Documente Academic

Documente Profesional

Documente Cultură

DMPT 2009 Velasquez Kraetge Krueger ENU

Încărcat de

Insan AzizDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

DMPT 2009 Velasquez Kraetge Krueger ENU

Încărcat de

Insan AzizDrepturi de autor:

Formate disponibile

0.

Noise in FRA Measurements: Sources, Effects and Suppression Methods

a

Juan L. Velsquez , Michael Krger , Sebastian kntter , Alexander Kraetge , Samuel Galceran ,

a

OMICRON electronics GmbH, Oberes Ried 1 , A-6833 Klaus, Austria

Center of Technological Innovation and Drives, Polytechnical University of Catalonia, Av. Diagonal 647, 08034

Barcelona, Spain

b

Abstract

1. Introduction to the FRA method

CMC

RMC

RLC Network

50

Rref=50

U1

U2

Rm=50

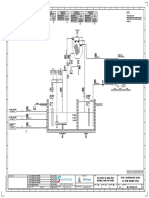

Figure 1: Measurement setup

1.000e+002

Magnitude (dB)

The application of the FRA method in the last years as

detection and diagnostic tool of mechanical

deformations and electrical failures in the active part of

power transformers has demonstrated its capabilities

and its potential. The advances in this technique allow

an excellent repeatability of results, however, similar to

other on-site diagnostic methods performed, FRA

measurements are also vulnerable to the harmful

effects of noise. Due to noise important information for

the assessment of FRA results can be lost. For this

reason, a good understanding of the sources of noise,

their effects as well as the suppression methods is

imperative. In this contribution, these noise relatedtopics are theoretically explained and exemplified by

real measurements performed in power transformers.

1.000e+003

1.000e+004

1.000e+005

f/Hz

-20

-30

-40

H( f ) =

-50

-60

-70

-80

-90

k = 20 log10 (U 2 / U1 ) (2)

-100

When talking about FRA it is important to distinguish

between Impulse Frequency Response Analysis (IFRA)

and Sweep Frequency Response Analysis (SFRA).

This work focuses the attention on the SFRA method.

As illustrated in Fig.1, the SFRA consists in applying a

frequency variable low-level sinusoidal signal "U" at one

end of a winding and from this point a reference signal

"U1"is measured. Simultaneously the output or

response signal at the other end of the winding "U2" is

measured. Subsequently, the transfer function H(f) is

computed. It can be easily demonstrated that H(f)

corresponds to the expression (1). This means that the

H(f) is only dependant on the measurement resistance

of the FRA instrument (Rm) and on the impedance of

the transformer (Ztra).

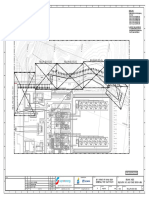

The most common way of representing the results is as

bode diagrams as shown in Fig. 2. In the majority of the

cases only the plot of the magnitude is used for

interpretation purposes. Nevertheless, the plot of the

phase also provides valuable information. The

magnitude and the phase are computed according to

the equations (2) and (3).

dB

Phase ()

The Frequency Response Analysis (FRA) has been

proven to be a powerful tool for the detection and

diagnosis of the active part of power transformers [1]. In

contrast to traditional diagnostic methods, the FRA

method is able to detect geometrical deformations in

the windings before the occurrence of a major or

catastrophic failure.

U2( f )

Rm

(1)

=

U1 ( f ) Rm + Z tra

150

100

1.000e+002

= tan

1.000e+003

1.000e+004

1.000e+005

H0 H1

H0 H2

( U 2 / U 1 ) (3)

f/Hz

H0 H3

Figure 2: Graphical representation of FRA results

2. Introduction to noise in FRA results

Noise can be defined as unwanted disturbances that

may be superimposed upon a useful (desired) signal.

Noise tends to obscure the information content of the

useful signal and for this reason its detection and

mitigation is necessary. As in any other electrical

diagnostic method, the FRA results can also be affected

by noise.

An understanding of the sources of noise, their effects

and suppression methods is very important especially

when FRA instruments of different manufacturers are

compared. In this work, the relationship between the

technical specifications of the FRA instrument and

noise suppression capabilities is explained and

exemplified by means of real FRA measurements in

power transformers.

Unfortunately, at present there are not international

standards available in which the minimal acceptable

specifications of the FRA instruments are stated. Only

in China there is one standard [1] that was published in

2004. In Europe the only available document is the

CIGR Report 342 that was published in April 2008 [2]

and at the present the elaboration of the IEC standard

60076-18 in under elaboration. In America, the

OMICRON electronics GmbH 2009 Workshop "Diagnostic Measurements on Power Transformers"

0.2

preparation of recommended practices is also under

elaboration and at present there is only a draft that is no

yet officially available [3]. Moreover, the literature on

FRA has been more focused on case studies and

interpretation of results and little importance has been

given to the effects of noise in FRA results.

