Documente Academic

Documente Profesional

Documente Cultură

Atnms Syllabus M&M

Încărcat de

Vinay KorekarTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Atnms Syllabus M&M

Încărcat de

Vinay KorekarDrepturi de autor:

Formate disponibile

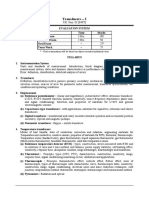

MECHANICAL MEASUREMENTS AND METROLOGY

Subject Code

Hours/Week

Total Hours

: 10ME32B /42B

: 04

: 52

IA Marks

Exam Hours

Exam Marks

: 25

: 03

: 100

PART- A

UNIT-1

Standards of measurement: Definition and Objectives of

metrology, Standards of length-International prototype meter, Imperial

standard yard, Wave length standard, subdivision of standards, line and

end standard, calibration of end bars (Numerical), Slip gauges, Wringing

phenomena, Indian Standards (M-81, M-12), Numerical problems on

building of slip gauges.

06 Hours

UNIT-2

System of Limits, Fits, Tolerance and Gauging: Definition of tolerance,

Specification in assembly, Principle of interchangeability and selective

assembly limits of size, Indian standards, concept of limits of size and

tolerances, compound tolerances, accumulation of tolerances, definition of

fits, types of fits and their designation (IS 919-1963), geometrical tolerance,

positional-tolerances, hole basis system, shaft basis system, classification of

gauges, brief concept of design of gauges (Taylor's principles), Wear

allowance on gauges, Types of gauges-plain plug gauge, ring gauge, snap

gauge, limit gauge and gauge materials.

07 Hours

UNIT-3

Comparators and Angular measurement: Introduction to comparators,

characteristics, classification of comparators, mechanical comparatorsJohnson Mikrokator, sigma comparators, dial indicator, optical comparatorsprinciples, Zeiss ultra optimeter, electric and electronic comparatorsprinciples, LVDT, pneumatic comparators, back pressure gauges, solex

comparators. Angular measurements, bevel protractor, sine principle and use

of sine bars, sine centre, use of angle gauges (numericals on building of

angles), clinometers.

07 Hours

UNIT-4:

Interferometer and screw thread, gear measurement: Interferometer,

interferometry, autocollimator. Optical flats. Terminology of screw threads,

measurement of major diameter, minor diameter, pitch, angle and effective

diameter of screw threads by 2-wire and 3-wire methods, best size

6

wire. Tool maker's microscope, gear tooth terminology, use of gear

tooth vernier caliper and micrometer.

06 Hours

PART-B

UNIT-5:

Measurements and measurement systems: Definition, significance of

measurement, generalized measurement system, definitions and concept of

accuracy, precision, calibration, threshold, sensitivity, hysterisis,

repeatability, linearity, loading effect, system response-times delay. Errors

in measurement, classification of errors. Transducers, transfer efficiency,

primary and secondary transducers, electrical, mechanical, electronic

transducers, advantages of each type transducers.

07 Hours

UNIT-6

Intermediate modifying and terminating devices: Mechanical systems,

inherent problems, electrical intermediate modifying devices, input

circuitry, ballast circuit, electronic amplifiers and telemetry. Terminating

devices, mechanical, cathode ray oscilloscope, oscillographs, X-Y plotters.

06 Hours

UNIT-7

Measurement of force, torque and pressure: Principle, analytical balance,

platform balance, proving ring. Torque measurement, Prony brake,

hydraulic dynamometer. Pressure measurements, principle, use of elastic

members, Bridgeman gauge, McLeod gauge, Pirani gauge.

06 Hours

UNIT-8

Temperature and strain measurement: Resistance thermometers,

thermocouple, law of thermo couple, materials used for construction,

pyrometer, optical pyrometer. Strain measurements, strain gauge, preparation

and mounting of strain gauges, gauge factor, methods of strain measurement.

07 Hours

TEXT BOOKS:

1. Mechanical Measurements, Beckwith Marangoni and

Lienhard, Pearson

Education, 6th Ed., 2006.

