Documente Academic

Documente Profesional

Documente Cultură

Standards Chemical Composition in % C 0.45

Încărcat de

kazdoelahDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Standards Chemical Composition in % C 0.45

Încărcat de

kazdoelahDrepturi de autor:

Formate disponibile

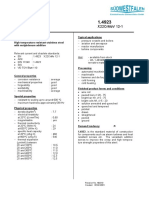

Cold Work Tool Steel with High Wear Resistance

2379 DIN X 153 CrMoV 12

Standards Europe : DIN EN ISO 4957; USA : ASTM A 681 / SAE J 438 B

Chemical C Si Mn P S Cr Mo V

Composition in % 0.45 - 1.60 0.30 - 0.50 0.30 - 0.50 < 0.030 < 0.030 11.00 - 13.00 0.70 - 1.00 0.70 - 1.00

Material High wear resistance; Relatively good toughness for a 12%-Cr ledeburitic steel; Resistant to tempering;

Characteristics Good cutting ability

A martensitic microstructure will be obtained in the core of bars up to a diameter 120 mm on hardening. Up

Transformation to a diameter of roughly 350 mm a martensitic / baintic structure will be obtained after hardening treatment,

Characteristics

o o o

Transformation temperatures : Ac1b :~790 C; Ac1e :~870 C; Ms:~180 C

Threading dies and rolls; Tools for cold forging; Tools for cutting and stamping sheets; Tools for deep

Applications drawing; Cutting and shearing blades; High resistance moulds for forming reinforced plastics; Cold pilger

mandrels.

Delivery Condition Annealed

Hardening Tempering Soft Annealing Hot Forming

Heat Treatment 0 830 - 860 0C with 850 - 1050 0C with

1000-1070 C / oil or Salt

170 - 190 0C subsequent slow cooling subsequent slow cooling

Bath 500-550oC

(e.g in furnance) (e.g in furnance)

Hardened 50oC o

100 C

o

150 C 200 C

o o

250 C

o

300 C

o

350 C

Hardness HRC in ~ 63.0 ~ 63.0 ~ 63.0 ~ 62.5 ~ 60.5 ~ 59.0 ~ 58.0 ~ 58.0

hardened and

o o o o o o

tempered condition 400 C 450 C 500 C 525 C 550 C 600 C

~ 58.0 ~ 58.0 ~ 58.0 ~ 60.0 ~ 56.0 ~ 51.0

Annealed

Hardness (HB)

Max. 255 HB

o 3

Density at 20 C approx. 7.80 kg / dm

20oC 100oC o

200 C

o

300 C

Heat Conductivity in W / ~17.5 ~18.5 ~19.4 ~20.0

(K*m) o

400 C

o

500 C

o

700 C

~21.7 ~ 22.6 ~ 23.8

o o o

20-100 C 20-200 C 20-300 C

Average Coefficient of ~ 10.7 ~ 11.3 ~11.8

Thermal Expansion in o o

20-400 C 20-500 C

10E-06 / K;

Physical Properties ~ 12.2 ~12.4

o o o o

20 C 100 C 200 C 300 C

Specific Electrical ~0.453 ~0.515 ~0.596 ~0.695

Resistance in

o o

Ohm*mm /m

2 400 C 500 C

~0.798 ~0.908

o

20 C 100oC o

200 C

Modulus of elasticity in ~215 ~211 ~ 204

Gpa o

300 C

o

400 C

o

500 C

~ 198 ~191 ~ 182

T emper-Hardness Diagram of Steel 1.2379

70

60

Hardness in °C

50

40

30

20

10

0

0 50 100 150 200 250 300 350 400 450 500 550 600

Te m pe ring Te m pe ra ture in °C

ISAN METALL

A Division of Otto Wolff Handelsgesellschaft mbH

ThyssenKrupp Services AG

Our official trading arm in Indonesia :

Jl. P. Jayakarta 24/10, Jakarta 10730 Tel .(021) 639-3933 Fax. (021) 639-8906

Website: www.krupindo.com E-mail : info@krupindo.com

S-ar putea să vă placă și

- Pitch AnythingDocument8 paginiPitch AnythingDoland drumb100% (1)

- Database Management Systems: Understanding and Applying Database TechnologyDe la EverandDatabase Management Systems: Understanding and Applying Database TechnologyEvaluare: 4 din 5 stele4/5 (8)

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopDe la EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopEvaluare: 4.5 din 5 stele4.5/5 (2)

- Company Profile 4Document54 paginiCompany Profile 4Khuloud JamalÎncă nu există evaluări

