Documente Academic

Documente Profesional

Documente Cultură

Comparison of Life-Cycle Inventory Databases A Case Study Using Soybean Production

Încărcat de

calolasiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Comparison of Life-Cycle Inventory Databases A Case Study Using Soybean Production

Încărcat de

calolasiDrepturi de autor:

Formate disponibile

RESEARCH AND ANALYSIS

Comparison of Life-Cycle

Inventory Databases

A Case Study Using Soybean Production

Shelie A. Miller and Thomas L. Theis

Keywords

agriculture

air emissions

boundary definition

economic input-output

energy use in transportation (GREET)

model

life-cycle assessment

Address correspondence to:

Shelie A. Miller

Institute for Environmental Science and

Policy

University of Illinois at Chicago

2121 West Taylor Street

Chicago, IL 60612 USA

<smille24@uic.edu>

<www.iesp.uic.edu>

Summary

Three established life-cycle inventories of agricultural operations were used to generate air emissions data for soybean production: the greenhouse gases, regulated emissions,

and energy use in transportation (GREET) model; the economic input-output life-cycle assessment (EIO-LCA) model;

and SimaPro software equipped with the Franklin database.

EIO-LCA and GREET baseline data were compared to evaluate differences in boundary definitions that apply specifically

to U.S. soybean agriculture and processing, which resulted in

several major findings. The EIO model estimated for emissions of particulate matter less than 10 micrograms (PM10 )

resulting from wind erosion that were not included in GREET,

but neglected indirect nitrous oxide (N2 O) and nitrogen oxides (NOx ) emissions from fertilizer application. EIO also assumed significantly lower process energy requirements and

lower volatile organic compounds (VOC) for soybean crushing and oil extraction. The GREET and SimaPro models were

compared using identical boundary and assumption data, to

reveal major discrepancies in fundamental assumptions of energy inventories. Key emission factors varied by several orders

of magnitude for basic energy generation and combustion

processes, potentially impacting results for any inventory analysis that contains significant energy consumption. The Franklin

database assumed VOC and sulfur oxides (SOx ) emissions

more than an order of magnitude higher than GREET for

all categories investigated, with significantly lower N2 O and

methane (CH4 ) emission factors.

2006 by the Massachusetts Institute of

Technology and Yale University

Volume 10, Number 12

http://mitpress.mit.edu/jie

Journal of Industrial Ecology

133

R E S E A R C H A N D A N A LY S I S

Introduction

The life-cycle inventory (LCI) process has often been criticized for extensive data requirements, uncertainties in reported data, and the

susceptibility of results to differing assumptions

and boundary definitions (Arnold 1993; Ayres

1995; Beattie 1995; Ehrenfeld 1997; Graedel

et al. 1995; Owens 1997; Thomas et al. 2003;

White and Shapiro 1993). Due to these difficulties, previously constructed studies or models are often used to obtain inventory data. Although numerous methods and modeling tools

exist to expedite the LCI process, results may vary

greatly between models, and it is often difficult to

determine the source of inconsistencies. Differing inventory estimates result from inconsistent

boundary definitions, disagreements in source assumptions regarding material and energy use, or

fundamental differences in the assumed emissions

associated with upstream processes. Overall discrepancies are generally a combination of these

factors, making the origin of disagreements difficult to identify.

In this study, two types of comparisons were

made between three widely used models. First,

models using different approaches (input-output

and process-based) were compared to identify

boundary and source assumption differences. Second, two process-based models with identical assumptions regarding energy and material use were

compared to illuminate fundamental differences

between key datasets. Although many tools can

benefit from this type of analysis, the three models

chosen represent the most common types of LCI

models currently available. Peereboom and colleagues (1998) conducted similar comparisons on

six European datasets analyzing PVC (polyvinyl

chloride) production and found differences ranging from 10 to 1100%. Other studies have also

evaluated inventory models and found similar results, highlighting the need for greater data agreement and transparency of results (Joshi 1999;

Lenzen 2000; Lenzen and Treloar 2002; Norris

and Yost 2001).

The use of biobased material, or biocommodities, as a substitute for petroleum-based products and subsequent environmental comparisons

are important contemporary research topics. Biocommodities are products made predominantly

134

Journal of Industrial Ecology

from biomass and are often proposed as substitutes for nonrenewable products currently on the

market (Lynd et al. 1999). The most prominent

biocommodities are biofuels such as biodiesel or

ethanol; however, there are numerous biobased

products1 that have the potential to become important substitutes, including plastics, polymers,

inks, solvents, packaging, and lubricants (Dale

1999; Hartmann 1998; Kosbar and Japp 2001;

Lynd et al. 1999; National Academy of Sciences 2000; U.S. Department of Energy and U.S.

Department of Agriculture 2002; Warwel et al.

2001). This study focuses specifically on soybean

production. Soybeans have many potential uses,

are abundantly grown, are inexpensive, and have

readily accessible inventory data.

Methods

Description of Models

The three models analyzed in this study are:

greenhouse gases, regulated emissions and energy use in transportation (GREET); economic

input-output life cycle assessment (EIO-LCA);

and SimaPro. A summary evaluating the attributes of each model can be found in table 1.

Each model compiles a different set of inventory

metrics: EIO-LCA quantifies economic contributions, energy and water consumption, and air

emissions; GREET focuses specifically on energy

consumption and air emissions; SimaPro generates output data that depend upon the organization of process modules. Metrics vary depending

upon information contained within the modules.

Because all three models consistently report air

emission data, these are the basis of comparison

for this study. Although an analysis of air emission data alone does not constitute a complete

LCI, it is an important component, and generates

sufficient comparative information about the differences in these types of modeling tools. A more

complete inventory, which includes supplemental aqueous and solid emissions as well as energy

consumption, is currently being conducted by the

authors.

GREET Model

The GREET 1.5 model was developed by

Argonne National Laboratory in the U.S. to

R E S E A R C H A N D A N A LY S I S

Table 1 Comparison of three inventory models for soybean farming

EIO-LCA

GREET

SimaPro

Description

Matrix-based model based

on the linkages of

economic sectors

Detailed process-based

model based on user

assumptions

Modules of process-based

inventory data that are

assembled by user

Scope

485 U.S. commodity

sectors; includes air

emissions, water, and

energy use

U.S. transportation, both

traditional and

alternative fuels,

includes air emissions

and energy use; current

and future estimates

U.S. and European data

for large variety of

sectors that is

expandable; includes

most environmental

impacts

Primary data

sources

U.S. Department of

Commerce Economic

Input-Output Model,

AIRS database

US EPA AP-42

documents, published

studies, government

documents

Franklin US LCI,

BUWAL 250,

IDEMAT 2001,

ETH-ESU 96, industry

and archival data,

others

Advantages

Quick, easy, publicly

available, uses monetary

units, boundary

expansion

Transparent, user

manipulation possible,

flexible to user

assumptions, relatively

quick, publicly available

Applicable to any process,

transparent,

multiple-user interface,

large inventory,

expandable, includes

impact assessment

capabilities

Disadvantages

Aggregation of data, only

for established sectors,

no manipulation

possible, difficult to

track data sources,

outdated data possible,

does not include use

phase

Limited to transportation

and related sectors

Expensive, laborintensive,

inconsistencies possible

between different

modules

Note: AIRS = Aerometric Information Retrieval System; AP-42 documents = U.S. Environmental Protection Agencys