2. Engineering Metrology, R.K. Jain, Khanna Publishers, 1994.

7

S-ar putea să vă placă și

- Geometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsDe la EverandGeometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsEvaluare: 4.5 din 5 stele4.5/5 (3)

- Thermodynamics MCQ 1800 MCQ With AnswersDocument133 paginiThermodynamics MCQ 1800 MCQ With Answersswai singh76% (119)

- Instrumentation and Measurement in Electrical EngineeringDe la EverandInstrumentation and Measurement in Electrical EngineeringEvaluare: 3.5 din 5 stele3.5/5 (5)

- Measurement and Instrumentation: Theory and ApplicationDe la EverandMeasurement and Instrumentation: Theory and ApplicationEvaluare: 4.5 din 5 stele4.5/5 (5)

- Question Bank: UNIT:1 Combustion ThermodynamicsDocument14 paginiQuestion Bank: UNIT:1 Combustion ThermodynamicsVinay KorekarÎncă nu există evaluări

- Personality Types and Character TraitsDocument5 paginiPersonality Types and Character TraitspensleepeÎncă nu există evaluări

- Adeptus Evangelion 2.5 - Operations ManualDocument262 paginiAdeptus Evangelion 2.5 - Operations ManualGhostwheel50% (2)

- Course DiaryDocument66 paginiCourse DiaryAishwarya RaviÎncă nu există evaluări

- AERONAUTICAL ENGINEERING SYLLABUSDocument8 paginiAERONAUTICAL ENGINEERING SYLLABUSaeroromeosÎncă nu există evaluări

- AutosyllDocument91 paginiAutosyllRashmi Gowda DÎncă nu există evaluări

- Vtu Mechanical EngineeringDocument175 paginiVtu Mechanical Engineeringsbhalesh40% (5)

- IEM Full SyllabusDocument130 paginiIEM Full Syllabusavishekagarwal_09Încă nu există evaluări

- IpsyllDocument134 paginiIpsyllsatish5269115Încă nu există evaluări

- Vtu Mechanical Engineering Syllabus 20101Document175 paginiVtu Mechanical Engineering Syllabus 20101api-257789307Încă nu există evaluări

- 8th Sem SyllabusDocument6 pagini8th Sem SyllabusAjay UllalÎncă nu există evaluări

- Measurements & Metrology BasicsDocument208 paginiMeasurements & Metrology BasicsPrabakaran Caleb0% (1)

- B.Tech. Mechanical Measurements & Control Semester CourseDocument2 paginiB.Tech. Mechanical Measurements & Control Semester CourseVishal SehrawatÎncă nu există evaluări

- 3 4 Syllabus 21 1 10Document24 pagini3 4 Syllabus 21 1 10ARUNGREESMAÎncă nu există evaluări

- MetrologyDocument3 paginiMetrologySachi DhanandamÎncă nu există evaluări

- Metrology and Instrumentation M 602 3Document1 paginăMetrology and Instrumentation M 602 3AnilkumarGopinathanNairÎncă nu există evaluări

- Btme 503 Mechancial Measurements and Metrology Internal Marks: 40 External Marks: 60 Total Marks: 100Document4 paginiBtme 503 Mechancial Measurements and Metrology Internal Marks: 40 External Marks: 60 Total Marks: 100taak41Încă nu există evaluări

- Annexure Syllabus (For Electrical Branch/AE) : 1. Electrical Circuits and NetworksDocument6 paginiAnnexure Syllabus (For Electrical Branch/AE) : 1. Electrical Circuits and NetworksnajiruddinshaikÎncă nu există evaluări

- State Board of Technical Education &training, Tamilnadu Diploma in Engineering / Technology Syllabus N - SchemeDocument15 paginiState Board of Technical Education &training, Tamilnadu Diploma in Engineering / Technology Syllabus N - SchemeIsrael Dharmaraj100% (1)

- IcasesyDocument40 paginiIcasesyPrem SagarÎncă nu există evaluări

- MMC SyllabusDocument3 paginiMMC SyllabusTejas DesaiÎncă nu există evaluări

- Transducers PDFDocument2 paginiTransducers PDFNahush BapatÎncă nu există evaluări

- 10ee81 Electrical Design, Estimating and CostingDocument16 pagini10ee81 Electrical Design, Estimating and CostingFzs LohiÎncă nu există evaluări

- MODERN CONTROL THEORY AND BIOMEDICAL INSTRUMENTATIONDocument32 paginiMODERN CONTROL THEORY AND BIOMEDICAL INSTRUMENTATIONRoman RoomannÎncă nu există evaluări

- M.Tech Syllabu 2007 2008Document8 paginiM.Tech Syllabu 2007 2008AkhilReddy SankatiÎncă nu există evaluări

- Fourth Semester SyllabusDocument3 paginiFourth Semester SyllabusShashwat GuptaÎncă nu există evaluări