4. Effects of noise in FRA results

Due to the lack of information on the subject noise in

FRA results, this work consisting on the effects of noise

in FRA results and suppression methods was

formulated.

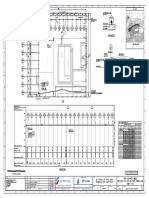

4.1 Effect of power frequency noise in FRA results

Power frequency noise is only present when

measurements on-site in substations with high

electromagnetic fields (typically in substations with live

busbars with rated voltages above 380 kV) are carried

out. The presence of this kind of noise is also

dependant on the size of the windings. In Fig. 4 the

frequency response of the windings of a 315 MVA

transformer is illustrated. As can be seen, the plot of

400 kV windings presents some noise in the band

between 30 Hz and 100 Hz, while in the plots of the 220

kV and 22 kV windings the effect of the narrowband

noise is minimal. This is due to the high attenuation of

the frequency response of the 400 kV winding. Around

50 Hz the attenuation is approximately -60 dB what

makes the signal more sensitive to noise when

compared to the 220 kV and 22 kV windings. It is also

interesting to appreciate that the first resonance points

of the 400 kV winding (in the range from 130 Hz till 180

Hz) are near to -90 dB and there is no noise at all.

3. Sources of noise in FRA measurements

In a substation environment the noise can be found

basically in two forms, i.e., as a wideband or as

narrowband noise.

A typical narrowband noise is the power frequency

noise (50 or 60 Hz noise). This kind of noise is called

narrowband because its effect can be seen in the FRA

plots normally in the frequency range from 30Hz till 100

Hz. At frequencies higher than 300 Hz is it very unusual

to find narrowband noise. In substations with high

harmonic pollution some narrowband noise at

frequencies multiple of the power frequency could also

be present. Other possible source of narrowband noise

could be some communication signals in the substation,

or noise generated by corona discharges, but these

sources take place are higher frequencies and are very

hardly found in the FRA plots.

With respect to wideband noise, there will be always a

noise floor that will affect the FRA plots. This presence

of this noise is very close related to the dynamic range

of the FRA instrument. For example, in FRA

instruments with a dynamic range of 80 dB (+20 dB60dB), below -60 dB the noise will be present.

In this work the attention is focused on the two most

important sources of noise, that is, power frequency

noise and noise floor. In this sense, the noise can be

characterized in the FRA plots in two regions as shown

in Fig. 3.

1. 000e+002

1. 000e+003

1. 000e+004

1. 000e+005

-30

-40

Power frequency

noise band

30Hz100Hz

-50

-60

-70

1.000e+002

1.000e+003

1.000e+004

1.000e+005

f/Hz

-10

-20

-30

-40

-50

-60

-70

22 kV Winding

-80

220 kV Winding

dB

400 kV Winding

Figure 4: Frequency response of a 315 MVA, 400/220/22 kV

Transformer

f/Hz

-10

-20

Both power frequency noise and noise floor can be

present in FRA plots.

Dynamic range of the

FRA instrument

-80

dB

Noise floor

Figure 3: Characterisation of noise sources in a typical FRA

plot

The effects of the power frequency noise take place

fortunately in the frequency range in which the linear

behavior of the magnetizing inductance domains the

response. From the interpretation of the results point of

view, this noise is not so harmful since the useful

information for the diagnosis remains intact. The first

resonance points which take normally place above 130

Hz are not affected by the noise which allows a reliable

assessment even when some 50 Hz noise is present.

Nevertheless it is worth to mention that some winding's

failure modes are visible at low frequencies, such as

short-circuits between turns and opened-circuits, what

makes the suppression of the power frequency noise

very advisable.

Noise at harmonic frequencies are not so usual but can

also be present in the FRA plot. In substations with

rated voltages higher than 400 kV the likelihood of

finding this noise is higher. As example, in Fig. 5 the

FRA plots measured in the 500 kV windings of a power

OMICRON electronics GmbH 2009 Workshop "Diagnostic Measurements on Power Transformers"

0.3

transformer are illustrated. From 30 Hz till 100 Hz the

effects of the noise are significant while at harmonic

frequencies (250Hz and 350Hz) the effects smaller but

can still be appreciated.

1.000e+002

1.000e+003

1.000e+004

1.000e+005

-20

f/Hz

-30

-40

-50

30

50

70

100

200

300

500

700

-60

f/Hz

-70

-80

250 Hz

5th

-50

-60

350 Hz

7th

-90

-100

-110

dB

-70

Noise floor

effect

AB phase

BC phase

CA phase

Figure 7: Example of the effect of noise floor in FRA

measurements in delta connected windings

-80

-90

5. Noise suppression methods in FRA results

dB

H0 H3

H0 H1

There are different methods that can be used for

suppressing the effects of noise in FRA results. These

methods can be structured in three groups: hardware

based methods, software based methods and

connection technique.