- CYPE 2021 + CYPE ArchitectureDocument15 paginiCYPE 2021 + CYPE ArchitectureHajar CypeMarocÎncă nu există evaluări

- Auditing Multiple Choice Questions and Answers MCQs Auditing MCQ For CA, CS and CMA Exams Principle of Auditing MCQsDocument30 paginiAuditing Multiple Choice Questions and Answers MCQs Auditing MCQ For CA, CS and CMA Exams Principle of Auditing MCQsmirjapur0% (1)

- RTD IncotestDocument2 paginiRTD IncotestJabari KaneÎncă nu există evaluări

- 1.7225 en PDFDocument2 pagini1.7225 en PDFTheodoros AtheridisÎncă nu există evaluări

- Leadership Nursing and Patient SafetyDocument172 paginiLeadership Nursing and Patient SafetyRolena Johnette B. PiñeroÎncă nu există evaluări

- Cold Work Tool Steel DIN 100 MNCRWDocument2 paginiCold Work Tool Steel DIN 100 MNCRWkazdoelahÎncă nu există evaluări

- Aisi M42 DIN 3247: StandardsDocument1 paginăAisi M42 DIN 3247: Standardswalid larouiÎncă nu există evaluări

- Aisi M2 DIN 3343: 770-860 Furnace FurnaceDocument1 paginăAisi M2 DIN 3343: 770-860 Furnace FurnaceMichel MancillaÎncă nu există evaluări

- High Tensile: Voestalpine High Performance Metals (Australia) Pty LTDDocument5 paginiHigh Tensile: Voestalpine High Performance Metals (Australia) Pty LTDSinan YıldızÎncă nu există evaluări

- Aisi 01 Din 2: It1Il - TtttiDocument1 paginăAisi 01 Din 2: It1Il - TtttiFebri SSÎncă nu există evaluări

- 39nicrmo3 en 10083-3: 2006: End Quench Hardenability Test TemperingDocument1 pagină39nicrmo3 en 10083-3: 2006: End Quench Hardenability Test Temperingvo thanh lamÎncă nu există evaluări

- 1 3243hs652513 PDFDocument1 pagină1 3243hs652513 PDFmarko9292Încă nu există evaluări

- X22CrMoV 12-1Document2 paginiX22CrMoV 12-1Prasad RvsÎncă nu există evaluări

- 20160401114119-6566 6569 6571 17NiCrMo64 17NiCrMoS64 20NiCrMoS64Document1 pagină20160401114119-6566 6569 6571 17NiCrMo64 17NiCrMoS64 20NiCrMoS64Önder YontarÎncă nu există evaluări

- 20160401114119-6566 6569 6571 17NiCrMo64 17NiCrMoS64 20NiCrMoS64Document1 pagină20160401114119-6566 6569 6571 17NiCrMo64 17NiCrMoS64 20NiCrMoS64Önder YontarÎncă nu există evaluări

- SKT 11Document1 paginăSKT 11aadhavan rÎncă nu există evaluări

- 34crnimo6: Steel GradeDocument4 pagini34crnimo6: Steel Gradeanu swamiÎncă nu există evaluări

- Steel Grade: Material Data SheetDocument3 paginiSteel Grade: Material Data Sheetreza amiriniaÎncă nu există evaluări

- 1 2344 PDFDocument2 pagini1 2344 PDFtayefehÎncă nu există evaluări

- Sae 1045Document1 paginăSae 1045Martin UrrizaÎncă nu există evaluări

- 1.3505 100cr6 PDFDocument1 pagină1.3505 100cr6 PDFmcÎncă nu există evaluări

- 1022 Carbon Steel Bar PDFDocument3 pagini1022 Carbon Steel Bar PDFjeyakumarÎncă nu există evaluări

- Precipitation Hardening Stainless Steel: Voestalpine High Performance Metals (Australia) Pty LTDDocument3 paginiPrecipitation Hardening Stainless Steel: Voestalpine High Performance Metals (Australia) Pty LTDAtlantic Heat Treat ShopÎncă nu există evaluări

- Electrode Booklet F Web 21Document1 paginăElectrode Booklet F Web 21satnamÎncă nu există evaluări

- AISI 4130: Category Type Steel GradeDocument2 paginiAISI 4130: Category Type Steel Gradetjt4779Încă nu există evaluări

- 16MnCr5 SpesifikasiDocument2 pagini16MnCr5 SpesifikasibagusalienÎncă nu există evaluări

- Werkstoff 1.5217 (20MnV6)Document2 paginiWerkstoff 1.5217 (20MnV6)alextentwentyÎncă nu există evaluări