- Syllabus M.tech MechanicalDocument23 paginiSyllabus M.tech Mechanicalडॉ. कनिष्क शर्माÎncă nu există evaluări

- Annexure - I Syllabus For Written Examination: Paper I (Objective Type) (200 Questions)Document2 paginiAnnexure - I Syllabus For Written Examination: Paper I (Objective Type) (200 Questions)kunusenseiÎncă nu există evaluări

- Mechanical Measurements and Metrology Module 1Document22 paginiMechanical Measurements and Metrology Module 1SUNIL SWAMY SÎncă nu există evaluări

- 13Document2 pagini13kusumgdasÎncă nu există evaluări

- Bachelor of Engineering in Electrical & Electronics Engineering - Specialization in Communication EngineeringDocument2 paginiBachelor of Engineering in Electrical & Electronics Engineering - Specialization in Communication EngineeringRandom EngineersÎncă nu există evaluări

- EE208 Measurements N InstrumentationDocument2 paginiEE208 Measurements N InstrumentationSangeetha SumamÎncă nu există evaluări

- Gujarat Technological University - MeasurementDocument4 paginiGujarat Technological University - MeasurementA SÎncă nu există evaluări

- EE208 Measurements and InstrumentationDocument2 paginiEE208 Measurements and InstrumentationSREEHARI S JÎncă nu există evaluări

- Bit Sindri, Dhanbad: NAMEOFDEPTT. /CENTRE: Department of Production EngineeringDocument1 paginăBit Sindri, Dhanbad: NAMEOFDEPTT. /CENTRE: Department of Production Engineeringtalk2sumantaÎncă nu există evaluări

- Limits, Fits and Tolerances PDFDocument22 paginiLimits, Fits and Tolerances PDFmirztrÎncă nu există evaluări

- Electronics and Communication - SyllabusDocument6 paginiElectronics and Communication - SyllabusDeepa ShreeÎncă nu există evaluări

- Metrology and Surface EngineeringDocument2 paginiMetrology and Surface EngineeringnvemanÎncă nu există evaluări

- Store Asst. Babmoo CorporationDocument5 paginiStore Asst. Babmoo CorporationDasapÎncă nu există evaluări

- IV Semester Mechanical Measurements and MetrologyDocument13 paginiIV Semester Mechanical Measurements and MetrologyIrfan AhmadÎncă nu există evaluări

- Annexure II SyllabusDocument9 paginiAnnexure II SyllabusVamshi KrishnaÎncă nu există evaluări

- IIT Kharagpur M.tech MD SyllabusDocument5 paginiIIT Kharagpur M.tech MD SyllabussyampnaiduÎncă nu există evaluări

- Measuring Quality in EngineeringDocument8 paginiMeasuring Quality in Engineeringnavneetkpatil8409Încă nu există evaluări

- 3.1 Control Systems: RationaleDocument15 pagini3.1 Control Systems: RationaleSoumya BhattacharyaÎncă nu există evaluări

- Course Curriculum of The Department of Industrial and Production EngineeringDocument24 paginiCourse Curriculum of The Department of Industrial and Production EngineeringRashedul Islam RanaÎncă nu există evaluări

- Sybtech PDFDocument33 paginiSybtech PDFSonali KahreÎncă nu există evaluări

- RTU-Syllabus of (VI Sem.)Document7 paginiRTU-Syllabus of (VI Sem.)mamta1008835366Încă nu există evaluări

- Mech AutoDocument36 paginiMech Autoapi-236544093Încă nu există evaluări

- 6 Sem EceDocument9 pagini6 Sem EceSachin DhinwaÎncă nu există evaluări

- Engineering Metrology and Measurements - 5th Sem Mechanical & Automobile SyllabusDocument1 paginăEngineering Metrology and Measurements - 5th Sem Mechanical & Automobile Syllabuspriyo21jwÎncă nu există evaluări

- Applied Metrology for Manufacturing EngineeringDe la EverandApplied Metrology for Manufacturing EngineeringEvaluare: 5 din 5 stele5/5 (1)

- Engineering Surveying: Theory and Examination Problems for StudentsDe la EverandEngineering Surveying: Theory and Examination Problems for StudentsEvaluare: 4.5 din 5 stele4.5/5 (8)

- Embedded Mechatronic Systems, Volume 1: Analysis of Failures, Predictive ReliabilityDe la EverandEmbedded Mechatronic Systems, Volume 1: Analysis of Failures, Predictive ReliabilityÎncă nu există evaluări

