Documente Academic

Documente Profesional

Documente Cultură

ICS R490说明书(ENGLISH) PDF

Încărcat de

Furqonudin SejahteraDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ICS R490说明书(ENGLISH) PDF

Încărcat de

Furqonudin SejahteraDrepturi de autor:

Formate disponibile

HONTON

www.szhonton.com

ICS-R490 BGA rework station

Operation Manual

SHENZHEN HONTON ELECTRONICS TECHNOLOGY CO.,LTD

Address: San Tin Tin Building, 4th Floor, Boulevard of Jiang, Bao'an,

Shenzhen, GuangDong,China.

TEL:0755-33801901/03

400 6420 299

http://www.szhonton.com

FAX:0755-33801902

Email:htbga@163.com

400-6420-299

htbga@163.com

1

HONTON

www.szhonton.com

Table of Contents

(A) introduce the basic functions of machine parameters and

(B) the combination of machine parts

(C) of the function of each machine introduction and operation precautions

(D) of the machine operating system and Features

(E) BGA solder frequently asked questions

(F) reference temperature curve

(Vii) technical support contact

Dear Customer:

Thank you for choosing our newest BGA rework equipment, device with

the industry's most advanced integrated intelligent control system-ICS

(Intelligent Control System) adds intelligent temperature control system

and intelligent fault detection and wide voltage Intelligent energy-saving

function and mute function. K-type thermocouple imported closed-loop

control system can automatically compensate for temperature control

in order to achieve more precise temperature control; is a sufficient

guide the industry's advanced equipment. Will bring you more intuitive

to use and more comfortable feel.

400-6420-299

htbga@163.com

2

HONTON

www.szhonton.com

(A) introduce the basic functions of machine parameters and

(A) of the machine parameters and basic functions introduced

Basic parameters of the machine:

1 Power: Single phase 220V AC 50/60HZ 4KVA

2 Total power: 4000W

The upper heating power: 800W

Bottom heating power: 800W at the bottom of infrared heating power: 2400W Standby power: 10W

3 temperature control mode: High-precision K-type thermocouple closed-loop control, with electronic

temperature compensation.

4.PCB positioning mode: V-groove + Z fonts universal fixture pairs of Y-direction adjustment

5 PCB size: MIN 10mm * 10mm MAX 350mm * 400mm

6. Infrared Preheating area: 210mm * 340mm

Machine Dimensions: (or so) wide and 580mm * (before and after) long 580mm high 650mm

Machine weight: Net weight 35KG

New features:

A: the world's most advanced "intelligent control system (Intelligent control system), referred to as" ICS

", BGA rework desoldering more humane, more simple, more intelligent.

B: The superior fault alarm function, the following fault detection and alarm control system integration:

1: K-type thermocouple open circuit detection and fault alarm protection. So that the temperature out of

control, such as temperature overshoot fault no longer occurs.

2: up and down the hot air fan fault detection and fault alarm protection. Heater burnout phenomenon

as history, to maximize the protection of machinery and personal safety.

3: heater fault detection and fault alarm, the machine's real-time status at a glance.

C: upper and lower blast volume electronic smart speed. Ask each group to different temperature curve

to match the different wind speed, improve repair efficiency, enhance the repair success rate. Exempt

from the tedious and repetitive traditional machine mechanical wind speed adjustment.

D: double-Y direction PCB clamping bracket to meet the larger PCB fixed.

Basic functions:

1 Precision imported raw materials (PLC. heater) precise control of BGA desoldering process.

2 The machine uses the independent control of three-zone temperature control is more accurate. The first

temperature zone. Second temperature zone can be set in paragraph 8 liters (down) 8 segments constant

temperature control, which can store 10 groups of temperature curve. The third zone warm-up, independent

temperature control to ensure fully preheat the PCB during the soldering process,

3 Selection of imported high-precision thermocouples, precise temperature detection.

4 walk alone the temperature curve in the upper heating and bottom heating, cross-flow fan rapid cooling

principle to ensure that the PCB during the soldering process, will not be deformed.

5 demolition welding and welding finished 20 seconds ahead of progressive alarm with a vacuum suction pen,

convenient desoldering suction trips to the BGA

6 PCB positioning using a V-shaped slot, flexible and convenient removable universal fixture, PCB protection.

For large thermal capacity of PCB and other high temperature requirements of lead-free soldering and so can

easily handle.

