Documente Academic

Documente Profesional

Documente Cultură

VIP4Tools Solution for Air/Oil and Dry Machining

Încărcat de

Nimo NingthoujaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

VIP4Tools Solution for Air/Oil and Dry Machining

Încărcat de

Nimo NingthoujaDrepturi de autor:

Formate disponibile

VIP4Tools

A Complete Solution for a

wide range of Air/Oil and Dry

Machining Applications.

Automatic Lubrication System

A Complete Range of components, lubricants and

accessories to realise your Dry Machining Application

By using the VIP4Tools product range you can take full advantage of recent advances

in machine tool and lubricant technology to achieve substantial cost saving and

environmental benefits. The aim of Dry machining is to create a thin lubricant film

between the tool and the part being machined.

Some of key advantages of Dropsa Vip4Tool:

Increased Tool Life

Significant Reduction in Lubricant Usage.

No Work-area Mist

Clean Machined Parts.

The Vip4Tool main unit can be fitted with a pneumatic timer, that automatically cycles

the system or alternatively with a 3-way solenoid valve for applications where the time

interval is controlled by the host machine. Additionally each lubrication outlet can be

individually regulated from 0-30 mm of oil discharge.

TECHNICAL INFORMATION

Operating Air

5 8 bar

Pressure

(74 118 psi)

Operating

-10 +80 C

Temperature

(14F 176F)

Humidity

90% max

Dropsa LRT

Lubricants

Oils

Level Switch, Max

50 W

Load

Level Switch, Max

1A

Current

Level Switch, Max

220 V AC

Voltage

Dropsa has two specially developed lubricants for use on Dry machining applications:

optimised either for Aluminum or Steel machining, both are completely non-toxic.

Included with the Lubricant is a Spec sheet giving recommendations on volume and

pressure requirements for a variety of machining operations.

To get the most from your installation, select from a range of spray, flexible hoses and

fixing accessories.

DESIGNING YOUR VIP4TOOLS APPLICATION IN 4 EASY STEPS

STEP 1 STEP 2 Choose the Number of spray points you

require and the size of Reservoir.

Choose how you want to control the system.

3132572 - Pneumatic Timer (operates in standalone) 1s 1 min.

No of

Points.

3132574 EV 24 V DC + 39979 + N 3 Pcs 53923 + N 3 Pcs 16077

1

2

3

4

5

6

7

8

STEP 4

1 Litre

Reservoir

3 Litre

Reservoir

3135091

3135092

3135093

3135094

3135095

3135096

3135097

3135098

3135111

3135112

3135113

3135114

3135115

3135116

3135117

3135118

3132575 EV 110 V AC + 39979 + N 3 Pcs 53923 + N 3 Pcs 16077

Panels arranged for kit mounting.

STEP 3 -

Qty

Select one or more Lubricants to suit your application.

3226661 LRT 30 - Oil optimised for Steel - 1 lt (*)

3226662 LRT 50 - Oil optimised for Aluminium 1 lt

(*) Also use this for general purpose applications.

Choose the number and type of spray fittings and accessories you require.

A

B

Item

A

B

C

-

P/N

3132583

3132714

1524486

1524487

5717242

1524548

Description

Spray Tube With Magnetic Base L = 180 mm

Spray Tube With Magnetic Base L = 400 mm

Saw Blade attachment, 32 mm (1.3 in.)

Saw Blade attachment, 48 mm (1.9 in)

Nylon Tube 4 x 1.5 Black

Nozzle 5/16 tube 4

Qty

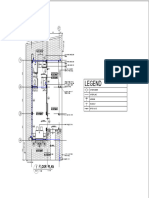

Panel dimensions

Elements

Web site:

http://www.dropsa.com

E-mail:

sales@dropsa.com

WK 05/04

C2040PE

1

2

3

4

5

6

7

8

Y

(mm)

363

391

419

447

475

503

531

559

Version 1 lt

X

Z

Weight

(mm) (mm) (Kg.)

2,7

3,2

3,7

4,2

235

220

4,7

5,2

5,7

6,2

Y

(mm)

365

393

421

449

477

505

533

561

Version 3 lt

X

Z

(mm) (mm)

320

305

Weight

(Kg.)

3,6

4,1

3

5,1

5,6

6,1

6,6

7,1

M6

ITALIA

Dropsa SpA

t.(+39) 02-250791

f.(+39) 02-25079767

U.S.A.