H0 H2

Figure 5: Frequency response of a 500 kV windings

4.2 Effects of

the noise

floor

in FRA

measurements

In signal theory, the noise floor is the measure of the

signal created from the sum of all the noise sources and

unwanted signals within a measurement system.

This noise is normally present in the FRA response

measured in transformers with high magnetizing

inductance, in windings connected in delta and in

capacitive inter-winding FRA measurements. Some

examples of the effect of the noise floor in the

frequency response in delta windings measured with an

FRA instrument with a dynamic range of -80 dB are

illustrated in Figures 6 and 7. In both cases it can be

appreciated that below -80dB the frequency response is

highly affected by the noise floor. This is due to the

limited dynamic range of the FRA instrument with which

the measurements were carried out. This indicates that

the dynamic range of the FRA instrument used (80 dB)

is not enough in many cases.

In Figures 6 and 7 it can be also appreciated that in

contrast to the power frequency noise, the effect of the

noise floor is very harmful. The presence of this noise

makes the assessment of the results difficult since

several resonance points which contain very important

information for the diagnosis are obscured by the noise.

1.000e+002

1.000e+003

1.000e+004

1.000e+005

-20

-30

-40

Power frequency

noise

f/Hz

5.1 Hardware based methods

Hardware based methods consists in the capacity of the

FRA instrument of minimizing the presence of noise

during the performance of the FRA measurements.

There are two key factors that are defined in the

technical specifications of the FRA instruments that are

close related to its capabilities of suppressing noise,

these are the output voltage of the instrument and the

input filters. Next an explanation of the effect of these

two important specifications is presented. Other typical

specification that is also here discussed is the

integration time in instruments that use the sine

correlation as noise suppression tool.

5.1.1

Output voltage

It is well known that transfer function measurements (as

the case of FRA) are not voltage dependant since a

power transformer winding is considered as a linear

system. Nevertheless, the output voltage is also related

to the signal to noise ratio, especially around 50/60 Hz

since as lower the output voltage, weaker the signal,

which could make the FRA measurements more

sensitive to noise.

For illustrating the effect of the output voltage in the

frequency response, let's consider the equivalent circuit

of typical SFRA measurements depicted in Fig. 8. In

this figure, Zs represents the internal impedance of the

source, Zr is the reference impedance, Zt is the

impedance of the transformer and Zm is the

measurement impedance.

-50

-60

-70

-80

-90

-100

-110

dB

Noise floor

effect

AB phase

BC phase

CA phase

Figure 6: Example of the simultaneous effect of noise floor in

FRA measurements in delta connected windings

OMICRON electronics GmbH 2009 Workshop "Diagnostic Measurements on Power Transformers"

0.4

Itot

Zt

Im

Zs

Zr

Ur

Zm

Um

Figure 8: Equivalent circuit of FRA measurements

The current Itot coming from the FRA instrument may be

computed according to (1). As can be seen, the current

is proportional to the output voltage U. In this manner

the effect of the output voltage in the flowing current

during the measurements is evident. But from the point

of view of FRA measurements, what is important to

know is the effect of U in the voltage drops in the

impedances Zr and Zm, since the transfer functions

depends on the quotient (Um/Ur). These voltages Um

and Ur can be computed by (3) and (5) respectively. As

can be appreciated in (6), the transfer function (Um/Ur)

depends only on the impedance of the transformer (Zt)

and the measurement resistance (Zm) which is typically

50 . From this it can be concluded that the output

voltage has no effect in the transfer function.

I tot

Z r + Z m + Zt

=

U (1)

(Zt + Z m )Z r + Z s (Zt + Z r + Z m )

also be sensitive to power frequency noise. In the

majority of the cases it is impossible to completely

remove the noise by just increasing the output voltage.

For investigating the effect of the output voltage, FRA

measurements were performed in a 400 kV winding

with FRA instruments with different output voltages. As

can be appreciated in Fig. 9, the measurement with an

instrument with 20 Vpp presents lesser noise around 50

Hz than the measurement carried out with the

instrument with 2.83 Vpp. Nevertheless, the plot

corresponding to the instrument with 20 Vpp present

much more noise bellow -65 dB. It was found that the

reason of this was a limited dynamic range of the

instrument.

