Documente Academic

Documente Profesional

Documente Cultură

Ams - Asset Management System

Încărcat de

cleitonmoyaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ams - Asset Management System

Încărcat de

cleitonmoyaDrepturi de autor:

Formate disponibile

Cover Story: Asset management systems increase reliability and efficiency | ISA

Pgina 1 de 5

Search

HOME

FEATURES

DEPARTMENTS

PRODUCTS

COMMUNITIES

WHITE PAPERS

ISA JOBS

E-NEWS

GO

CALENDAR

PEOPLE

CONTRIBUTE

SUBSCRIBE ADVERTISE FEEDBACK ABOUT INTECH CONTACT LOGIN

InTech Home

Home

Coming Next

Comment

Submit Rating

Cover Story: Salary Survey

May/June 2013

COVER STORY

Process Automation: Single-to-Multi-Product

Production Conversion

Factory Automation: System Commissioning &

Startup

Asset management systems increase reliability and

efficiency

System Integration: Specifying Automation

Make use of technology to overcome barriers to better maintenance practices

Special Section: Electrical Test Equipment

Fast Forward

Automation IT: Automation System Lifecycle

Management

Basics: Intrinsic Safety

Asset management software improves work practices, reduces reactive maintenance, and lowers overtime

labor.

Asset diagnostics and other data can be integrated into one holistic reliability performance management

system.

Personnel in plants frequently have no good way of knowing if routine maintenance is being done too often or

not often enough.

By Augie DiGiovanni and John Renick

No matter how well you maintain production assets,

including measurement instruments, control valves, and

mechanical equipment, there is always room for

Ask The Experts

improvement. In fact, the diagnostics and other data

gathered from all those assets can now be integrated into

one holistic reliability performance management system

that will improve maintenance practices and result in

higher reliability. Your plant should be more productive

and deliver larger profits than you are reporting today.

We make that statement with a good deal of confidence,

since maintenance can be improved in most plants.

According to the ARC Advisory Group of Boston, plants in

Read questions answered by our

experts or join the email list.

Feedback Hub

Less theory, more practice and

more

the process industries typically operate 20 percent below full operational capacity, and equipment

reliability issues have been identified as one of the principal reasons for that wasteful record.1

Furthermore, things are not getting better; overall plant maintenance has not improved much in the past

25 years. Despite heavy investments in automation, smart instrumentation, digitally operated control

valves, and smart machinery (all under the umbrella of computerized maintenance management

systems), reactive maintenance (the most expensive but least effective) has remained at about 55

percent.2

Limited manpower is most frequently cited as the greatest barrier to progress, yet nothing saps

manpower like having to respond to unplanned needs, especially emergencies when everyone is called

away from assigned tasks to fight the fire.

Newbie engineers

Sparking an Interest and more

ISA Jobs

Instrumentation Engineer |

Northern Tier Energy

Field Control Engineer |

Colonial Pipeline Company

Instrumentation Technician |

Northern Tier Energy

We believe the best way to overcome the manpower problem and other barriers is by making better use

of technology, including systems that are probably already in your plant. The following summary, which is

based on the actual experience of our customers over a 10-year period, shows just how much can be

accomplished:

Shift maintenance from reactive to predictive while improving uptime by as much as 15 percent

Reduce overtime labor by up to 50 percent

Lower turnaround costs by as much as 30 percent

Increase plant availability by 10 percent or more

Reduce spare parts consumption

What will it take to produce results like this in your plant? Integrate the diagnostics generated by your

smart field devices and predictive data gathered from plant machinery with a reliability asset management

system. Reliable information will be organized to generate work requests to be automatically delivered to

an enterprise asset management (EAM) system. The degree of improvement will depend on the current

state of your maintenance program and the amount of effort you put into the integration of these

technologies.

http://www.isa.org/InTechTemplate.cfm?template=/ContentManagement/ContentDis...

16/09/2013

Cover Story: Asset management systems increase reliability and efficiency | ISA

Pgina 2 de 5

All contents copyright of ISA 1995-2012 All rights reserved.

