Documente Academic

Documente Profesional

Documente Cultură

Section 2

Încărcat de

Nida I. FarihahTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Section 2

Încărcat de

Nida I. FarihahDrepturi de autor:

Formate disponibile

Section 2 - Materials

A, B

2-1

Section 2

Materials

A.

General

All materials to be used for the structural members indicated

in the Construction Rules are to be in accordance with the

Rules for Materials, Volume V. Materials the properties

of which deviate from these Rule requirements may only

be used upon special approval.

B.

be determined by the following formula:

Note

Especially when higher strength hull structural steels are

used, limitation of permissible stresses due to buckling and

fatigue strength criteria may be required.

Hull Structural Steel for Plates and Sections

Table 2.1 Material factor k

1.

Normal strength hull structural steel

1.1

Normal strength hull structural steel is a hull structural

steel with a minimum nominal upper yield point ReH

of 235 N/mm2 and a tensile strength Rm of 400 - 520 N/mm2,

see also Section 17.A.3.

1.2

The material factor k in the formulae of the following

Sections is to be taken 1,0 for normal strength hull structural

steel.

315

0,78

355

0,72

390

0,66

2.2

Higher strength hull structural steel is grouped into

the following grades, which differ from each other in their

toughness properties:

KI-A 32/36/40

1.3

Normal strength hull structural steel is grouped into

the grades KI-A, KI-B, KI-D, KI-E, which differ from each

other in their toughness properties. For the application

of the individual grades for the hull structural members,

see 3.

1.4

If for special structures the use of steels with yield

properties less than 235 N/mm2 has been accepted, the

material factor k is to be determined by:

ReH [N/mm2]

KI-D 32/36/40

KI-E 32/36/40

KI-F 32/36/40.

In Table 2.7 the grades of the higher strength hull structural

steels are marked by the letter "H".

2.3

Where structural members are completely or partly

made from higher strength hull structural steel, a suitable

Notation will be entered into the Ship's Certificate.

2.

Higher strength hull structural steels

2.1

Higher strength hull structural steel is a hull structural

steel, the yield and tensile properties of which exceed those

of normal strength hull structural steel. According to the

Rules for Materials, Volume V, for three groups of higher

strength hull structural steels the nominal upper yield stress

ReH has been fixed at 315, 355 and 390 N/mm2 respectively.

Where higher strength hull structural steel is used, for

scantling purposes the values in Table 2.1 are to be used

for the material factor k mentioned in the various Sections.

For higher strength hull structural steel with other nominal

yield stresses up to 390 N/mm2, the material factor k may

2.4

In the drawings submitted for approval it is to be

shown which structural members are made of higher strength

hull structural steel. These drawings are to be placed on board

in case any repairs are to be carried out.

2.5

Regarding welding of higher strength hull structural

steel, see Rules for Welding, Volume VI, Section 12.

3.

Material selection for the hull

3.1

Material classes

For the material selection for hull structural members material

classes as given in Table 2.2 are defined.

2-2

Section 2 - Materials

Table 2.2

Material classes and grades for ships in general

Structural member category

Material class or grade

Secondary :

A1.

A2.

A3.

Longitudinal bulkhead strakes, other than that belonging to the Primary Class I within 0,4 L amidships

category

Grade A/AH outside 0,4 L amidships

Deck plating exposed to weather, other than that belonging to the

Primary or Special category

Side plating

Primary :

B1.

Bottom plating, including keel plate

B2.

Strength deck plating, excluding that belonging to the Special category Grade A/AH outside 0,4 L amidships

B3.

Continuous longitudinal members above strength deck, excluding

hatch coamings

B4.

Uppermost strake in longitudinal bulkhead

B5.

Vertical strake (hatch side girder) and uppermost sloped strake in

top wing tank

Class I within 0,4 L amidships

Special :

C1.

Sheer strake at strength deck 1)

Class III within 0,4 L amidships

C2.

Stringer plate in strength deck 1)

Class II outside 0,4 L amidships

C3.

Deck strake at longitudinal bulkhead excluding deck plating in way

of inner-skin bulkhead of double-hull ships 1)

C4.

Strength deck plating at outboard corners of cargo hatch openings Class III within 0,4 L amidships

in container ships and other ships with similar hatch openings

Class II outside 0,4 L amidships

configurations

Class I outside 0,6 L amidships

Class I outside 0,6 L amidships

Min. Class III within cargo region

C5.