30

50

70

100

200

300

500

30

50

70

100

200

300

500

f/Hz

-55

-60

-65

-70

-75

-80

-85

dB

f/Hz

-50

-100

-150

Output voltage 20 Vpp

Zr

Im =

I tot (2)

Zt + Z m + Z r

Um =

Output voltage 2.83 Vpp

Figure 9: Experimental investigation of the effect of the output

voltage in the noise

Zr

I tot Z m (3)

Zt + Z m + Z r

Ir =

Zt + Z m

I tot

Zt + Z m + Z r

Ur =

Zt + Zm

I tot Z r

Zt + Z m + Z r

(4)

Um

Zm

50

=

=

U r Z m + Z t 50 + Z t

(5)

(6)

In summary, the frequency response or transfer

function is not dependant on the output voltage but the

signal (Itot) can be increased by increasing the output

voltage according to (1) what can be used for improving

the noise to signal ratio and therefore for avoiding noise

at power frequency. However, by increasing the output

voltage of the FRA instrument it is not possible to

reduce the wideband noise that as before shown is very

harmful for the assessment of FRA results.

Moreover even measurements carried out with FRA

instruments with output voltages higher than 10 V can

Regarding standards requirements, neither the CIGR

Report 342 [2] nor the Chinese standard [1] imposes

minimal requirements for the output voltage of the FRA

instrument. The output voltage of the most popular FRA

instruments is presented in Table 1.

Table 1. Output voltage of most popular FRA instruments

FRA Instrument

Output voltage

Impedance

OMICRON

2:83 V peak to

50 Ohm

FRAnalyzer

peak

M5200/M5300

of 20 V peak to

50 Ohm

Doble Engineering

peak

FRAX-101

of

10 V peak to

50 Ohm

Megger-PAX

peak

Diagnostics

12 V peak to

50 Ohm

FRA 5310 of Tettex peak

instruments

24 V peak to

1 MOhm

peak

5.1.2

Input filters

Normally at the inputs of the FRA instruments, there are

filters that have as objective to suppress noising

signals. The noise suppression capabilities of such

filters can be controlled by the bandwidth. The selection

of the bandwidth is a compromise between

measurement time and noise. An optimal setting of the

bandwidth can also be obtained by adapting

automatically the receiver bandwidth as function of the

OMICRON electronics GmbH 2009 Workshop "Diagnostic Measurements on Power Transformers"

0.5

attenuation of the signal. In Fig. 10, this concept is

illustrated.

if

OMICRON's FRAnalyzer is presented in Fig. 13. As

can be observed, thanks to the narrow bandwidth of the

instrument, it is possible to achieve a dynamic range of

at least 130 dB (-110 dB+20 dB).

FRA instrument

BW

Output

if: intermediate frequency

BW: bandwidth

Sampling points

Reference

Measurement

Figure 12: Connection scheme for measuring the dynamic

range of FRA instruments

Figure 10: Illustration of the noise filtering methods bay

The Chinese standard [1] states that the testing

instrument shall have frequency selective filtering

function and the bandwidth shall be less than 5% of the

centre frequency of frequency selector filter.

It can be demonstrated that by a proper setting of the

bandwidth it is possible to suppress both the power

frequency noise and the noise floor. The suppression of

the noise floor leads to an increase the dynamic range

of the instrument, which is one of the most important

specifications of an FRA instruments.

The dynamic range is normally defined as the absolute

value of the negative measurement range plus 20 dB.

This definition is graphically illustrated in Fig. 11.

According to the CIGR report 342 [2], a measurement

range of -100 dB to +20 dB should be enough to cover

all the cases. The only FRA standard available at

present [1] also states that the FRA instrument shall

have a dynamic range of -100 dB ~ 20 dB. The dynamic

range of the most popular FRA instruments is

presented in Table 2.

20 dB

1.000e+002

1.000e+003

1.000e+004

1.000e+005

1.000e+006

-120

-130

-140

-150

-160

dB

Figure 13: Dynamic range of the OMICRON's FRAnalyzer

5.1.3

Integration and sine correlation

This method is based on the fact that the noise is

sometimes positive, sometimes negative, at random.

For this reason, when random positive and negative

numbers are added together, they "eat" each other up.

It has been established that when the sum of n periods

of signal with uncorrelated noise is performed, the

signal/noise ratio is increased by a factor

Dynamic Range of the

FRA instruments:

+20dBNoise floor

Noise floor

Figure 11: Illustration of the dynamic range concept

Table 2. Dynamic range of the most popular FRA instruments

FRA Instrument

Dynamic range

OMICRON FRAnalyzer

>120 dB

M5200/M5300 of Doble Engineering

>90 dB

FRAX-101 of Megger-PAX Diagnostics

>130 dB

FRA 5310 of Tettex instruments

f/Hz

-110

n [4].