Hot air Tsui 360 degree rotation, easy to replace. With a variety of size of hot air nozzle, special requirements

can be customized for notebook computer motherboard, desktop computers, motherboards, and other

large-scale circuit board repair, and cell phone motherboard micro maintenance of the chip

400-6420-299

htbga@163.com

3

HONTON

www.szhonton.com

(B) Introduce the basic functions of the machine

1: head heater limit rod. (To prevent head heater crushed PCB)

2: head heater. (Temperature zone)

3: The head heater adjust the handle up and down. (Adjustable up and down position)

4: LED lights. (Increase the brightness of the work area)

5: head heater, hot air nozzle. (Can be replaced according to different chip size)

6: Infrared heating panels warm-up area. (Third zone)

7: PCB clamping bracket. (Fixed PCB board with a holding device)

8: PCB clamping bracket locking screw. (Tighten the right side of the PCB clamping

bracket)

9: The display and control buttons. (Show and set parameters)

10: the upper heater, locking handle and move around.

11: the upper part of the heater cable

12: the lower part of the heater and wind mouth. (Second temperature)

13: shaped plate fixture and tighten the screws.

14: shaped plate fixture. (Clamping irregular PCB, such as notebook panels)

15: plywood jig and move around to tighten the screws.

(B) the combination of machine parts

(1) The head of ejector assembly

400-6420-299

htbga@163.com

4

HONTON

www.szhonton.com

(2)shaped plateas sembly fixture.

(3) the lower nozzle assembly screw thimble

(4) PCB assembly thimble screw.

(C)of the function of each machine introduction and operation

precautions

Step 1: Select to set a good temperature curve.

Step two: Select the appropriate hot-air nozzle to the center of the upper and lower temperature zone

aligned.

See below

The third step: the transferred zone on the top position, holding good the bad plate welded to be

demolished, the area transferred to the nozzle temperature on the edge of the chip from about a

distance of about 3-5MM.

400-6420-299

htbga@163.com

5

HONTON

www.szhonton.com

Transferred to the next zone to withstand the wind the mouth of the thimble lower PCB, pay attention

to avoid the lower component. Figure:

Step Four: Press the start button for 2-3 seconds, the machine starts, observe the ball changes, such

as a ball can not start the melting temperature to extend the pause button time.

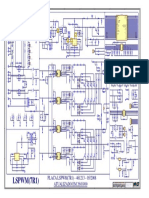

(D) part of the operating system and machine control

functions introduced

I. Introduction panel buttons and display contents

Curve

Name field

Curve

number field

Curve indicates

the current column

Machine status

indication bar

Cursor keys

X4

Run time

remaining

indicator bar

Set / confirm key

Parameter

display area

Status indicator

Fan speeding

dicator bar

Lights on /

off

Password

The first column

input field /

current

temperature

indicates the set

temperature zone

Run /

Pause

Stop /

Exit

indicator bar

1: Introduction display

Item column

Display content

Curve Name field

Each curve is representative of the IC with a model

named user choose to use

Curve number field

The machine can remember 0-9 a total of ten commonly

400-6420-299

htbga@163.com

6

HONTON

www.szhonton.com

used parameters for the user to choose

Machine status indication bar

Indicates the current working state machine, a total of

"Settings", "Run," "pause", "cool", "stop" the five states

Column indicates the current

Displays the current operating curve segment number,

number of curve segments

including the 1-8 segment elevation and temperature

phase

Run time remaining indicator bar

Running time remaining display unit for the second

Fan speed indicator bar

The current fan speed display, 0-9, were Ten Speed

Password input field or the

1: In the set state when the password input field

current temperature indicator

2: In the running for the first, second, third zone of the

measured temperature

The first column indicates the set

temperature zone

The current time zone of the first set temperature

Parameter display area

The current curve setting parameters, such as rising

slope, constant temperature, constant time.

2: Key Features

Item column

Press the function key

Run / Pause

Start or pause the operation of the machine

Stop / Exit

Stop the machine running or exit setting mode

Lights on / off

Lights on or off

Set / confirm key

Enter setup mode or to set parameters to determine

the

Move the cursor / key addition and

subtraction

Move the current cursor position or the current value

plus or minus

Two common operations Functions

(I): set and modify parameters

For the user to modify the current parameters: such as constant temperature, platform time, the slope

of temperature rise, or the curve of the name, you must first set the machine to "set" state, in order to

carry out related operations, detailed steps are as follows:

A: by (ii) Stop / Exit button, set the machine to "stop" state.

B: Press (D) Set / confirm button, setting the machine to: "Set" state.

C: the fan speed changes: (can not enter a password)

In the "Set" state, if the user only need to modify the fan speed, it can not enter a password, press

repeatedly v "right" to move the cursor to fan speed indicator bar, and then (d) Set / confirm button,

the cursor so that high bright as then (v) "down key", you can adjust the fan speed.

