Documente Academic

Documente Profesional

Documente Cultură

Technical Specifications and GTP For 11KV XLPE Cable SP 574

Încărcat de

hafizrahimmitTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Technical Specifications and GTP For 11KV XLPE Cable SP 574

Încărcat de

hafizrahimmitDrepturi de autor:

Formate disponibile

TENDER No.

: UGVCL/SP/I/CPC/574/2014-15/11KV XLPE Cable

_______________________________________________________________________________________________

1.1

TECHNICAL SPECIFICATION FOR 11 KV XLPE POWER CABLE

(CROSS LINKED POLYTHELENE DRY GAS CURED)

SECTION I

SCOPE:

1.1.1

This Section of the Specification covers design, manufacturing, testing,

packing, supply & delivery of 11 KV XLPE Dry gas cured insulated power

cable for effectively earthed specification system.

1.2

STANDARDS:

1.2.1

Unless otherwise specified, the cable shall conform in all respect to IS:

7098 (Part-II)-1985 with latest amendment thereof.

1.3

1.3.1

CLIMATIC CONDITIONS:

The climatic conditions under which the cables shall operate satisfactorily

are as follows:

Maximum ambient temperature of air

(b)

Minimum ambient temperature of air in shade

(c)

Maximum daily average ambient temperature

(a)

50

40

(d)

Maximum yearly average ambient temperature 0C

30

(e)

Maximum relative humidity

95

(f)

Average number of thunder storm days per annum

15

(g)

Average annual rainfall

cm

150

150

mtrs.

1000

30

C cm/watt

150

(h)

Maximum wind pressure

(i)

Altitudes not exceeding above MSL

(j)

Maximum soil temperature at cable depth

(k)

1.4

1.4.1

Maximum soil thermal resistively

Kg/cm

PRINCIPAL PARAMETERS:

11 KV (E) Grade XLPE, 3-Core, power cable shall be of high conductivity,

stranded compacted, H.D. aluminum circular shaped conductor with XLPE

(cross linked Poly Ethelene) Dry/Gas cured insulation provided with

shielding of extruded semi-conducting materials over conductor and XLPE

insulation. Each insulated core shall have copper tape screen, laid together

and provided with common covering of PVC Inner Sheath (Extruded).

Overall galvanized steel strip armour and PVC outer sheath shall be

provided.

Signature of Tenderer:

Date:

Place:

Companys Round Seal:

Page 1 of 13

TENDER No. : UGVCL/SP/I/CPC/574/2014-15/11KV XLPE Cable

The specification for manufacture of cable shall be conforming to IS: 7098

(Part-II) 1985 (latest edition) for 11KV (E), 3-phase, 50 Hz. Earthed

systems.

1.4.2

Outer sheath shall be designed to afford high degree of mechanical

protection and shall also be heat, oil, chemical and weather resistant,

Common acid, alkalis and sealing solution shall not have adverse effect on

material of PVC sheath.

1.4.3

Cable shall be suitable for laying in covered trenches and / or buried

under-ground in outdoor.

1.4.4

Cable Parameters :

(i)

(ii)

(iii)

(iv)

(v)

(vi)

(vii)

(viii)

(ix)

(x)

Voltage grade (Uo / U) KV

Cores (Nos)

Nominal system voltage KV

Highest system voltage KV

System frequency

Hz

Variation in frequency

%

(a) Maximum allowable temp.

of conductor during

continuous normal operation

at rated full load current. 0C

(b) Maximum allowable temp.

under short circuit condition

0

C

1.2/50 microsecond lightning

impulse withstand voltage wave

value.

KVp

5 Min, Power frequency

withstand voltage

KV rms

System earthling

:

:

:

:

:

:

:

11 KV

6.35 / 11

3

11

12

50

3

90

:

250

75

17

Effectively

Earthed

1.5 GENERAL TECHNICAL REQUIREMENTS:

1.5.1

Conductor:

The cable conductor shall be made from high conductivity stranded High

Density aluminum to form compacted circular shaped conductor having

resistance within limits specified in IS: 8130/1984 and any latest

amendment to it.

1.5.2

Conductor shield:

The conductor having semi-conducing screen shall ensure perfectly smooth

profile & avoid concentration of stress. The conductor screen shall be

extruded in the same operation as the insulation. The semi-conducting

polymer shall be cross linked.

1.5.3

Insulation:

The XLPE insulation shall be suitable for 11 KV system voltage and should

be manufactured with Dry / Gas curing process. The bidder shall submit

the description of dry / gas curing process, with the clear inclusion of

Signature of Tenderer:

Date:

Place:

Companys Round Seal:

Page 2 of 13

TENDER No. : UGVCL/SP/I/CPC/574/2014-15/11KV XLPE Cable

equipments / parameters involved. The manufacturing process shall ensure

that the insulation shall be free of voids. The insulation shall withstand

mechanical and thermal stress under steady state and transient operating

conditions. The extrusion method should give very smooth interface

between semi-conducting screen and insulation. The insulation of the cable

shall be of high standard quality generally conforming to IS: 7098 (Part II)

1985 and any latest amendment to it.

1.5.4

Insulation shield:

Non-metallic semi-conducting shield shall be provided over the insulation

to confine electrical field to the insulation. The insulation shield shall be

extruded in the same operation as the conductor shield and the insulation

by suitable extrusion process. The XLPE insulation shield shall be of tended

type. The copper metallic overlapped tape shield shall be provided.

1.5.5.

Filler and Inner-Sheath:

Fillers and Inner-sheath should be confirming to IS: 7098(Part-II)-1985. The

sheath shall be suitable to withstand the site conditions and the desired

temperature. It shall be of consistent quality and free from all defects. The

PVC sheath shall be extruded. The material of fillers and inner-sheath shall

be compatible with the temperature ratings of the cable and shall have no

deleterious effect on any other component of the cable. Central filler shall

also, be provided with other peripheral fillers to have proper circular

section.