Dropsa Corporation

t.(+1) 586-566-1540

f.(+1) 586-566-1541

BRAZIL

Dropsa

t.(+55) 011-563-10007

f.(+55) 011-563-19408

AUSTRALIA

Dropsa Australia Ltd.

t.(+61) 02-9938-6644

f.(+61) 02-9938-6611

ESPAA

Polydrop, S.A.

t.(+34) 93-260-22-50

f.(+34) 93-260-22-51

U.K.

Dropsa (UK) Ltd

t.(+44) 01784-431177

f.(+44) 01784-438598

GERMANY

Dropsa Gmbh

t.(+49) 0211-394-011

f.(+49) 0211-394-013

FRANCE

Dropsa Ame

t.(+33) 01-3993-0033

f.(+33) 01-3986-2636

S-ar putea să vă placă și

- VW Transporter T4 Workshop Manual Diesel 2000-2004De la EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Evaluare: 5 din 5 stele5/5 (5)

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)De la EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Încă nu există evaluări

- Logan Lathe Model 922 ManualDocument16 paginiLogan Lathe Model 922 Manualnjsmith5Încă nu există evaluări

- Model D4BDocument165 paginiModel D4BTorque100% (13)

- 734 Opp. Man. GBDocument0 pagini734 Opp. Man. GBChristian Kunze67% (3)

- Automotive Air Conditioning and Climate Control SystemsDe la EverandAutomotive Air Conditioning and Climate Control SystemsEvaluare: 4 din 5 stele4/5 (6)

- Ficha Doosan Compresoresportatiles XHP1170 en 0Document4 paginiFicha Doosan Compresoresportatiles XHP1170 en 0death666darkÎncă nu există evaluări

- en WHB Hatz W35Document76 paginien WHB Hatz W35Guido Giovanni Franco Rodriguez100% (1)

- Bomag BW213Document148 paginiBomag BW213edascribd80% (10)

- 2954 4200 00 XRYS 557-577 CD - Product ReferenceDocument6 pagini2954 4200 00 XRYS 557-577 CD - Product ReferenceALP69Încă nu există evaluări

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDe la EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualÎncă nu există evaluări

- 12-2218-r01 (59552105) SP5Document11 pagini12-2218-r01 (59552105) SP5Brad KerrÎncă nu există evaluări

- MANN Filters for Industrial LiquidsDocument48 paginiMANN Filters for Industrial LiquidsRoccinanteÎncă nu există evaluări

- Service Tool Catalog: Performance PartsDocument90 paginiService Tool Catalog: Performance PartsOsvaldo Vargas Vergara100% (2)

- Wirtgen+machine Seriola+1510Document8 paginiWirtgen+machine Seriola+1510Nunnun NaezÎncă nu există evaluări

- Lubrication Equipment CatalogDocument60 paginiLubrication Equipment Catalogjairo269Încă nu există evaluări

- 19. OUTLINE OF SERVICEDocument34 pagini19. OUTLINE OF SERVICEgerman gualavisiÎncă nu există evaluări

- MLP - Mobile Lube Pump: User and Maintenance Manual Warranty InformationDocument23 paginiMLP - Mobile Lube Pump: User and Maintenance Manual Warranty InformationTimon2005Încă nu există evaluări

- SureFire-PDI Pumps 8-10Document7 paginiSureFire-PDI Pumps 8-10Joel Muñoz BernalÎncă nu există evaluări

- ARO Page LubricationDocument30 paginiARO Page LubricationEsteban Fernando Meza IbacetaÎncă nu există evaluări

- Sotras ManualDocument24 paginiSotras ManualcivodulÎncă nu există evaluări

- 7480J Section A (Mobile)Document244 pagini7480J Section A (Mobile)Hoang Minh Hung100% (1)

- Catalog 01 Single LineDocument24 paginiCatalog 01 Single Lineangela draguÎncă nu există evaluări

- Lubrication Order 31 July 2008Document8 paginiLubrication Order 31 July 2008richardgary52DÎncă nu există evaluări

- Condensadora TTB TraneDocument24 paginiCondensadora TTB TraneRoberto Reyes Lara100% (1)

- Centralised lubrication system guideDocument32 paginiCentralised lubrication system guideShivakumar PattarÎncă nu există evaluări