Getting started

Personnel in plants with thousands of pieces of equipment frequently have no good way of knowing if

routine maintenance is being done too often or not often enough. Nor can they easily identify which

machines, valves, and instruments are causing the most problems. It is equally difficult to identify

equipment on the verge of failure so that immediate repairs can be ordered to prevent sudden work

Find Local Sections | ISA Home | Report a Problem | Privacy &

Legal Policies | Site Map | Help | Contact Us

ISA | 67 T.W. Alexander Drive, Research Triangle Park, NC 27709

USA | (919) 549-8411

stoppages.

An essential element for integrated asset performance management is predictive maintenance software.

Predictive maintenance software, such as AMC Suite, facilitates the online retrieval of accurate, real-time

diagnostics from across a broad scope of plant assets. For smart field devices, such as instruments and

digital valve controllers, data is collected via the HART, WirelessHART, or Foundation Fieldbus

communications protocols. Field device information can also be gathered by technicians attaching a

laptop or field communicator to one instrument at a time. A more progressive approach allows assets to

be monitored continuously. Vibration data can also be obtained online or uploaded to the system from

handheld analyzers or online monitoring systems connected to sensors mounted on rotating machinery.

Data from oil analysis and other diagnostic methods are also available.

The information acquired is organized and displayed on easy-to-read graphical displays on the system. A

single technician can monitor the health of hundreds of assets from the safety of a control room or other

plant location. If the performance of an asset drifts beyond established limits, signals are raised to call

attention to the event.

The predictive maintenance system generates alerts to make personnel aware of slight operating

changes. Generally, minor repairs or adjustments can be made to address such issues, or the condition

may simply be watched for further change.

Alarms indicate a need for corrective action to avoid unplanned downtime. There is generally time to

determine if repairs can be delayed until a favorable time, such as a scheduled maintenance shutdown.

But in severe cases, immediate action may be necessary to prevent an impending failure that could have

costly consequences.

This predictive maintenance software has been instrumental in preventing countless failures and saving

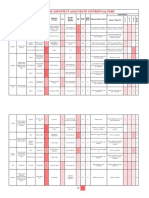

thousands of dollars in losses and manpower expenses. Figure 1 presents actual data collected by a U.S.

chemical company after implementing a system. The application of diagnostic data greatly reduced the

amount of manpower required to annually perform just five labor-intensive tasks. They simply did not

need to be done as often.

Figure 1. Actual data collected by a U.S. chemical company on

savings

Asset management

Each asset management software module contains a database that can be tailored according to the

equipment in any specific plant. The asset names (or tag numbers) are entered along with the threshold

information, i.e., the high and low limits that will trigger alerts and/or alarms. If this information is not

entered correctly, the result can be a flood of erroneous alerts. Operators may become frustrated to the

point that all warnings from the field assets are ignored, especially if the plant seems to be operating

satisfactorily. This, of course, defeats the purpose of early warnings.

The users of this technology do not necessarily know where to set the thresholds for alerts and alarms.

For example, where would you set the high and low vibration limits on rotating pumps, all of which may

have different loads and run at different speeds? In addition, the criticality factors are different for each

machine. Yet, if the limits are not correct, you may never learn about an imminent failure until it is too late.

Asset management requires a substantial amount of experience with the assets and knowledge of the

databases, which is why many users employ experienced industry firms that have subject-matter experts

to configure systems for best results.

http://www.isa.org/InTechTemplate.cfm?template=/ContentManagement/ContentDis...

16/09/2013

Cover Story: Asset management systems increase reliability and efficiency | ISA

Pgina 3 de 5

Figure 2. Not all functions need to be implemented simultaneously you can start small

and build a reliability program to fit your own needs and capabilities

There are a number of asset performance management (APM) functions that should be present in a full

implementation (Figure 2). Users can take a building block approach over time, since not all five APM

modules shown need to be implemented simultaneously. You can start small and build a reliability

program to fit your own needs and capabilities. Vendors provide assistance to guide you, especially in

developing asset strategies, which are critical to the success of the APM process. These strategies are

the culmination of the periodic maintenance tasks and diagnostic tests that must be accomplished in a

well-planned reliability program.

We equate this to the daily tasks required to keep our bodies functioning well: eating properly, getting

enough sleep, exercising regularly, etc. That is the strategy one ought to follow to maintain good personal

health. Just as your doctor employs periodic tests to determine if you have any potential health problems,

many diagnostic tests, such as control valve travel or a motors vibration level, have been developed to

help identify asset health issues that could have an adverse effect on productivity, including unexpected

stoppages.