Fan speed of 0-9 were ten, of which 9 is the wind speed maximum, minimum 1, 0 to stop. Prohibit any

fan speed set to "0"

D: curve number modification: (can not enter a password)

Machine in the "stop" state, according to (d) to enter the "Settings" state, if the user only needs to

modify the current curve number, can not enter a password, according to (v) "the key" to move the

cursor to the column curve number, then (iv) Set / confirm button, so when the cursor is

highlighted, then (v) "arrow keys" to modify the current curve number.

E: Modify the curve parameters (password must be entered before operational)

400-6420-299

htbga@163.com

7

HONTON

www.szhonton.com

1: All in the password input box is highlighted, move the cursor by (v) / plus or minus key "up" "down"

"left" "right" in the password input box enter the password "123456", then (iv) Set / confirm key, such

as password input box displays "OK" indicates that the password entered successfully. Then enter the

parameters can be modified, or (iv) and then set / confirm key, repeat steps 1. Until the password is

entered successfully.

2: (v) the cursor / subtraction key "up" "down" "left" "right", move the cursor to the need to modify the

value of the position, according to (d) Set / confirm button, highlighting the need to modify the value,

then Move the cursor by (v) / plus or minus key "on", "next" was changed to the desired value.

3: When a temperature rise of a number of the slope is set to 0, it means the end of the curve.

Note:

1: When the screen display when the cursor is half the height of the text, such as, this time can only

move the cursor (v) / plus or minus keys to move the cursor position.

2: When the screen shows the cursor is changed to the text height, for example, that the current value

of the cursor can be modified. Available at this time (v) the cursor / keys to set the value plus or minus

size.

(Ii) The operating status of the set

A: (i) in the stopped state, press RUN / PAUSE two - three seconds, you can start the machine running,

(vi) status indicator "RUN" LED flashes once per second, the machine automatically move the line to

set the curve. run remaining time indication bar under the curve parameters, automatically

calculate the total run time, and start the countdown, the current curve segment number field has

been run to automatically update the number of curve segments, when the "1-8" section of the figure

highlighted , this means that the curve in the current number of heating stages, and "segment" is

highlighted, then the number of the current temperature in the platform stage. a zone set

temperature indicator bar shows the current curve of the set temperature, password input field /

current temperature indicator bar shows, in order "first zone" "second zone" "third zone" of the

measured the temperature.

B: When the curve to run to the final thirty seconds, the machine will automatically issue a warning

tone to alert the user, and with the remaining time will be shortened, a warning tone becomes more

rapid, run to the end when sounding loudly. Automatic machine to "cool" status, stop heating, cooling

fan cooled three minutes and the vacuum pump working one minute, remaining time indicator bar

started running three-minute countdown,

C: (i) when the state is in the running to run / pause button, set the machine to pause, (vi) status

indicator "RUN" LED flashes twice per second, the machine will automatically maintai n the current

temperature, run time remaining indicator bar stop the countdown.

D: In the suspended state, then i run / pause, resume to normal operation. (Vi) status indicator "RUN"

LED flashes once per second.

E: (ii) when the state is in the running to stop / exit button for two seconds, to stop the operation of the

machine automatically to "cool" status in the "cool" state, the cross-flow fan to cool for three minutes,

while vacuum pump work one minute, three minutes after the machine is automatically set to stop, the

user can start the next cycle of work.

(Iii) The lights on / off

Press to turn on / off LED lights.

400-6420-299

htbga@163.com

8

HONTON

www.szhonton.com

Note: 1: The machine has been the experience under the BGA rework, set the relevant values of the

upper and lower limits, to minimize the customer's misuse. Detailed parameters are as follows

1: the first, second, third, three-zone temperature slope of 0-6 degrees / sec.

2: first and second zone temperature is 30 to 320 degrees.

3: The third zone temperature of 30 to 200 degrees.

4: first, second, third, three-zone platform time from 0 to 250 seconds.

Two: During operation, when the machine detects abnormal temperature line, it will display the

appropriate warning information, (vi) The status indicator of "ERR" indicator light, and sound an alarm,

the machine will automatically stop in the state, after troubleshooting can continue to run.

(E) BGA solder frequently asked questions

1, BGA How do you debug, find their own use of the curve?

BGA chip desoldering, is affected by a variety of environmental impact, air temperature, humidity,

indoor breeze flow, PCB thickness, PCB copper distribution. Can not be a curve in the country, a

variety of environments can be done welding, according to our statistics, only about 45% of customers

use our curve can not be adjusted. Our factory debugging environment for indoor 25 degrees.