- Lo 5-3895-385-13Document20 paginiLo 5-3895-385-13AdvocateÎncă nu există evaluări

- Almig Combi GB WebDocument8 paginiAlmig Combi GB WebRomanCHubaÎncă nu există evaluări

- Stornillador Atlas CopcoDocument204 paginiStornillador Atlas CopcoTuro SánchezÎncă nu există evaluări

- TRANSFIX Users Guide MODBUS ProtocolDocument19 paginiTRANSFIX Users Guide MODBUS ProtocolsantoshkumarÎncă nu există evaluări

- MOPX Operation IsntructionsDocument28 paginiMOPX Operation IsntructionsEser67% (3)

- Sanden AC System Charge Weight&DescriptionDocument1 paginăSanden AC System Charge Weight&DescriptionElie JosephÎncă nu există evaluări

- Almig Screw Air CompDocument8 paginiAlmig Screw Air CompMohamed HarbÎncă nu există evaluări

- SAB Screw CompressorsDocument2 paginiSAB Screw CompressorsVolvouser0% (1)

- Nitrogen Compressor Guide: "Compair Provide High Quality and Reliable Nitrogen SolutionsDocument5 paginiNitrogen Compressor Guide: "Compair Provide High Quality and Reliable Nitrogen Solutionskalpesh_1588Încă nu există evaluări

- Catalogo Control ContaminantesDocument132 paginiCatalogo Control ContaminantesJose Jaramillo50% (2)

- Workshop Layout SampleDocument44 paginiWorkshop Layout Sampleautocarewin83% (6)

- Portable Air Compressors with Deutz EnginesDocument20 paginiPortable Air Compressors with Deutz EnginesTaz Juan GÎncă nu există evaluări

- Single Drum P54K K2B K4B Rev 0 Ops Manual DataId 18454 Version 1Document44 paginiSingle Drum P54K K2B K4B Rev 0 Ops Manual DataId 18454 Version 1Vikas MahajanÎncă nu există evaluări

- Compresor AC SanDen Service Guide Rev.2Document30 paginiCompresor AC SanDen Service Guide Rev.2MArco Zaragoza100% (2)

- Solvent Flow Meter Catalogue PDFDocument6 paginiSolvent Flow Meter Catalogue PDFJR DadisÎncă nu există evaluări

- TURBOIL F Oil SepratorsDocument11 paginiTURBOIL F Oil SepratorsMohammad AmerÎncă nu există evaluări

- Centro-Matic Automated Lubrication Systems: System ControlsDocument8 paginiCentro-Matic Automated Lubrication Systems: System ControlsAlex Rivera RiveraÎncă nu există evaluări

- Engine Lubrication GuideDocument6 paginiEngine Lubrication GuideNicu PascalutaÎncă nu există evaluări

- Memolub Triptyque en 140402 LRA4Document6 paginiMemolub Triptyque en 140402 LRA4Diego Felipe Gavilán RetamalesÎncă nu există evaluări

- Garage Equipment Tools Mot Supplies PrintingDocument48 paginiGarage Equipment Tools Mot Supplies Printingmark5765Încă nu există evaluări

- ScrollDocument8 paginiScrolltrung2iÎncă nu există evaluări

- User'S Manual: Digital Diesel Compression Test Kit MODEL MV5535Document28 paginiUser'S Manual: Digital Diesel Compression Test Kit MODEL MV5535Segundo Francisco Jauregui ValenciaÎncă nu există evaluări

- DG FuelDocument42 paginiDG Fuelruchir_bhoglekarÎncă nu există evaluări

- Re92105 2003-11Document32 paginiRe92105 2003-11Madhu RajagopalanÎncă nu există evaluări

- Air Line AccessoriesDocument4 paginiAir Line AccessoriesZeckÎncă nu există evaluări

- SRP 3000 Rotary Screw Compressors 15-100 hpDocument6 paginiSRP 3000 Rotary Screw Compressors 15-100 hpcecoelsacÎncă nu există evaluări

- Double-Stage Vacuum Transformer Oil Purifier Series ZYDDocument10 paginiDouble-Stage Vacuum Transformer Oil Purifier Series ZYD130792Încă nu există evaluări

- Troubleshooting and Repair of Diesel EnginesDe la EverandTroubleshooting and Repair of Diesel EnginesEvaluare: 1.5 din 5 stele1.5/5 (2)

