Documente Academic

Documente Profesional

Documente Cultură

RINNER Motor 57 Series

Încărcat de

char_lynDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

RINNER Motor 57 Series

Încărcat de

char_lynDrepturi de autor:

Formate disponibile

Top speed on 37 Series Code 62 is 1100 RPM

37 CID

32 CID

26 CID

20 CID

16 CID

12 CID

1200

T

O

R

Q

U

E

SPEED - RPM

1000

A

N

D

800

37 CID

32 CID

26 CID

20 CID

16 CID

12 CID

1800

600

400

1500

1200

All values are theoretical

and are affected by oil

viscosity and temperature.

200

0

2100

TORQUE - FT. LBS.

1400

S

P

E

E

D

CODE 62 HIGH PERFORMANCE MOTOR

Features:

Code 62 Ports - 4500 PSI Continuous

5000 PSI Intermittent

Higher Speeds up to 1100 RPM

Up to 300 Horsepower Output

900

600

Tapered Roller Bearings

with Increased Radial

and Axial Capacity

Larger Diameter Output Shafts

300

0

0 10 20 30 40 50 60 70 80 90 100 110

FLOW - GPM

500 1K 1500 2K 2500 3K 3500 4K 4500

PRESSURE - PSI

Model Code

37D2 / 37D4

-2S

-037

-31

-T1

-DVD

Seal Package Selection

37D2 = 37 C62

37D4 = 37 4-Port C62

012 = 12 in3 (197cc)/rev.

016 = 16 in3 (262cc)/rev.

020 = 20 in3 (328cc)/rev.

026 = 26 in3 (426cc)/rev.

032 = 32 in3 (524cc)/rev.

037 = 37 in3 (606cc)/rev.

31 = Splined Shaft

40 = Double Splined

2S = C62 Std.

2L = C62 Low Speed

2H = C62 High Speed

57D2 / 57D4

Double Stacked

or 4-port

Single Stacked

-2S

-048

-31

57D2 = 57 C62

57D4 = 57 4-Port C62

-T1

-DVD

37

57

Bearing Package

Selection

024 = 24 in3 (393cc)/rev.

028 = 28 in3 (459cc)/rev.

032 = 32 in3 (525cc)/rev.

036 = 36 in3 (590cc)/rev.

040 = 40 in3 (656cc)/rev.

046 = 46 in3 (754cc)/rev.

052 = 52 in3 (852cc)/rev.

064 = 64 in3 (1049cc)/rev.

074 = 74 in3 (1213cc)/rev.

096 = 96 in3 (1573cc)/rev.

048 = 48 in3 (787cc)/rev. 103 = 103 in3 (1688cc)/rev.

055 = 55.5 in3 (910cc)/rev. 111 = 111 in3 (1819cc)/rev.

Envelope - 57/37 4-Port

1/2-13

x 1" DEEP

TAPPED

HOLE

15.20

12.45

.48

.75

8.35

B1

6.500

6.498

8.63

5.00

B2

A2

4.81

2.50

EFFECTIVE

SPLINE LG.

A1

Single stack - 37/57 series 112/127 lbs.

Double stack - 37/57 series 149/179 lbs.

4-port 37/57 series 187/216 lbs.

Same starting, stall,

and low speed torque

2-speed operation on 4-port

with some external valving

CROSS SECTION

7.91

2.375

2.370

8.13

6.36

STD. 1/2" O-RING BOSS

CASE DRAIN

(2) PLACES

SAE 4-BOLT FLANGE PORT

CODE 62 HIGH PRESSURE

1-1/4" (4) PLACES

1.50

13.95

1.07

4.44

SAE-FLAT ROOT

SIDE FIT 18T., 8/16

DP., 30 INVOLUTE

SPLINE - CLASS 7

6.36

7.91

.812 DIA. (4) HOLES

331 Breesport San Antonio, Texas 78216 (210)341-6333 Fax: (210)341-1231

Website: www.rineer.com E-mail: sales@rineer.com

Made in U.S.A.