Sine correlation is a noise suppression method based

on the integration principle before mentioned. A detailed

explanation of this method is presented in [5]. The sine

correlation analyzer uses one sine channel to calculate

the real part of the response R(T), and one cosine

channel to calculate the imaginary part I(T) as shown in

Fig. 14. The response signal coming from the device

under test (DUT) is multiplied by the sin and cosine of

the output signal of the instrument. Then real and

imaginary parts of the signal are integrated in order to

average the signal along T seconds. As the averaging

or integration time is increase, the unwanted frequency

components, i.e., noise, decreases.

90 dB

The dynamic range of one FRA instrument can be

easily measured by connecting the instrument as

shown in Fig. 12. The dynamic range measured in the

OMICRON electronics GmbH 2009 Workshop "Diagnostic Measurements on Power Transformers"

0.6

H(j)

DUT

Asint

R(T)

50

70

100

200

300

500

30

50

70

100

200

300

500

f/Hz

-20

sint

Signal

Generators

30

-10

cost

Multipliers

R(T)

-30

-40

Integrators

Figure 14: Sine correlation circuit

-50

-60

5.2 Software based methods

Software based methods consists in removing the noise

of an already measured FRA plot by means of signal

processing techniques. Some methods have been

found in the literature for the detection and suppression

of noising signals. The method described in [6] is based

in variance analysis which was developed for detecting

and quantifying the nonlinear distortions and the

disturbing noise in frequency response measurements.

Other examples are the application of the Wavelet

transformation that was used in [7] for suppressing

noise in time domain FRA measurements and the

application of Kalman filters [8] for eliminating the

narrow-band noise and wideband noises from FRA

plots.

Other methods of easier implementation consists in

typical averaging filters such as the well know moving

average filter, exponential weighted moving average

filter, etc. Applications of fittings algorithms such as

vector fitting [9] can also be used for reconstructing

noising FRA plots.

Some commercially available FRA instruments, such as

the OMICRON FRAnalyzer, have some signal

processing tools implemented in the software that can

be used for removing noise in FRA plots. As shown in

Fig. 15.

-70

dB

f/Hz

-50

-100

-150

N W Before noise removal

N W After noise removal

Figure 16: Comparison of the FRA plot before and after noise

removal

5.3 Connection technique

The connection technique can also help to reduce the

noise. In Fig. 17 the FRA plots measured in a

substation with very high noise interferences using

aluminium braids and wire as connection technique are

compared. It is clear that the use of aluminium braids

also helps to reduce the noise.

1.000e+002

1.000e+003

1.000e+004

1.000e+005

1.000e+002

1.000e+003

1.000e+004

1.000e+005

f/Hz

-20

-30

-40

-50

-60

-70

dB

150

100

Figure 15: Noise removal in FRA plots with average filtering

The noising plot shown in Fig. 9 was cleaned up by

using the averaging filter of the FRAnalyzer software. A

comparison of the plots before and after noise removal

is presented in Fig. 16.

N C with Alu braid

f/Hz

N C with Wire

Figure 17: Connection technique and noise suppression

6 Conclusions

The effects of the power frequency noise takes place

around 50/60 Hz. Because in this frequency range the

linear behavior of the magnetizing inductance domains

the response, this kind of noise is not as harmful as the

noise floor for the assessment and interpretation of the

FRA results and its suppression can be easily achieved.

It was demonstrated that the output voltage of the FRA

instrument can help in reducing power frequency noise,

OMICRON electronics GmbH 2009 Workshop "Diagnostic Measurements on Power Transformers"

0.7

however

depending

on

the

electromagnetic

environment of the substation even measurements

carried out with FRA instruments with output voltages

higher than 10 V are sensitive to noise. Neither the

Chinese standard nor the CIGR Report establishes

minimal requirements for the output voltage of the FRA

instrument.

The effects of the wideband noise or noise floor of the

FRA instrument are very critical. The frequency

response of transformers with big magnetizing

inductances or of delta connected windings as well as

capacitive inter-winding requires a dynamic range of al

least -100 dB20 dB. If the FRA instrument has not

enough dynamic range, the high content of noise

obscures the frequency response signal which makes

difficult the assessment and interpretation of the results.

It was also found that the only available standard

establish as requirement that the dynamic range of the

FRA instruments shall be of at least -100 dB20 dB.

The CIGR Report 342 also agrees with this dynamic

range requirement..

There are different methods of mitigating the effects of

noise in FRA results. With a narrow bandwidth of the

FRA instrument the noise can be highly mitigated

during the measurement. In cases in which the noise

cannot be completely suppressed during the

measurement, there are software based methods such

as averaging filters that can be used for removing the

noise from FRA results.