Strength deck plating at corners of cargo hatch openings in bulk Class III within 0,6 L amidships

carriers, ore carriers, combination carriers and other ships with similar

Class II within rest of cargo region

hatch openings configurations

C6.

Bilge strake in ships with double bottom over the full breadth and Class III within 0,6 L amidships

length less than 150 m 1)

Class I outside 0,6 L amidships

C7.

Bilge strake in other ships 1)

Class III within 0,4 L amidships

Class II outside 0,4 L amidships

Class I outside 0,6 L amidships

C8.

Longitudinal hatch coamings of length greater than 0,15 L

Class III within 0,4 L amidships

C9.

End brackets and deck house transition of longitudinal cargo hatch Class II outside 0,4 L amidships

coamings

Class I outside 0,6 L amidships

Not to be less than grade D/DH

1)

Single strakes required to be of class III within 0,4 L amidships are to have breadths not less than 800 + 5 L [mm] need not be grater than 1800 mm,

unless limited by the geometry of the ship's design.

Section 2 - Materials

2-3

Table 2.3 Minimum material grades for ships with length exceeding 150 m and single strength deck

Structural member category

Material grade

Longitudinal strength members of strength deck plating

Grade B/AH within 0,4 L amidships

Continuous longitudinal strength members above strength deck

Grade B/AH within 0,4 L amidships

Single side strakes for ships without inner continuous

longitudinal bulkhead(s) between bottom and the strength deck

Grade B/AH within cargo region

Table 2.4 Minimum material grades for ships with length exceeding 250 m

Structural member category

Material grade

Shear strake at strength deck 1)

Grade E/EH within 0,4 L amidships

Stringer plate in strength deck 1)

Grade E/EH within 0,4 L amidships

Bilge strake 1)

Grade D/DH within 0,4 L amidships

1)

Single strakes required to be of Grade E/EH and within 0,4 L amidships are to have breadths not less than 800 + 5 L [mm], need not be grater

than 1800 mm, unless limited by the geometry of the ship's design.

Table 2.5 Minimum material grades for single-side skin bulk carriers subjected to SOLAS regulation XII/6.5.3

Structural member category

Lower bracket of ordinary side frame

Material grade

1), 2)

Grade D/DH

Side shell strakes included totally or partially between the two

points located to 0,125 R above and below the intersection of side

shell and bilge hopper sloping plate or inner bottom plate 2)

Grade D/DH

1)

The term "lower bracket" means webs of lower brackets and webs of the lower part of side frames up to the point of 0,125 R above the intersection

of side shell and bilge hopper sloping plate or inner bottom plate.

2)

The span of the side frame R is defined as the distance between the supporting structures.

Table 2.6 Minimum material grades for ships with ice strengthening

Structural member category

Material grade

Shell strakes in way of ice strengthening area for plates

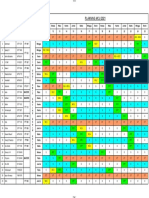

Table 2.7

Grade B/AH

Steel grades to be used, depending on plate thickness and material class

Thickness t [mm] 1)

> 15

> 20

> 25

> 30

> 35

> 40

> 50

# 15

# 20

# 25

# 30

# 35

# 40

# 50

# 1003)

A/AH

A/AH

A/AH

A/AH

B/AH

B/AH

D/DH

D/DH2)

II

A/AH

A/AH

B/AH

D/DH

D/DH 4)

D/DH 4)

E/EH

E/EH

III

A/AH

B/AH

D/DH

D/DH 4)

E/EH

E/EH

E/EH

E/EH

Material class

1)

Actual thickness of the structural member.

2)

For thicknesses t > 60 mm E/EH.

3)

For thicknesses t > 100 mm the steel grade is to be agreed with BKI.

4)

For nominal yield stresses ReH $ 390 N/mm2 EH.

2-4

3.2

Section 2 - Materials

Material selection for longitudinal structural

members

Materials in the various strength members are not to be of

lower grades than those corresponding to the material classes

and grades specified in Table 2.2 to Table 2.7. General

requirements are given in Table 2.2, while additional

minimum requirements for ships with length exceeding

150 m and 250 m, bulk carriers subject to the requirements

of SOLAS regulation XII/6.5.3, and ships with ice

strengthening are given in Table 2.3 to Table 2.6. The

material grade requirements for hull members of each class

depending on the thickness are defined in Table 2.7.