Once an asset strategy is created and placed in the software, it can be changed as the assets role in the

process becomes more (or less) important. Information flowing into the software may cast a light on

certain tasks that should be performed more or less frequently or possibly discontinued altogether if

deemed unnecessary. Changing work strategies should reflect the operational tempo to which the asset is

subjected.

Systems now are utilizing field-generated data and facilitating the timely preparation of work requests that

are capable of managing high volumes of field-based intelligence and providing a single point of entry to

existing EAM systems. This combines predictive intelligence with asset reliability, enabling real-time

analysis of asset health and availability.

Dashboards can be customized for each user to provide an instant view of the current state of asset

performance, availability, and maintenance (Figure 3). Also displayed are historical charts showing

monthly results for overall equipment effectiveness (OEE), availability, and maintenance costs. Greater

detail can be obtained on any asset simply by clicking on an item.

Figure 3. Dashboards provide users information

Critical asset failures and how much they are costing your plant can be determined (Figure 4). This

enables users to quickly identify where maintenance time and money are being spent, pinpointing pieces

of costly equipment by tag number. Failure information pulled from predictive diagnosis applications and

cost information in EAM records is used to illuminate the bad actors, or assets that require maintenance

too often. The bars on this display indicate the number of time-consuming failures by each asset over the

past year, and the green line shows the total maintenance cost of each piece of equipment. These reports

can be updated frequently, so decisions can be made in real time.

http://www.isa.org/InTechTemplate.cfm?template=/ContentManagement/ContentDis...

16/09/2013

Cover Story: Asset management systems increase reliability and efficiency | ISA

Pgina 4 de 5

Figure 4. Critical asset failures and cost summary information

All plant equipment is prioritized on the basis of failure modes and effects, its operational significance, and

risk of failure. This provides more focus on the assets that are critically important to overall production.

System customization allows specific objectives to be established and tracked. For example, you can

quickly determine whether key established performance indicators are being hit or missed. If overall

equipment effectiveness is declining, those assets contributing to the lackluster performance can be

identified with a single click, so you know instantly where to focus attention to reverse the trend. The

same is true of critical asset availability.

Automated work requests

EAM systems do a wonderful job of creating work orders for maintenance to be accomplished on specific

pieces of equipment, scheduling the work, following up until the job is completed, and archiving a

maintenance history on each asset. However, most work requests are created manually and may be

based on faulty or incomplete information. The subsequent work order may be totally erroneous as a

result.

APM systems automate the creation and submission of accurate and timely work requests to your EAM.

Your maintenance program will change from being predominantly reactive to being much more proactive,

with work scheduled according to well-established performance management benchmarks. That is a

powerful, manpower-saving capability.

The diagnostics can also be used in a predictive manner. Depending on the criticality of the asset and the

severity of its condition, the system may indicate whether to delay repairs until a scheduled shutdown. Or,

if the condition is severe, corrective action may be ordered soon to avoid a failure that could be

catastrophic.

Summary

If your plant is one that operates up to 20 percent below capacity, or if you spend too much time reactively

fighting fires, it is time to improve your maintenance practices. Even if your facility is full of smart

instrumentation, and you are employing an up-to-date EAM, the only way to get the expected results is to

make sure the field-generated diagnostics are utilized to automate the creation of work requests for your

EAM.

Follow this program, and your maintenance practices will be less reactive and overtime labor will be

substantially reduced. Turnaround costs will start to drop, and your spare parts will get more shelf time.

Best of all, you will see availability and uptime increase by as much as 10 percent. We hope you get the

recognition you deserve.

ABOUT THE AUTHORS

John Renick is the partner solutions manager for Meridium, Inc. He has more than 12 years of

experience working with asset-intensive industries. Prior to this position, he was the product manager

overseeing Meridiums APM framework, production loss accounting module, mobile framework, and

Meridium mobile solutions.

Augie DiGiovanni (augie.digiovanni@emerson.com) is vice president of asset optimization services in

Emersons asset optimization business. He is responsible for leading the design, implementation, and

completion of service projects, machinery health management programs, and reliability solutions.