Semi-closed debug room. Air humidity. Debugging material is generally notebook motherboard

Northbridge. So, when this problem occurs, we want to provide us with the actual situation based on

the curve, make the appropriate adjustments.

Testing method, the use of desktop or laptop Northbridge Northbridge (debug board using waste, but

requires PCB level, try not to be deformed, PCB no deterioration). Not recommended or smaller

notebook graphics chip temperature debugging.

The welding of the board, the use of clamps clamping formation, first observed in the fourth paragraph

of the complete set running time, observe the line of the test temperature from the temperature, the

ideal temperature is lead-free curve can reach 217 degrees, the curve has lead to 183 degrees. These

two temperatures is lead-free and lead-melting point materials. But this time the lower part of the chip

solder balls not melting, from the maintenance point of view, the ideal temperature is 235 degrees

lead-free, lead-200 degrees, then melted and then cooled ball will reach the ideal strength.

Lead-free solder, for example:

After the fourth paragraph of heating, the temperature does not reach 217 degrees, then according to

the size of the gap and improve the third, four temperature. For example: the measured temperature

reaches 205 degrees, then the hot air up and down independently adjustable by 10 degrees each. If a

big gap between the measured 195 degrees, 30 degrees is recommended to improve the bottom,

raise the upper 20 degrees, the upper temperature should not increase too much, so as to avoid

thermal shock of the chip is too large.

After heating, the fourth paragraph of the temperature reached 217 degrees, for the ideal state, if it is

over 220 degrees, will have to observe the fifth paragraph (maximum temperature above) before the

end of the chip to reach the maximum temperature. Advisable not to exceed 240 degrees. If more than

more, may be appropriate to lower the temperature of the fifth paragraph.

2, the welding, the bottom bracket on the PCB board thimble not always withstand the same time,

some feet to the top of the component, how do?

PCB on the bottom of the bracket has been designed thimble we can adjust the height by turning the

screw, according to the six foot level of the difference can be flexible to adjust the height of six feet.

Feet to the top component, may be appropriate to stagger 1-2mm.

3, the air volume control What is the role?

We provide nozzle sizes from 25mm to 40mm five kinds of specifications, even if the same

400-6420-299

htbga@163.com

9

HONTON

www.szhonton.com

temperature setting, using a different nozzle, the final heating temperature of the chip is different. The

smaller the nozzle, the higher the heat within the same unit, the chip temperature is higher, this is a

very simple truth, all the hot air welding equipment, are not escape this law. When the smaller chip

welding when using smaller nozzles, air volume control knob can be passed, the wind speed reduction,

say this greatly reduces the chance of explosion chip.

Of course, another way is to increase the appropriate distance from the nozzle to the chip, an

appropriate increase in 1-2mm, so the chip will greatly reduce the heat.

1, welding 775CPU seat to pay attention to what issues?

775 of the PCB copper distribution is very uneven, is near the outer half of the copper ground wire and

power distribution, on the inside of the half then all of the PCB signal line. According to our tests,

775CPU Block PCB temperature difference between the two largest copper can reach 20 degrees, it

is because a lot of ground and power supply copper PCB heat divergence to other locations.

775, direct plus welding (not removed, then welded directly once), you must use liquid flux.

775 When welding, be sure to remove the metal cover the new socket.

Nozzle selection must be appropriate to select and 775 within the frame of the same size plastic

nozzles.

When welding, be sure to keep holding fixture socket 775 can smooth. Do not bother, to be repeated

by adjusting the lower part of the nozzle to ensure that the top part of the 775 PCB level.

2, the choice of solder paste

Recommended to use environment-friendly liquid flux (for additional welding), or BGA special paste.

But notes that: BGA solder paste is a limitation of use, high temperature solder paste to preserve the

environment can easily lead to failure. Such as 30 degrees room temperature, direct sunlight, within

10 days of solder paste is completely degenerate. Solder paste deterioration, will be completely lost

flux effect. Please select the shady, cool place to store BGA solder paste.

3. BGA soldering cleaning

Recommend the use of a dedicated network of steel plate washer water with ultrasonic cleaning. After

a ball is not recommended to use recycled, once contaminated with dust and eyes can not see a small

amount of solder paste, the next time the plant will cause trouble. PCB recommends using clean cloth

dipped in clean water washer. Plant is completed. Do not allow hand-ball, sweat or grease

contamination after the failure may be caused by welding. Remember: the details determine success

or failure.