Compilation of Air Pollutant Emission Factors; BUWAL = Bundesamt fur Umwelt, Wald und Landschaft [Federal agency

for the environment, forests, and land] (Switzerland); IDEMAT = Inventory Data of Materials (Technical University

of Delft, The Netherlands); ETH-ESU = Eidgenossische Technische Hochschule, Gruppe Energie-Stoffe-Umwelt [the

Energy-Materials-Environment Group at the Swiss Federal Institute of Technology in Zurich] (Switzerland).

assess the environmental impacts of using traditional and alternative fuel sources in transportation (Wang 1999; Wang 2000). GREET uses

an Excel-based spreadsheet to determine energy

consumption and material releases of criteria air

pollutants and greenhouse gases (volatile organic

compounds [VOCs], carbon monoxide [CO], nitrogen oxides [NOx ], particulate matter less than

10 micrograms (m) [PM10 ], sulfur oxides [SOx ],

methane [CH4 ], nitrous oxide [N2 O], and carbon

dioxide [CO2 ]) for both current and future scenarios. By relying on detailed user assumptions,

emission factors obtained through the U.S. Environmental Protection Agencys Compilation of

Air Pollutant Emission Factors, also known as AP42 documents (USEPA 1995), government documents, and previous studies, GREET calculates

air emissions and energy use for each stage of

fuel cycles from production to use (Ahmed 1994;

Baker and Johnson 1981; Davis and McFarlin

1997; Delucchi 1993; Delucchi and Lipman

1997; Mudahar and Hignett 1987; Shapouri et al.

1995; Sheehan et al. 1998). Because the inventory spreadsheet is entirely transparent, users can

Miller and Theis, Comparison of LCI Databases: Soybean Production

135

R E S E A R C H A N D A N A LY S I S

manipulate any of the inputs and view all calculation cells to determine how a value was derived.

In addition to detailed petroleum refining and energy generation data, GREET contains inventory

data for corn and soybean agriculture, transportation, and processing into ethanol and biodiesel,

respectively.

Of the three models examined, GREET has

the most clearly defined boundary definitions and

baseline assumptions. GREET includes material

and energy flows within the agricultural system

and the manufacturing stages of the materials

used within the system (i.e., fertilizers and chemicals). No capital goods are included, and the

model focuses solely on air emissions and energy use. Air emissions data pertain primarily to

emissions from the combustion of fossil fuels, although estimates of N2 O and NO emissions resulting from residual fertilizer in water runoff are

included. For soybeans, the emission rates of N2 O

and NO are 1.3% and 0.65%, respectively, of the

total amount of applied nitrogen fertilizer. VOC

emissions resulting from hexane extraction are

also incorporated. Particulate emissions due to

wind erosion of agricultural fields are included

for corn farming, although not for soybean farming. The default input parameters for the GREET

model are detailed in table 2, although these values may be manipulated at the users discretion.

The electricity generation mix is assumed to be

53.8% coal, 18.0% nuclear, 14.9% natural gas,

1.0% oil, and 12.3% others (predominantly renewable energy in the form of hydropower). Air

emissions from nonfossil electricity sources are assumed to be zero, although precursors of electricity generation (i.e., uranium mining for nuclear

power) are included. Efficiencies and emissions

are calculated using industry standard values, national averages, and the AP-42 documents.

A recently released beta version of GREET 1.6

uses Monte Carlo analysis to incorporate variability into life-cycle assessment (Wang 2005).

The values reported in this study are taken from

GREET 1.5; the updated version, however, only

makes minor changes in the emission factors relevant to this study. Both versions are available

at <http://www.transportation.anl.gov/software/

GREET/index.html>.

Table 2 Default inputs for the greenhouse gases, regulated emissions, and energy use in transportation

(GREET) model

Chemicals

Nitrogen fertilizer

Phosphate fertilizer

Potash fertilizer

Herbicide

Insecticide

(g/kg soybeans)

4.36

13.68

23.28

1.75 (36.2% atrazine, 63.8% metolachor)

0.018

Energy usage in farming

Diesel

Gasoline

LPG

Electricity

Transportation to extraction facility

(as diesel fuel)

(kJ/kg soybeans)

823

368

32.3

19.9

203

Inputs for soybean oil extraction

Soybeans

N-Hexanea

Natural gas for steam generation

Natural gas

Electricity

5.7 (kg/kg oil)

0.013 (kg/kg oil)

6,730 (kJ/kg oil)

6,500 (kJ/kg oil)

1,423 (kJ/kg oil)

Note: LPG = liquefied propane gas. N-Hexane = solvent used to extract soybean oil from meal. One kilogram (kg,

SI) 2.204 pounds (lbs); one gram (g) = 103 kilograms (kg, SI) 0.035 ounces (oz); one kilojoule (kJ) = 103 joules

(J, SI) 0.239 kilocalories (kcal) 0.948 British Thermal Units (BTU).

a GREET assumes hexane upstream production is similar to LPG from crude. GREET default settings show a value of

476 kJ LPG/kg oil.

136

Journal of Industrial Ecology

R E S E A R C H A N D A N A LY S I S

EIO-LCA Model

Economic input-output life cycle assessment

places LCI in the context of complex interactions within an economy. Originally developed

by Leontief (1986), EIO can model the interdependence of sectors within an economy, tracking

the exchange of goods and services. It tracks the

interrelations of 485 economic sectors, based on

the 1992 U.S. Department of Commerce commodity input-output matrix of the U.S. economy.

When economic activity is stimulated within a

single sector, the model quantifies the economic

impact of all relevant sectors that contribute to

the operation of that sector. EIO-LCA attributes

inventory data to each economic sector using

data collected from a variety of sources, including the Aerometric Information Retrieval System (AIRS) database, the Toxic Release Inventory, emissions factors from AP-42 documents,

commodity purchasing obtained from the inputoutput workfiles, and census data. EIO-LCA assigns emissions to each commodity sector and

then determines the aggregate emissions of a

product by examining the sectors that contribute

to that process (Hendrickson et al. 1998). An

electronic version of the EIO-LCA model and a

more detailed description of the process, developed by the Green Design Initiative at Carnegie

Mellon University, is available on the Internet at

<www.eiolca.net> (Carnegie Mellon University

2003). In addition to linking environmental impacts to economic drivers, the EIO-LCA model

reduces uncertainties concerning boundary definitions, because the system has been expanded to

include an entire economy. In this way, capital

goods are included, although they generally do

not contribute significantly to the inventory of a

product or process.