1www.arcweb.com,

Emerson and Meridium Partner to Help Resolve the Asset Performance

Management Puzzle,11/1/2010

2Source:

Maintenance Technology magazine

Post a Comment

Related Files

Cover Story Image

http://www.isa.org/InTechTemplate.cfm?template=/ContentManagement/ContentDis...

16/09/2013

Cover Story: Asset management systems increase reliability and efficiency | ISA

http://www.isa.org/InTechTemplate.cfm?template=/ContentManagement/ContentDis...

Pgina 5 de 5

16/09/2013

S-ar putea să vă placă și

- UptimeDowntimeEventTracking RTtech - SRowlandsDocument56 paginiUptimeDowntimeEventTracking RTtech - SRowlandsalisterjosephÎncă nu există evaluări

- Plant Management TafskillsDocument4 paginiPlant Management TafskillsTHEOPHILUS ATO FLETCHERÎncă nu există evaluări

- Nasa Standardized Facilities Preventive Maintenance Work Task GuideDocument33 paginiNasa Standardized Facilities Preventive Maintenance Work Task Guidekerusacba_2011Încă nu există evaluări

- Instruction Manual 854 Density OptionDocument20 paginiInstruction Manual 854 Density OptionThái NgọcÎncă nu există evaluări

- 3226OSI8 - What Are Recommended Exception and Compression SettingsDocument2 pagini3226OSI8 - What Are Recommended Exception and Compression Settingscleitonmoya0% (1)

- 3226OSI8 - What Are Recommended Exception and Compression SettingsDocument2 pagini3226OSI8 - What Are Recommended Exception and Compression Settingscleitonmoya0% (1)

- Instrumentation Drawings GuideDocument17 paginiInstrumentation Drawings GuideJason GarrettÎncă nu există evaluări

- Downtime AnalysisDocument7 paginiDowntime AnalysisRuchir100% (1)

- Condition Monitoring EbookDocument13 paginiCondition Monitoring EbookFELIX VALERAÎncă nu există evaluări

- Evaluating FMEA, FMECA and FMEDADocument6 paginiEvaluating FMEA, FMECA and FMEDAZakaria RadaÎncă nu există evaluări

- Apm Book PDFDocument314 paginiApm Book PDFZahid MasoodÎncă nu există evaluări

- AV ME SOP 02 Criticality AnalysisDocument4 paginiAV ME SOP 02 Criticality AnalysisjfejfeÎncă nu există evaluări

- An Insider's Guide To CMMS Functions, Selection and ImplementationDocument26 paginiAn Insider's Guide To CMMS Functions, Selection and ImplementationPedro ViegasÎncă nu există evaluări

- TPM Reliability FormulasDocument35 paginiTPM Reliability FormulasjapeleÎncă nu există evaluări

- 1 - Compressors and Surge Control Rev0 - C - S5VDocument103 pagini1 - Compressors and Surge Control Rev0 - C - S5VDev0009100% (1)

- A Two-Stage Failure Mode and Effect Analysis of Offshore Wind Turbines - 2020Document24 paginiA Two-Stage Failure Mode and Effect Analysis of Offshore Wind Turbines - 2020johnÎncă nu există evaluări

- Maintenance Management System Guideline For Maintenance Operating Procedures Global Maintenance Service ManagementDocument43 paginiMaintenance Management System Guideline For Maintenance Operating Procedures Global Maintenance Service ManagementGlad BlazÎncă nu există evaluări

- Rel CodeDocument148 paginiRel CodeJorge FracaroÎncă nu există evaluări

- Alarm Philosophy Tata Steel IJmuidenDocument13 paginiAlarm Philosophy Tata Steel IJmuidenRaul GonzalezÎncă nu există evaluări

- CMMS StrategyDocument12 paginiCMMS StrategyDia Putranto HarmayÎncă nu există evaluări

- Electrical Rotating Machine Asset Performance Management: GE PowerDocument13 paginiElectrical Rotating Machine Asset Performance Management: GE PowerMuhammad Tilal AshrafÎncă nu există evaluări

- Sil PresentationDocument33 paginiSil PresentationValeriano BarrilàÎncă nu există evaluări