4. Explosion on chip chip issues and how to save

BGA chip soldering, I heard a slight crackling sound, w e may be called the explosive bridge, the

bridge explosion caused no more than two reasons: First, the air flow is uneven, a point the

temperature is too high, resulting in explosive bridge; second chip internal humidity, moisture, welding

process, rapid spillover of water vapor, resulting in short circuit or chip the copper circuit. PCB will

have this same problem, a serious damp layer PCB board likely to cause serious short and deformed.

So for some time longer to place the chip, the proposed drying operation, the drying is done using a

simple repair station on the chip temperature of 150 degrees, 15 minutes of heating time. Professional

approach is to use the oven at 100 degrees, the entire piece of board and chip for 10 hours of drying.

Chips stored in the indoor environment, even if the new chips will still absorb moisture from the air,

causing damage, so it is recommended to buy Cabinets (generally used to store drugs) to save the

400-6420-299

htbga@163.com

10

HONTON

www.szhonton.com

chip.

5, How to Take Glue chip?

If the use of temperature on the bottom line of BGA chip to test the temperature of 230 degrees, this

time, the ball has melted but why take the chip as usual approach, the chip holding forceps not get

down, because the adhesive of the chip, so hard Take, then force will take off point? No. Beca use the

pad on the tin has melted into a liquid state, while the glue is between perfusion in the ball and did not

stick on the pad of course not hard to take off points.

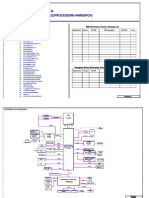

(F) reference temperature curve

it82801dbm

3

100

60

3

165

45

3

195

40

3

210

40

3

220

40

3

100

60

3

165

45

3

195

40

3

210

40

3

220

40

3

80

60

3

110

40

3

130

40

3

150

40

3

180

45

3

100

60

3

185

45

3

215

40

3

225

45

3

245

40

3

255

40

3

100

60

3

185

45

3

215

40

3

225

45

3

245

40

3

255

40

3

80

60

3

110

40

3

130

40

3

150

40

3

180

45

3

200

45

it82845PM

it82801HBM

3

100

60

3

165

45

3

195

45

3

215

45

3

225

40

400-6420-299

htbga@163.com

11

HONTON

it82945GM

ATI 7500

nvid g6150

www.szhonton.com

3

100

60

3

165

45

3

195

45

3

215

45

3

225

40

3

80

60

3

110

40

3

130

40

3

150

40

3

180

45

3

100

60

3

185

45

3

215

40

3

225

40

3

245

45

3

252

40

3

262

30

3

100

60

3

185

45

3

215

40

3

225

40

3

245

45

3

252

40

3

262

30

3

80

60

3

110

40

3

130

40

3

150

40

3

170

45

3

180

40

3

200

45

3

100

60

3

165

45

3

185

50

3

200

45

3

210

35

3

100

60

3

165

45

3

195

45

3

210

40

3

220

45

3

80

60

3

110

40

3

130

40

3

150

40

3

180

60

3

185

45

3

215

40

3

225

40

3

235

40

3

245

40

3

255

40

3

100

60

400-6420-299

htbga@163.com

12

HONTON

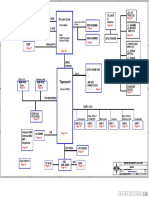

amd

775cpu sck

479cpu sck

www.szhonton.com

100

60

185

45

215

40

225

40

235

40

245

40

255

40

3

80

60

3

110

40

3

130

40

3

150

40

3

180

45

3

190

40

3

200

40

3

100

60

3

185

45

3

215

40

3

225

40

3

235

40

3

243

45

3

253

40

3

100

60

3

185

45

3

215

40

3

225

40

3

235

40

3

243

45

3

253

40

3

80

60

3

110

40

3

130

40

3

150

40

3

180

45

3

190

45

3

210

45

3

100

60

3

185

45

3

215

40

3

225

40

3

245

50

3

255

50

3

275

45

3

285

45

3

100

60

3

185

45

3

215

40

3

225

40

3

245

50

3

255

50

3

275

45

3

285

45

3

80

60

3

110

40

3

130

40

3

150

40

3

180

45

3

200

45

3

210

45

3

220

60

3

100

60

3

185

45

3

215

40

3

225

40

3

245

45

3

255

40

3

265

45

3

100

60

3

185

45

3

215

40

3

225

40

3

245

45

3

255

40

3

265

45

400-6420-299

htbga@163.com

13

HONTON

www.szhonton.com

3

80

60

zhiqiu

3

110

40

3

130

40

3

225

60

3

255

45

3

225

60

3

255

45

3

80

60

3

110

40

3

150

40

3

180

45

3

190

45

3

200

45

(G) after-sales support and contact

The whole year warranty, two-year service warranty thermostat.