PUBLICATION DS371015 5/02

Technical Information

Envelope Drawing - High Performance Motor - All Displacements

8.50

.48

.75

5.75

2.50

EFFECTIVE

SPLINE LG.

1/2-13

x 1" DEEP

TAPPED

HOLE

4.81

6.500 7.91

6.498

8.63

5.00

2.375

2.370

8.12

SAE 4-BOLT FLANGE PORT

CODE 62 HIGH PRESSURE

1-1/4" (2) PLACES

1.07

7.25

4.44

The Rineer motor produces torque curves which are virtually

flat, with starting and stall torque equal to approximately 9094% of theoretical torque.

MORE POWER STROKES PER REVOLUTION

The 37 Series has four stator cavities and 10 rotor vanes.

Each rotor vane works in each stator cavity once per

revolution, which results in 40 power strokes per revolution.

This helps produce higher mechanical efficiency and flatter

torque curves.

6.36

7.91

.812 DIA. (4) HOLES

NOTE! 57 SERIES IS 1" LONGER

Envelope Drawing - Double Stack High Performance Motor - All Displacements

10.89

.48

2.50

EFFECTIVE

SPLINE LG.

.75

8.14

6.500

6.498

8.63

5.00

1/2-13

x 1" DEEP

TAPPED

HOLE

4.81

6.36

1.50

STD. 1/2" O-RING BOSS

CASE DRAIN

(2) PLACES

9.64

SAE 4-BOLT FLANGE PORT

CODE 62 HIGH PRESSURE

1-1/4" (2) PLACES

1.07

4.44

.48

SAE-FLAT ROOT SIDE

FIT 18T., 8/16 DP.,30

INVOLUTE SPLINE CLASS 7

6.36

7.91

.812 DIA. (4) HOLES

NOTE! 57 SERIES IS 2" LONGER

14.20

6.500

6.498

8.63

5.00

B2

A2

A1

2.375

2.370

8.13

STD. 1/2" O-RING BOSS

CASE DRAIN

(2) PLACES

12.95

SAE 4-BOLT FLANGE PORT

CODE 62 HIGH PRESSURE

1-1/4" (4) PLACES

4.81

2.50

EFFECTIVE

SPLINE LG.

.75

7.35

B1

1.50

1.07

4.44

1/2-13

x 1" DEEP

TAPPED

HOLE

.812 DIA. (4) HOLES

WEIGHT

The weight of the 37/57 series High Performance Motor is as

follows for all displacements:

37 single stack motor = 112 lbs. 57 single stack = 127 lbs.

37 double stk. motor = 149 lbs. 57 double stk. = 179 lbs.

37 4-port motor = 187 lbs.

57 4-port motor = 216 lbs.

FLUID

We suggest premium grade fluids containing high quality rust,

oxidation and foam inhibitors, along with anti-wear additives.

For best performance, viscosity should be maintained between

100 and 200 SUS at operating temperature. Fluid temperature

should not exceed 180O F. Elevated fluid temperature will

adversely affect seal life while accelerating oxidation and fluid

breakdown. Fire resistant fluids may be used with certain

limitations. Contact Rineer for additional information.

CASE DRAIN

The 37 Series High Performance Motor is designed for

external case drain. Two case drain ports are supplied; use the

port at the highest elevation. We recommend case drain

pressure of 35 PSI or less when using the standard seals.

CASE DRAIN CIRCULATION

BEARING LOADING

MOUNTING

SEALS

Viton shaft seals are supplied as standard on the Rineer HP

series motors.

2S or 2L

The 37 Series Motor rotates equally well in either direction

and smoothly throughout its entire pressure and speed

range. Looking into the end of the shaft, rotation is clockwise

when oil is supplied to the ports nearest the shaft output end

(A1 and A2).

6.36

7.91

25 micron minimum.

Female shaft motors are available with either female keyed

or splined output. This shaft configuration allows for quick

and easy installation by utilizing a torque arm mount.