- Electromagnetic Well Logging: Models for MWD / LWD Interpretation and Tool DesignDe la EverandElectromagnetic Well Logging: Models for MWD / LWD Interpretation and Tool DesignEvaluare: 5 din 5 stele5/5 (1)

- Structural Dynamics of Electronic and Photonic SystemsDe la EverandStructural Dynamics of Electronic and Photonic SystemsÎncă nu există evaluări

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageDe la EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageÎncă nu există evaluări

- The Fast Track to Your Extra Class Ham Radio License: Covers All FCC Amateur Extra Class Exam Questions July 1, 2020 Through June 30, 2024De la EverandThe Fast Track to Your Extra Class Ham Radio License: Covers All FCC Amateur Extra Class Exam Questions July 1, 2020 Through June 30, 2024Încă nu există evaluări

- Automotive Product Design and Development of Car Dashboard Using Quality Function DeploymentDocument12 paginiAutomotive Product Design and Development of Car Dashboard Using Quality Function DeploymentVinay KorekarÎncă nu există evaluări

- Factors For Consideration in Space Planning:: Office Receiving Storage Production Shipping Tool Room and Tool CribDocument39 paginiFactors For Consideration in Space Planning:: Office Receiving Storage Production Shipping Tool Room and Tool CribVinay KorekarÎncă nu există evaluări

- Efm Cia 1 2020-2021Document2 paginiEfm Cia 1 2020-2021Vinay KorekarÎncă nu există evaluări

- QualityfunctiondeploymentDocument28 paginiQualityfunctiondeploymentVinay KorekarÎncă nu există evaluări

- Plant Design: - Basic Layout TypesDocument10 paginiPlant Design: - Basic Layout TypesVinay KorekarÎncă nu există evaluări

- Initial Layout Construction: - PreliminariesDocument43 paginiInitial Layout Construction: - PreliminariesVinay KorekarÎncă nu există evaluări

- EFM Final QuizDocument1 paginăEFM Final QuizVinay KorekarÎncă nu există evaluări

- Customer-Focused Development With QFDDocument7 paginiCustomer-Focused Development With QFDVinay KorekarÎncă nu există evaluări

- ETD Question Bank 2021-22Document14 paginiETD Question Bank 2021-22Vinay KorekarÎncă nu există evaluări

- Factors For Consideration in Space Planning:: Office Receiving Storage Production Shipping Tool Room and Tool CribDocument39 paginiFactors For Consideration in Space Planning:: Office Receiving Storage Production Shipping Tool Room and Tool CribVinay KorekarÎncă nu există evaluări

- FPD Unit 1-Facility Planning and DesignDocument35 paginiFPD Unit 1-Facility Planning and DesignVinay KorekarÎncă nu există evaluări

- EFM Final QuizDocument1 paginăEFM Final QuizVinay KorekarÎncă nu există evaluări

- Everything You Need to Know About Internal Combustion EnginesDocument135 paginiEverything You Need to Know About Internal Combustion EnginesVinay KorekarÎncă nu există evaluări

- Facility Planning and DesignDocument9 paginiFacility Planning and DesignVinay KorekarÎncă nu există evaluări

- Question BankDocument7 paginiQuestion BankVinay KorekarÎncă nu există evaluări

- Fluid Mechanics MCQDocument1 paginăFluid Mechanics MCQVinay KorekarÎncă nu există evaluări

- FPD Unit-2 Material HandlingDocument58 paginiFPD Unit-2 Material HandlingVinay KorekarÎncă nu există evaluări

- Thermodynamics MCQDocument1 paginăThermodynamics MCQVinay KorekarÎncă nu există evaluări

- Thermodynamics MCQDocument1 paginăThermodynamics MCQVinay KorekarÎncă nu există evaluări

- Ic Engine AssignmentDocument2 paginiIc Engine AssignmentVinay KorekarÎncă nu există evaluări

- Course: Maximum Marks: 100: Computer Aided Machine DrawingDocument3 paginiCourse: Maximum Marks: 100: Computer Aided Machine DrawingVinay KorekarÎncă nu există evaluări

- Management Information SystemDocument3 paginiManagement Information SystemVinay KorekarÎncă nu există evaluări

- FMM Cia 2 2019Document2 paginiFMM Cia 2 2019Vinay KorekarÎncă nu există evaluări

- FMM Cia 2 2019Document2 paginiFMM Cia 2 2019Vinay KorekarÎncă nu există evaluări