The primary disadvantage of using EIO-LCA

data is that assumptions for the model are not

readily transparent. They are drawn from numerous databases, and although specific assumption information can be gathered by examination

of source data, it can be difficult and timeconsuming. Material outputs from EIO are described as mass emission/$ activity, which must

be converted to mass emission/mass functional

unit (in this case, soybean oil) for purposes of

comparison with other models, which may lead

to additional uncertainty if there are significant

price fluctuations or market instability. If a product is new, or if the sector has changed dramatically, the information obtained through EIO may

not be reliable. This model also pertains specifically to the U.S. economy. Although this is not

a liability in the case study of U.S. soybean production, it may need to be taken into account

in analyses outside the U.S., or those including

significant international trade. It should also be

noted that the EIO model uses the 1992 matrix,

thus commodities undergoing analysis need to be

converted into 1992 dollars. The EIO sector Oil

Bearing Crops was used for values pertaining to

soybean agriculture, based on the assumption that

soybeans are the predominant oil-bearing crop

within the United States and that other common oil crops such as corn and cotton are contained within other sectors. Soybean processing

data were obtained from the EIO sector Soybean

Oil Mills.

SimaPro

SimaPro software (Version 5.1) was developed by PRe Consultants (2001). It is an expandable and transparent software program that

integrates inventory data for a broad spectrum

of industrial and economic sectors. Process-based

inventories of many common systems are compiled into modules of information to be assembled by the user into a complete inventory. In

this way, a user does not need to determine emissions data for basic inputs, such as electricity use

or transportation, but may use available information to simplify an analysis. Users may utilize

their own data to build new modules, or to update

and supplement the softwares libraries. It contains both European and U.S. databases, including BUWAL 250, IDEMAT 2001, ETH-ESU 96,

and the Franklin Database, and is expandable

with new libraries (Frischknecht and Jungbluth

2001; Goedkoop 2003; Norris 2003; Spriensma

2003). It also provides impact assessment tools,

including Eco-Indicator 99, to be used to correlate inventory data with environmental impacts.

The SimaPro software contains data on most

basic processes, with significantly more European

than U.S. data. Data completeness varies from

process to process, because the files are obtained

Miller and Theis, Comparison of LCI Databases: Soybean Production

137

R E S E A R C H A N D A N A LY S I S

from many data sources, which seldom have the

same level of detail. Like the GREET 1.6 model,

a newer version of the software, SimaPro 6, incorporates Monte Carlo Analysis to quantify uncertainty in inventory results (PRe Consultants

2005).

Because the SimaPro model is not equipped

with soybean farming or processing modules, default GREET values, as shown in table 2, were

used to create soybean-specific data. Because the

results of both SimaPro and GREET are based

on similar input data, inconsistencies in results

are indicative of discrepancies in the emissions

of fundamental processes assumed by the two

databases, such as petroleum refining, transportation, chemical production or electricity generation. All data used in this analysis were obtained

from the Franklin U.S. LCI database. The electricity generation mix from the Franklin database

is 67.0% coal, 19.1% natural gas, 6.3% nuclear,

4.0% hydropower, and 3.6% refined and distillate

fuel oils (2.4% and 1.2%, respectively).

Soybean Agriculture and Processing

The United States produces approximately

75 million metric tons of soybeans annually,

representing 45% of global soybean production.

Soybeans are produced throughout the United

States, with intensive agriculture throughout

the Midwest, especially Illinois, Iowa, Minnesota, and Indiana. Average yields throughout

this region are 4146 bushels/acre or 2,800

3,100 kilograms/hectare (Ash and Dohlman

2002). Soybeans are generally rotated with corn

or other crops to maintain soil nutrient balances.

Because soybeans are legumes, and thus nitrogenfixers, they have lower fertilizer requirements

than most other crops, with approximately 20%

of soybean acreage receiving fertilizer annually

(USDA 2003). Insecticide use for soybeans is

also relatively low. Due to the prevalence of

genetic modifications to U.S. soybeans, most

are glyphosate-resistant (Round-Up Ready);

therefore the primary herbicides used on soybean

fields contain glyphosate (Carpenter et al. 2002).

Once soybeans are harvested, they are transported to processing plants to be separated into

oil and meal. Approximately 74% of soybeans by

weight is soy meal, 18% is oil, and hulls make up

138

Journal of Industrial Ecology

the remaining 8%. In many cases, the hulls are

ground into the meal, except for better quality,

high-protein meal, where the soybean hulls are

separated and can be used for other purposes. The

soybeans are dried and cleaned and then cracked

into suitable pieces for dehulling and flaking. The

beans are then coarsely ground and pressed before being subjected to hexane extraction, which

draws the oil from the meal. The hexane is recovered and recycled through the process. Once

separated, the oil is usually passed through a clay

filter to refine, bleach, and deodorize the crude

oil. The soybean meal can be processed into numerous forms depending upon the end use (White

1995). This process is described in figure 1.

In todays market, soy meal is more valuable

than soybean oil, due to its abundant use in the

feed industry. In recent years, increased demand

for soy meal and reduced desirability of hydrogenated soybean oil in foodstuffs has created a

surplus of oil, which can be used for nonedible

commodity goods, including biodiesel fuel, lubricants, inks, and solvents. Because these products

are derived from soybean oil, the functional unit

for this analysis is the kg of soybean oil, which can

easily be converted to the appropriate functional

unit for the end biocommodity. Reported emissions for soybean farming have been converted

to soybean oil, but not allocated. If allocation is

conducted on a mass basis, the reported values

should be multiplied by 0.18.

Results and Discussion

Inventory data for soybean farming and processing were compiled from the three models, using default assumptions. For the purposes of this

study, only criterion air pollutants and greenhouse gases are analyzed, because these metrics

are common to all three models.

Boundary and Assumption Comparison

To make the data comparable, the inventories were normalized to mass of emissions per

kg of soybean oil. The EIO-LCA model generates data in the form of emissions/$ of activity

(in 1992 dollars), which were converted to a

mass basis. A bushel of soybeans was assumed

to cost $5.60, and soybean oil was calculated at

$0.27/lb,2 as determined by pricing data supplied

R E S E A R C H A N D A N A LY S I S

Soy Meal

Soybean

Grinding and

Flaking

Ground

Beans

Oil Extraction

Meal Processing

Soybean Oil

+

Hexane

Oil Recovery

Hexane

Crude Oil

Oil Degumming

Oil

Figure 1

(1998).

Process flow diagram for soybean crushing process. Adapted from Sheehan and colleagues

by the United States Department of Agriculture

(USDA) (Ash et al. 2002; Good 2001). Also, to

convert from soybeans to soy oil, an allocation

factor of 18% was assumed. The hulls were assumed to be incorporated into the meal, and not

separated.

The results of baseline model comparisons for

soybean farming are normalized to kg of oil produced, allocating emissions on a mass basis to

the co-products. The most apparent difference in

these data is the EIO output for PM10 emissions,

resulting from a difference in source data for the

models, with EIO and GREET containing emission values of 40.84 g PM10 /kg and 0.41 g PM10 /kg

soybean oil, respectively. The National Emissions Trends (NET) network contained within

the AIRS database on which EIO emission information is based (US EPA 1996) reports wind erosion from fields as the largest contributor of PM10

emissions in agriculture. The GREET model includes only PM10 emissions associated with fuel

combustion, and does not incorporate wind erosion. If the effects of wind erosion are subtracted

from the EIO estimates, values similar to the

GREET estimates are obtained. Similarly, this parameter, or some fraction thereof, could be added

to the GREET calculations, depending on the

scope of the assessment.