Other accessories:

1, the nozzle does not provide warranty service.

2, CD-ROM does not provide warranty service. If damaged, please contact us for download.

Website http://www.szhonton.com

E-mail: htbga@163.com

Technology QQ: 611650545 QQ Group: 42738780

National Toll Free: 400--6420--299

(mechanical failure) 13922807635 (electrical failure)

400-6420-299

htbga@163.com

14

S-ar putea să vă placă și

- LSPWM (7R1) 26 03 09Document1 paginăLSPWM (7R1) 26 03 09Ricardo EmilioÎncă nu există evaluări

- Acopos PDFDocument19 paginiAcopos PDFHoàng Mỹ NguyễnÎncă nu există evaluări

- Ipxlp-Mb Manual (5!26!08)Document6 paginiIpxlp-Mb Manual (5!26!08)Gleizer FerreiraÎncă nu există evaluări

- A14HM02 REV.B M/B and Daughter Board SchematicDocument7 paginiA14HM02 REV.B M/B and Daughter Board SchematicAndré HipnotistaÎncă nu există evaluări

- Dell Inspiron 1545 - Wistron Dr1 Roberts Uma - 48.4aq01.031 08212-3Document59 paginiDell Inspiron 1545 - Wistron Dr1 Roberts Uma - 48.4aq01.031 08212-3_Spiritum_75% (4)

- Esquema Gigabyte GA-945GZM-S2 V3.0Document33 paginiEsquema Gigabyte GA-945GZM-S2 V3.0tecboard100% (1)

- Delta Tau TURBO CLIPPER User ManualDocument83 paginiDelta Tau TURBO CLIPPER User ManualHAFIZ RASHIDÎncă nu există evaluări

- Datasheet 8V1010002-ACOPOS 1010Document20 paginiDatasheet 8V1010002-ACOPOS 1010Umut ÖnalÎncă nu există evaluări

- CFW500 User's Manual: Motors, Automation, Energy & TransmissionDocument168 paginiCFW500 User's Manual: Motors, Automation, Energy & TransmissionRodney PimentaÎncă nu există evaluări

- Viper22a Equivalent PDFDocument16 paginiViper22a Equivalent PDFXande Nane Silveira0% (1)

- PL Ga800 01 PDFDocument50 paginiPL Ga800 01 PDFBock DharmaÎncă nu există evaluări

- AOC 212Va+SERVICE+MANUAL PDFDocument60 paginiAOC 212Va+SERVICE+MANUAL PDFMarcos RangelÎncă nu există evaluări

- Intellispec™: System Monitor Addendum For SVDocument21 paginiIntellispec™: System Monitor Addendum For SVdave afolaluÎncă nu există evaluări

- EEM 03.09 - Manual HAPN - Inversor de Frequencia HPI6000Document76 paginiEEM 03.09 - Manual HAPN - Inversor de Frequencia HPI6000Luiz Ushijima0% (1)

- LSPWM (7R1) 27 11 09Document1 paginăLSPWM (7R1) 27 11 09ShermanFreitasdeLima50% (2)

- MINAS LIQI servo drive solutionDocument4 paginiMINAS LIQI servo drive solutionPaladini100% (1)

- VTwin ENDocument4 paginiVTwin ENnguyennganbÎncă nu există evaluări

- Acsd SeriesDocument82 paginiAcsd SeriesSebeliÎncă nu există evaluări

- MT6070iH Spec Eng 110607Document2 paginiMT6070iH Spec Eng 110607rmorenodx4587Încă nu există evaluări

- Ed Laboratory Dsa8400Document2 paginiEd Laboratory Dsa8400Jose Cesar Souza GebaraÎncă nu există evaluări

- Leaflet Delem Profile-W enDocument2 paginiLeaflet Delem Profile-W enTanvon MalikÎncă nu există evaluări

- Aoz1212ai PDFDocument18 paginiAoz1212ai PDF060279Încă nu există evaluări

- EPower 029669 5 PDFDocument14 paginiEPower 029669 5 PDFrajabharath12Încă nu există evaluări

- Installation and Operation ManualDocument19 paginiInstallation and Operation Manualciornei7romicaÎncă nu există evaluări

- Manual OmbiraDocument16 paginiManual Ombirazz2nktÎncă nu există evaluări

- VLT Automationdrive FC 360Document78 paginiVLT Automationdrive FC 360Carlos XÎncă nu există evaluări

- Pmac Tuning Pro PDFDocument63 paginiPmac Tuning Pro PDFAnonymous HGOomkn69Încă nu există evaluări