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 paginiQuenched and Tempered Alloyed Engineering Steel DINkazdoelahÎncă nu există evaluări

- GB Formadur2083Document1 paginăGB Formadur2083ayman emmadÎncă nu există evaluări

- S235JR Sau OL 37Document1 paginăS235JR Sau OL 37Pișta GonzalesÎncă nu există evaluări

- 1.8550 34cralni7 Ni50: Chemical CompositionDocument2 pagini1.8550 34cralni7 Ni50: Chemical CompositionMichel PortalÎncă nu există evaluări

- NIC Component Series NTIDocument4 paginiNIC Component Series NTINICCompÎncă nu există evaluări

- Westermann Tables: Steels For Hardening and TemperingDocument1 paginăWestermann Tables: Steels For Hardening and Temperingmuhd.qasimÎncă nu există evaluări

- Electrode Booklet F Web 73Document1 paginăElectrode Booklet F Web 73satnamÎncă nu există evaluări

- Steel Grade: Material Data SheetDocument5 paginiSteel Grade: Material Data Sheetdan howsÎncă nu există evaluări

- 42 CR Mo 4Document3 pagini42 CR Mo 4lucasÎncă nu există evaluări

- CaseHard AISI8620Document2 paginiCaseHard AISI8620Anonymous B3I6zYNhqdÎncă nu există evaluări

- CPM Magnacut - Technical Data: Your in Specialty MetalsDocument2 paginiCPM Magnacut - Technical Data: Your in Specialty MetalscpÎncă nu există evaluări

- 94B15, 94B15HDocument2 pagini94B15, 94B15HGil CabreraÎncă nu există evaluări

- Electrode Booklet F Web 23Document1 paginăElectrode Booklet F Web 23satnamÎncă nu există evaluări

- Quality C10E: Lucefin GroupDocument3 paginiQuality C10E: Lucefin Grouptuananh638Încă nu există evaluări

- Quality C10E: Lucefin GroupDocument3 paginiQuality C10E: Lucefin Grouptuananh638Încă nu există evaluări

- Wb35S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 paginăWb35S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78Încă nu există evaluări

- Tenalloy Z PlusDocument1 paginăTenalloy Z Plushemal ChauhanÎncă nu există evaluări

- Hussey Copper Electrolytic Tough Pitch CDA Copper C 110 00Document1 paginăHussey Copper Electrolytic Tough Pitch CDA Copper C 110 00Michael DoyleÎncă nu există evaluări

- Construction Materials For Pressure Vesel NewDocument34 paginiConstruction Materials For Pressure Vesel NewArun ArumugamÎncă nu există evaluări

- Tempering Conditions For 30CrNiMo8Document2 paginiTempering Conditions For 30CrNiMo8madyeÎncă nu există evaluări

- Cosmos Alminium-Technical - Specifications PDFDocument2 paginiCosmos Alminium-Technical - Specifications PDFmindsopenÎncă nu există evaluări

- Tenalloy 125: LOW ALLOY STEEL (High Strength)Document1 paginăTenalloy 125: LOW ALLOY STEEL (High Strength)satnamÎncă nu există evaluări

- Product Catalog AluminiuDocument32 paginiProduct Catalog AluminiusnoofsnoofÎncă nu există evaluări

- Quality 16Mncr5: Lucefin GroupDocument2 paginiQuality 16Mncr5: Lucefin GroupPrasadÎncă nu există evaluări

- Profile Soldering VishayDocument2 paginiProfile Soldering VishayRafael Palhas DomingosÎncă nu există evaluări

- AISI 4140 Steel, Oil Quenched, 650°C (1200°F) Temper, 25 MM (1 in PDFDocument2 paginiAISI 4140 Steel, Oil Quenched, 650°C (1200°F) Temper, 25 MM (1 in PDFDiegoAlvarezHuguezÎncă nu există evaluări

- Bohler Fox N CM 2 KBDocument1 paginăBohler Fox N CM 2 KBkamals55Încă nu există evaluări

- 30crnimo8: Steel GradeDocument2 pagini30crnimo8: Steel GradewemersonsrÎncă nu există evaluări

- 20 MN CR 5Document2 pagini20 MN CR 5sansmgÎncă nu există evaluări

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 paginiQuenched and Tempered Alloyed Engineering Steel DINkazdoelahÎncă nu există evaluări

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 paginiQuenched and Tempered Alloyed Engineering Steel DINkazdoelahÎncă nu există evaluări

- Annealed Engineering Steel C45E / 1042 (ASTMDocument2 paginiAnnealed Engineering Steel C45E / 1042 (ASTMkazdoelahÎncă nu există evaluări