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityDe la EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityEvaluare: 3 din 5 stele3/5 (4)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceDe la EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceÎncă nu există evaluări

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDe la EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualEvaluare: 3.5 din 5 stele3.5/5 (2)

- 11 Eleven 12 Twelve 13 Thirteen 14 Fourteen 15 Fifteen 16 Sisteen 17 Seventeen 18 Eighteen 19 Nineteen 20 TwentyDocument1 pagină11 Eleven 12 Twelve 13 Thirteen 14 Fourteen 15 Fifteen 16 Sisteen 17 Seventeen 18 Eighteen 19 Nineteen 20 TwentyNimo NingthoujaÎncă nu există evaluări

- Qip Ice 06 Valve Timing DiagramsDocument29 paginiQip Ice 06 Valve Timing Diagramsام احمدÎncă nu există evaluări

- Cursive Practice A ZDocument26 paginiCursive Practice A Zavabhyankar9393Încă nu există evaluări

- Amitabha Ghosh and Ashok Kumar Malik Pearson IndiaDocument2 paginiAmitabha Ghosh and Ashok Kumar Malik Pearson IndiaNimo NingthoujaÎncă nu există evaluări

- Mechanical Bulletin - Issue 1Document4 paginiMechanical Bulletin - Issue 1Nimo NingthoujaÎncă nu există evaluări

- HistoryDocument1 paginăHistoryamar345Încă nu există evaluări

- Rubiks Cube 3x3 Solution-En PDFDocument13 paginiRubiks Cube 3x3 Solution-En PDFMidhun U K100% (1)

- (Ƒ (Ñ - V¡Û¡ &Ƒ ( ( Ìñ - Î Kã V¡Û¡À &G ˺ïj Šãúå - A¡ ( (T¡Document1 pagină(Ƒ (Ñ - V¡Û¡ &Ƒ ( ( Ìñ - Î Kã V¡Û¡À &G ˺ïj Šãúå - A¡ ( (T¡Nimo NingthoujaÎncă nu există evaluări

- The SangaiDocument1 paginăThe SangaiNimo NingthoujaÎncă nu există evaluări

- 1984 Surf Roughness PGDocument8 pagini1984 Surf Roughness PGHussn YazdanÎncă nu există evaluări

- Gear BoxDocument36 paginiGear BoxNimoÎncă nu există evaluări

- Calibration of Pressure GaugeDocument43 paginiCalibration of Pressure GaugechonubobbyÎncă nu există evaluări

- Usrguid 3Document10 paginiUsrguid 3dtcoilleyÎncă nu există evaluări

- Clutch Systems - PPSXDocument40 paginiClutch Systems - PPSXNimo NingthoujaÎncă nu există evaluări

- Clutch Systems - PPSXDocument40 paginiClutch Systems - PPSXNimo NingthoujaÎncă nu există evaluări

- Statistical Software: Learn What's NewDocument8 paginiStatistical Software: Learn What's NewNimo NingthoujaÎncă nu există evaluări

- Power Mixed Electric Discharge MachiningDocument14 paginiPower Mixed Electric Discharge MachiningNimo NingthoujaÎncă nu există evaluări

- Som Sample Prep+procedure - 2013Document1 paginăSom Sample Prep+procedure - 2013Nimo NingthoujaÎncă nu există evaluări

- Umc PerformaDocument4 paginiUmc PerformaNimo NingthoujaÎncă nu există evaluări

- Faculty Recruitment 2013-2014 - DetailsDocument18 paginiFaculty Recruitment 2013-2014 - DetailsNimo NingthoujaÎncă nu există evaluări

- V LAbDocument1 paginăV LAbNimo NingthoujaÎncă nu există evaluări

- AstrologyDocument203 paginiAstrologyPraveen Kumar0% (1)

- UVM CatalogDocument3 paginiUVM CatalogNimo NingthoujaÎncă nu există evaluări

- Mechanical Gate Paper ADocument16 paginiMechanical Gate Paper AAbhilash G NairÎncă nu există evaluări

- Accumulators and Intensifiers in Hydraulic SystemsDocument7 paginiAccumulators and Intensifiers in Hydraulic SystemsNimo NingthoujaÎncă nu există evaluări

- Crushing Plant For Sale1Document18 paginiCrushing Plant For Sale1Vicky NonatoÎncă nu există evaluări