As shown in figure 2, which neglects particulate matter emissions from wind erosion, EIO

and GREET estimates of CH4 , N2 O, and SOx

emissions vary by more than a factor of 2. For

N2 O values, this inconsistency is attributed to assumptions about fertilizer application and nitrogen transport from the fields. The GREET model

incorporates the denitrification/nitrification reactions of NO

3 in agricultural runoff into N2 O

and NO emissions (assuming an aggregate 1.3%

of applied fertilizer ultimately transforms into

N2 O and 0.65% into NO). Unfortunately, the

data sources for the NET database are not readily

available, so it is uncertain whether this transformation is taken into account in their estimates.

It is a logical assumption that this information

is not included within the EIO data, because

the differential between the models is similar to

the GREET value for nitrogen transformation.

This difference is also partially responsible for

Miller and Theis, Comparison of LCI Databases: Soybean Production

139

R E S E A R C H A N D A N A LY S I S

Soybean Farming Air Emissions

Neglecting Wind Erosion

9.0

Emissions (g/kg oil)

8.0

7.0

6.0

EIO

GREET

SimaPro

5.0

4.0

3.0

2.0

1.0

0.0

CO

PM10

CH4

N2O

NOx

VOC

SOx CO2**

Figure 2 Agricultural air emissions from EIO, GREET, and SimaPro, neglecting particulate emissions due to

wind erosion. All emissions are given in grams per kilogram (g/kg) of oil, except for CO2 , which is in kg/kg

oil. CO = carbon monoxide; PM10 = particulate matter less than 10 m in size; CH4 = methane; N2 O =

nitrous oxide; NOx = nitrogen oxides; VOC = volatile organic compounds; SOx = sulfur oxides; CO2 =

carbon dioxide.

the higher value of NOx emissions in the GREET

model.

In the case of CH4 and SOx emissions, the

primary discrepancy in the data appears to be

differences in the quantity of emissions assumed

to be released through electricity generation.

Although the majority of air emission values for

electricity generation are within the same range

for EIO and GREET, air emissions of SOx and

CH4 are quite dissimilar. GREET generates values of 510 and 280 milligrams emissions per megajoule (mg emissions/MJ),3 whereas EIO gives values of 1,150 and 1,130 mg emissions/MJ for SOx

and CH4 , respectively, assuming a price of 5.12

cents per kilowatt-hour for industrial electricity consumption4 (Energy Information Administration 2003). Because the EIO calculations are

not readily transparent, the source of disagreement pertaining to electricity generation emissions cannot be verified; however, it appears that

EIO assumes greater fugitive methane emissions

140

Journal of Industrial Ecology

during natural gas firing or during mining operations. This is likely due to the variability associated with methane release and whether flaring

is employed. The explanation for the SOx differential may be assumptions about sulfur emissions

generated at coal-fired plants before Title IV of

the 1990 Clean Air Act Amendments was enacted. If electricity consumption during farming

is factored out of EIO, the levels of SOx become

almost identical, and the CH4 values are also

similar.

Initially, energy consumption patterns in the

models are within a factor of 2, with total energy

consumption estimated at 3.1 MJ/kg soybeans for

GREET and 2.2 MJ/kg soybeans for EIO. This differential is a result of higher process energy allocated to upstream processes by GREET. GREET

assumes upstream energy consumption of fertilizers and pesticides to be 0.89 and 0.64 MJ/kg

soybeans, respectively. EIO assumes values of

0.23 and 0.12 MJ/kg soybeans. Although sectors

R E S E A R C H A N D A N A LY S I S

such as transportation are responsible for some

of this difference, the differences in assumed energy consumption during chemical processes are

responsible for the majority of the energy discrepancy. Although total assumed electricity consumption associated with soybean agriculture is

similar (0.067 kWh/kg soybeans for both models),

the allocation of electricity to various processes is

quite different. EIO assumes that electricity used

during agricultural operations is 0.030 kWh/kg

soybeans, and the remaining 0.036 kWh/kg soybeans is used for upstream operations. GREET assumes electricity usage of 0.006 kWh/kg soybeans

for farming operations and 0.61 kWh/kg soybeans

in upstream processes. It therefore appears that

the agreement of total electricity consumption

values is coincidental. Due to the nature of EIO,

the lower upstream electricity consumption is surprising due to the expanded system boundaries; it

would be expected that EIO would include electricity consumption from all stimulated sectors

and would therefore be greater.

Air emissions generated from soybean oil mills

are shown in figure 3. Values from the EIO model

for soybean oil processing are consistently lower

than GREET values, particularly in the case of

VOC emissions. The overall lower values are a result of lower process energy assumptions, whereas

the VOC discrepancy originates from differences

in assumptions pertaining to hexane loss. During

the solvent extraction process, which separates

the oil from the meal, large quantities of hexane are consumed. Although most is recycled,

a fraction is volatilized and lost to the environment. The GREET assumptions regarding hexane emissions derive from the study by Sheehan

and colleagues (Sheehan et al. 1998), which assumes a loss of 2.4 g solvent/kg flaked beans,

using a recovery rate of 99.8%. Other studies

have shown a range of hexane emissions from

1.4 to 2.8 g solvent/kg flaked beans (Woerfel

1995). The VOC emissions in this process are

extremely sensitive to this assumption; advances

in technology that either reduce the amount of

Air Emissions from Soybean Oil Extraction

Emissions (g/kg oil)

3.5

3.0

2.5

EIO

GREET

SimaPro

2.0

1.5

1.0

0.5

2*

C

O

SO

C

VO

N

O

2O

C

H

10

PM

C

O

0.0

Figure 3 Air emissions from soybean oil processing from the EIO, GREET, and SimaPro models. All

emissions are given in grams per kilogram (g/kg) of oil, except for CO2 , which is in kg/kg oil. CO = carbon

monoxide; PM10 = particulate matter less than 10 m in size; CH4 = methane; N2 O = nitrous oxide;

NOx = nitrogen oxides; VOC = volatile organic compounds; SOx = sulfur oxides; CO2 = carbon dioxide.

Miller and Theis, Comparison of LCI Databases: Soybean Production

141

R E S E A R C H A N D A N A LY S I S

hexane consumed or increase the recovery rate

will greatly impact the amount of VOCs emitted.

For instance, if hexane emissions are assumed to

be 1.4 g VOC/kg flaked beans, VOC emissions associated with the GREET model would decrease

by almost 50%. The sensitivity of the analysis to

this factor is important in the case of soybean biocommodities, because products such as soy-based

inks, solvents, and lubricants are viewed as favorable alternatives to the higher-vapor-pressure

petroleum counterparts currently in use. Because

it is difficult to determine the exact assumptions

for the EIO sector of Soybean Oil Mills used to

generate the EIO data, the true source of the differential cannot be determined, although lower

overall process energy assumptions appear to be

a logical conclusion.