Literature

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

Frequency Response Analysis on Winding Deformation of

Power Transformers, The Electric Power Industry

Standard of Peoples Republic of China, Std. DL/T9112004, ICS27.100, F24, Document No. 15182-2005, June

1st, 2005.

CIGRE Report 342 WG A2.26, "Mechanical conditionassessment of transformer windings using Frequency

Response Analysis, April 2008.

IEEE PC57.149/D6, Draft Trial Use Guide for the

Application and Interpretation of Frequency Response

Analysis for Oil Immersed Transformers April. 2009.

E. Brasseur, "How does a receiver work?", 1997,

http://www.4p8.com/eric.brasseur/receiv.html

N.D. Cogger, R.V.Webb, Frequency Response

Analysis, Solartron Analytical, Technical Report 10,

1997.

Tom Dhaene, Rik Pintelon, Johan Schoukens, Els Van

Gheem, 'Variance Analysis of Frequency Response

Function Measurements Using Periodic Excitations', IEEE

Transactions on Instrumentation and Measurement, Vol.

54, No. 4, August 2005.

R. Wimmer, K. Feser,

S. Tenbohlen, M. Krger,

'Erhhung der Reproduzierbarkeit von FRA-Messungen

durch Standardisierung', HV Simposium 2006.

A.R. Moniri, S. Farshad, 'Modeling the Frequency

Response Movements in PowerTransformers for

Predicting

Purposes'Iranian

Journal

of

Electrical&Electronical Engineering, Vol. 2, No. 1, Jan.

2006', pp. 26-33.

B. Gustavsen, A. Semlyen: Rational Approximation of

Frequency Domain Responses by Vector Fitting. IEEE

Transactions on Power Delivery, 14:1052{1061, 1999.

OMICRON electronics GmbH 2009 Workshop "Diagnostic Measurements on Power Transformers"

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Movie Theater Building DesignDocument16 paginiMovie Theater Building DesignPrathamesh NaikÎncă nu există evaluări

- Using FTIR-ATR Spectroscopy To Teach The Internal Standard MethodDocument3 paginiUsing FTIR-ATR Spectroscopy To Teach The Internal Standard MethodEdgar VegaÎncă nu există evaluări

- RD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CDocument2 paginiRD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CInsan Aziz100% (1)

- RD P WW P00 1022 - Rev.3 - P&ID Waste Water Treatment SystemDocument2 paginiRD P WW P00 1022 - Rev.3 - P&ID Waste Water Treatment SystemInsan AzizÎncă nu există evaluări

- RD-P-WA-P07-2002 - Rev.4 - Piping & Instrumentation Diagram HP & LP Steam Scrubbing (UNIT2)Document1 paginăRD-P-WA-P07-2002 - Rev.4 - Piping & Instrumentation Diagram HP & LP Steam Scrubbing (UNIT2)Insan Aziz100% (2)

- RD-I-CI-G00-1018-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-BDocument3 paginiRD-I-CI-G00-1018-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-BInsan Aziz100% (1)

- RD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CDocument2 paginiRD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CInsan Aziz100% (1)

- RD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CDocument2 paginiRD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CInsan Aziz100% (1)

- RD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CDocument2 paginiRD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CInsan Aziz100% (1)

- RD-I-CI-G00-1015-17 - Rev.0 - Typical Drawing For Instrument Installation Cable Installation Detail (1 of 3)Document1 paginăRD-I-CI-G00-1015-17 - Rev.0 - Typical Drawing For Instrument Installation Cable Installation Detail (1 of 3)Insan AzizÎncă nu există evaluări

- RD-PRD01-EnG-CSPC-2076 - Rev.0 - Piping Material Class For Lube Oil, Control Oil, Gland Steam SystemDocument3 paginiRD-PRD01-EnG-CSPC-2076 - Rev.0 - Piping Material Class For Lube Oil, Control Oil, Gland Steam SystemInsan AzizÎncă nu există evaluări

- RD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CDocument2 paginiRD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CInsan Aziz100% (1)

- RD-I-CI-G00-1018-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-BDocument3 paginiRD-I-CI-G00-1018-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-BInsan Aziz100% (1)

- RD-I-CI-G00-1020-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-MDocument3 paginiRD-I-CI-G00-1020-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-MInsan Aziz100% (1)

- RD-I-CI-G00-1020-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-MDocument3 paginiRD-I-CI-G00-1020-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-MInsan Aziz100% (1)

- RD-I-CI-G00-1017-01 - Rev.1 - Layout of Instrument J Main Cable Way and Cable Way For SeparatorDocument2 paginiRD-I-CI-G00-1017-01 - Rev.1 - Layout of Instrument J Main Cable Way and Cable Way For SeparatorInsan AzizÎncă nu există evaluări