ROTATION

6.36

FILTRATON

Fluid should be circulated through the case when a

temperature differential exists between the motor and the

system in excess of 50O F or when motor output exceeds 150

horsepower. Should this occur, contact a Rineer

Application Engineer.

When rotating at speeds below 500 RPM, 2L (Low

Clearance) design should be used. 2S design should be

used when normal speeds are above 500 RPM.

7.91

SAE-FLAT ROOT SIDE

FIT 18T., 8/16 DP.,30

INVOLUTE SPLINE CLASS 7

NOTE! 57 SERIES IS 2" LONGER

4-Ported motors have displacements normally ranging from

24 in3 to 74 in3 in the 37 series motor and 97 in3 to 114 in3 in

the 57 series motor and are comprised of two rotor stator

packages separated by a mid-inlet housing. This allows the

packages to function individually or in parallel. Any of the

standard displacement packages may be combined to

satisfy total displacement requirements.

The Timken bearings in the 37 Series High Performance

Motor can accept thrust load up to 7,080 lbs. dynamic or

62,000 lbs. static. Radial loading is also permissible up to

9,840 lbs. dynamic or 50,000 lbs. static. For details, request

load vs. RPM & life data. Consult with a Rineer Application

Engineer for optional bearing configurations to match your

application.

Envelope Drawing - 4-Port High Performance Motor - All Displacements

11.45

4-PORTED MOTOR CONFIGURATION

HIGH PERFORMANCE MOTOR, FEMALE SHAFT

7.91

2.375

2.370

8.13

The Rineer patented vane crossing vane design produces

much higher volumetric and mechanical efficiencies than is

possible with a standard vane type design. This design

provides a sealing vane between cavities to improve

mechanical and volumetric efficiencies.

STARTING AND STALL TORQUE

6.36

SAE-FLAT ROOT SIDE

FIT 18T., 8/16 DP.,30

INVOLUTE SPLINE CLASS 7

1.50

STD. 1/2" O-RING

BOSS CASE DRAIN

(2) PLACES

VANE CROSSING VANE

HORSEPOWER LIMITATION

Maximum horsepower limitation may vary with different

applications. When using the 37-57 Series High

Performance Motor above 300 HP, consult a Rineer

Application Engineer.

The mounting position is unrestricted. The shafts, pilots, and

mounting faces should be within .002 TIR.

INTERMITTENT CONDITIONS

Intermittent conditions are to be less than 10% of every minute.

TWO-SPEED OPERATION

The High Performance 4-Ported Motor can be used as a

two-speed when combined with external valving. A series

parallel circuit can only be used when both cartridges are of

equal displacement. A circuit using two-way or logic valves can

be used with equal or unequal displacement cartridges. When

using the logic circuit, it should be connected to insure proper

mixing of oil in the circulating cartridge. Particular attention

should be given to the size and flow capacity, as this valve

must handle the displacement of the circulating cartridge when

in the high speed mode. For example: a 37 C.I.D. + 26 C.I.D. =

63 C.I.D. with speed ratios of 3.08:1 or 1.48:1.

OTHER AVAILABLE MOTORS

For information on additional Rineer Motors, request one of the

following publications:

15 Series ..............................................Publication DS151001

15 Series Two Speed Motor..................Publication DS151002

15 Series Wheel Motor..........................Publication DS151003

37 Series ..............................................Publication DS371003

57 Series ..............................................Publication DS571003

125 Series ............................................Publication DS1251003

S-ar putea să vă placă și

- Code 62: High Performance Motor FeaturesDocument5 paginiCode 62: High Performance Motor FeaturesSACHINÎncă nu există evaluări

- Rcoa1806 03 03Document36 paginiRcoa1806 03 03Fernando Sabino100% (1)

- Hagglunds Viking MK 64 163000 Bo LN 0100Document26 paginiHagglunds Viking MK 64 163000 Bo LN 0100thijssilderhuis100% (1)