- Cable Accessories CatalogDocument66 paginiCable Accessories CatalogAhmed NoamanÎncă nu există evaluări

- Helioscope Simulation 13233814 SummaryDocument3 paginiHelioscope Simulation 13233814 SummaryandisaputrawuÎncă nu există evaluări

- Better Packages, Inc.: Bp555E Item ListDocument8 paginiBetter Packages, Inc.: Bp555E Item ListGORDÎncă nu există evaluări

- Armoire Midea MfgaDocument1 paginăArmoire Midea MfgalacothÎncă nu există evaluări

- Lexus NX 200tDocument28 paginiLexus NX 200tSopheak LimÎncă nu există evaluări

- Nu Files-Abtecn3s-A4-OrlinoDocument4 paginiNu Files-Abtecn3s-A4-Orlinojoshua.orlino123Încă nu există evaluări

- Manual para USCC-1L2MDocument104 paginiManual para USCC-1L2Mcharles.schlaepfer7998Încă nu există evaluări

- Dodge Avenger IAT Sensor DTC P0112 P0113 FixDocument7 paginiDodge Avenger IAT Sensor DTC P0112 P0113 Fixflash_24014910Încă nu există evaluări

- Digital Laser MFP SCX-6322DN Service ManualDocument185 paginiDigital Laser MFP SCX-6322DN Service ManualjaimecamoÎncă nu există evaluări

- Deep Groove Ball Bearings, Single Row - 6312-2ZDocument2 paginiDeep Groove Ball Bearings, Single Row - 6312-2ZHamada HussienÎncă nu există evaluări

- Mobel SofaDocument55 paginiMobel SofaNikhil R KÎncă nu există evaluări

- Ex.2 - Ecad 1Document6 paginiEx.2 - Ecad 1Saturn MoonÎncă nu există evaluări

- OBSM - Mandatory Annexes - Nov 2015Document41 paginiOBSM - Mandatory Annexes - Nov 2015Bibo KhoÎncă nu există evaluări

- 30gtn 1pd UpdateDocument100 pagini30gtn 1pd UpdateSyed Ali KhanÎncă nu există evaluări

- Manual transmission disassembly and reassembly guideDocument62 paginiManual transmission disassembly and reassembly guidearmawanÎncă nu există evaluări

- Bluetooth HC-05 and HC-06 pinout guideDocument11 paginiBluetooth HC-05 and HC-06 pinout guidesaravananÎncă nu există evaluări

- 7 A H-Bridge For DC-Motor Applications 30348: Preliminary DatasheetDocument4 pagini7 A H-Bridge For DC-Motor Applications 30348: Preliminary DatasheetallisonÎncă nu există evaluări

- Course: Industrial Electrician: Day 4: TopicsDocument37 paginiCourse: Industrial Electrician: Day 4: TopicsKiyoshi Jiro MalinaoÎncă nu există evaluări

- FPGA Based Hardware Acceleration A CPU - Accelerator Interface ExplorationDocument4 paginiFPGA Based Hardware Acceleration A CPU - Accelerator Interface ExplorationPratibha V. HegdeÎncă nu există evaluări

- Power Analysis: Prof. Jagannadha Naidu KDocument23 paginiPower Analysis: Prof. Jagannadha Naidu KParth VijayÎncă nu există evaluări

- Fan Drive System: Systems OperationDocument5 paginiFan Drive System: Systems Operationallan lariosaÎncă nu există evaluări

- Protection Engineering and Research Laboratories: Session VII: Transformer ProtectionDocument105 paginiProtection Engineering and Research Laboratories: Session VII: Transformer Protectionsupermannon100% (8)

- Ficha Tecnica JLG E600Document2 paginiFicha Tecnica JLG E600David GordilloÎncă nu există evaluări

- Datasheet Tensite Batteries AGM 12 300Document3 paginiDatasheet Tensite Batteries AGM 12 300Juan F. MarínÎncă nu există evaluări

- Tvs XL 100Document49 paginiTvs XL 100Jose JohnÎncă nu există evaluări

- Voltage Sag (Dip) and Voltage Swell (Surge)Document3 paginiVoltage Sag (Dip) and Voltage Swell (Surge)Suneet Kumar RathÎncă nu există evaluări

- GMI Student ReportDocument3 paginiGMI Student ReportdmufqiÎncă nu există evaluări