Documente Academic

Documente Profesional

Documente Cultură

Craft A Winning Project Execution Strategy For Construction Projects

Încărcat de

franka4100Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Craft A Winning Project Execution Strategy For Construction Projects

Încărcat de

franka4100Drepturi de autor:

Formate disponibile

Craft a winning project execution strategy for construction

projects

Wednesday, June 3, 2015

Projects are the complex process and collaborative work of turning an

idea into an actual profit making facility. From Concept to Feasibility to

Project Strategy then Design Basis to Basic Design to Detailed Design

then Construction and Finally Close-Out. Every phase is critical to

achieve a successful project and as they say A chain is only as strong

as its weakest link. Yet taking the Logical sequence of projects one

could realize that construction is the most critical part of a Project, it is

what could make or break a project. Despite its being one of the later

phases of a project, Construction will only be successful if you think

about it from the beginning (FEL and Design Basis). There are few

things to keep in mind to have successful Construction phase:

1. Put more weight on construction activities as opposed to

back office engineering activities in the Cost Breakdown

Structure. Most construction companies tend to put the most

weight of the contract value on engineering work since they link

it with material procurement, which happens during engineering

period. When negotiating the value of the contract, it is essential

to put more weight on actual construction work. Even if the

construction company refuse, which is something expected, then

Project Management can still manipulate the percentages in

material procurement progress to serve the construction work

portion. For instance, procurement progress consist of: issuing

P/O to supplier, Supplier confirming quantities and committing to

delivery dates, Receiving Material, Inspection at supplier

premises then arrival at site. So by putting more weight Arrival

at site (which is still part of construction work the team are

helping Construction activity in an indirect way).

2. Obtain the necessary approvals from Authorities.

Authorities require several forms that need to be submitted in

timely manner to ensure construction take place on time. Like an

Environmental Impact Report. Once that document is approved,

authorities will issue Environmental Consent to Construct (ECC)

allowing starting the construction work. Another document that

have to be submitted to the authorities is the site wide

Construction safety plan, which has to be submitted prior to start

effective construction. Other permits that have to submitted to

the authorities like: Permit for Waste Disposal, Allocation of Pipe

routing, Request for Water tie-in, Permit for sanitary Tie-In, Permit

for Fence Installation and many others more. Authorities are

serving many users and often they are under-staffed. Thats why

submitting those documents way ahead of time ensures they are

approved at the right time.

3. Good Selection of Subcontractors especially Civil. Civil will

live the whole cycle of the project site activity from the first

activities of land leveling to the final activity of road asphalt

paving. Civil subcontractor is a key element and could set the

rhythm for whole project. The cheapest subcontractor is not

always the best. Some subcontractors are short on Manpower

(Carpenter, Steel Fixer, Welder etc). other subcontractors are

short on equipment (Pilling, Dewatering, Concrete Mixers Mobile

Crane etc). careful selection of civil subcontractor could be one

of the project successes factors. it pays-off to consider other

projects the subcontractor handling simultaneously and which

phases are they.

4. Specialized Subcontractors for specialized Jobs. There are

several Subcontractors that have a proven record in doing

specific Jobs. Some are specialized by discipline like being a well

reputed Electrical or mechanical subcontractor. It pays to ask

people of experience in similar projects.

5. Early site preparation is Key in two ways: first, it gives the

project team a sense of urgency which will help push the

contractor during the engineering stage. Second, it will give a lot

of work front when the actual construction begin. There are some

tasks that dont require waiting for detailed design. Things like:

Digging obstacles in the construction area, Backfilling site with

soft sand, Leveling and Compacting process area based on

preliminary drawings, Pilling work which is one of the earliest

drawings to be produced by civil, Installing Security Fence,

Installing Temporary Gates, Site and Plant Roads. All those tasks

can be done in an early stage given their nature of requiring no

or minimum drawings and doing them in an early stage could

open lots of work fronts for other tasks to follow.

6. Preparation of Lay-down Area. Depending on the area of the

project, Logistics could be a nightmare. The Lay-Down Area

should be close enough to be able to move material easily to

construction site yet not too close to interfere with construction

site. In some previous projects and due to limited area parts of

the construction area was used as a lay-down area which

restricted accessibility to site causing delay in work progress.