- Steel Comp A Ration TableDocument1 paginăSteel Comp A Ration TablekazdoelahÎncă nu există evaluări

- Manganese Steel 3401Document1 paginăManganese Steel 3401kazdoelahÎncă nu există evaluări

- Digital Speed Control of DC Motor For Industrial Automation Using Pulse Width Modulation TechniqueDocument6 paginiDigital Speed Control of DC Motor For Industrial Automation Using Pulse Width Modulation TechniquevendiÎncă nu există evaluări

- Chapter 2.2 Quantitative Analysis NewDocument44 paginiChapter 2.2 Quantitative Analysis NewMinase TilayeÎncă nu există evaluări

- FDP VLSI Design at Deep Submicron Node PDFDocument2 paginiFDP VLSI Design at Deep Submicron Node PDFpraneethshubÎncă nu există evaluări

- Do I Need A 1PPS Box For My Mulitbeam SystemDocument3 paginiDo I Need A 1PPS Box For My Mulitbeam SystemutkuÎncă nu există evaluări

- NST 029Document123 paginiNST 029Riaz Ahmad BhattiÎncă nu există evaluări

- Résumé Emily Martin FullDocument3 paginiRésumé Emily Martin FullEmily MartinÎncă nu există evaluări

- File 1038732040Document70 paginiFile 1038732040Karen Joyce Costales MagtanongÎncă nu există evaluări

- AAPG 2012 ICE Technical Program & Registration AnnouncementDocument64 paginiAAPG 2012 ICE Technical Program & Registration AnnouncementAAPG_EventsÎncă nu există evaluări

- Cet Admissions 2018 FinalDocument225 paginiCet Admissions 2018 FinalkiranÎncă nu există evaluări

- d10 Sandra Darby FinalDocument3 paginid10 Sandra Darby FinalFirstCitizen1773Încă nu există evaluări

- Distribution of Continuous R.V.: Normal Distribution (CH 1.4) TopicsDocument7 paginiDistribution of Continuous R.V.: Normal Distribution (CH 1.4) TopicsPhạm Ngọc HòaÎncă nu există evaluări

- Max9924 Max9927Document23 paginiMax9924 Max9927someone elseÎncă nu există evaluări

- INA Over Drive Pulley SystemDocument1 paginăINA Over Drive Pulley SystemDaniel JulianÎncă nu există evaluări

- Regression Week 2: Multiple Linear Regression Assignment 1: If You Are Using Graphlab CreateDocument1 paginăRegression Week 2: Multiple Linear Regression Assignment 1: If You Are Using Graphlab CreateSamÎncă nu există evaluări

- Description - GB - 98926286 - Hydro EN-Y 40-250-250 JS-ADL-U3-ADocument6 paginiDescription - GB - 98926286 - Hydro EN-Y 40-250-250 JS-ADL-U3-AgeorgeÎncă nu există evaluări

- Form 1 1 MicroscopeDocument46 paginiForm 1 1 MicroscopeHarshil PatelÎncă nu există evaluări

- Consequences of Self-Handicapping: Effects On Coping, Academic Performance, and AdjustmentDocument11 paginiConsequences of Self-Handicapping: Effects On Coping, Academic Performance, and AdjustmentAlliah Kate SalvadorÎncă nu există evaluări

- Chapter 3: Verbal Communication SkillsDocument14 paginiChapter 3: Verbal Communication SkillsFares EL DeenÎncă nu există evaluări

- DR - Rajinikanth - Pharmaceutical ValidationDocument54 paginiDR - Rajinikanth - Pharmaceutical Validationمحمد عطاÎncă nu există evaluări

- Perbandingan Implementasi Smart City Di Indonesia: Studi Kasus: Perbandingan Smart People Di Kota Surabaya Dan Kota MalangDocument11 paginiPerbandingan Implementasi Smart City Di Indonesia: Studi Kasus: Perbandingan Smart People Di Kota Surabaya Dan Kota Malanglely ersilyaÎncă nu există evaluări

- 10 - SHM, Springs, DampingDocument4 pagini10 - SHM, Springs, DampingBradley NartowtÎncă nu există evaluări

- Feb-May SBI StatementDocument2 paginiFeb-May SBI StatementAshutosh PandeyÎncă nu există evaluări

- Datasheet - HK ml7012-04 3364913Document22 paginiDatasheet - HK ml7012-04 3364913kami samaÎncă nu există evaluări

- WDP Process Diagrams v1Document6 paginiWDP Process Diagrams v1Ryan HengÎncă nu există evaluări