- 8 DtekDocument1 pagină8 DtekAlexander WieseÎncă nu există evaluări

- Error ACOPOS enDocument34 paginiError ACOPOS enAHMED AwashaÎncă nu există evaluări

- Prpic (7) 24V 25 11 04 PDFDocument1 paginăPrpic (7) 24V 25 11 04 PDFAnildo Eldivar De Oliveira Sarmento100% (1)

- Gefran GTF Xtra ManualDocument29 paginiGefran GTF Xtra ManualjilfÎncă nu există evaluări

- MT506TV46 DatasheetDocument2 paginiMT506TV46 DatasheetJederVieiraÎncă nu există evaluări

- Qirox V7.10eDocument442 paginiQirox V7.10estorekeyÎncă nu există evaluări

- DP TerminationDocument2 paginiDP Terminationsteam100deg8229Încă nu există evaluări

- Samsung Xpress SL-M2885FW - SL-M2870FD - ETS - Parts.Document28 paginiSamsung Xpress SL-M2885FW - SL-M2870FD - ETS - Parts.Júlio Cesar Guimarães de SouzaÎncă nu există evaluări

- Compal La-B016p r1.0 Schematics PDFDocument57 paginiCompal La-B016p r1.0 Schematics PDFBivek BasnetÎncă nu există evaluări

- Crouzet M2Document32 paginiCrouzet M2shadi2010Încă nu există evaluări

- FE2.1 Data Sheet 1.4 PDFDocument23 paginiFE2.1 Data Sheet 1.4 PDF3degreesÎncă nu există evaluări

- Kirisun PT8100-Service-ManualDocument35 paginiKirisun PT8100-Service-ManualRobertino100% (1)

- Configure Studio 5000 Clock Sync ServiceDocument14 paginiConfigure Studio 5000 Clock Sync ServiceIrfan Khan100% (1)

- HIK-7604NI-K1-4P User Manual PDFDocument275 paginiHIK-7604NI-K1-4P User Manual PDFfuiconÎncă nu există evaluări

- Allied Catalog For Email 2019Document87 paginiAllied Catalog For Email 2019sigurdur hannessonÎncă nu există evaluări

- Esquema Elétrico Receptor Orbisat S-2200 Plus IIDocument6 paginiEsquema Elétrico Receptor Orbisat S-2200 Plus IIeletronicagauchoÎncă nu există evaluări

- Hybrid Power Boost (HPB) and Narrow VDC (NVDC) Combo Battery Charger With Smbus InterfaceDocument2 paginiHybrid Power Boost (HPB) and Narrow VDC (NVDC) Combo Battery Charger With Smbus InterfaceSelmar Cavalcanti0% (1)

- DSE9701 & DSE9702: Vertical 5 Amp Battery ChargersDocument2 paginiDSE9701 & DSE9702: Vertical 5 Amp Battery Chargersasuhuane100% (1)

- Ford Ethernet-IP Interface: Controller OptionDocument31 paginiFord Ethernet-IP Interface: Controller Optionbrenobenilson santosÎncă nu există evaluări

- Ic 693 Cpu 313Document5 paginiIc 693 Cpu 313mubashersaeedÎncă nu există evaluări

- Kds3 Manual Final Lr1Document51 paginiKds3 Manual Final Lr1Rener Ware100% (1)

- Msi Ms-n01x Rev 0a - Ms-n0141Document32 paginiMsi Ms-n01x Rev 0a - Ms-n0141Region 51100% (1)

- Drive 21481044 - 200929Document84 paginiDrive 21481044 - 200929kevin kurnia marpaung100% (1)

- Maquina de Instrumentação PDFDocument4 paginiMaquina de Instrumentação PDFhecirlene vieiraÎncă nu există evaluări

- Esquema Nhs Laser 3000 vaPRPWM (9R2) - 96V.10.02.10Document1 paginăEsquema Nhs Laser 3000 vaPRPWM (9R2) - 96V.10.02.10AlexandreÎncă nu există evaluări

- Esquema La-E993pDocument78 paginiEsquema La-E993pc4rl0slinuxÎncă nu există evaluări

- XT20101227 Turning Lathe CNC Controller CNC4620Document99 paginiXT20101227 Turning Lathe CNC Controller CNC4620Mohammed MagdyÎncă nu există evaluări

- ICS-490 BGA Rework Station Operation ManualDocument14 paginiICS-490 BGA Rework Station Operation ManualfranzysÎncă nu există evaluări

- ZM r5850Document30 paginiZM r5850taslim4uÎncă nu există evaluări

- ZM r5830Document27 paginiZM r5830Camilo JimenezÎncă nu există evaluări

- Bauer BGA Rework Station ManualDocument27 paginiBauer BGA Rework Station ManualEduardo Adrat100% (1)