7. Sequential arrival of material. Lay-down Area is a temporary

area to keep material that are ready to be installed. It is not to be

used as a permanent storage area for late needed material.

Optimum use of Lay-down area could help speed up the structure

and piping erection and reduce congestion on limited plot plans.

8. Use of New Construction Methods. For instance Modular

construction methods could save significant time. Shop built

structures could save time more than conventional site built.

9. Early Assembly of Site team. in the early days of site work

few people are needed. Mainly Civil Supervises, Construction

supervisors and Safety Supervisors. Mobilizing them early to

work site will push the construction contractor to establish their

site presence. The project management team could help the

construction team in logistics such as Custom Clearance, Duty

Exemption and others more.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Case Study - So What Is It WorthDocument7 paginiCase Study - So What Is It WorthJohn Aldridge Chew100% (1)

- Quarry of Agreement JuliusDocument2 paginiQuarry of Agreement JuliusLavon Naze50% (2)

- Bill LipschutzDocument4 paginiBill Lipschutzartus14Încă nu există evaluări

- Harley DavidsonDocument5 paginiHarley DavidsonpagalinsanÎncă nu există evaluări

- IT Business Plan Chapter SummaryDocument35 paginiIT Business Plan Chapter SummaryKap DemonÎncă nu există evaluări

- COA Audit Report of Mabini National High SchoolDocument6 paginiCOA Audit Report of Mabini National High SchoolgilbertÎncă nu există evaluări

- 000.100.8100 Baseline Centric Execution - Deliver To The Baseline WorkflowDocument1 pagină000.100.8100 Baseline Centric Execution - Deliver To The Baseline WorkflowmiltonÎncă nu există evaluări

- Quality Manual for ISO 9001 CertificationDocument56 paginiQuality Manual for ISO 9001 CertificationMunavwar Khan100% (1)

- Cooperative Training ModuleDocument38 paginiCooperative Training ModuleAndreline AnsulaÎncă nu există evaluări

- Chapter 12Document57 paginiChapter 12Crestu Jin0% (1)

- TOA Quizzer With AnswersDocument55 paginiTOA Quizzer With AnswersRussel100% (1)

- Eir January2018Document1.071 paginiEir January2018AbhishekÎncă nu există evaluări

- VcoDocument61 paginiVcoJivithra ParamasiumÎncă nu există evaluări

- A Comparison of Each Cash Flow MetricDocument1 paginăA Comparison of Each Cash Flow Metricfranka4100Încă nu există evaluări

- BankruptcyDocument26 paginiBankruptcyfranka4100Încă nu există evaluări

- A Cheap, Diversified, Mortgage-Backed-Securities ETFDocument2 paginiA Cheap, Diversified, Mortgage-Backed-Securities ETFfranka4100Încă nu există evaluări

- Amazon Capital QuestionsDocument1 paginăAmazon Capital Questionsfranka4100Încă nu există evaluări

- Digital Currencies in Valuation PDFDocument6 paginiDigital Currencies in Valuation PDFfranka4100Încă nu există evaluări

- Equity Research and Valuation B Kemp Dolliver-0935015213Document69 paginiEquity Research and Valuation B Kemp Dolliver-0935015213rockkey76Încă nu există evaluări

- Degrees of Hardship For StudentsDocument14 paginiDegrees of Hardship For Studentsfranka4100Încă nu există evaluări

- 2013 FPA Guide-ForecastingDocument26 pagini2013 FPA Guide-Forecastingfranka4100Încă nu există evaluări

- Attraction To Internet Stocks Love or SmallpoxDocument3 paginiAttraction To Internet Stocks Love or Smallpoxfranka4100Încă nu există evaluări

- Dividends Do MatterDocument4 paginiDividends Do Matterfranka4100Încă nu există evaluări

- The Sales Managers' Index - United States - May DataDocument4 paginiThe Sales Managers' Index - United States - May Datafranka4100Încă nu există evaluări

- Corporations Not Hoarding CashDocument2 paginiCorporations Not Hoarding Cashfranka4100Încă nu există evaluări