Armour:

Armouring of galvanized steel strip shall be provided. The dimensions of

steel strips shall be as per latest edition of IS: 3975 1979.

1.5.6

1.5.7

1.5.8

1.5.8.1

1.5.8.2

Outer-Sheath:

Extruded type ST-2 PVC outer-sheath, conforming to IS: 5831-(1984)

(latest edition) over armouring with suitable additives (to prevent attack

by redents & termites), shall be provided.

Construction:

The cable shall have suitable fillers laid up with insulation cores to have

subsequently circular cross-section before the inner sheath is applied. The

fillers shall be suitable for operating temperature of the cable.

All materials used in manufacturing of cable shall be new, unused and of

finest quality. All materials should comply with the requirements / tests as

per applicable IS / IEC specification, Indian Electricity Rules and any other

statutory provision of rules & regulations.

1.5.8.3

The PVC material used in the manufacture of cable shall be of reputed

manufacturer. No recycling of PVC is permitted. The purchaser reserves

the right to ask for documentary evidence of the purchase of various

materials, (to be used for the manufacture of cable) as per checking of

quality control. Quality Assurance plans shall be submitted.

1.5.9

Current Rating:

The indicative values of continuous current carrying capacities at

Maximum conductor temperature of 90C (for design purpose by field) of

the various sizes of the cables are given below:

Signature of Tenderer:

Date:

Place:

Companys Round Seal:

Page 3 of 13

TENDER No. : UGVCL/SP/I/CPC/574/2014-15/11KV XLPE Cable

Continuous Current Carrying

Capacity in Amp

(For 11 KV cable)

Sr.

No.

Size of 3 Core Cable

(Sq.mm)

95

185

200

150

235

265

185

270

310

in Air

in Ground

1.5.9.1

Short circuit ratings of various sizes of 3 core cable calculated for duration

of one second at maximum temperature of 2500 C, are given below:

Sr. No.

Size of 3 Core Cable

(Sq. mm)

Conductor short circuit rating in

kA (rms)

(For 11 KV cable)

95

8.93

150

14.1

185

17.4

1.5.9.2

The current rating shall be based on maximum conductor temperature of

900 with ambient site condition specified for continuous operation at the

rated current.

1.5.10

1.5.10.1

Operation :

Cable shall be suitable for operation under frequency variation of +3% and

voltage variation of +10% to -15% and combined frequency - voltage

variation of 10% (absolute sum).

1.5.10.2

Cable shall be suitable for laying in duct or burried underground.

1.5.10.3

Cable shall have heat & moisture resistance properties. These shall be of

type & design with proven record on distribution network service.

1.5.10.4

Length :

The cable shall be supplied in standard drum length of 300 mtrs. 5%

tolerance for all the sizes of cable except for 3 C x 240mm2 and 3 C x 300

mm2 size cable. The drum length for 3 C x 240mm2 and 3C x 300 mm2 cable

shall be 200 mtrs. 5%. Over all tolerance in total quantity of ordered

cables shall be + 2%.

1.5.10.5

Identification Mark:

(i) The cable drum shall be printed with information as per cl. 21.2 of IS

and ISI Certification mark. Bidder shall submit attested photo copy

of valid ISI Licenses with technical bid.

(ii) For identification of cores, coloured strip of Red, Yellow and Blue

colours shall be used for identification of phases. Following details of

identification shall be embossed at intervals of length of one meter of

cable outer sheath.

Signature of Tenderer:

Date:

Place:

Companys Round Seal:

Page 4 of 13

TENDER No. : UGVCL/SP/I/CPC/574/2014-15/11KV XLPE Cable

(iii)

1.6

1.6.1

(a) Name of manufacturer (b) year of manufacture (c) voltage grade

(d) Name of purchaser DGVCL/MGVCL/UGVCL/PGVCL.

TESTS:

(A)

Type Tests:

All the cable sizes i.e. items offered should have been fully type tested as

per the relevant standards at any Govt. recognized Laboratory.

The bidder shall furnish the type test reports along with the offer. These

type tests must have been conducted within last five years prior to date of

Bid opening. For any change in design/type, already type tested and the

design / type offered against this specification, the purchaser reserves the

right to demand reputation of type tests without any extra cost.

The purchaser also reserves the right to have tests carried out at his own

cost by an independent agency, whenever there is a dispute regarding the

quality of supply.

1.6.1

(B) Type tests certificates for following type tests shall be

furnished invariably with the offer:

(a)

(b)

(c)

(d)

(e)

(f)

(g)

(h)

(i)

(j)

(k)

(l)

(m)

Tests on conductor :

(i)

Tensile test

(ii) Wrapping test

(iii) Resistance test

Tests for armouring strips / wires. :

Tests for thickness of insulation and sheath. :

Physical tests for insulation. :

(i)

Tensile strength and elongation at break.

(ii) Ageing in air oven

(iii) Hot set

(iv) Shrinkage test

(v) Water absorption

Physical tests on outer sheath :

(i)

Tensile strength and elongation at break.

(ii) Ageing in air oven

(iii) Shrinkage test

(iv) Hot deformation

Partial discharge test

Bending test

Dielectric power factor test

i)

as a function of voltage

ii)

as a function of temperature

Insulation resistance test (volume resistivity)

Heating cycle test

Impulse withstand test

High voltage test

Flammability test

Signature of Tenderer:

Date:

Place:

Companys Round Seal:

Page 5 of 13

TENDER No. : UGVCL/SP/I/CPC/574/2014-15/11KV XLPE Cable

1.6.2

1.6.2.1

Acceptance Test:

The selection of samples for acceptance test shall be as under.

