Documente Academic

Documente Profesional

Documente Cultură

Questionaire

Încărcat de

Rod Lester de GuzmanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Questionaire

Încărcat de

Rod Lester de GuzmanDrepturi de autor:

Formate disponibile

Questionaire:

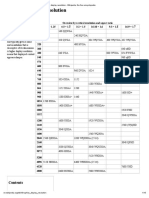

Receiving and Storing Raw Materials

How are raw materials received? Is there a separate receiving room? How does it move from this

room?

Received ny the purchasing

Endorse to invty clerk, Sam Aniano

He kept it in a small stock room.

Apprrove request

Issue a stock transfrer form

How are raw materials documented in the system? What is the source of the info?

PO. DR SI

Goods Received notes; before you go to GRN may PO na. Tapos Purchase invoice na.

Accounting will validate the GRN based on DR and SI. If conflicting, for reconciliation and the payment

process will be put on hold.

Who receives raw materials?

If outside suppliers purchasing

If Chemworld Sam wii received

What are the procedures upon receiving? Sam Aniano, Inventory Clerk

Check the documents, the Stock transfer from the main warehouse. Actual Checking of Stocks.

Quantity based on documents vs actual. If complete he will sign the stock transfer as a proof that the

stocks were actually received and checked. If there is shortage the inventory clerk will call the

warehouse head and will note the actual quantity received.

Sign and date when received?

The item was signed and they will generate a monthly report based on actual amount

received.

Is it checked to the purchase order? If the month already ended close na yung PO.

Is it recounted? Yes

Is it checked for defective material? Yes

What happens if short shipped or receive defective goods?

The defective goods were returned to supplier or in the warehouse. Transmittal to the warehouse and

then will be the one to dpo a report on defective items. Partially delivered goods.

Who enters info into system?

Not applicable since it is manually done by

What is the source of the information? PO and Stock Transfer

How is info recorded accurately?

Purchase orders matched to packing slips? PO Vs Stock Transfer Vs, actual

Is a purchase order edit report run and how often?

How is raw material inventory tracked (i.e. stamps/tags/electronically)? Excel and hard copy of Stock

transfer.

How are returns of raw materials dealt with? Goods returned are added to inventory and when the

others are bad they are segregated.

Cut-off - how do they ensure timely recording and in the appropriate period?

Upon delivery ang ownership

Requisitioning Raw Materials

What is the flow in the general ledger and the system - if a separate system from the general ledger,

how does it get to the general ledger?

Requisition slip and then PO if new item they engaged price quote

Requisitions

Forms are they pre-numbered? How are they controlled?

Who can request? By the department, Assistant to Managers and Directors. In Branches the

DM will request. Sa HO who needs it.

Who approves?

CEO, Geric Reyes(GGR)

FCR( President) Frederick Reyes

Any limits?

Branch- No limit once approved

HO as long as approved.

Who relieves from raw material inventory?

Warehouse will release the inventory

Direct from the suppliers

What is the source i.e. signed requisition form or other documentation?

Requisition slip

And pO once the request was approved.

Physically?

Move to WIP?

What is the journal entry?

No Entry was made.

Managing Inventory

Safeguarding of Assets

What physical access controls are there to assets and sub-ledger / general ledger (i.e. fire systems,

locks)?

Who has access to assets and the sub-ledger?

What reports are generated / are they based on inventory levels? How often are they generated? Who

do they go to? What do they do with them? Are they reviewed and if so do they sign off on their

review? How long are the reports kept for?

What level of insurance is maintained?

Inventory Counts (some of the info contained below may be covered off in

the count memo)

Are counts performed / how / what are the procedures?pag tapos na ang count pwede na ulit mag

received at mag out.

Who performs the counts? Mr Sam and the ASIM

How often are counts performed? Month end inventory count

Book to physical adjustments - what are the procedures? Do they investigate the reasons for the

adjustments and document this?

How is WIP counted and valued?

How is inventory organized - is obsolete inventory kept separated?

How is cut-off handled during the count e.g. receipt of goods during the count?

Do they have consignment inventory? How is this handled? How is it accounted for?

Obsolescence

How is obsolete inventory managed / what reports are run e.g. movement/shipping reports?

Who determines obsolescence? Is it part of the inventory count?

What is the policy on obsolescence e.g. specific ID of goods or a % allocation?

Who reviews the obsolescence? Is authorization required to label the goods obsolete?

Producing/Costing Inventory

How are labour and overhead expenses allocated to WIP? What is the journal entry?

How is labour tracked/costed i.e. timecards?

How is it determined what should be allocated? Is the allocation reviewed and approved? By who?

When is labour and overhead charged?

Standard costing

How are labour standards developed?

How are overhead standards developed?

How are they updated in the system / by whom / how often?

When is it recorded in the system?

How and when is it updated? Is it reviewed? By whom?

Does it represent actual costs?

Are variances tracked? Are the reasons investigated?

Can standards be adjusted during the year? By whom? Is authorization needed?

What is the journal entry?

Are suspense accounts used? If so, are they reconciled / cleared on a regular basis?

What is the costing system used i.e. FIFO, LIFO?