For structural members not specifically mentioned in

Table 2.2, grade A/AH material may generally be used.

3.3

Material selection for local structural members

3.3.1 The material selection for local structural members,

which are not part of the longitudinal hull structure, may

in general be effected according to Table 2.8. For parts made

of forged steel or cast steel C. is to be applied.

Table 2.8 Material selection for local structural

members

Structural member

Material

class

hawse pipe, stern tube, pipe stanchion3)

face plates and webs of girder systems, hatch

cover

1)

rudder body 2), rudder horn, sole piece, stern

frame, propeller brackets, trunk pipe

II

II

1)

Class I material sufficient, where rolled sections are used or the

parts are machine cut from plates with condition on delivery of either

"normalized", "rolled normalized" or "rolled thermo-mechanical".

2)

See 3.3.2

3)

For pipe stanchions for cargo reefer holds Table 2.10 is applicable.

3.3.2 Rudder body plates, which are subjected to stress

concentrations (e.g. in way of lower support of semi-spade

rudders), are to be of class III material.

3.3.3 For topplates of machinery foundations located

outside 0,6 L amidships, grade A ordinary hull structural

steel may also be used for thicknesses above 40 mm.

For members not specifically mentioned normally

grade A/AH may be used. However, BKI may require also

higher grades depending on the stress level.

3.4

Material selection for structural members which

are exposed to low temperatures

3.4.1 The material selection for structural members, which

are continuously exposed to temperatures below 0 C, e.g.

in or adjacent to refrigerated cargo holds, is governed by

the design temperature of the structural members. The design

temperature is the temperature determined by means of a

temperature distribution calculation taking into account the

design environmental temperatures. The design

environmental temperatures for unrestricted service are:

air

: + 5 C

sea water

: 0 C.

3.4.2 For ships intended to operate permanently in areas

with low air temperatures (below and including - 20 C),

e.g. regular service during winter seasons to Arctic or

Antarctic waters, the materials in exposed structures are

to be selected based on the design temperature tD , to be

taken as defined in 3.4.5.

Materials in the various strength members above the lowest

ballast waterline (BWL) exposed to air are not to be of lower

grades than those corresponding to classes I, II and III, as

given in Table 2.9, depending on the categories of structural

members (Secondary, Primary and Special). For non-exposed

structures and structures below the lowest ballast waterline,

see 3.2 and 3.3.

3.4.3 The material grade requirements of each material

class depending on thickness and design temperature are

defined in Table 2.10. For design temperatures tD < - 55 C,

materials are to be specially considered.

3.4.4 Single strakes required to be of class III or of grade

E/EH or FH are to have breadths not less 800 + 5 L [mm],

maximum 1800 mm.

Plating materials for stern frames, rudder horns, rudders

and shaft brackets are not to be of lower grades than those

corresponding to the material classes given in 3.3.

3.4.5 The design temperature tD is to be taken as the lowest

mean daily average air temperature in the area of operation,

see Fig. 2.1. The following definitions apply:

Mean

Statistical mean over an observation period

of at least 20 years

Average

Average during one day and night.

Lowest

Lowest during the year.

For seasonally restricted service the lowest expected value

within the period of operation applies.

4.

Structural members which are stressed in

direction of their thickness

In case of high local stresses in the thickness direction, e.g.

due to shrinkage stresses in single bevel or double bevel

T-joints with a large volume of weld metal, steels with

guaranteed material properties in the thickness direction

according to the Rules for Materials, Volume V, Section 4, I.

are to be used.

Section 2 - Materials

C, D, E

2-5

for the construction of superstructures, deckhouses, hatchway

covers and similar parts, the conversion from steel to

aluminium scantlings is to be carried out by using the

material factor:

Rp0,2 = 0,2% proof stress of the aluminium alloy [N/mm2]

Rm

= tensile strength of the aluminium alloy [N/mm2]

For welded connections the respective values in welded

condition are to be taken. Where these figures are not

available, the respective values for the soft-annealed

condition are to be used.