No. of drums in the

No. of drums to be

Permissible No. of

lot

taken as sample

Defectives

Up to 25

3

0

26 to 50

5

0

51 to 100

8

0

101 to 300

13

1

301 and above

20

1

1.6.2.2

The following acceptance tests shall be carried cut on the selected samples

as per IS: 7098 (Part-II) 1985.

(a)

Annealing test (for copper)

(b)

Tensile test (for aluminum)

(c)

Wrapping test (for aluminum)

(d)

Conductor resistance test.

(e)

Test for thickness of insulation and sheath

(f)

Hot set test for insulation

(g)

Tensile strength and elongation at break test for insulation and

sheath.

(h)

Partial discharge test (for screened cables only)

(i)

High voltage test for 4 hours (as per cl. No. 19.7.1)

(j)

Insulation resistance (volume resistivity) test.

1.6.2.3

All the acceptance tests shall be carried out by the firm, in the presence of

purchasers representative at their works. The firm shall give at least 15

days advance notice to the purchaser to enable him to depute the

engineer for witnessing the tests.

The test certificates for acceptance tests witnessed by inspecting officer/

engineer shall be submitted for approval before dispatch of material.

1.6.3

1.6.3.1

Tests:

The bidder shall have to submit, well in advance, the test certificates for

the following routine test for approval prior to inspection of the materials

for the complete lot offered for inspection at a time.

(a) Conductor resistance test

(b) Partial discharge test

(c) High-voltage test for 5 minutes [as per Clause 19.7.2 of IS: 7098

(Part-II) 1985].

1.7

STAGE INSPECTION:

1.7.1

The inspection may be carried out by the purchaser at any stage of

manufacture. The successful bidder shall grant free access to the

purchasers representative at reasonable time, when the work is in

progress. Inspection and acceptance, of any cables under this specification

by the purchaser, shall not relieve the supplier of his obligation of

Signature of Tenderer:

Date:

Place:

Companys Round Seal:

Page 6 of 13

TENDER No. : UGVCL/SP/I/CPC/574/2014-15/11KV XLPE Cable

supplying cable in accordance with the specification and shall not prevent

subsequent rejection, if the cables are found defective.

1.7.2

The supplier shall keep the purchaser informed in advance about the

programme of manufacturing of cables so that arrangement can be made

for inspection.

1.7.3

The purchaser reserves the right to insist for witnessing the acceptance /

routing tests of the bought out items.

1.8

DOCUMENTATION:

1.8.1

The bidder shall furnish following documents alongwith his offer.

1.8.1.1

Sectional view, showing the General constructional feature with conductor

/ conductor screen / insulation / armouring / inner and outer sheath etc.

1.8.1.2

Drawing of cable drums with details of material dimension and paint etc.

shall be submitted.

1.8.1.3

All the required type test reports for offered items tested at any

Government recognized Laboratory as stated under Clause No. 1.6.1

(B).

1.8.1.4

Literature, pamphlets for the record items.

1.8.1.5

List of orders (size wise) executed during last Three years for supply of

specified sizes of XLPE cables, supplied to State Electricity Boards, Private

firms & MGVCL/DGVCL/UGVCL/PGVCL/GETCO/GUVNL(formerly GEB) etc.

alongwith quantity, value of the orders, year of supply and delivery

schedule. List of orders executed and under execution shall be submitted

separately. The annual turn over in rupees, of the firms to whom the

cables have been supplied during last two years shall be stated.

1.9

1.9.1

PACKING AND FORWARDING:

The cable shall be wound on wooden drums as per IS: 10418 1972 and

packed in drums suitable for vertical / horizontal transport, as the case

may be and shall be suitable to withstand rough handling during transport

and outer storage.

The outer surface of the drum shall be painted with white aluminum pint.

Similarly, the inside surface of drum shall have the protective layer of

varnish / paint to protect it from white ants.

1.9.2

The wooden drums shall be reinforced with steel bends and strips for

better protection.

1.9.3

The ends of the cable shall be sealed by means of non-hygroscopic sealing

materials.

1.9.4

The following information may be stenciled on the drum with either water

proof ink or oil paint:

i.

Reference of IS / IEC standard.

ii.

Manufacturers name or trademark.

iii.

Type of cable and voltage grade.

Signature of Tenderer:

Date:

Place:

Companys Round Seal:

Page 7 of 13

TENDER No. : UGVCL/SP/I/CPC/574/2014-15/11KV XLPE Cable

iv.

No. of cores.

v.

Nominal cross-sectional area of conductor.

vi.

Cable code.

vii.

Length of cable on the drum

viii.

No. of lengths on the drum (if more than one)

ix.

Direction of rotation of drum (by means of an arrow)

x.

Position of outer end of cable

xi.

Gross weight

xii.

Country of manufacture

xiii.

Year of manufacture

xiv.

Reference of A/T No. & date

xv.

Property of DGVCL/MGVCL/UGVCL/PGVCL

xvi.

Name of consignee and the destination.

The drum may also be marked with ISI Certification Mark.

Over and above, name plate of aluminum of suitable size and thickness,

containing all the above information, shall be fixed on the drum in addition

to the painting.

1.9.5

The firm shall be responsible for any damage to the cables during transit

due to improper and inadequate packing. Wherever necessary, proper

arrangement for lifting, such as lifting hooks, shall be provided. Any cable

found short inside the packing cases shall be supplied by the supplier,

without any extra cost.

1.9.6

Each consignment shall be accompanied by a detailed packing list,

containing the following information:

1.10

(a)

Name of consignee

(b)

Details of consignment

(c)

Destination

(d)

Total weight of consignment

(e)

Handling and unpacking instruction

(f)

Bill of materials, indicating contents of each package.

TECHNICAL AND GUARANTEED PARTICULARS:

The bidder shall furnish all Guaranteed Technical Particulars, as called for,

in Appendix - I of this Specification. Particulars, which are subject to

guarantee, shall be clearly identified. Offer not containing these

information will not be considered for acceptance.