- BGA Rework Station User ManualDocument18 paginiBGA Rework Station User ManualFrancisco Jose Padrino GoyaÎncă nu există evaluări

- 5860C English ManualDocument22 pagini5860C English ManualFengky Cleons ChouÎncă nu există evaluări

- CM - Scope of ServicesDocument3 paginiCM - Scope of ServicesMelvin MagbanuaÎncă nu există evaluări

- S 20A Specification Forms PDFDocument15 paginiS 20A Specification Forms PDFAlfredo R Larez0% (1)

- Chapter 27 Protists I. Evolution of EukaryotesDocument7 paginiChapter 27 Protists I. Evolution of EukaryotesNadeem IqbalÎncă nu există evaluări

- Making An Appointment PaperDocument12 paginiMaking An Appointment PaperNabila PramestiÎncă nu există evaluări

- ms360c Manual PDFDocument130 paginims360c Manual PDFEdgardoCadaganÎncă nu există evaluări

- Final Reflective Essay by Georgi ShopovDocument7 paginiFinal Reflective Essay by Georgi ShopovMd Siddique UllahÎncă nu există evaluări

- Awwa c207 Flanges Spec SheetDocument13 paginiAwwa c207 Flanges Spec SheetVincent DiepÎncă nu există evaluări

- Unit 4 AE Scan OCRed PDFDocument44 paginiUnit 4 AE Scan OCRed PDFZia AhmedÎncă nu există evaluări

- An IDEAL FLOW Has A Non-Zero Tangential Velocity at A Solid SurfaceDocument46 paginiAn IDEAL FLOW Has A Non-Zero Tangential Velocity at A Solid SurfaceJayant SisodiaÎncă nu există evaluări

- Remembering Manoj ShuklaDocument2 paginiRemembering Manoj ShuklamadhukarshuklaÎncă nu există evaluări

- TH255C Engine CAT PartsDocument134 paginiTH255C Engine CAT PartsKevine KhaledÎncă nu există evaluări

- Attribute Achievement FormDocument15 paginiAttribute Achievement FormMiguel MenesesÎncă nu există evaluări

- DRUG LISTDocument45 paginiDRUG LISTAmitKumarÎncă nu există evaluări

- A Final Project For The Course Title "Monetary Policy and Central Banking"Document11 paginiA Final Project For The Course Title "Monetary Policy and Central Banking"Elle SanchezÎncă nu există evaluări

- HandoutDocument4 paginiHandoutZack CullenÎncă nu există evaluări

- NT140WHM N46Document34 paginiNT140WHM N46arif.fahmiÎncă nu există evaluări

- 01 Lab ManualDocument5 pagini01 Lab ManualM Waqar ZahidÎncă nu există evaluări

- New Directions Formative TestDocument1 paginăNew Directions Formative TestAnonymous xGQcti3qK100% (1)

- RPH Sains DLP Y3 2018Document29 paginiRPH Sains DLP Y3 2018Sukhveer Kaur0% (1)

- Future War in Cities Alice Hills PDFDocument5 paginiFuture War in Cities Alice Hills PDFazardarioÎncă nu există evaluări

- JE Creation Using F0911MBFDocument10 paginiJE Creation Using F0911MBFShekar RoyalÎncă nu există evaluări

- Uhde Painting SpecificationDocument34 paginiUhde Painting Specificationmohamed elmasryÎncă nu există evaluări

- OWASP Dependency-Check Plugin: DescriptionDocument10 paginiOWASP Dependency-Check Plugin: DescriptionFelipe BarbosaÎncă nu există evaluări

- A-00 IndexDocument10 paginiA-00 IndexNizarHamrouniÎncă nu există evaluări

- 09 Lift Cylinder Drift (Bulldozer) - CheckDocument2 pagini09 Lift Cylinder Drift (Bulldozer) - CheckFredy Manrique AstoÎncă nu există evaluări

- Flexural Analysis of Beams (Part 2)Document7 paginiFlexural Analysis of Beams (Part 2)Johnnette Nafuerza AggabaoÎncă nu există evaluări

- Gild PitchDocument19 paginiGild PitchtejabharathÎncă nu există evaluări

- Sine and Cosine Exam QuestionsDocument8 paginiSine and Cosine Exam QuestionsGamer Shabs100% (1)

- Ted Hughes's Crow - An Alternative Theological ParadigmDocument16 paginiTed Hughes's Crow - An Alternative Theological Paradigmsa46851Încă nu există evaluări