- Managing A Condition Monitoring Program: Get The Monitoring Right!Document9 paginiManaging A Condition Monitoring Program: Get The Monitoring Right!Michaelben Michaelben100% (1)

- Total Motor MaintenanceDocument6 paginiTotal Motor MaintenanceWilson PinacateÎncă nu există evaluări

- Maximize Your Uptime: InsulgardDocument8 paginiMaximize Your Uptime: InsulgardAODVÎncă nu există evaluări

- Subject: Production and Operations Management Unit 5: Maintenance and Waste ManagementDocument19 paginiSubject: Production and Operations Management Unit 5: Maintenance and Waste ManagementAnonymous yL88Jj100% (1)

- Equipment Criticality AnalysisDocument20 paginiEquipment Criticality AnalysisArmandoÎncă nu există evaluări

- DNV RAM FPSO White PaperDocument7 paginiDNV RAM FPSO White PaperOkonji C Stephen100% (1)

- Root Cause Analysis: Motivation, Process, Tools, and PerspectivesDocument15 paginiRoot Cause Analysis: Motivation, Process, Tools, and PerspectivesMohamed HamdallahÎncă nu există evaluări

- Plant Wellness Way Book Process3-Numerate Your Options PDFDocument30 paginiPlant Wellness Way Book Process3-Numerate Your Options PDFrbdubey2020Încă nu există evaluări

- Advanced Diagnostics and Prognostics For Gas Turbine Engine Risk AssessmentDocument10 paginiAdvanced Diagnostics and Prognostics For Gas Turbine Engine Risk AssessmentВячеслав НадежкинÎncă nu există evaluări

- Failure Mode Effects and Criticality Analysis PDFDocument2 paginiFailure Mode Effects and Criticality Analysis PDFMacÎncă nu există evaluări

- Application of Reliability Centered Maintenance On A Drilling SystemDocument67 paginiApplication of Reliability Centered Maintenance On A Drilling SystemMohammad Reza NajafiÎncă nu există evaluări

- 1 13936 Fixed Asset Management Evaluation GuideDocument6 pagini1 13936 Fixed Asset Management Evaluation GuideRagul MohanÎncă nu există evaluări

- ARP E Reliability Engineer CourseDocument4 paginiARP E Reliability Engineer CourseLyonelÎncă nu există evaluări

- LCAM Whitepaper 204 PDFDocument7 paginiLCAM Whitepaper 204 PDFShashank JainÎncă nu există evaluări

- Unit 2 Maintenance EnggDocument46 paginiUnit 2 Maintenance EnggVenkadeshwaran KuthalingamÎncă nu există evaluări

- Maintenance Management SystemDocument21 paginiMaintenance Management SystemPrerna Makhijani100% (1)

- Reliability Centered Asset Mgmet For Power SystemDocument8 paginiReliability Centered Asset Mgmet For Power Systemmilne_christopherÎncă nu există evaluări

- Report ReliabilityDocument28 paginiReport ReliabilityKei HotaruÎncă nu există evaluări

- OM Manuals TemplateDocument9 paginiOM Manuals TemplatejanempatricioÎncă nu există evaluări

- Asset Management Practises at Qatargas PDFDocument11 paginiAsset Management Practises at Qatargas PDFJuandeDios Huayllani DelgadoÎncă nu există evaluări

- Isograph RASWG PresentationDocument41 paginiIsograph RASWG Presentationjohn100% (1)

- Maintenance Journal 171fullDocument85 paginiMaintenance Journal 171fullJorge MartinezÎncă nu există evaluări

- 02-Safeethernet 12 e FDocument67 pagini02-Safeethernet 12 e FDario FaoroÎncă nu există evaluări

- Downtime Analysis in Sugar IndustryDocument10 paginiDowntime Analysis in Sugar IndustryAnandNarayanamÎncă nu există evaluări

- Asset Maintenance ManagementDocument28 paginiAsset Maintenance ManagementMayÎncă nu există evaluări

- IBM MaximoHEalth Safety EnvironmentDocument18 paginiIBM MaximoHEalth Safety EnvironmentAkshay PanditaÎncă nu există evaluări

- Fire Protection Standard For Fire Fighting EquipmentDocument57 paginiFire Protection Standard For Fire Fighting Equipmentjonodo89Încă nu există evaluări