Due to lack of consensus and uncertain inventory results, updated mills and data may have

significant impacts on this stage of the process.

Neither the GREET nor EIO model data should

be used as stand-alone data. Supplemental process data should be used to obtain the appropriate

inventory values.

Fundamental Assumptions Comparison

In the previous section, the EIO and GREET

models were used to isolate differences in overall

system assumptions, such as boundary definitions

and material and energy flows. The other major

source of model discrepancy is differences in detailed assumptions pertaining to individual processes common to many inventories. In this study,

differences between the GREET and Franklin

datasets were isolated using the same material

and energy flow data. The default GREET values shown in table 2 were inserted into the

SimaPro model, using the Franklin database for

upstream processes. Ideally, similar parameter inputs would yield similar output values. As seen

in figure 2, substantial differences are observed at

the agricultural stage for CH4 , VOC, and SOx

emissions. These inconsistencies result from different sets of emission factors associated with the

upstream processing and use phases of combustion fuels.

Table 3 demonstrates the disparities in emission factors from fundamental supply chain

Table 3 Comparison of GREET and Franklin emission factors for supply chain production of basic energy

sectors (shown as mg/MJ)

VOC

Electricity

GREET

Franklin

Diesel

GREET

Franklin

Gasoline

GREET

Franklin

Natural gas

GREET

Franklin

LPG

GREET

Franklin

RFO

GREET

Franklin

CO

NOx

PM10

SOx

CH4

N2 O

CO2

0.06

0.47

0.20

0.34

1.43

2.41

0.10

0.13

1.75

5.19

0.96

1.46

0.00

0.01

666.09

665.63

8.39

167.58

22.70

21.23

29.63

28.28

2.73

5.54

16.36

86.14

98.44

13.53

0.19

0.01

14,104.71

8,780.71

16.44

161.76

25.73

20.48

36.74

27.29

3.49

5.37

21.19

83.15

106.96

13.04

0.25

0.01

18,476.89

8,481.67

2.93

246.30

19.41

106.89

29.54

55.77

0.79

1.76

3.19

915.50

187.08

176.59

0.12

0.01

6,423.19

7,309.38

6.71

159.00

20.18

20.52

24.12

27.18

1.78

5.13

9.91

82.58

100.48

12.82

0.14

0.01

10,224.92

8,431.30

6.66

167.58

18.16

21.30

18.65

28.41

1.49

5.57

8.82

86.48

91.49

13.57

0.11

0.01

8,292.97

8,825.01

Note: VOC = volatile organic compounds; CO = carbon monoxide; NOx = nitrogen oxides; PM10 = particulate matter

less than 10 m in size; SOx = sulfur oxides; CH4 = methane; N2 O = nitrous oxide; CO2 = carbon dioxide; LPG =

liquefied propane gas; RFO = residual fuel oil. One milligram (mg, SI) = 103 grams (g) 3.53 105 ounces (oz);

one megajoule (MJ) = 106 joules (J, SI) 239 kilocalories (kcal) 948 British Thermal Units (BTU).

142

Journal of Industrial Ecology

R E S E A R C H A N D A N A LY S I S

Table 4 Comparison of GREET and Franklin emission factors for combustion during basic energy

processes (shown as mg/MJ)

VOC

Natural gas industrial

boilers

GREET

Franklin

RFO industrial boilers

GREET

Franklin

LPG industrial boilers

GREET

Franklin

Coal-fired industrial

boilers

GREET

Franklin

Diesel industrial

boilers

GREET

Franklin

Diesel trucks

GREET

Franklin

Gasoline trucks

GREET

Franklin

CO

NOx

PM10

SOx

CH4

N2 O

CO2

2.56

4.41

38.96

27.86

88.05

143.92

3.51

4.36

0.29

34.82

1.04

1.62

1.04

56,738.95

54,781.53

0.86

0.86

15.35

15.39

168.90

169.25

5.83

43.08

122.88

735.48

3.07

3.08

0.34

78,360.47

80,010.22

1.79

1.33

17.44

17.44

102.36

102.58

3.07

3.08

0.00

0.09

1.02

4.61

67,816.05

69,752.50

1.42

0.36

11.91

4.15

270.15

29.50

12.00

3.33

568.91

88.51

0.71

0.43

0.28

0.21

92,108.51

12,894.44

0.67

0.67

16.78

16.83

80.28

80.78

3.35

5.05

11.95

97.61

0.17

0.18

0.37

76,206.09

75,394.25

85.30

126.89

473.91

703.46

284.34

706.82

41.25

100.30

11.95

121.84

4.18

1.90

75,212.78

76,740.57

199.04

76.47

1137.38

1417.43

189.56

217.46

7.40

161.51

9.16

16.19

32.05

1.90

69,306.96

68,655.86

Note: Dash indicates no reported emissions. VOC = volatile organic compounds; CO = carbon monoxide; NOx =

nitrogen oxides; PM10 = particulate matter less than 10 m in size; SOx = sulfur oxides; CH4 = methane; N2 O =

nitrous oxide; CO2 = carbon dioxide; LPG = liquefied propane gas; RFO = residual fuel oil.

processes for GREET and SimaPro. Table 4 reports emission factors for the combustion phase.

As seen in table 3, only 20 of the 48 upstream

emission factors are within a factor of 2, predominantly those pertaining to CO and NOx emissions. Emission factors associated with electricity

production are also consistently similar for the

two models, unlike the EIO and GREET comparison, which demonstrated significant disagreement for CH4 and SOx emissions during electricity generation. The Franklin database assumes

consistently higher emission factors for SOx ,

PM10 , and VOC emissions than the GREET values, whereas GREET demonstrates significantly

higher emission factors for CH4 and N2 O. It

is difficult to determine the source of discrepancies in these factors. GREET uses data obtained from the US Environmental Protection

Agencys (US EPA) AP-42 documents, which

rely on calculated emission factors, whereas the

Franklin database uses aggregated data obtained

from industry sources. Both datasets have been

peer-reviewed for appropriateness.

It appears that the Franklin model may neglect CH4 emissions during petroleum extraction. GREET assumes an emission factor of 86 mg

CH4 /MJ during extraction and 13 mg CH4 /MJ

during processing. The Franklin emission factor for methane is 13 mg CH4 /MJ, which appears to be solely for processing. The sources of

the other differentials are not apparent. In addition, high variability is associated with emissions from energy sectors. The recently released

GREET 1.6 beta version and SimaPro 6 version

address variability by incorporating Monte Carlo

analysis to report ranges of values. This type of

data enhances assessments, in order to show the

range of possibilities given different conditions.

Miller and Theis, Comparison of LCI Databases: Soybean Production

143

R E S E A R C H A N D A N A LY S I S

A study examining the use of uncertainty data in

LCA is currently underway.