Signature of Tenderer:

Date:

Place:

Companys Round Seal:

Page 8 of 13

TENDER No. : UGVCL/SP/I/CPC/574/2014-15/11KV XLPE Cable

1.11

PERFORMANCE CERTIFICATE:

Bidders shall also submit performance reports for the specified size of

cables supplied to other State Electricity Boards / reputed firms, with the

clear indication of the period since when the cables performed satisfactory

service.

1.12

LEGIBLE SUBMISSION:

Only required relevant, legible documents shall be submitted to avoid

delay

due

to

back

reference.

Signature of Tenderer:

Date:

Place:

Companys Round Seal:

Page 9 of 13

TENDER No. : UGVCL/SP/I/CPC/574/2014-15/11KV XLPE Cable

APPENDIX I

SCHEDULE OF GUARANTEED TECHNICAL PARTICULARS FOR 11KV XLPE POWER CABLE

(G.T.P.)

(To be filled in and signed by the Tenderer)

1.00.0

GENERAL:

1.01.0

Name of Manufacturer

:

1.02.0

Place of Manufacturing

:

1.03.0

Applicable standard IS/IEC

:

0

1.04.0

Design ambient temperature C

:

1.05.0

Cable

particulars,

whether, :

Yes/No

confirmed, as per clause 1.5 of

Section I of Technical Specification

2.00.0

CABLES:

185 sqmm

2.01.0

Voltage grade (Uo / U)

:

2.02.0

Whether suitable for neutral :

earthed / unearthed System

2.03.0

Permissible voltage & frequency :

variation for satisfactory operation

2.04.0

Nos. of cores & size

:

2.05.0

Continuous

current

carrying :

capacity

2.05.1

For standard condition as per IS

:

1) In air

(Amp.)

:

2) In ground

( )

:

3) In duct

( )

:

4) In trench

( )

2.05.2

For site condition

:

1) In air

(Amp.)

:

2) In ground

( )

:

3) In duct

( )

:

4) In trench

( )

3.00.0

3.01.0

3.02.0

3.03.0

3.04.0

3.05.0

CONDUCTOR:

Material & its applicable IS.

Shape of conductor

Nominal cross section area (mm2)

Number of wires per core

Nominal diameter & cross section

area of each wire used in each core

of the conductor

4.00.0

4.01.0

4.02.0

4.03.0

4.04.0

CONDUCTOR SCREENING:

Type

Material & its applicable IS.

Continuous working temp 0C

Nominal thickness (mm)

:

:

:

:

:

:

:

:

:

Signature of Tenderer:

Date:

Place:

Companys Round Seal:

Page 10 of 13

TENDER No. : UGVCL/SP/I/CPC/574/2014-15/11KV XLPE Cable

5.00.0

5.01.0

5.02.0

5.03.0

5.04.0

5.05.0

5.06.0

6.00.0

6.01.0

6.02.0

6.03.0

6.04.0

6.05.0

7.00.0

7.01.0

7.02.0

7.03.0

INSULATION:

Material & its applicable IS

Thickness of insulation (mm)

a) Between cores

b) Between cores & inner sheath

Tolerance in thickness (percent) of

insulation

Diameter of core over insulation

(mm)

Specific insulation resistance at

ninety (90) degree Centigrade

(Ohm-Cm)

Whether insulation is removable

without damaging the conductor

INSULATION SCREENING:

Material & its applicable IS.

Thickness (mm):

1) Semi-conducting part

2) Metallic part (copper tape)

Whether overlapping provided for

copper tape

Current carrying capacity

a) Continuous (Amps.)

b) S.C. current duration of

3-Sec. (KA)

Diameter of core over screening

(mm)

:

:

:

:

:

:

:

:

:

:

:

:

:

:

FILLER:

Material & its applicable IS

:

Whether suitable for operating :

temperature of Cable (Yes/ No)

No of fillers provided including :

central filler

8.00.0

8.01.0

8.02.0

8.03.0

8.04.0

INNER SHEATH:

Material & its applicable IS

Extruded or wrapped

Thickness (mm)

Diameter of cable over inner-sheath

(mm)

9.00.0

9.01.0

9.02.0

9.04.0

9.05.0

ARMOURING:

Material & its applicable IS

Type of armouring

Nos. of strips

Diameter of cable over armouring

Yes/No

:

:

:

:

:

:

:

:

Signature of Tenderer:

Date:

Place:

Companys Round Seal:

Page 11 of 13

TENDER No. : UGVCL/SP/I/CPC/574/2014-15/11KV XLPE Cable

9.06.0

Current carrying capacity of armour

a) on continuous basis (Amp)

b) short circuit current duration of

1 sec (KA)

10.00.0

10.01.0

10.02.0

10.03.0

10.04.0

10.05.0

OUTER SHEATH:

Material & its applicable IS.

Thickness of sheath

Tolerance on thickness of sheath

Over all diameter of cable (mm)

Scheme for identification

11.00.0

11.01.0

11.06.0

CABLE CONSTANT:

AC resistance per core at operating

temp. (Ohm/KM)

DC resistance per core at 200C

(Ohm/KM)

Reactance per core (Ohm/KM)

Capacitance per core

(Microfarad/ KM)

Insulation resistance at 270C

(Ohm/ KM)

Loss tangent

11.07.0

Dielectric constant

11.08.0

Maxi. Cable charging current at :

normal operating voltage (Amp/KM)

11.02.0

11.03.0

11.04.0

11.05.0

12.00.0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

OTHER PARAMETERS:

12.01.0

Recommended minimum braiding :

radius (mm)

12.02.0

Safe pulling force

12.03.0

Cable weight (Kg./KM)

13.00.0

CABLE DRUM:

13.01.0

Net weight of cable (Kg.)