What do they do with scrap - physically and for accounting?

Handling Finished Goods

Movement from WIP to Finished Goods

Physically

Who

What is the journal entry? Is this done electronically/manually? What basis is it posted i.e.

batch?

What reports are generated? Who reviews them? Do they sign off? What are they looking for? How

long are they kept for?

Returns of finished goods

How are they handled?

What is the journal entry?

Cut-off?

Who decides what can be returned?

Shipping

How do you make sure all shipments are recorded shipping log, packing slip? Transmittal, Shippers

Copy. one week.

How are finished goods relieved from inventory? Transmittal was given to accounting for their copy

Physically and logically?

What is the journal entry? Recorded in the excel file for the in and out.

How is accurate and timely recording ensured? Pag nilabas sa stock room minus na kagad siya.

Accountability na ni Delivery.

Who approves goods for shipment/ is approval needed?Prepared by Mr. Sam checked by the

warehouse and will be received by the branch.

What reconciliations are performed i.e. shipping log to invoice register?Yes

Maintaining Inventory Masterfile (list of standard costs or list of the

parts in the product)

Who has access to file?

Maricel Magsombol, Accounting Specialist Inventory Management

Dianne Mariano, Accounting Specialist Inventory Management

How is the access restricted?

The branch has online account. Only the two individual has access to the account. The access was

restricted using a password.

Are changes authorized? Yes because there are some adjustments that were not yet counted during the

count that needs some adjustment.

By whom? By the two individual through the information sent by the branch

Are changes valid? Through pictures and transmittals make it valid.

What initiates the changes i.e. what is the source? Pull out and uncounted stocks during the count.

Is an edit file produced when changes are made? Who reviews it? Do they sign off?

A monthly report was created, all discrepancy noted was adjusted accordingly by the ASIM.

Is the file up to date? How often is it updated? By whom? Not updated only the retail were updated.

The clinic supplies were not updated since the Aestheticians update the inventory. Usual update

should be daily. But they are only updating when they are not busy.

Segregation of Duties

In an inventory management system, different individuals should be responsible for:

initiating or requesting a purchase- Branches and Various Department

placing and inputting purchase orders- Purchasing Department headed by Virginia Hernandez,

Purchasing Manager

receiving goodscustody of inventoriesmaintaining inventory records and/or authorizing adjustments to costs or quantities including

authorizing disposal

making changes to inventory master files

performing independent inventory counts

following up on inventory count discrepancies

authorizing production requests and/or materials transfers

receiving/transferring goods into/from manufacturing

shipping goods

S-ar putea să vă placă și

- Order Sales and Entry ProjectDocument15 paginiOrder Sales and Entry ProjectAnonymous PfFi2XAÎncă nu există evaluări

- Eastern Medditerranean Maritime v. SurioDocument6 paginiEastern Medditerranean Maritime v. SurioMailah AwingÎncă nu există evaluări

- Pichel v. Alonzo Facts: Respondent Prudencio Alonzo Was Awarded by TheDocument4 paginiPichel v. Alonzo Facts: Respondent Prudencio Alonzo Was Awarded by TheAlex RabanesÎncă nu există evaluări

- Session 4 ECCD in CEPC (Sept 2021)Document23 paginiSession 4 ECCD in CEPC (Sept 2021)Daniphine A. Badua100% (1)

- ch03 Test Consumer BehaviorDocument16 paginich03 Test Consumer Behaviorfbm2000Încă nu există evaluări

- DLP G8 Q1 WK 1 D2 (2) GoldahDocument8 paginiDLP G8 Q1 WK 1 D2 (2) GoldahClarissa HugasanÎncă nu există evaluări

- Subject: SCIENCE Grade Level:8: Quarter: 4 Week: 2Document7 paginiSubject: SCIENCE Grade Level:8: Quarter: 4 Week: 2Cathy MoronioÎncă nu există evaluări

- Tolentino v. Sec of FinanceDocument2 paginiTolentino v. Sec of FinancezelayneÎncă nu există evaluări

- ATT EXCEL GEN-Monthly AttendanceDocument1 paginăATT EXCEL GEN-Monthly AttendanceNikka N. Nazario0% (1)

- Household Waste Management PDFDocument5 paginiHousehold Waste Management PDFSteven SambranaÎncă nu există evaluări

- Polytechnic University of The Philippines Taguig CampusDocument316 paginiPolytechnic University of The Philippines Taguig CampusMichelle Taton HoranÎncă nu există evaluări

- Sales - 2nd Week CompilationDocument33 paginiSales - 2nd Week CompilationThirdy DemonteverdeÎncă nu există evaluări

- School ConductDocument79 paginiSchool ConductJames lolec J. TapiruÎncă nu există evaluări

- Slides of Project MGMTDocument76 paginiSlides of Project MGMTPerminder Singh KhalsaÎncă nu există evaluări

- Ngec 10 Lesson 1Document22 paginiNgec 10 Lesson 1Joselito GelarioÎncă nu există evaluări