- Iso22000 2005Document48 paginiIso22000 2005STELLA MARISÎncă nu există evaluări

- MOC Flow ChartDocument2 paginiMOC Flow ChartImran AhmedÎncă nu există evaluări

- Optimizing Spare Parts ManagementDocument36 paginiOptimizing Spare Parts ManagementBartolomeu SilvaÎncă nu există evaluări

- Top 10 Reasons Why Maintenance Planning Is Not EffectiveDocument7 paginiTop 10 Reasons Why Maintenance Planning Is Not Effectivemenz502Încă nu există evaluări

- W3a Reliability, MTTF, Availability, RedundancyDocument67 paginiW3a Reliability, MTTF, Availability, RedundancyShahid ShajaÎncă nu există evaluări

- 2605 Using SAP To Manage The Root Cause Failure Analysis ProcessDocument27 pagini2605 Using SAP To Manage The Root Cause Failure Analysis Process5starsÎncă nu există evaluări

- Applications of Risk Management Tools in Maintenance Operations of Swedish Industries - A Survey AnalysisDocument111 paginiApplications of Risk Management Tools in Maintenance Operations of Swedish Industries - A Survey AnalysisStanislavÎncă nu există evaluări

- 3BSE065503 C en DCS Life Cycle Parts ServicesDocument16 pagini3BSE065503 C en DCS Life Cycle Parts Servicesjunges99Încă nu există evaluări

- Mobius Institute ARP Brochure Aug 2021Document29 paginiMobius Institute ARP Brochure Aug 2021kalatzoiÎncă nu există evaluări

- Defect EliminationDocument8 paginiDefect EliminationHariKishore SudarsanamÎncă nu există evaluări

- Special Report PDM Guidebook2016Document44 paginiSpecial Report PDM Guidebook2016Vinoth KumarÎncă nu există evaluări

- Failure Mode and Effect Analysis of Centrifugal PumpDocument2 paginiFailure Mode and Effect Analysis of Centrifugal PumpHAFIZMUHAMMAD SAJIDÎncă nu există evaluări

- Inventory Management PowerPoint PresentationDocument30 paginiInventory Management PowerPoint PresentationHisaan KamranÎncă nu există evaluări

- Asset Management A Complete Guide - 2020 EditionDe la EverandAsset Management A Complete Guide - 2020 EditionÎncă nu există evaluări

- Difference Between Acronis Backup 12.5 Standard, Acronis Backup 12.5 Advanced and Acronis True Image 2018 - Knowledge BaseDocument4 paginiDifference Between Acronis Backup 12.5 Standard, Acronis Backup 12.5 Advanced and Acronis True Image 2018 - Knowledge BasecleitonmoyaÎncă nu există evaluări

- 1994 - Recursive-Bayesian-Location-Of-A-Discontinuity-In-Time-SeriesDocument4 pagini1994 - Recursive-Bayesian-Location-Of-A-Discontinuity-In-Time-SeriescleitonmoyaÎncă nu există evaluări

- Rosemount 2120 Vibrating Fork Liquid Level SwitchDocument20 paginiRosemount 2120 Vibrating Fork Liquid Level SwitchcleitonmoyaÎncă nu există evaluări

- Vibration Switches Modelo 365 e 366Document1 paginăVibration Switches Modelo 365 e 366cleitonmoyaÎncă nu există evaluări

- Myths (Vinyl) - Hydrogenaudio KnowledgebaseDocument7 paginiMyths (Vinyl) - Hydrogenaudio KnowledgebasecleitonmoyaÎncă nu există evaluări

- Unsupervised Model Selection For Time-Series Anomaly DetectionDocument25 paginiUnsupervised Model Selection For Time-Series Anomaly DetectioncleitonmoyaÎncă nu există evaluări

- Differences C# X JavaDocument62 paginiDifferences C# X JavacleitonmoyaÎncă nu există evaluări

- Calculate OEE - Definitions, Formulas, and ExamplesDocument4 paginiCalculate OEE - Definitions, Formulas, and ExamplescleitonmoyaÎncă nu există evaluări

- Developmentofan Infinite Series Representationfor Phithe Golden Meanor Golden RatioDocument5 paginiDevelopmentofan Infinite Series Representationfor Phithe Golden Meanor Golden RatiocleitonmoyaÎncă nu există evaluări