- Hägglunds Compact Hydraulic Motor Product ManualDocument25 paginiHägglunds Compact Hydraulic Motor Product ManualP Venkata Suresh100% (2)

- Planetgear Catalog PDFDocument134 paginiPlanetgear Catalog PDFvegamarco80Încă nu există evaluări

- S1 AM019 C DenisonDocument25 paginiS1 AM019 C DenisonEmerson MazzaroloÎncă nu există evaluări

- Rotrex Technical Datasheet C38 RangeDocument7 paginiRotrex Technical Datasheet C38 RangezamporpsÎncă nu există evaluări

- 1GA2GASDocument2 pagini1GA2GASFulton Xavier ZambranoÎncă nu există evaluări

- Axial Piston Motors: Series Fixed Displacement M24 Design D Goldcup M30 Design A Service InformationDocument24 paginiAxial Piston Motors: Series Fixed Displacement M24 Design D Goldcup M30 Design A Service InformationjosueÎncă nu există evaluări

- Amc CrowerDocument3 paginiAmc CrowerPablo Etp100% (1)

- Chevrolet - HYDRAULIC & SOLID CAMSHAFTSDocument48 paginiChevrolet - HYDRAULIC & SOLID CAMSHAFTScrower_scribdÎncă nu există evaluări

- Spec Pump Hd2-4000Document24 paginiSpec Pump Hd2-4000SAKDA MAPRADITKUL100% (2)

- Motor Grader Terex DimensionDocument16 paginiMotor Grader Terex DimensionMaulana Fajriansyah100% (2)

- Series PGP, PGM 620 CharacteristicsDocument13 paginiSeries PGP, PGM 620 CharacteristicsAnonymous OFKjccHOÎncă nu există evaluări

- NissanDocument3 paginiNissancrower_scribdÎncă nu există evaluări

- Big Red 600Document4 paginiBig Red 600sergesxÎncă nu există evaluări

- Amd Amg Afg PDFDocument72 paginiAmd Amg Afg PDFpaulinhacoruÎncă nu există evaluări

- Rexroth Hydraulic Axial Piston A2FM Motor Features and SpecificationsDocument21 paginiRexroth Hydraulic Axial Piston A2FM Motor Features and Specificationstestas cia100% (1)

- HYD. PumpDocument40 paginiHYD. Pumprohitbhat2345Încă nu există evaluări

- Ra 92003 PDFDocument35 paginiRa 92003 PDFferdyak1100% (1)

- Viking: Product ManualDocument26 paginiViking: Product ManualMailson Apaza KatataÎncă nu există evaluări

- Twindisc 1Document4 paginiTwindisc 1Dian SikumbangÎncă nu există evaluări

- Ledeen Actuator General Catalogue - Entire LineDocument24 paginiLedeen Actuator General Catalogue - Entire LineJair LamasÎncă nu există evaluări

- K79746-747 Technical DescriptionDocument12 paginiK79746-747 Technical DescriptionJon Lopez100% (1)

- LEDEEN ActuatorsDocument24 paginiLEDEEN ActuatorssalmonsilalahiÎncă nu există evaluări

- Manual EatonDocument92 paginiManual Eatonruben_cruz_34100% (1)

- Radial piston hydraulic motor technical catalogDocument54 paginiRadial piston hydraulic motor technical catalogBoban SimicÎncă nu există evaluări

- Crower - Barras de Levas ToyotaDocument6 paginiCrower - Barras de Levas ToyotaChristian RedinÎncă nu există evaluări

- Riner Hydraulic MotorDocument6 paginiRiner Hydraulic Motora_salehiÎncă nu există evaluări

- Z Series: Pump Assemblies Custom Built To Your Replacement or New Installation RequirementsDocument8 paginiZ Series: Pump Assemblies Custom Built To Your Replacement or New Installation RequirementsWalter Pachi Venegas AriasÎncă nu există evaluări