- Le Crédit Crunch Isn't OverDocument2 paginiLe Crédit Crunch Isn't Overfranka4100Încă nu există evaluări

- Mauldin Out of Box 13 FebruaryDocument29 paginiMauldin Out of Box 13 Februaryrichardck61Încă nu există evaluări

- Construction Management: ENCE4331: Cost and Price ExamplesDocument7 paginiConstruction Management: ENCE4331: Cost and Price ExamplesTania MassadÎncă nu există evaluări

- Project Demo On Pet Shop: Group Members: Muhammad Talha Malik Shamook Saad Muhammad HamzaDocument10 paginiProject Demo On Pet Shop: Group Members: Muhammad Talha Malik Shamook Saad Muhammad HamzaRaja Saad0% (1)

- Word On The Street-Starting Business-Support-PackDocument3 paginiWord On The Street-Starting Business-Support-PackЕлена ХасьяноваÎncă nu există evaluări

- Configure MSS (WDA) Settings in SAP NetWeaver BCDocument6 paginiConfigure MSS (WDA) Settings in SAP NetWeaver BCThandile FikeniÎncă nu există evaluări

- Eleanor Shaw CVDocument1 paginăEleanor Shaw CVEllie JeanÎncă nu există evaluări

- Handbook FISTF 2009Document78 paginiHandbook FISTF 2009JagoPTÎncă nu există evaluări

- Analisis Pendapatan Berdasarkan PSAK No. 23 Pada PDAM Tirta Wampu Stabat Putri Kemala Dewi LubisDocument21 paginiAnalisis Pendapatan Berdasarkan PSAK No. 23 Pada PDAM Tirta Wampu Stabat Putri Kemala Dewi LubisIdrus MohammadÎncă nu există evaluări

- Shankara Building Products Ltd-Mumbai Registered Office at Mumbai GSTIN Number: 27AACCS9670B1ZADocument1 paginăShankara Building Products Ltd-Mumbai Registered Office at Mumbai GSTIN Number: 27AACCS9670B1ZAfernandes_j1Încă nu există evaluări

- Tax Holiday in BangladeshDocument7 paginiTax Holiday in BangladeshAulad Hossain100% (2)

- Got $3.1 Million?? Judge Magner Fines Wells Fargo in Her Scathing Opinion For Wells Fargo Bad Mortgage Servicing ConductDocument21 paginiGot $3.1 Million?? Judge Magner Fines Wells Fargo in Her Scathing Opinion For Wells Fargo Bad Mortgage Servicing Conduct83jjmackÎncă nu există evaluări

- Bahasa Inggris AkunDocument2 paginiBahasa Inggris AkunGaptek IDÎncă nu există evaluări

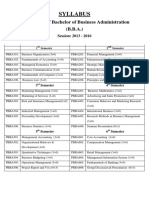

- BBA Syllabus 2013-2016Document59 paginiBBA Syllabus 2013-2016GauravsÎncă nu există evaluări

- Ch02-Project Selection-Agustus 2023Document57 paginiCh02-Project Selection-Agustus 2023Tota SimatupangÎncă nu există evaluări

- Modern Systems Analysis and Design: The Sources of SoftwareDocument39 paginiModern Systems Analysis and Design: The Sources of SoftwareNoratikah JaharudinÎncă nu există evaluări

- Global Trust in Advertising Report Sept 2015Document22 paginiGlobal Trust in Advertising Report Sept 2015Jaime CubasÎncă nu există evaluări

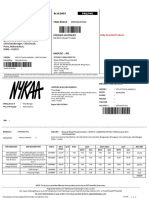

- TRACKING#:89761187821: BluedartDocument2 paginiTRACKING#:89761187821: BluedartStone ColdÎncă nu există evaluări

- Cordillera Regional Science High School: Wangal, La Trinidad, Benguet Tel. Fax (074) 422-5662 School ID No.: 305140Document2 paginiCordillera Regional Science High School: Wangal, La Trinidad, Benguet Tel. Fax (074) 422-5662 School ID No.: 305140LÎncă nu există evaluări

- Strategic Change ManagementDocument38 paginiStrategic Change ManagementFaisel MohamedÎncă nu există evaluări