- mgpg11 - A Beginner's Guide To Uncertainty of Measurement by Stephanie BellDocument41 paginimgpg11 - A Beginner's Guide To Uncertainty of Measurement by Stephanie Bellarylananyla100% (2)

- Bayes Formula For Medical Decision MakingDocument6 paginiBayes Formula For Medical Decision MakingcleitonmoyaÎncă nu există evaluări

- Accessing ION Enterprise OPC Server On Windows From A Remote ClientDocument5 paginiAccessing ION Enterprise OPC Server On Windows From A Remote ClientcleitonmoyaÎncă nu există evaluări

- Sizing of Relief Valves For Two-Phase Flow in The Bayer ProcessDocument11 paginiSizing of Relief Valves For Two-Phase Flow in The Bayer Processjonyboy_1234915100% (1)

- Manufacturing IT TrendDocument4 paginiManufacturing IT TrendcleitonmoyaÎncă nu există evaluări

- FTP Commands List PDFDocument6 paginiFTP Commands List PDFcleitonmoyaÎncă nu există evaluări

- Advancements in Conformal Coating Process Controls PDFDocument10 paginiAdvancements in Conformal Coating Process Controls PDFcleitonmoyaÎncă nu există evaluări

- A Guard-Band Strategy For Managing False Accept RiskDocument11 paginiA Guard-Band Strategy For Managing False Accept RiskcleitonmoyaÎncă nu există evaluări

- CMX Calibrator SoftwareDocument196 paginiCMX Calibrator SoftwarecleitonmoyaÎncă nu există evaluări

- Uncertinity and Error by NASADocument275 paginiUncertinity and Error by NASAdeepam0187Încă nu există evaluări

- Measurement Uncertainty and Metrological Confirmation in Docuented Quality SystemsDocument5 paginiMeasurement Uncertainty and Metrological Confirmation in Docuented Quality SystemscleitonmoyaÎncă nu există evaluări

- A Guard-Band Strategy For Managing False Accept RiskDocument11 paginiA Guard-Band Strategy For Managing False Accept RiskcleitonmoyaÎncă nu există evaluări

- Calibration Uncertainty ENGDocument7 paginiCalibration Uncertainty ENGmagtrolÎncă nu există evaluări

- Pharmaceutical Company Improves Air FlowDocument2 paginiPharmaceutical Company Improves Air FlowcleitonmoyaÎncă nu există evaluări

- Acidente Carro TeslaDocument4 paginiAcidente Carro TeslacleitonmoyaÎncă nu există evaluări

- mgpg11 - A Beginner's Guide To Uncertainty of Measurement by Stephanie BellDocument41 paginimgpg11 - A Beginner's Guide To Uncertainty of Measurement by Stephanie Bellarylananyla100% (2)

- Acoustics 2008 Acoustics and Sustainability:: How Should Acoustics Adapt To Meet Future Demands?Document9 paginiAcoustics 2008 Acoustics and Sustainability:: How Should Acoustics Adapt To Meet Future Demands?cleitonmoyaÎncă nu există evaluări

- STS CSV ArticleDocument10 paginiSTS CSV ArticleConstantin TomaÎncă nu există evaluări

- Industrial Energy Efficiency Down UnderDocument64 paginiIndustrial Energy Efficiency Down UndercleitonmoyaÎncă nu există evaluări

- Understanding of The ScopeDocument2 paginiUnderstanding of The ScopeSijo JoyÎncă nu există evaluări

- JCCP - Annual Program For FY2022 (Fixed Ver.) - 20220218Document48 paginiJCCP - Annual Program For FY2022 (Fixed Ver.) - 20220218NÄndo PelÄezÎncă nu există evaluări

- FD-BF-001 Foxboro FieldDevices 010715 LowRes PDFDocument24 paginiFD-BF-001 Foxboro FieldDevices 010715 LowRes PDFThiago FernandesÎncă nu există evaluări

- SopDocument1 paginăSopKimberly MitchellÎncă nu există evaluări

- S10332300-3003 - 0 Process MeasurmentDocument27 paginiS10332300-3003 - 0 Process Measurmentappril26Încă nu există evaluări