13.02.0

Drum weight (Kg.)

13.03.0

Shipping weight (Kg.)

13.04.0

Whether ISI Mark shall be indicated :

on drum

Length of cable per drum (Meter)

:

13.05.0

Yes/No

Signature of Tenderer:

Date:

Place:

Companys Round Seal:

Page 12 of 13

TENDER No. : UGVCL/SP/I/CPC/574/2014-15/11KV XLPE Cable

14.00.0

Whether details shall be embossed :

as stated under Cl. 1.9.4 of

Technical Specification

Yes/ No

15.00.0

Whether

type

test

reports :

submitted, as stated under Cl. 1.6.1

of Technical Specification

Whether drawings submitted as :

specified under Cl. 1.8.1 of

Technical Specification.

Yes/ No

Whether unpriced schedule of :

offered items submitted with

Technical offer.

Yes/ No

16.00.0

17.00.0

Yes/ No

Agreed for page no.1 to 13 as above,

IMPORTANT NOTE: Please sign & seal on each page above. It is mandatory

Signature of Tenderer:

Date:

Place:

Companys Round Seal:

Page 13 of 13

S-ar putea să vă placă și

- 11kv CablesDocument46 pagini11kv CablesS.k. RathÎncă nu există evaluări

- EPR Insulated EVA Sheathed Copper Cable NPCIL SpecificationDocument23 paginiEPR Insulated EVA Sheathed Copper Cable NPCIL SpecificationVarun ThakurÎncă nu există evaluări

- Intruduction Final LVDocument37 paginiIntruduction Final LVmealysrÎncă nu există evaluări

- Determining Cross Section Area of The Protective ConductorDocument4 paginiDetermining Cross Section Area of The Protective ConductorS Amila C RajapaksaÎncă nu există evaluări

- 2 0.2 Acsr Panther Conductor 1 14Document14 pagini2 0.2 Acsr Panther Conductor 1 14Anurag SanodiaÎncă nu există evaluări

- 220kV RRVPNL Cable SpecificationDocument22 pagini220kV RRVPNL Cable Specificationanurag_pugaliaaÎncă nu există evaluări

- Inspection Report For Gemscab LT CablesDocument4 paginiInspection Report For Gemscab LT Cablespb21Încă nu există evaluări

- Is 8623Document19 paginiIs 8623Gaurav AgarwalÎncă nu există evaluări

- 10-Tmss-07-Substation Grounding Materials-R0Document17 pagini10-Tmss-07-Substation Grounding Materials-R0m3eenÎncă nu există evaluări

- 66 KV Single Core XLPE Power Cable PDFDocument11 pagini66 KV Single Core XLPE Power Cable PDFRani VjÎncă nu există evaluări

- 8.I-11 KV Xlpe CablesDocument5 pagini8.I-11 KV Xlpe CablesAnkur SinhaÎncă nu există evaluări

- FEWA HV Joints & TerminationsDocument29 paginiFEWA HV Joints & TerminationsMuhammad RazaÎncă nu există evaluări

- Joints and Terminations of Polymeric Cables For Working Voltages From 6.6 KV Up To and Including 33 KV - Performance Requirements and Type TestsDocument14 paginiJoints and Terminations of Polymeric Cables For Working Voltages From 6.6 KV Up To and Including 33 KV - Performance Requirements and Type TestsPrashant TrivediÎncă nu există evaluări

- Interleaved Bus Bar Explanation PDFDocument4 paginiInterleaved Bus Bar Explanation PDFVikram Singh100% (2)

- Ni-CD Alkaline Battery SpecificationDocument8 paginiNi-CD Alkaline Battery SpecificationAdrianne DouglasÎncă nu există evaluări

- p-29-10 (Power Cables)Document17 paginip-29-10 (Power Cables)sohaib0% (1)

- DGADocument47 paginiDGAAbdullah GhannamÎncă nu există evaluări

- 44AD0600-00-E.02-0002-A4 - Rev 0 - Standard Specification For LCSDocument5 pagini44AD0600-00-E.02-0002-A4 - Rev 0 - Standard Specification For LCSAvinash ShuklaÎncă nu există evaluări

- Advisory Boards 36A 37: Section 35Document48 paginiAdvisory Boards 36A 37: Section 35kittiey100% (6)

- Earthing Protection SpecificationDocument5 paginiEarthing Protection SpecificationNi ReÎncă nu există evaluări

- Is 5484 1997Document9 paginiIs 5484 1997Cristian Walker100% (2)

- Bus Bar Current Carrying CapacityDocument8 paginiBus Bar Current Carrying CapacityMichael Zhang0% (1)

- 11-SDMS-03 REV. 02: Saudi Electricity CompanyDocument17 pagini11-SDMS-03 REV. 02: Saudi Electricity CompanyMalik MalikÎncă nu există evaluări

- Is 398 Part5 1992Document13 paginiIs 398 Part5 1992skc1234Încă nu există evaluări

- Tes P 103.03Document6 paginiTes P 103.03KarthikeyanÎncă nu există evaluări

- ABB (Pro-E Type Test) - PanelDocument16 paginiABB (Pro-E Type Test) - Panelari bowoÎncă nu există evaluări

- NGR Installation GuideDocument10 paginiNGR Installation Guidemartins73Încă nu există evaluări

- P-192-94 WAPDA SPECIFICATION For 132kV CAPACITOR BANKSDocument12 paginiP-192-94 WAPDA SPECIFICATION For 132kV CAPACITOR BANKSHasnain AwanÎncă nu există evaluări

- Ampacities of Underground CablesDocument7 paginiAmpacities of Underground CablessuzanamgÎncă nu există evaluări

- Iec 889Document18 paginiIec 889martinpellsÎncă nu există evaluări

- 12 SwitchyardErectionRev07Document91 pagini12 SwitchyardErectionRev07Rajesh Sirigirisetty SÎncă nu există evaluări