Method of conversion:

section modulus: WAR

plate thickness:

= WSt @ kAR

tAR = tSt @

Fig. 2.1 Commonly used definitions of temperatures

C.

Forged Steel and Cast Steel

Forged steel and cast steel for stem, stern frame, rudder post

as well as other structural components, which are subject

of this Rule, are to comply with the Rules for Materials,

Volume V. The tensile strength of forged steel and of cast

steel is not to be less than 400 N/mm2. Forged steel and cast

steel are to be selected under consideration of B.3. In this

respect beside strength properties also toughness

requirements and weldability shall be observed.

2.

The smaller modulus of elasticity is to be taken into

account when determining the buckling strength of structural

elements subjected to compression. This is to be applied

accordingly to structural elements for which maximum

allowable deflections have to be adhered to.

3.

The conversion of the scantlings of the main hull

structural elements from steel into aluminium alloy is to

be specially considered taking into account the smaller

modulus of elasticity, as compared with steel, and the fatigue

strength aspects, specifically those of the welded connections.

E.

D.

Austenitic Steels

Aluminium Alloys

1.

Where aluminium alloys, suitable for seawater, as

specified in the Rules for Materials, Volume V, are used

Where austenitic steels are applied having a ratio

Rp0,2/Rm 0,5, after special approval the 1% proof stress

Rp1,0 may be used for scantling purposes instead of the 0,2%

proof stress Rp0,2.

2-6

Section 2 - Materials

Table 2.9 Material classes and grades for structures exposed to low temperatures

Material class

Structural member category

Within 0,4 L

amidships

Outside 0,4 L

amidships

II

III

II

Secondary:

Deck plating exposed to weather, in general

Side plating above BWL 5)

Transverse bulkheads above BWL 5)

Primary:

Strength deck plating 1)

Continuous longitudinal members above strength deck, excluding

longitudinal hatch coamings

Longitudinal bulkhead above BWL 5)

Top wing tank plating above BWL 5)

Special:

Sheer strake at strength deck 2)

Stringer plate in strength deck 2)

Deck strake at longitudinal bulkhead

3)

Continuous longitudinal hatch coamings 4)

1)

2)

3)

4)

5)

Plating at corners of large hatch openings to be specially considered. Class III or grade E/EH to be applied in positions where high local stresses

may occur.

Not to be less than grade E/EH within 0,4 L amidships in ships with length exceeding 250 metres.

In ships with breadth exceeding 70 metres at least three deck strakes to be of class III.

Not to be less than grade D/DH

BWL = ballast waterline.

Section 2 - Materials

Table 2.10

2-7

Material grade requirements for classes I, II and III at low temperatures

Class I

Plate thickness

[mm]

10

tD

tD

tD

tD

20 C to 25 C

26 C to 35 C

36 C to 45 C

46 C to 55 C

normal

strength

higher

strength

normal

strength

higher

strength

normal

strength

higher

strength

normal

strength

higher

strength

AH

AH

DH

DH

10 < t

15

AH

DH

DH

DH

15 < t

20

AH

DH

DH

EH

20 < t

25

DH

DH

DH

EH

25 < t

30

DH

DH

EH

EH

30 < t

35

DH

DH

EH

EH

35 < t

45

DH

EH

EH

FH

45 < t

50

EH

EH

FH

FH

Class II

Plate thickness

[mm]

10

tD

tD

tD

tD

20 C to 25 C

26 C to 35 C

36 C to 45 C

46 C to 55 C

normal

strength

higher

strength

normal

strength

higher

strength

normal

strength

higher

strength

normal

strength

higher

strength

AH

DH

DH

EH

EH

10 < t

20

DH

DH

EH

20 < t

30

DH

EH

EH

FH

30 < t

40

EH

EH

FH

FH

40 < t

45

EH

FH

FH

45 < t

50

EH

FH

FH

Class III

Plate thickness

[mm]

10

tD

tD

tD

tD

20 C to 25 C

26 C to 35 C

36 C to 45 C

46 C to 55 C

normal

strength

higher

strength

normal

strength

higher

strength

normal

strength

higher

strength

normal

strength

higher

strength

DH

DH

EH

EH

EH

FH

10 < t

20

DH

EH

20 < t

25

EH

EH

FH

FH

25 < t

30

EH

EH

FH

FH

30 < t

35

EH

FH

FH

35 < t

40

EH

FH

FH

40 < t

50

FH

FH

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- JHHKJGGDocument6 paginiJHHKJGGMuhammad Fajrul IlmiÎncă nu există evaluări