- Oldsmobile - HYDRAULIC CAMSHAFTSDocument2 paginiOldsmobile - HYDRAULIC CAMSHAFTScrower_scribdÎncă nu există evaluări

- 1 M2QA - IEC StandardDocument28 pagini1 M2QA - IEC StandardgabrielÎncă nu există evaluări

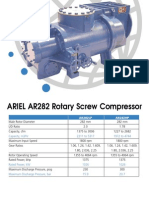

- ARIEL AR282 Rotary Screw Compressor: Capacity, m3/hr 2211 To 5317 1972 To 4744Document2 paginiARIEL AR282 Rotary Screw Compressor: Capacity, m3/hr 2211 To 5317 1972 To 4744michaelxiaoÎncă nu există evaluări

- Compresoras de Tornillo KAISHAN Serie LGDocument8 paginiCompresoras de Tornillo KAISHAN Serie LGcecoelsacÎncă nu există evaluări

- Mud Agitator Manual PDFDocument7 paginiMud Agitator Manual PDFAnonymous JMuM0E5YOÎncă nu există evaluări

- DT190CBROCDocument4 paginiDT190CBROCJhonny RodriguezÎncă nu există evaluări

- Refrigeration Screw Compressors and Chilling Units PDFDocument8 paginiRefrigeration Screw Compressors and Chilling Units PDFAmandeep singhÎncă nu există evaluări

- Waukesha L5794GSI SpecDocument2 paginiWaukesha L5794GSI SpecPaulusIwan100% (3)

- Reductores Browning SMTPDocument68 paginiReductores Browning SMTPEnriqe Puentes0% (1)

- CASE 580 Super R Series 2/590 Super R Series 2 Backhoe Loaders SpecsDocument8 paginiCASE 580 Super R Series 2/590 Super R Series 2 Backhoe Loaders SpecsZelislav Lidija Sirka100% (1)

- Lantec LH Series Hoists CatalogDocument16 paginiLantec LH Series Hoists CatalogAnonymous 1qAH6CKC100% (1)

- Compressor L7044GSI-7045 - 1210Document2 paginiCompressor L7044GSI-7045 - 1210Dedy Chasan Aflah MutoharÎncă nu există evaluări

- RT - 125xxDocument92 paginiRT - 125xxAnGel AmayaÎncă nu există evaluări

- Finisher Ap1000bDocument12 paginiFinisher Ap1000bDaniel FarfanÎncă nu există evaluări

- Install and Maintain Premium Helical Geared MotorsDocument8 paginiInstall and Maintain Premium Helical Geared MotorsKUNALJAYÎncă nu există evaluări

- Product Manual for Hägglunds Drives Viking Hydraulic MotorsDocument26 paginiProduct Manual for Hägglunds Drives Viking Hydraulic MotorsKOSTAS100% (1)

- Grundfosliterature 1191240Document72 paginiGrundfosliterature 1191240Árpád VassÎncă nu există evaluări

- L7044gsi 7045 0710Document2 paginiL7044gsi 7045 0710Martin Alejandro NievaÎncă nu există evaluări

- Rotrex Technical Datasheet C30 Range V4.0Document7 paginiRotrex Technical Datasheet C30 Range V4.0Blake Newman0% (1)

- Bomba Rexroth A4SGCDocument32 paginiBomba Rexroth A4SGCEdgarRetuertoÎncă nu există evaluări

- Waukesha L7042 GSI SpécificationsDocument2 paginiWaukesha L7042 GSI SpécificationssuptedÎncă nu există evaluări

- G20-G30 Series Hydraulico PumpsDocument46 paginiG20-G30 Series Hydraulico PumpsJInna0% (1)

- Hydro 350X: Instruction Manual For ModelDocument13 paginiHydro 350X: Instruction Manual For Modelpython78Încă nu există evaluări

- Honda / AcuraDocument7 paginiHonda / Acuracrower_scribdÎncă nu există evaluări

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDe la EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualÎncă nu există evaluări

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDe la EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualEvaluare: 3.5 din 5 stele3.5/5 (2)