- API 612 2014 Mechanical Running TestDocument2 paginiAPI 612 2014 Mechanical Running Testşenol LimanÎncă nu există evaluări

- Mr. Jagdish Singh: Scientific Officer Gd-IIDocument2 paginiMr. Jagdish Singh: Scientific Officer Gd-IIPrasad DÎncă nu există evaluări

- Direct 2nd Year ITI MCVC RulesDocument6 paginiDirect 2nd Year ITI MCVC RulesPankaj KulkarniÎncă nu există evaluări

- Electrical Instrumentation ContractorsDocument28 paginiElectrical Instrumentation ContractorsMrudul PatilÎncă nu există evaluări

- Pump Station Checklist & Test ProceduresDocument26 paginiPump Station Checklist & Test Procedurestinkerman02100% (1)

- Soal Quiz InstrumentDocument5 paginiSoal Quiz InstrumentAfifah khainurÎncă nu există evaluări

- Dynamic Behavior of Second Order Systems: Department of Chemical Engineering, U.E.T. Lahore PakistanDocument51 paginiDynamic Behavior of Second Order Systems: Department of Chemical Engineering, U.E.T. Lahore PakistanqamarVEXÎncă nu există evaluări

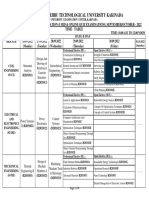

- Controller of Examinations: M.E. Electronics and Communication Engineering (Industry Integrated) BranchDocument48 paginiController of Examinations: M.E. Electronics and Communication Engineering (Industry Integrated) Branchsubha_aeroÎncă nu există evaluări

- P&ID Symbols (Complete List & PDF) - ProjectmaterialsDocument23 paginiP&ID Symbols (Complete List & PDF) - ProjectmaterialsSudÎncă nu există evaluări

- MeasurementDocument22 paginiMeasurementDany TrendsÎncă nu există evaluări

- Measurement Concepts and Classification of SensorsDocument26 paginiMeasurement Concepts and Classification of SensorsArvind kumar PrajapatiÎncă nu există evaluări

- List of E-Books: Mechanical DepartmentDocument9 paginiList of E-Books: Mechanical DepartmentmusitefaÎncă nu există evaluări

- Bio InstrumentationDocument42 paginiBio InstrumentationozrdrlÎncă nu există evaluări

- BASIC ELECTRICAL MATERIALS AND METHODS - Specs - AllDocument202 paginiBASIC ELECTRICAL MATERIALS AND METHODS - Specs - AllAdnan NajemÎncă nu există evaluări

- Foxboro PH Control System: Delivers Long-Lasting, Accurate PH Analysis in Corrosive Fertilizer PlantsDocument4 paginiFoxboro PH Control System: Delivers Long-Lasting, Accurate PH Analysis in Corrosive Fertilizer PlantsPhaniÎncă nu există evaluări

- Chapter # 6: Instrumentation & ControlDocument8 paginiChapter # 6: Instrumentation & ControlAhmed HassanÎncă nu există evaluări

- Class 5: Advanced Control Loops: Ice401: Process Instrumentation and ControlDocument19 paginiClass 5: Advanced Control Loops: Ice401: Process Instrumentation and Controlmohammd imran azizÎncă nu există evaluări

- Red Bag Checklist For Mechanical CompletionDocument9 paginiRed Bag Checklist For Mechanical Completionhitm357Încă nu există evaluări

- In ES 001 General Instrument Design - Rev.0Document56 paginiIn ES 001 General Instrument Design - Rev.0chedaniel100% (1)

- Armfield FT74XA - Datasheet - V1eDocument4 paginiArmfield FT74XA - Datasheet - V1eminhtu159Încă nu există evaluări

- Measureme NT Science & TechniquesDocument18 paginiMeasureme NT Science & TechniquesRishabh KÎncă nu există evaluări

- OeGG Monitoring HandbookDocument100 paginiOeGG Monitoring HandbookMark EdowaiÎncă nu există evaluări

- 20 3 1 R20 Mid1Document6 pagini20 3 1 R20 Mid1NADELLA Jhansi raniÎncă nu există evaluări

- ds81 - Process Engineering - Design StandardDocument51 paginids81 - Process Engineering - Design StandardNatts NatiÎncă nu există evaluări