- RD-I-CI-G00-1017-02 - Rev.1 - Layout of Instrument J Main Cable Way and Cable Way For SeparatorDocument2 paginiRD-I-CI-G00-1017-02 - Rev.1 - Layout of Instrument J Main Cable Way and Cable Way For SeparatorInsan AzizÎncă nu există evaluări

- RD M PO P00 1030 - Rev.0 - Welding Map Overhead CranesDocument7 paginiRD M PO P00 1030 - Rev.0 - Welding Map Overhead CranesInsan AzizÎncă nu există evaluări

- 33 File 20210813-135348 PRODUCT CATALOGUE 2021 PDFDocument20 pagini33 File 20210813-135348 PRODUCT CATALOGUE 2021 PDFInsan AzizÎncă nu există evaluări

- RD-PRD01-EnG-CTEN-2003 - Rev.6 - Setting Value List For STG & AuxiliariesDocument24 paginiRD-PRD01-EnG-CTEN-2003 - Rev.6 - Setting Value List For STG & AuxiliariesInsan AzizÎncă nu există evaluări

- RD P WW P00 1022 - Rev.3 - P&ID Waste Water Treatment SystemDocument2 paginiRD P WW P00 1022 - Rev.3 - P&ID Waste Water Treatment SystemInsan AzizÎncă nu există evaluări

- RD-L-PO-G00-1003-005 - Rev.0 - PA Sheet Relocation SWS Line at PWR Station SHT 5Document1 paginăRD-L-PO-G00-1003-005 - Rev.0 - PA Sheet Relocation SWS Line at PWR Station SHT 5Insan AzizÎncă nu există evaluări

- RD-PRD01-EnG-CDAT-1602 - Rev.1 Special Motorized Control Valve (MOV) For SGSDocument17 paginiRD-PRD01-EnG-CDAT-1602 - Rev.1 Special Motorized Control Valve (MOV) For SGSInsan AzizÎncă nu există evaluări

- RD I PC p00 2002 - Rev.3 - Dcs I o ListDocument87 paginiRD I PC p00 2002 - Rev.3 - Dcs I o ListInsan AzizÎncă nu există evaluări

- RD L Po g00 1005 0009 - Rev.0 - Isometric Drawing For DW (Line No. Rd00 Ghd10 Drain Wastafel Dn50 120a)Document1 paginăRD L Po g00 1005 0009 - Rev.0 - Isometric Drawing For DW (Line No. Rd00 Ghd10 Drain Wastafel Dn50 120a)Insan AzizÎncă nu există evaluări

- RD L Po g00 1005 0003 - Rev.0 - Isometric Drawing For DW (Line No. Rd00 Ghd10 Ven Dn50 120a)Document1 paginăRD L Po g00 1005 0003 - Rev.0 - Isometric Drawing For DW (Line No. Rd00 Ghd10 Ven Dn50 120a)Insan AzizÎncă nu există evaluări

- RD-L-PO-G00-1003-003 - Rev.0 - Piping Alignment Sheet Relocation SWS Sheet 3 of 6Document1 paginăRD-L-PO-G00-1003-003 - Rev.0 - Piping Alignment Sheet Relocation SWS Sheet 3 of 6Insan AzizÎncă nu există evaluări

- RD-L-PO-G00-1003 - Rev.0 - DWG Index Relocation SWS Line PWR Station AreaDocument2 paginiRD-L-PO-G00-1003 - Rev.0 - DWG Index Relocation SWS Line PWR Station AreaInsan AzizÎncă nu există evaluări

- RD L PO G00 1005 0004 - Rev.0 - Isometric Drawing For DW (Line No. RD00 GHD10 BR005 DN50 120A)Document1 paginăRD L PO G00 1005 0004 - Rev.0 - Isometric Drawing For DW (Line No. RD00 GHD10 BR005 DN50 120A)Insan AzizÎncă nu există evaluări

- RD-L-PO-G00-1003-004 - Rev.0 - Piping Alignment Sheet Relocation SWS Sheet 4 of 6Document1 paginăRD-L-PO-G00-1003-004 - Rev.0 - Piping Alignment Sheet Relocation SWS Sheet 4 of 6Insan AzizÎncă nu există evaluări

- RD L Po g00 1005 0001 - Rev.0 - Isometric Drawing For DW (Line No. Rd00 Ggdb10 Li Cl501 Dn50 120a) Rd00 Gdb10 Li Cl501 Dn50 120a - sht1 001Document1 paginăRD L Po g00 1005 0001 - Rev.0 - Isometric Drawing For DW (Line No. Rd00 Ggdb10 Li Cl501 Dn50 120a) Rd00 Gdb10 Li Cl501 Dn50 120a - sht1 001Insan AzizÎncă nu există evaluări