- Unit 1 Definition of ReengineeringDocument7 paginiUnit 1 Definition of ReengineeringVinay KorekarÎncă nu există evaluări

- IC EnginesDocument2 paginiIC EnginesVinay Korekar0% (1)

- MIS Unit-4 and 5Document38 paginiMIS Unit-4 and 5Vinay KorekarÎncă nu există evaluări

- MIS AssignmentDocument1 paginăMIS AssignmentVinay KorekarÎncă nu există evaluări

- Three Bucket Method & Food ServiceDocument4 paginiThree Bucket Method & Food Servicerose zandrea demasisÎncă nu există evaluări

- Lesson 1 - Simple StressDocument5 paginiLesson 1 - Simple StressJohn Philip NadalÎncă nu există evaluări

- Product CataloguepityDocument270 paginiProduct CataloguepityRaghuRags100% (1)

- High Risk Medications in AyurvedaDocument3 paginiHigh Risk Medications in AyurvedaRaviraj Pishe100% (1)

- HS-2172 Vs HS-5500 Test ComparisonDocument1 paginăHS-2172 Vs HS-5500 Test ComparisonRicardo VillarÎncă nu există evaluări

- Blood Group 3Document29 paginiBlood Group 3Hamirie JoshuaÎncă nu există evaluări

- Semen RetentionDocument3 paginiSemen RetentionMattÎncă nu există evaluări

- Sundar KandvalmikiDocument98 paginiSundar Kandvalmikifactree09Încă nu există evaluări

- DGPS Sensor JLR-4331W Instruction ManualDocument42 paginiDGPS Sensor JLR-4331W Instruction ManualantonioÎncă nu există evaluări

- Cooling System Exhaust System: RadiatorDocument2 paginiCooling System Exhaust System: RadiatorMd ShÎncă nu există evaluări

- Regenerative Medicine Manual ISSCA 2020 EnglishDocument21 paginiRegenerative Medicine Manual ISSCA 2020 EnglishDana MihutÎncă nu există evaluări

- Stories of Prophets - 2Document19 paginiStories of Prophets - 2Hadis MusaÎncă nu există evaluări

- Qand ADocument5 paginiQand AJoshua PascasioÎncă nu există evaluări

- NitrocelluloseDocument7 paginiNitrocellulosejumpupdnbdjÎncă nu există evaluări

- Analysis of Financial Statements Project: GUL AHMAD Textile MillsDocument32 paginiAnalysis of Financial Statements Project: GUL AHMAD Textile MillsHanzala AsifÎncă nu există evaluări

- Overlord - Volume 01 - The Undead KingDocument223 paginiOverlord - Volume 01 - The Undead KingPaulo FordheinzÎncă nu există evaluări

- Digestion Unit 1 QDocument15 paginiDigestion Unit 1 QKajana Sivarasa ShenthanÎncă nu există evaluări

- Schaeffler - Account Insights - Mar 2020Document13 paginiSchaeffler - Account Insights - Mar 2020mohit negiÎncă nu există evaluări

- 500 Important Spoken Tamil Situations Into Spoken English Sentences SampleDocument7 pagini500 Important Spoken Tamil Situations Into Spoken English Sentences SamplerameshdurairajÎncă nu există evaluări

- Sample Field Trip ReportDocument6 paginiSample Field Trip ReportBILAL JTTCÎncă nu există evaluări

- Cosmic Freedom: David MolineauxDocument2 paginiCosmic Freedom: David Molineauxsalomon46Încă nu există evaluări

- Plow Moldboard or Disc PlowDocument7 paginiPlow Moldboard or Disc PlowAdewaleÎncă nu există evaluări

- ATEX Certified FiltersDocument4 paginiATEX Certified FiltersMarco LoiaÎncă nu există evaluări

- Maya Keyboard ShortcutsDocument0 paginiMaya Keyboard ShortcutsDaryl Gomez TimatimÎncă nu există evaluări

- 35.2 - ING - El Puente NewsletterDocument13 pagini35.2 - ING - El Puente NewsletterIrmali FrancoÎncă nu există evaluări

- Science Section A UPSRDocument2 paginiScience Section A UPSRvinno8556% (9)

- POLIOMYELITISDocument26 paginiPOLIOMYELITISIzhra Margate100% (1)

- Revised fire drill performance standardsDocument47 paginiRevised fire drill performance standardsKartikeya GuptaÎncă nu există evaluări