- Essex Terraplane Six 1933 Owner's Manual of InformationDe la EverandEssex Terraplane Six 1933 Owner's Manual of InformationÎncă nu există evaluări

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe la EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceÎncă nu există evaluări

- API HoistingDocument5 paginiAPI Hoistingchar_lynÎncă nu există evaluări

- Townsend - Kb2-Type 81 RepairDocument39 paginiTownsend - Kb2-Type 81 Repairchar_lyn100% (1)

- ApplicationGuide Maximator ProDocument4 paginiApplicationGuide Maximator Prochar_lynÎncă nu există evaluări

- Demco Gate ValveDocument1 paginăDemco Gate Valvechar_lynÎncă nu există evaluări

- DOdgeDocument26 paginiDOdgechar_lynÎncă nu există evaluări

- Wire Thermal SprayDocument6 paginiWire Thermal SprayDeden KurniawanÎncă nu există evaluări

- Oil Country 45000Document70 paginiOil Country 45000char_lyn100% (2)

- Motores Electricos BaldorDocument32 paginiMotores Electricos Baldorchar_lynÎncă nu există evaluări

- Gate Valve MaintenanceDocument8 paginiGate Valve Maintenancechar_lynÎncă nu există evaluări

- Townsend - Kb2-Type 84 RepairDocument35 paginiTownsend - Kb2-Type 84 Repairchar_lyn100% (1)

- Product CatalogueDocument44 paginiProduct CatalogueNitin AggarwalÎncă nu există evaluări

- Owner'S Manual: Installation, Operation and Maintenance Instructions For Rotzler Titan Planetary Hydraulic WinchesDocument44 paginiOwner'S Manual: Installation, Operation and Maintenance Instructions For Rotzler Titan Planetary Hydraulic Wincheschar_lyn100% (1)

- Steam BasicsDocument8 paginiSteam Basicsjoe_pulaskiÎncă nu există evaluări

- Townsend - Kb2-Type 81 RepairDocument39 paginiTownsend - Kb2-Type 81 Repairchar_lyn100% (1)

- Engineering Properties of Drill Pipe CasingDocument14 paginiEngineering Properties of Drill Pipe Casingchar_lynÎncă nu există evaluări

- Maxx ControlDocument4 paginiMaxx Controlchar_lynÎncă nu există evaluări

- Townsend - Kb2-Type 81 RepairDocument39 paginiTownsend - Kb2-Type 81 Repairchar_lyn100% (1)

- 520L0603 - Series 90 Pumps - TI - Rev. F - 03-2004Document68 pagini520L0603 - Series 90 Pumps - TI - Rev. F - 03-2004char_lyn100% (1)

- UnionWireRope Oil and Gas Drilling User GuideDocument16 paginiUnionWireRope Oil and Gas Drilling User Guidechar_lynÎncă nu există evaluări

- Service Manual SectionDocument30 paginiService Manual SectionJKLUIS_593% (14)

- Erin Alles BipDocument39 paginiErin Alles Bipapi-270220688Încă nu există evaluări

- Unit 5 Lesson 5: If I Built A HouseDocument2 paginiUnit 5 Lesson 5: If I Built A HousePlamenna Pavlova PavlovaÎncă nu există evaluări

- 2008 MechDocument80 pagini2008 MechRajesh Kumar DasÎncă nu există evaluări

- #1 Basic Functions of The Hand-1Document29 pagini#1 Basic Functions of The Hand-1Yosep Gustiy PanguestueÎncă nu există evaluări

- Vertical Cross Section ChartDocument1 paginăVertical Cross Section Charthamza elomariÎncă nu există evaluări

- Chapter 10 Meiosis and Sexual Reproduction: Multiple Choice QuestionsDocument12 paginiChapter 10 Meiosis and Sexual Reproduction: Multiple Choice Questionsquiet19Încă nu există evaluări

- Cath Basin: Detailed ofDocument1 paginăCath Basin: Detailed ofGwapo AkoÎncă nu există evaluări