- RD-L-PO-G00-1003-001 - Rev.0 - PA Sheet Relocation SWS Line at PWR Station SHT 1Document2 paginiRD-L-PO-G00-1003-001 - Rev.0 - PA Sheet Relocation SWS Line at PWR Station SHT 1Insan AzizÎncă nu există evaluări

- Opnet BasicsDocument9 paginiOpnet BasicsDuong Duc HungÎncă nu există evaluări

- Tolerance Stackup Analysis 2.0Document6 paginiTolerance Stackup Analysis 2.0Leon WangÎncă nu există evaluări

- Mva - 2008 India School Rick LoydDocument86 paginiMva - 2008 India School Rick Loydamar_saxena60857Încă nu există evaluări

- Continuation Power Flow ExampleDocument7 paginiContinuation Power Flow ExampleSudheerKumarÎncă nu există evaluări

- NotesDocument33 paginiNotesMohammad ZaheerÎncă nu există evaluări

- SHS - E1 - Story (He-Y, Come On Ou-T!)Document3 paginiSHS - E1 - Story (He-Y, Come On Ou-T!)dyaataha7902Încă nu există evaluări

- VK1000 Quick Start Guide v52 - 3 7Document11 paginiVK1000 Quick Start Guide v52 - 3 7Kirk WonÎncă nu există evaluări

- 9990 Y18-20 Sy PDFDocument40 pagini9990 Y18-20 Sy PDFmashalÎncă nu există evaluări

- Code Book For MA/M.Sc. Examinations, 2011Document4 paginiCode Book For MA/M.Sc. Examinations, 2011Aditi GoyalÎncă nu există evaluări

- Art Intg Proj CL 6-10Document5 paginiArt Intg Proj CL 6-10Sarthak JoshiÎncă nu există evaluări

- Operations Management: Module F - SimulationDocument29 paginiOperations Management: Module F - SimulationNiña CaracenaÎncă nu există evaluări

- Gland Pharma LimitedDocument1 paginăGland Pharma LimitedParas MaloutÎncă nu există evaluări

- Assignment No. 2 MTH 432A: Introduction To Sampling Theory 2021Document1 paginăAssignment No. 2 MTH 432A: Introduction To Sampling Theory 2021Krishna Pratap MallÎncă nu există evaluări

- Nichols, Ashton. The Loves of Plants and Animals: Romantic Science and The Pleasures of NatureDocument15 paginiNichols, Ashton. The Loves of Plants and Animals: Romantic Science and The Pleasures of NatureBarbara RossinÎncă nu există evaluări

- 20130222210228kuliah 1 - Falsafah MatematikDocument54 pagini20130222210228kuliah 1 - Falsafah Matematikkharol1211100% (1)

- Resume 1Document5 paginiResume 1pradeep_machirajuÎncă nu există evaluări

- Biochemistry Lab FR Isolation Characterization ProteinsDocument5 paginiBiochemistry Lab FR Isolation Characterization ProteinsJason AnthonyÎncă nu există evaluări

- Dr. Nirav Vyas Numerical Method 4 PDFDocument156 paginiDr. Nirav Vyas Numerical Method 4 PDFAshoka Vanjare100% (1)

- Correlation and Regression-1Document32 paginiCorrelation and Regression-1KELVIN ADDOÎncă nu există evaluări

- Joseph Cote WeeblyDocument2 paginiJoseph Cote Weeblyapi-232220181Încă nu există evaluări

- Circuit AnalysisDocument20 paginiCircuit AnalysisShadoo TarimoÎncă nu există evaluări

- Star Trek: The Newspaper Strips, Vol. 2: 1981 - 1983 PreviewDocument16 paginiStar Trek: The Newspaper Strips, Vol. 2: 1981 - 1983 PreviewGraphic Policy100% (8)

- Exercise Efficient and Effective Sustainable Practices in The Workplace PDFDocument4 paginiExercise Efficient and Effective Sustainable Practices in The Workplace PDFMa Joan Aguilar RodriguezÎncă nu există evaluări

- Issue 88 PDFDocument56 paginiIssue 88 PDFrbnsolucionesÎncă nu există evaluări

- Unit 4 Review Worksheet APDocument12 paginiUnit 4 Review Worksheet APphantomofthekeysÎncă nu există evaluări

- PMS & PaDocument24 paginiPMS & PashikhaajainÎncă nu există evaluări

- KABIR HASION CV Executive-1 PDFDocument2 paginiKABIR HASION CV Executive-1 PDFraiyanduÎncă nu există evaluări

- Quantum Field Theory A Cyclist Tour: Predrag Cvitanovi CDocument48 paginiQuantum Field Theory A Cyclist Tour: Predrag Cvitanovi COliver BardinÎncă nu există evaluări