- GTP - 33KV (E) 3C AL XLPE Armd CableDocument1 paginăGTP - 33KV (E) 3C AL XLPE Armd Cableshivam dwivediÎncă nu există evaluări

- 2B P6 MVCC - RDSS - PGVCL - Infra SBD - Part 2 - TS - Version-2 - 28062022Document202 pagini2B P6 MVCC - RDSS - PGVCL - Infra SBD - Part 2 - TS - Version-2 - 28062022Mrugesh Samsung.m31sÎncă nu există evaluări

- IEC 60502 3 6 6kv ArmouredDocument2 paginiIEC 60502 3 6 6kv ArmouredBajjaliÎncă nu există evaluări

- ECS 06-0022 Grid and Primary Earthing Construction PDFDocument38 paginiECS 06-0022 Grid and Primary Earthing Construction PDFRajendra Prasad ShuklaÎncă nu există evaluări

- Cable SizingDocument25 paginiCable Sizing54045114100% (1)

- Technical Specification For Sandwiched BusductDocument12 paginiTechnical Specification For Sandwiched BusductJishnu M PillaiÎncă nu există evaluări

- Safety Clearance For ElectricalDocument24 paginiSafety Clearance For ElectricalbabuaravindÎncă nu există evaluări

- 5.surge ArrestorDocument5 pagini5.surge Arrestorraj_stuff006Încă nu există evaluări

- Total Standard For CablesDocument14 paginiTotal Standard For CablesjamilÎncă nu există evaluări

- Abb 11kv Vd4 VCB CatalogueDocument10 paginiAbb 11kv Vd4 VCB CataloguePithoon UngnaparatÎncă nu există evaluări

- PGCIL Power & Control Cable Rev-5Document14 paginiPGCIL Power & Control Cable Rev-5uttam100% (1)

- Technical Specification FOR 66kV, 132kV & 220 KV XLPE Insulated Single Core Power CableDocument13 paginiTechnical Specification FOR 66kV, 132kV & 220 KV XLPE Insulated Single Core Power CableGokul VenugopalÎncă nu există evaluări

- Specification For BULL Conductor.Document4 paginiSpecification For BULL Conductor.boopelectra100% (2)

- 11 TMSS 10 R0Document0 pagini11 TMSS 10 R0renjithas2005Încă nu există evaluări

- Certificate of Calibration and Conformance: OmicronDocument1 paginăCertificate of Calibration and Conformance: OmicronNadiaÎncă nu există evaluări

- Auto Recloser Solid Type 11KVDocument6 paginiAuto Recloser Solid Type 11KVNajeeb MaghnagÎncă nu există evaluări

- Three Core Cables To VDE 0276Document15 paginiThree Core Cables To VDE 0276A. HassanÎncă nu există evaluări

- ALSTOM Reverse Power Relay CCUM 21 High ResDocument4 paginiALSTOM Reverse Power Relay CCUM 21 High ResArun KumarÎncă nu există evaluări

- Types of Earthing (As Per IEC Standards)Document6 paginiTypes of Earthing (As Per IEC Standards)anuragpugaliaÎncă nu există evaluări

- Section-6 Chapter-1 Part-I Technical Specification For 66 KV (Cross Linked Polyethylene Insulated Power Cable: 1.1 SCOPEDocument5 paginiSection-6 Chapter-1 Part-I Technical Specification For 66 KV (Cross Linked Polyethylene Insulated Power Cable: 1.1 SCOPESandeep SharmaÎncă nu există evaluări

- Technical SpecificationDocument7 paginiTechnical Specificationshivam dwivediÎncă nu există evaluări

- 11kV - 3-C - 300 - AL - Cable - Specification Final PDFDocument18 pagini11kV - 3-C - 300 - AL - Cable - Specification Final PDFShubham BaderiyaÎncă nu există evaluări

- Tech - Spec. 1.1KV Grade Control Cable-2008Document4 paginiTech - Spec. 1.1KV Grade Control Cable-2008Pratik SarkarÎncă nu există evaluări

- FEWA LV Cable SpecsDocument46 paginiFEWA LV Cable Specsjtwani100% (2)

- CSC-XII 1 C Is 7098 Part 2Document8 paginiCSC-XII 1 C Is 7098 Part 2Ashish bhattÎncă nu există evaluări

- 06-POWER AND CONTROL CABLE - Rev5 PDFDocument14 pagini06-POWER AND CONTROL CABLE - Rev5 PDFSanjay RoutÎncă nu există evaluări

- Detail Technical SpecificationDocument39 paginiDetail Technical Specificationshivmishra229Încă nu există evaluări

- BESCOM Technical-Specification-HT-UG-CablesDocument15 paginiBESCOM Technical-Specification-HT-UG-Cablesಪರಮಮಿತ್ರಸಂಪತ್ಕುಮಾರ್ಶೆಟ್ಟಿÎncă nu există evaluări

- CSC XxxxixDocument10 paginiCSC XxxxixAshish bhattÎncă nu există evaluări

- KODIYATTUDocument1 paginăKODIYATTUhafizrahimmitÎncă nu există evaluări

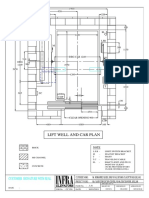

- Infra: Lift Well and Car PlanDocument1 paginăInfra: Lift Well and Car PlanhafizrahimmitÎncă nu există evaluări

- Application For Renewal of Electrical Contractor LicenceDocument1 paginăApplication For Renewal of Electrical Contractor LicencehafizrahimmitÎncă nu există evaluări

- Infra: Lift SpecificationsDocument1 paginăInfra: Lift SpecificationshafizrahimmitÎncă nu există evaluări