- Hse Management SystemDocument8 paginiHse Management SystemJamie LucasÎncă nu există evaluări

- FET Static CharacteristicDocument4 paginiFET Static CharacteristicAzim Kamal0% (1)

- Thesis Paper Final Report PDFDocument3 paginiThesis Paper Final Report PDFFiraol NegasiÎncă nu există evaluări

- SC upholds conviction of accused who pleaded guilty to kidnapping and murderDocument3 paginiSC upholds conviction of accused who pleaded guilty to kidnapping and murderTelle MarieÎncă nu există evaluări

- TO: Belverd E. Needles, JR., PH.D., CPA, CMA From: Melanie Patton Date: May 9, 2013 SUBJECT: Evaluation of Comptronix CorporationDocument6 paginiTO: Belverd E. Needles, JR., PH.D., CPA, CMA From: Melanie Patton Date: May 9, 2013 SUBJECT: Evaluation of Comptronix CorporationjasminekalraÎncă nu există evaluări

- Meditation GuideDocument168 paginiMeditation Guideaade100% (1)

- CSC 2209 NotesDocument102 paginiCSC 2209 NotesWilliam manzhi KajjubiÎncă nu există evaluări

- Med-Surg Ch25 Patient With Cancer Study Guide and NCLEX QuestionsDocument19 paginiMed-Surg Ch25 Patient With Cancer Study Guide and NCLEX QuestionsKyla Mae JumaritoÎncă nu există evaluări

- Sonovita AWS Presentation SKDocument34 paginiSonovita AWS Presentation SK1234abcdÎncă nu există evaluări

- Maint - N00272a2Document76 paginiMaint - N00272a2bobbyÎncă nu există evaluări

- Katalog Optibelt Remenice PDFDocument128 paginiKatalog Optibelt Remenice PDFluky ivanÎncă nu există evaluări

- Contractor Classification PDFDocument4 paginiContractor Classification PDFKendrick RickÎncă nu există evaluări

- 06 - SS - 09082021 To 20082021 Bridge, SR - DEnDocument52 pagini06 - SS - 09082021 To 20082021 Bridge, SR - DEnAl OkÎncă nu există evaluări

- GstarCAD Mechanical 2020 User Guide PDFDocument238 paginiGstarCAD Mechanical 2020 User Guide PDFlgfldfxhz9Încă nu există evaluări

- Sas Lesson - MathDocument6 paginiSas Lesson - Mathapi-280008473Încă nu există evaluări

- Nature-Based+tourism+and+biodiversity+conservation+in+protected+areas +philippine+contextDocument17 paginiNature-Based+tourism+and+biodiversity+conservation+in+protected+areas +philippine+contextRene John Bulalaque EscalÎncă nu există evaluări

- Line Follower Robot ProjectDocument8 paginiLine Follower Robot ProjectPuneeth ShettigarÎncă nu există evaluări

- Cooling Fan Motor (Spin-on Element) (Square Solenoid Coil) Parts ListDocument2 paginiCooling Fan Motor (Spin-on Element) (Square Solenoid Coil) Parts ListEdgar SanchezÎncă nu există evaluări

- Astm D-3300Document4 paginiAstm D-3300Ovi Nafisa Zabeen OviÎncă nu există evaluări

- BCM Nano Materials PDFDocument1 paginăBCM Nano Materials PDFruchira prathyushaÎncă nu există evaluări

- 14902-37163-1-PB JPVDocument12 pagini14902-37163-1-PB JPVridwanÎncă nu există evaluări

- Communication Network Architecture of A Smart Grid: by Manasa Swamireddy and Koushik PuppalaDocument28 paginiCommunication Network Architecture of A Smart Grid: by Manasa Swamireddy and Koushik Puppalamanasa28112002Încă nu există evaluări

- Competency Appraisal 1Document13 paginiCompetency Appraisal 1Catherine AteradoÎncă nu există evaluări