- GGHJGFFDocument3 paginiGGHJGFFMuhammad Fajrul IlmiÎncă nu există evaluări

- IjhhjkhhDocument3 paginiIjhhjkhhMuhammad Fajrul IlmiÎncă nu există evaluări

- JJGHHJGHDocument12 paginiJJGHHJGHMuhammad Fajrul IlmiÎncă nu există evaluări

- Juli 20 (Mtb2)Document3 paginiJuli 20 (Mtb2)Muhammad Fajrul IlmiÎncă nu există evaluări

- IjhhjkhhDocument3 paginiIjhhjkhhMuhammad Fajrul IlmiÎncă nu există evaluări

- JHVBHGDocument3 paginiJHVBHGMuhammad Fajrul IlmiÎncă nu există evaluări

- Juni 20 (Mtb1)Document3 paginiJuni 20 (Mtb1)Muhammad Fajrul IlmiÎncă nu există evaluări

- Agustus 20 (MTB1)Document6 paginiAgustus 20 (MTB1)Muhammad Fajrul IlmiÎncă nu există evaluări

- JugjjjjhDocument3 paginiJugjjjjhMuhammad Fajrul IlmiÎncă nu există evaluări

- HygghhjjDocument9 paginiHygghhjjMuhammad Fajrul IlmiÎncă nu există evaluări

- IjhjjjjhDocument12 paginiIjhjjjjhMuhammad Fajrul IlmiÎncă nu există evaluări

- GDDHHBBDocument8 paginiGDDHHBBMuhammad Fajrul IlmiÎncă nu există evaluări

- Rekap Fosto Pompa 1Document6 paginiRekap Fosto Pompa 1Muhammad Fajrul IlmiÎncă nu există evaluări

- Planning Mcu DriverDocument1 paginăPlanning Mcu DriverMuhammad Fajrul IlmiÎncă nu există evaluări

- Planning Mcu DriverDocument1 paginăPlanning Mcu DriverMuhammad Fajrul IlmiÎncă nu există evaluări

- Rev Planning Mcu FuelmanDocument1 paginăRev Planning Mcu FuelmanMuhammad Fajrul IlmiÎncă nu există evaluări

- Rekap Logsheet NewDocument16 paginiRekap Logsheet NewMuhammad Fajrul IlmiÎncă nu există evaluări

- Confirmation - Jjggh-InDocument2 paginiConfirmation - Jjggh-InMuhammad Fajrul IlmiÎncă nu există evaluări

- Scan Template Report KPI 2021 - Supply Via LautDocument2 paginiScan Template Report KPI 2021 - Supply Via LautMuhammad Fajrul IlmiÎncă nu există evaluări

- RDSGDSRHDDocument1 paginăRDSGDSRHDMuhammad Fajrul IlmiÎncă nu există evaluări

- Planning Mcu Fuelman & AdminDocument1 paginăPlanning Mcu Fuelman & AdminMuhammad Fajrul IlmiÎncă nu există evaluări

- 08 Rosster Agustus-SeptemberDocument3 pagini08 Rosster Agustus-SeptemberMuhammad Fajrul IlmiÎncă nu există evaluări

- Total Return (Potential)Document6 paginiTotal Return (Potential)Muhammad Fajrul IlmiÎncă nu există evaluări

- Scholarship Form 2014-15Document6 paginiScholarship Form 2014-15Muhammad Fajrul IlmiÎncă nu există evaluări

- Link BeasiswaDocument1 paginăLink BeasiswaMuhammad Fajrul IlmiÎncă nu există evaluări

- Google TerjemahanDocument2 paginiGoogle TerjemahanMuhammad Fajrul IlmiÎncă nu există evaluări

- Worksheet in Book1Document1 paginăWorksheet in Book1Muhammad Fajrul IlmiÎncă nu există evaluări

- SfaaaaaaDocument1 paginăSfaaaaaaMuhammad Fajrul IlmiÎncă nu există evaluări

- Print A4Document1 paginăPrint A4Muhammad Fajrul IlmiÎncă nu există evaluări