- KODIYATUDocument1 paginăKODIYATUhafizrahimmitÎncă nu există evaluări

- Infra: Customer Signature With SealDocument1 paginăInfra: Customer Signature With SealhafizrahimmitÎncă nu există evaluări

- Ledger PDFDocument1 paginăLedger PDFhafizrahimmitÎncă nu există evaluări

- Electrical PDFDocument4 paginiElectrical PDFhafizrahimmitÎncă nu există evaluări

- TKM Institute of Technology: Lecture PlanDocument3 paginiTKM Institute of Technology: Lecture PlanhafizrahimmitÎncă nu există evaluări

- Proposal s8Document1 paginăProposal s8hafizrahimmitÎncă nu există evaluări

- Tour Schedule (S5Eee) : Tour To - COORG-MYSORUDocument1 paginăTour Schedule (S5Eee) : Tour To - COORG-MYSORUhafizrahimmitÎncă nu există evaluări

- Maintain Your Hot EquipmentDocument2 paginiMaintain Your Hot EquipmenthafizrahimmitÎncă nu există evaluări

- Electrical Machines LaboratoryDocument3 paginiElectrical Machines LaboratoryhafizrahimmitÎncă nu există evaluări

- SUB: Permission For Displaying FlexDocument1 paginăSUB: Permission For Displaying FlexhafizrahimmitÎncă nu există evaluări

- TKM Institute of Technology: Karuvelil.P.O, KollamDocument1 paginăTKM Institute of Technology: Karuvelil.P.O, KollamhafizrahimmitÎncă nu există evaluări

- Vaibhav: RJ HuntDocument3 paginiVaibhav: RJ HunthafizrahimmitÎncă nu există evaluări

- New Microsoft Word DocumentDocument12 paginiNew Microsoft Word DocumenthafizrahimmitÎncă nu există evaluări

- TKM Institute of Technology, Karuvelil Department of Computer Sceince & Engineering S7 CSE (2013-2017) BATCHDocument4 paginiTKM Institute of Technology, Karuvelil Department of Computer Sceince & Engineering S7 CSE (2013-2017) BATCHhafizrahimmitÎncă nu există evaluări

- Roll List S2 ECDocument11 paginiRoll List S2 EChafizrahimmitÎncă nu există evaluări

- Current AffairsDocument2 paginiCurrent AffairshafizrahimmitÎncă nu există evaluări

- 1 Female 2 Female 3 Female: Niranjana A Arathy Sreekumar Susmitha SugathanDocument1 pagină1 Female 2 Female 3 Female: Niranjana A Arathy Sreekumar Susmitha SugathanhafizrahimmitÎncă nu există evaluări

- Study of The Further Reduction of Shaft Voltage of Brushless DC Motor With Insulated Rotor Driven by PWM InverterDocument6 paginiStudy of The Further Reduction of Shaft Voltage of Brushless DC Motor With Insulated Rotor Driven by PWM InverterhafizrahimmitÎncă nu există evaluări

- First Name Second Name E Mail Id Talia Jude Reshma VP Haripriya S Anjali A Sambhu Mohan Jaisal ThomasDocument1 paginăFirst Name Second Name E Mail Id Talia Jude Reshma VP Haripriya S Anjali A Sambhu Mohan Jaisal ThomashafizrahimmitÎncă nu există evaluări

- Tour Report s8Document2 paginiTour Report s8hafizrahimmitÎncă nu există evaluări

- Mechanical s2 Roll ListDocument2 paginiMechanical s2 Roll ListhafizrahimmitÎncă nu există evaluări

- S 8 EiDocument11 paginiS 8 EihafizrahimmitÎncă nu există evaluări

- ELECTRICAL LAB Attendance Statement S2ME Feb 16Document9 paginiELECTRICAL LAB Attendance Statement S2ME Feb 16hafizrahimmitÎncă nu există evaluări

- Electrical LabDocument11 paginiElectrical LabhafizrahimmitÎncă nu există evaluări

- ELECTRICAL LAB Attendance Statement S2ME Feb 16Document9 paginiELECTRICAL LAB Attendance Statement S2ME Feb 16hafizrahimmitÎncă nu există evaluări

- Mechanical s2 Roll ListDocument2 paginiMechanical s2 Roll ListhafizrahimmitÎncă nu există evaluări

- Supplier Quality Assurance ManualDocument48 paginiSupplier Quality Assurance ManualRamón G. PachecoÎncă nu există evaluări

- Costco Factoryevaluation 12-Aug-04 ExplanationDocument19 paginiCostco Factoryevaluation 12-Aug-04 ExplanationShaaban NoamanÎncă nu există evaluări

- Configuration & Installation of A Base Transceiver Station (BTS) - Telemax's WeblogDocument4 paginiConfiguration & Installation of A Base Transceiver Station (BTS) - Telemax's WeblogRohail AfzalÎncă nu există evaluări

- Sistemas Hidrostáticos para Rodillos VibratoriosDocument12 paginiSistemas Hidrostáticos para Rodillos VibratoriosJheins GupeÎncă nu există evaluări

- CSM MAXI CompressorDocument8 paginiCSM MAXI Compressorandy131078Încă nu există evaluări

- ABAP - Advanced Debugging - Spider's Web PDFDocument4 paginiABAP - Advanced Debugging - Spider's Web PDFVineetKumarSinghÎncă nu există evaluări

- F913 Gaskets For Joining Plastic PipeDocument5 paginiF913 Gaskets For Joining Plastic Pipelepm30Încă nu există evaluări

- Standby 5 0 0 e K W 6 2 5 K V A 60 HZ 1800 RPM 480 Volts: Diesel Generator SetDocument6 paginiStandby 5 0 0 e K W 6 2 5 K V A 60 HZ 1800 RPM 480 Volts: Diesel Generator Setlpolo12Încă nu există evaluări