Assumptions regarding combustion emissions

for basic energy processes are found in table 4.

For these processes, 28 of the 56 categories vary

by more than a factor of 2. Similar to upstream

process emissions, sulfur oxide emissions are consistently higher in the Franklin database. Nitrous

oxide emissions are not reported for any of the

Franklin combustion processes except coal-fired

industrial boilers. Emissions from coal-fired boilers and mobile equipment yield the most dissimilar factors, whereas the two models are most consistent in reporting emissions factors for diesel,

liquefied petroleum gas (LPG), and residual fuel

oil (RFO) boilers. Carbon dioxide emission factors are consistent throughout, with the exception of coal-fired industrial boilers, where data

from the Franklin database are obviously too

low.

To ascertain whether emission factors were

the primary contributor to discrepancies between

GREET and SimaPro values, the Franklin data

contained within SimaPro were amended to

reflect GREET emission factors. This resolved

the major disparities between the models output

values, demonstrating that the emission factors

are primarily responsible for differences in

model outputs, not material and energy flows in

upstream processes.

Figure 3 shows the default results from the

soybean oil processing stage for the models. The

differences in results from both SimaPro and

GREET are similar to those from soybean farming, resulting from differences in emission factors.

Using similar emission factors, the two models are

in good agreement.

GREET, with default values obtained from

AP-42 documentation, predicts significantly

higher greenhouse gas emission values than

SimaPro for any analysis in which combustion processes represent a significant fraction.

SimaPro generates consistently higher SOx and

VOC estimates.

Inventory Assessment and Model

Sensitivity

One of the important steps in life-cycle

assessment is to evaluate which process stage is

144

Journal of Industrial Ecology

responsible for the majority of the environmental impacts. In discussions of biocommodities,

agriculture is often cited as energy- and materialintensive. This assertion is confirmed by the

findings of this study, with soybean oil extraction

producing a smaller fraction of the aggregate

emissions, with the exception of VOC emissions.

Because LCI data can vary widely according

to user assumptions, the sensitivity of models

to changes in assumptions should be analyzed.

EIO data cannot be manipulated by the user, and

therefore cannot undergo as rigorous an analysis

as the GREET model. The GREET database was

therefore examined further to test the sensitivity

of the model.

Figure 4 shows the contribution of each sector

to the total quantity of emissions, as estimated

by the GREET model. It can be seen that nitrogen fertilizer production contributes negligible

emissions when compared to the use of the farming equipment in all cases except SOx and CH4 ,

whereas emissions from runoff are predominantly

responsible for the evolution of N2 O and for some

portion of NOx . This also implies that changes in

assumptions for the use of farming equipment will

have a much greater impact on VOC, CO, NOx ,

and PM10 than changes in fertilizer assumptions.

Emissions are sensitive to changes in each sector

commensurate with the percentage of the emissions generated by that sector. For instance, N2 O

emissions are almost directly related to changes

in the amount of nitrogen in runoff. Halving assumptions pertaining to farming equipment operation will reduce SOx emission values by 15%,

but will reduce VOC emissions by nearly 40%.

Future work will focus on significant changes in

agriculture, such as a shift to sustainable practices, but this is too extensive a topic to discuss

in this article.

Figure 4 also shows that to improve the environmental impacts of current soybean farming practices, reduction in farming equipment

use would have the greatest impact on improving the majority of air emissions. Reduction of

fertilizer inputs would have the greatest impact

on improving N2 O and SOx emissions. Changes

in agricultural practices, such as an increase in

conservation tillage farming, would allow net decreases in farming equipment use, and its subsequent emissions.

R E S E A R C H A N D A N A LY S I S

Allocation of Emissions

100%

90%

Runoff

Transportation

Herbicide

Potash

Phosphorus

Nitrogen

Farming Equip

80%

70%

60%

50%

40%

30%

20%

10%

0%

C

VO

CO

x

NO

1

PM

x

SO

4

CH

O

N2

2

CO

Figure 4 Allocation of emissions for various farming sectors contained within the GREET model. VOC =

volatile organic compounds; CO = carbon monoxide; NOx = nitrogen oxides; PM10 = particulate matter

less than 10 m in size; SOx = sulfur oxides; CH4 = methane; N2 O = nitrous oxide; CO2 = carbon dioxide.

Conclusions

Three different techniques were used to generate LCI data for the production of soybeans. This

study shows that widely accepted models contain

dissimilar data, reinforcing the need for detailed

boundary and source assumptions to help identify

the sources of discrepancies. Initial air emissions

comparisons between GREET and EIO resulted

in five of eight categories having values differing

by a factor greater than 2. The largest disparity,

PM10 emissions, was a result of whether the models included wind erosion of fields in the analysis.

Differences in N2 O emissions were traced back

to air emissions due to chemical transformation

of nitrogen in agricultural runoff. Discrepancies

in CH4 and SOx between the EIO and GREET

models were shown to be a result of differences

in electricity use assumptions during farming, as

well as differences in assumptions about emissions

during electricity generation.

Large dissimilarities were found to exist in

basic emission factors assumed for the GREET

and SimaPro models, in some cases exceeding

a factor of 300. The SimaPro data, which were

taken from the Franklin database, exhibited significantly larger emission factors for SOx , PM10 ,

and VOC, whereas GREET consistently calculated greater CH4 and N2 O emissions. These assumptions ultimately impact the output values.

While initial analysis of the three models

revealed significant differences, the major discrepancies in source assumptions were identified.

This article has sought to evaluate the different assumptions associated with each in order

to demonstrate how these will impact the final

results. Using this knowledge, it may be possible

to use one of the models, but incorporate aspects

or assumptions from other models that may seem

relevant.

Acknowledgments

The authors would like to thank Dr. Michael

Wang of Argonne National Laboratories for

his valuable expertise and advisement, and Dr.

Miller and Theis, Comparison of LCI Databases: Soybean Production

145

R E S E A R C H A N D A N A LY S I S

Thomas Seager of the University of New Hampshire for his insightful comments. This research

was funded by the National Science Foundations Integrative Graduate Education Research

and Training (IGERT) (Grant DGE-9720779)

and PREMISE (Grant DMI-0225912) programs

and Alcoa, Inc.

Notes

1. Editors Note: For articles on the industrial ecology

of biobased products, see the special issue of the

Journal of Industrial Ecology on biobased products

(volume 7, issue 34).

2. One pound (lb) 0.4536 kilograms (kg, SI).

3. One milligram (mg, SI) = 103 grams (g) 3.53

105 ounces (oz); one megajoule (MJ) = 106 joules

(J, SI) 239 kilocalories (kcal) 948 British Thermal Units (BTU).

4. One kilowatt-hour (kWh) 3.6 106 joules (J,

SI) 3.412 103 British Thermal Units (BTU).

References

Ahmed, I. 1994. How much energy does it take to make a

gallon of soy diesel? Jefferson City, MO: Institute for

Local Self-Reliance for the National Soy Diesel

Development Board.

Arnold, F. S. 1993. Why environmental life cycle assessment doesnt work. Journal of Environmental

Law and Practice 2(5): 414.

