini4204 Livello Ad Ultrasuoni ENGAdam SamyÎncă nu există evaluări

- Sor Adjustable Dead Band Pressure SwitchDocument16 paginiSor Adjustable Dead Band Pressure SwitchAdam SamyÎncă nu există evaluări

- 6900DZ - 2013 12 06pRESSUREDocument2 pagini6900DZ - 2013 12 06pRESSUREAdam SamyÎncă nu există evaluări

- Honeywell Sensing Switch 5000 Series ProductsheetDocument2 paginiHoneywell Sensing Switch 5000 Series ProductsheetAdam SamyÎncă nu există evaluări

- SGSM 3000, SGCM 3000, SGCO 3000 53414-4-MM, Rev 4 09-08-1Document2 paginiSGSM 3000, SGCM 3000, SGCO 3000 53414-4-MM, Rev 4 09-08-1Adam SamyÎncă nu există evaluări

- Product Catalogue: Minicomb EDSDocument8 paginiProduct Catalogue: Minicomb EDSAdam SamyÎncă nu există evaluări

- Pressure Switches For Process Applications Gi496Document8 paginiPressure Switches For Process Applications Gi496Adam SamyÎncă nu există evaluări

- 05 602 PS10EX Pressure Switch (Ex-Proof) .Document8 pagini05 602 PS10EX Pressure Switch (Ex-Proof) .Adam SamyÎncă nu există evaluări

- Interruptor de Presion - AscoDocument9 paginiInterruptor de Presion - AscoJosephGutierrezÎncă nu există evaluări

- En - 5.11.37105 602 PS10Switch (Ex-Proof)Document3 paginiEn - 5.11.37105 602 PS10Switch (Ex-Proof)Adam SamyÎncă nu există evaluări

- Tipe SwitchDocument1 paginăTipe Switchdwi mahadiyanÎncă nu există evaluări

- Barksdale 7000pRESSUREDocument4 paginiBarksdale 7000pRESSUREAdam SamyÎncă nu există evaluări

- 05 602 PS10EX Pressure Switch (Ex-Proof)Document3 pagini05 602 PS10EX Pressure Switch (Ex-Proof)Adam SamyÎncă nu există evaluări

- 6900DZ - 2013 12 06pRESSUREDocument2 pagini6900DZ - 2013 12 06pRESSUREAdam SamyÎncă nu există evaluări

- P RESSUREDocument5 paginiP RESSUREAdam SamyÎncă nu există evaluări

- MODEL 703-UJ: Description FeaturesDocument2 paginiMODEL 703-UJ: Description FeaturesAdam SamyÎncă nu există evaluări

- Case Report Form (CRF) : Design and DevelopmentDocument26 paginiCase Report Form (CRF) : Design and Developmentapi-3810976Încă nu există evaluări

- Test AND Measurement: Eagle PhotonicsDocument90 paginiTest AND Measurement: Eagle PhotonicsPankaj SharmaÎncă nu există evaluări

- Ogm 25Document1 paginăOgm 25azimsabudinÎncă nu există evaluări

- Exercises 1 FinalDocument2 paginiExercises 1 FinalRemalyn Quinay CasemÎncă nu există evaluări

- Autocad R12 Autocad R13 Autocad R14 Autocad 2000 Autocad 2000I Autocad 2002 Autocad 2004Document12 paginiAutocad R12 Autocad R13 Autocad R14 Autocad 2000 Autocad 2000I Autocad 2002 Autocad 2004veteranul13Încă nu există evaluări

- のわる式証明写真メーカー|PicrewDocument1 paginăのわる式証明写真メーカー|PicrewpapafritarancheraÎncă nu există evaluări

- Humboldt Triaxial Equipment Guide-LR0417Document21 paginiHumboldt Triaxial Equipment Guide-LR0417Dilson Loaiza CruzÎncă nu există evaluări

- AeroDocument27 paginiAeroBALAKRISHNANÎncă nu există evaluări

- What Is Marketing MixDocument12 paginiWhat Is Marketing Mixmansi mehtaÎncă nu există evaluări

- Automatic Railway Gate Control SystemDocument24 paginiAutomatic Railway Gate Control SystemDIPAK VINAYAK SHIRBHATE100% (12)

- BrochureDocument2 paginiBrochurearvind katyayn100% (1)

- Final Report - Submitted - ExactspaceDocument118 paginiFinal Report - Submitted - ExactspaceParasuram PadmanabhanÎncă nu există evaluări

- Water Jug & MissionariesDocument52 paginiWater Jug & MissionariesAdmire ChaniwaÎncă nu există evaluări

- Rahul Soni BiodataDocument2 paginiRahul Soni BiodataRahul SoniÎncă nu există evaluări

- RC Design EC2 v1.9Document64 paginiRC Design EC2 v1.9mohammed alebiedÎncă nu există evaluări

- RFQ - Printer Cartridge HP - A0066Document1 paginăRFQ - Printer Cartridge HP - A0066منتظر عليÎncă nu există evaluări

- Eaton Fuller FS-4205A Transmission Parts ManualDocument18 paginiEaton Fuller FS-4205A Transmission Parts ManualJuan Diego Vergel RangelÎncă nu există evaluări

- 17 - Defining Service Level Agreement (SLA) For E-Gov ProjectsDocument9 pagini17 - Defining Service Level Agreement (SLA) For E-Gov ProjectsdevÎncă nu există evaluări

- Linux InterviewDocument35 paginiLinux InterviewTao FengÎncă nu există evaluări

- Os Se VB Mis SadDocument336 paginiOs Se VB Mis SadMuhammad Sikandar DarÎncă nu există evaluări

- Golden Sun CNC-201R Rotary TableDocument10 paginiGolden Sun CNC-201R Rotary TableGerald100% (2)

- 5 Arduino IDE GyroDocument12 pagini5 Arduino IDE Gyrowaleed_buttzÎncă nu există evaluări