- 440001-2 (Ari-Armaturen) Control ValvesDocument36 pagini440001-2 (Ari-Armaturen) Control ValvesnitestarÎncă nu există evaluări

- Technical Bid EvaluationDocument3 paginiTechnical Bid EvaluationAdvisÎncă nu există evaluări

- CD 4071 e CD 4081Document9 paginiCD 4071 e CD 4081Loganh NiassiÎncă nu există evaluări

- Directional Control Valves Ng6 Ng32 Do3 d10 PDFDocument92 paginiDirectional Control Valves Ng6 Ng32 Do3 d10 PDFchidambaram kasiÎncă nu există evaluări

- Mono Pitched Portal Frames in Fire Boundary Conditions: Contact: W I Simms Tel: EmailDocument1 paginăMono Pitched Portal Frames in Fire Boundary Conditions: Contact: W I Simms Tel: EmailJianhua WuÎncă nu există evaluări

- Smart 452Document14 paginiSmart 452Macovei Lucian FlorinÎncă nu există evaluări

- PyPMU - Open Source Python Package For Synchrophasor Data TransferDocument4 paginiPyPMU - Open Source Python Package For Synchrophasor Data Transferwvargas926Încă nu există evaluări

- Ug Awus036achDocument19 paginiUg Awus036achEd PMÎncă nu există evaluări

- 01-OptiX RTN 905 Hardware DescriptionDocument65 pagini01-OptiX RTN 905 Hardware DescriptionPaulo DembiÎncă nu există evaluări

- How To Setup DD-WRT On VirtualboxDocument13 paginiHow To Setup DD-WRT On VirtualboxCamil TipterÎncă nu există evaluări

- 3016c Instruction Manual PDFDocument2 pagini3016c Instruction Manual PDFfranekzapaÎncă nu există evaluări

- Allgon SpecsDocument1 paginăAllgon SpecsMUJTABA RASHID BHATÎncă nu există evaluări

- Dry Van ManualDocument234 paginiDry Van ManualMichael Yoanito Oliviano100% (1)

- Pp1095 Xp95 Is Epg Issue 4Document20 paginiPp1095 Xp95 Is Epg Issue 4Aquitec SeguridadÎncă nu există evaluări

- RRB Alp CBT 1 Paper 31 Aug 2018 Shift 02Document22 paginiRRB Alp CBT 1 Paper 31 Aug 2018 Shift 02maheshÎncă nu există evaluări

- PowerClamping Metric PDFDocument92 paginiPowerClamping Metric PDFdiegomilitojÎncă nu există evaluări

- Plastiment® 100Document3 paginiPlastiment® 100Troy AustinÎncă nu există evaluări

- Uht-56 Asme Viii Div 1 2010Document1 paginăUht-56 Asme Viii Div 1 2010Germán Lobo Clavijo100% (1)

- Android Networking - TutorialDocument4 paginiAndroid Networking - TutorialmurksanÎncă nu există evaluări

- Assessment of Fogging Resistance of AntiDocument6 paginiAssessment of Fogging Resistance of AntiMehrshad GhasemabadiÎncă nu există evaluări

- Essay Regarding Safe Use of RadiationDocument6 paginiEssay Regarding Safe Use of RadiationmaaseialÎncă nu există evaluări

- Building Construction Technology: A Useful Guide - Part 1De la EverandBuilding Construction Technology: A Useful Guide - Part 1Evaluare: 4 din 5 stele4/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDe la EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedEvaluare: 5 din 5 stele5/5 (1)

- Field Guide for Construction Management: Management by Walking AroundDe la EverandField Guide for Construction Management: Management by Walking AroundEvaluare: 4.5 din 5 stele4.5/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDe la EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionEvaluare: 4.5 din 5 stele4.5/5 (2)

- A Place of My Own: The Architecture of DaydreamsDe la EverandA Place of My Own: The Architecture of DaydreamsEvaluare: 4 din 5 stele4/5 (242)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseDe la EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseEvaluare: 5 din 5 stele5/5 (3)

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEDe la EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEEvaluare: 4 din 5 stele4/5 (1)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftDe la EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftEvaluare: 5 din 5 stele5/5 (5)

- Nuclear Energy in the 21st Century: World Nuclear University PressDe la EverandNuclear Energy in the 21st Century: World Nuclear University PressEvaluare: 4.5 din 5 stele4.5/5 (3)

- Civil Engineer's Handbook of Professional PracticeDe la EverandCivil Engineer's Handbook of Professional PracticeEvaluare: 4.5 din 5 stele4.5/5 (2)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsDe la EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsÎncă nu există evaluări

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDe la Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideEvaluare: 3.5 din 5 stele3.5/5 (7)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishDe la EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishEvaluare: 4 din 5 stele4/5 (3)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADe la EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AÎncă nu există evaluări

- How to Build a Tiny Portable House: With Plans and InstructionsDe la EverandHow to Build a Tiny Portable House: With Plans and InstructionsEvaluare: 4 din 5 stele4/5 (1)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsDe la EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsÎncă nu există evaluări

- Construction Project Management 101: For Beginners & New GraduatesDe la EverandConstruction Project Management 101: For Beginners & New GraduatesÎncă nu există evaluări

- Markup & Profit: A Contractor's Guide, RevisitedDe la EverandMarkup & Profit: A Contractor's Guide, RevisitedEvaluare: 5 din 5 stele5/5 (11)

- New Code of Estimating PracticeDe la EverandNew Code of Estimating PracticeÎncă nu există evaluări

- Building Construction and DrawingDe la EverandBuilding Construction and DrawingEvaluare: 2.5 din 5 stele2.5/5 (3)

- Shipping Container Homes: How to build a shipping container home, including plans, cool ideas, and more!De la EverandShipping Container Homes: How to build a shipping container home, including plans, cool ideas, and more!Încă nu există evaluări