Ash, M. and E. Dohlman. 2002. Soybeans and oil

crops: Background. Washington, DC: Economic

Research Service, U.S. Department of Agriculture.

Ash, M., E. Dohlman, and W. Davis. 2002. Oil crops

situation and outlook yearbook. Washington, DC:

Economic Research Service, U.S. Department of

Agriculture. OCS-2002.

Ayres, R. U. 1995. Life cycle analysis: A critique. Resources, Conservation and Recycling 14(34): 199

223.

Baker, J. L. and H. P. Johnson. 1981. Nitrate-nitrogen

in tile drainage as affected by fertilization. Journal

of Environmental Quality 10(4): 519522.

Beattie, R. B. 1995. Everything you already know (but

dont often admit). Environmental Impact Assessment Review 15(2): 109114.

Carnegie Mellon University. 2003. Economic InputOutput Life Cycle Assessment (EIO-LCA)

Model. Pittsburgh, PA: Carnegie Mellon University Green Design Initiative. <www.eiolca.net>.

Accessed October 2004.

Carpenter, J., A. Felsot, M. Goode, M. Hammig, D.

Onstad, and S. Sankula. 2002. Comparative envi-

146

Journal of Industrial Ecology

ronmental impacts of biotechnology-derived and traditional soybean, corn and cotton crops. Ames, IA:

Council for Agricultural Science and Technology, sponsored by the United Soybean Board.

Dale, B. E. 1999. Biobased industrial products: Bioprocess engineering when cost really counts. Biotechnology Progress 15(5): 775776.

Davis, S. C. and D. N. McFarlin. 1997. Transportation data book: Edition 17. Oak Ridge, TN: Center

for Transportation Analysis, Oak Ridge National

Laboratory.

Delucchi, M. A. 1993. Emissions of greenhouse gases from

the use of transportation fuels and electricity, Volume 1: Main Text. ANL/ESD/TM-22. Argonne,

IL: Center for Transportation Research, Argonne

National Laboratory.

Delucchi, M. A. and T. E. Lipman. 1997. Emissions of non-CO2 greenhouse gases from the use of

transportation fuels and electricity. Davis, CA: Institute of Transportation Studies, University of

CaliforniaDavis.

Ehrenfeld, J. R. 1997. The importance of LCAsWarts

and all. Journal of Industrial Ecology 1(2): 4149.

Energy Information Administration. 2003. Historical

1990 through current month retail sales, revenues,

and average revenue per kilowatt hour by state and

by sector. Washington, DC: Energy Information

Administration.

Frischknecht, R. and N. Jungbluth. 2001. Database

manual: The ETH-ESU 96 library. The Netherlands: PRe Consultants and ESU-services.

Goedkoop, M. 2003. Database manual: Dutch input output database 95. Amersfoort, the Netherlands: PRe

Consultants.

Good, D. 2001. Soybeans: Are prices low enough?

Grain Price Outlook. UrbanaChampaign, IL:

University of Illinois Extension.

Graedel, T. E., B. R. Allenby, and P. Comrie. 1995.

Matrix approaches to abridged life cycle assessment. Environmental Science and Technology 29(3):

134A139A.

Hartmann, M. H. 1998. Biopolymers from renewable resources. New York: Springer-Verlag.

Hendrickson, C., A. Horvath, S. Joshi, and L. Lave.

1998. Economic input-output models for environmental life-cycle assessment. Environmental Science and Technology 32(7): 184A191A.

Joshi, S. 1999. Product environmental life-cycle assessment using input-output techniques. Journal

of Industrial Ecology 3(23): 95120.

Kosbar, L. L. and R. M. Japp. 2001. Introducing

biobased materials into the electronics industry:

Developing a lignin-based resin for printed wiring

boards. Journal of Industrial Ecology 4(3): 93

105.

R E S E A R C H A N D A N A LY S I S

Lenzen, M. 2000. Errors in conventional and inputoutputbased life-cycle inventories. Journal of Industrial Ecology 4(4): 127148.

Lenzen, M. and G. Treloar. (2002). Differential convergence of life-cycle inventories toward upstream production layers: Implications for lifecycle assessment. Journal of Industrial Ecology 6(3

4): 137160.

Leontief, W. 1986. Input-output economics. New York:

Oxford University Press.

Lynd, L. R., C. E. Wyman, and T. U. Gerngross. 1999.

Biocommodity engineering. Biotechnology Progress

15: 777793.

Mudahar, M. S. and T. P. Hignett. 1987. Energy in plant

nutrition and pest control. New York: Elsevier.

National Academy of Sciences. 2000. Biobased industrial products: Priorities for research and commercialization. Washington, DC: National Academy of

Sciences.

Norris, G. A. 2003. Database manual: The Franklin US

LCI library. The Netherlands: PRe Consultants

and Sylvatica.

Norris, G. A. and P. Yost. 2001. A transparent, interactive software environment for communicating

life-cycle assessment results: An application to

residential windows. Journal of Industrial Ecology

5(4): 1528.

Owens, J. W. 1997. Life-cycle assessment: Constraints

on moving from inventory to impact assessment.

Journal of Industrial Ecology 1(1): 3749.

Peereboom, E. C., R. Kleijn, S. Lemkowitz, and S.

Lundie. 1998. The influence of inventory data sets

on life cycle assessment results: A case study on

PVC. Journal of Industrial Ecology 2(3): 109130.

PRe Consultants. 2001. SimaPro v. 5.1. Amersfoort,

the Netherlands.

PRe Consultants. 2005. SimaPro v. 6.0. Amersfoort,

the Netherlands.

Shapouri, H., J. A. Duffield, and M. Graboski. 1995. Estimating the net energy balance of corn ethanol.

Agricultural Economic Report 721. Washington,

DC: Economic Research Service, U.S. Department of Agriculture.

Sheehan, J., V. Camobreco, J. Duffield, M. Graboski,

and H. Shapouri. 1998. Life cycle inventory of

biodiesel and petroleum diesel for use in an

urban bus. NREL/SR-580-24089. Golden, CO:

National Renewable Energy Laboratory.

Spriensma, R. 2003. Database manual: The BUWAL

250 library. The Netherlands: PRe Consultants.

Thomas, V., T. Theis, R. Lifset, D. Grasso, B. Kim, C.

Koshland, and R. Pfahl. 2003. Industrial ecology:

Policy potential and research needs. Environmental Engineering Science 20(1): 19.

U.S. Department of Agriculture (USDA). 2003. Agricultural chemical usage: 2002 field crops summary.

Washington, DC: USDA National Agricultural

Statistics Service.

U.S. Department of Energy and U.S. Department

of Agriculture. 2002. Vision for bioenergy and

biobased products in the United States. Washington, DC: Biomass Technical Advisory Committee, Biomass R&D Act of 2000.

U.S. Environmental Protection Agency (USEPA).

1995. Compilation of air pollutant emission factors,

Volume 1: Stationary point and area sources. Research Triangle Park, NC: USEPA.

U.S. Environmental Protection Agency (USEPA).

1996. National air pollutant emissions trends, 1900

1995. EPA 454/R-96-007. Research Triangle

Park, NC: USEPA Office of Air Quality.

Wang, M. Q. 1999. GREET 1.5 Transportation fuelcycle model, Volume 1: Methodology, development, use, and results. ANL/ESD-39. Argonne,

IL: Argonne National Laboratory.

Wang, M. Q. 2000. GREET Greenhouse gases, regulated emissions and energy use in transportation,

v. 1.5a. Argonne, IL: Argonne National Laboratory.

Wang, M. Q. 2005. GREET Greenhouse gases, regulated emissions and energy use in transportation,

v. 1.6 beta. Argonne, IL: Argonne National Laboratory.

Warwel, S., F. Bruse, C. Demes, M. Kunz, and M. R.

Klaas. 2001. Polymers and surfactants on the basis

of renewable resources. Chemosphere 43(1): 39

48.

White, A. L. and K. Shapiro. 1993. Life cycle assessment: A second opinion. Environmental Science

and Technology 27(6): 10161017.

White, N. H. 1995. Soybean meal processing and utilization. In Practical handbook of soybean processing

and utilization. Edited by D. R. Erickson. Champaign, IL: American Oil Chemists Society Press

and United Soybean Board.

Woerfel, J. B. 1995. Extraction. In Practical handbook of soybean processing and utilization. Edited

by D. R. Erickson. Champaign, IL: American

Oil Chemists Society Press and United Soybean

Board.

About the Authors

Shelie A. Miller is a graduate student at the Institute for Environmental Science and Policy at the University of Illinois at Chicago in Chicago, Illinois, USA,

where Thomas L. Theis is the Institutes director.

Miller and Theis, Comparison of LCI Databases: Soybean Production

147

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- DOSF4001-Body Cream Cleanser Course NotesDocument11 paginiDOSF4001-Body Cream Cleanser Course NotesSiglo Cero Riviera Maya Fer in TulumÎncă nu există evaluări

- KEY Macromolecules Chart 2015Document4 paginiKEY Macromolecules Chart 2015Joshua BernilÎncă nu există evaluări

- Advanced PharmacognosyDocument13 paginiAdvanced PharmacognosyLisa DamayantiÎncă nu există evaluări

- Conceptual Density Functional Theory PDFDocument82 paginiConceptual Density Functional Theory PDFAurélio Moreira100% (1)

- Genie: Hot Water Driven Vapor Absorption MachineDocument39 paginiGenie: Hot Water Driven Vapor Absorption MachineObayomi KennyÎncă nu există evaluări

- Cryocap Air Liquide - BrochureDocument20 paginiCryocap Air Liquide - BrochurePriyanshi VÎncă nu există evaluări

- Kanthal Appliance Heating Alloys Handbook PDFDocument33 paginiKanthal Appliance Heating Alloys Handbook PDFwillwÎncă nu există evaluări

- Manufacturing Ammonia Using The Haber Process: BSC IllDocument8 paginiManufacturing Ammonia Using The Haber Process: BSC Illdigukharade9848Încă nu există evaluări

- T.9.2.7 Reinforcing For Shear - EUROCODE2: RAPT User ManualDocument16 paginiT.9.2.7 Reinforcing For Shear - EUROCODE2: RAPT User Manualtailieuxaydung2019Încă nu există evaluări

- Cambridge IGCSE (9-1) : PHYSICS 0972/41Document16 paginiCambridge IGCSE (9-1) : PHYSICS 0972/41dowanahamidÎncă nu există evaluări

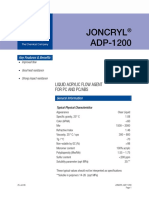

- 1200 TDSDocument2 pagini1200 TDSRoxana LencinaÎncă nu există evaluări

- Ceilcote 2000 Flakeline+ds+engDocument4 paginiCeilcote 2000 Flakeline+ds+englivefreakÎncă nu există evaluări

- Enhanced Hybrid Science 6 Quarter1 Module 1 Week1Document10 paginiEnhanced Hybrid Science 6 Quarter1 Module 1 Week1KATHLENE CORPUS100% (1)

- Class11 - Environmental ChemistryDocument3 paginiClass11 - Environmental Chemistryh_fazilÎncă nu există evaluări

- Figure 1: Coordinate of Plant LocationDocument11 paginiFigure 1: Coordinate of Plant LocationJonathon John100% (1)

- June 2017 (v1) QP - Paper 6 CIE Biology IGCSEDocument12 paginiJune 2017 (v1) QP - Paper 6 CIE Biology IGCSEbandana dekaÎncă nu există evaluări

- Edexcel Science Past Paper 2020Document17 paginiEdexcel Science Past Paper 2020Rumika PereraÎncă nu există evaluări

- Pta Petrochemical ProcessDocument27 paginiPta Petrochemical ProcessMugiiz BhattiÎncă nu există evaluări

- Reasons to Replace Expired Fire ExtinguishersDocument3 paginiReasons to Replace Expired Fire ExtinguishersswapnilmanwtkarÎncă nu există evaluări

- Alcohol DistillationDocument4 paginiAlcohol DistillationprocesspipingdesignÎncă nu există evaluări

- Analisis de Gas de Aceite de Transformador Utilizando Una Columna de Separacion Astm d3612 KasalabDocument2 paginiAnalisis de Gas de Aceite de Transformador Utilizando Una Columna de Separacion Astm d3612 KasalabJohnatan HernándezÎncă nu există evaluări

- Marshall Tufflex: GRP Cable Management SystemsDocument18 paginiMarshall Tufflex: GRP Cable Management SystemsGabriel BroascaÎncă nu există evaluări

- Novabrite RGB Full Color High Power Led Application Note: R&D CenterDocument15 paginiNovabrite RGB Full Color High Power Led Application Note: R&D CenterVinu KumarÎncă nu există evaluări

- SY 2022-2023 Updated Chem 301 Biochem Lec Synch and AsynchDocument3 paginiSY 2022-2023 Updated Chem 301 Biochem Lec Synch and AsynchLYKA ANTONETTE ABREGANAÎncă nu există evaluări

- Booster in Sunscreen INOLEX PDFDocument18 paginiBooster in Sunscreen INOLEX PDFrenatoporangaÎncă nu există evaluări

- International Maritime Dangerous Goods CodeDocument8 paginiInternational Maritime Dangerous Goods CodeSachin chaudharyÎncă nu există evaluări

- College of Engineering and Computer TechnologyDocument2 paginiCollege of Engineering and Computer TechnologyRoss Sonny CruzÎncă nu există evaluări

- ATP Production From Carbs Protein FatsDocument16 paginiATP Production From Carbs Protein Fatshuraira bhattiÎncă nu există evaluări

- Lattice VibrationDocument21 paginiLattice VibrationPandu lalÎncă nu există evaluări

- Density Calculations Worksheet IDocument2 paginiDensity Calculations Worksheet Iapi-218999959Încă nu există evaluări