- Ca5101 PDFDocument12 paginiCa5101 PDFNiccoRobDeCastroÎncă nu există evaluări

- Erp SystemDocument104 paginiErp SystemYasserÎncă nu există evaluări

- Classroom ManagementDocument59 paginiClassroom ManagementConstanza MayerÎncă nu există evaluări

- Entreprenarial Case Study PDFDocument8 paginiEntreprenarial Case Study PDFPriyanka ChoudharyÎncă nu există evaluări

- CA5101 Mock Prelim Exam FinalwithanswersDocument8 paginiCA5101 Mock Prelim Exam FinalwithanswersJomel MelchorÎncă nu există evaluări

- Process CostingDocument29 paginiProcess Costingrikesh radhe100% (1)

- Reading Material Civil SocietyDocument2 paginiReading Material Civil SocietyChristy FramediaÎncă nu există evaluări

- GRADE 8 - QUARTER 1 LIST of ACTIVITIES - PHYSICSDocument61 paginiGRADE 8 - QUARTER 1 LIST of ACTIVITIES - PHYSICSsarah joy velascoÎncă nu există evaluări

- QuestionaireDocument23 paginiQuestionaireMohamed AwadÎncă nu există evaluări

- G8 Science Q1W1 For Simulation PDFDocument12 paginiG8 Science Q1W1 For Simulation PDFRose May OmbidÎncă nu există evaluări

- Date: June 4, 2020: TO: Engr. Robin OlfindoDocument2 paginiDate: June 4, 2020: TO: Engr. Robin OlfindoJa VillamonteÎncă nu există evaluări

- Cac NotesDocument14 paginiCac Notescoco credo100% (1)

- Aaa vs. BBB, G.R. No. 212448, 11 January 2018Document12 paginiAaa vs. BBB, G.R. No. 212448, 11 January 2018Marco AndalÎncă nu există evaluări

- Republic of The Philippines Manila: Lexal Laboratories, Inc. v. CIR G.R. No. L-24632Document3 paginiRepublic of The Philippines Manila: Lexal Laboratories, Inc. v. CIR G.R. No. L-24632Jopan SJÎncă nu există evaluări

- The Labor Code of The PhilipphinesDocument81 paginiThe Labor Code of The PhilipphinesMarx AndreiOscar Villanueva YaunÎncă nu există evaluări

- ITPM ProjectDocument32 paginiITPM ProjectAreeb ShahidÎncă nu există evaluări

- Subject: Notice of Warning Letter For Tardiness and Recurrent Absence From WorkDocument1 paginăSubject: Notice of Warning Letter For Tardiness and Recurrent Absence From WorkUzoma FrancisÎncă nu există evaluări

- Civil CodeDocument266 paginiCivil CodeApl Dugui-es ToleroÎncă nu există evaluări

- 2 - P - G - D - in Hospital Administration - 418 22 - Health Care System PDFDocument188 pagini2 - P - G - D - in Hospital Administration - 418 22 - Health Care System PDFSivaranjani RadhakrishnanÎncă nu există evaluări

- Gaite V FonacierDocument3 paginiGaite V FonacierKat Manongsong-AntalanÎncă nu există evaluări

- GR 7Document2 paginiGR 7Jennifer A. IñigoÎncă nu există evaluări

- Marking of ArticlesDocument26 paginiMarking of ArticlesninarogdawÎncă nu există evaluări

- Flipped Classrooms PresentationDocument20 paginiFlipped Classrooms PresentationAnbu AndalÎncă nu există evaluări

- l2 Becoming Member of Society (Autosaved)Document34 paginil2 Becoming Member of Society (Autosaved)Melody Grace DacubaÎncă nu există evaluări

- Recruitment & SelectionDocument58 paginiRecruitment & SelectionMohammed ShuaibÎncă nu există evaluări

- Q&A Credit TransactionsDocument168 paginiQ&A Credit TransactionsBa ShangÎncă nu există evaluări

- Gender and Society Module 1Document8 paginiGender and Society Module 1ella fabilaÎncă nu există evaluări

- Summary of My Learning in The Subject of Philippine Politics and Governance From WEEKS 1-6Document13 paginiSummary of My Learning in The Subject of Philippine Politics and Governance From WEEKS 1-6Ray Phillip G. JorduelaÎncă nu există evaluări

- Erp 3 Business Processes and BenefitsDocument31 paginiErp 3 Business Processes and BenefitsJacob EdwardsÎncă nu există evaluări

- Test Specification Table and Item Analysis: DistributionDocument1 paginăTest Specification Table and Item Analysis: DistributionAicy G. Dalidig-DisaripÎncă nu există evaluări

- ECHS Referral FormDocument17 paginiECHS Referral FormBrem AnandÎncă nu există evaluări

- This Extensive List of Questions Can Be Asked During An Interview For AnDocument4 paginiThis Extensive List of Questions Can Be Asked During An Interview For AnRenz IbañezÎncă nu există evaluări

- Purchasing and Inventory QuestionnaireDocument4 paginiPurchasing and Inventory QuestionnaireJasjeet KaurÎncă nu există evaluări

- Sample Inventory QuestionnaireDocument5 paginiSample Inventory Questionnairekrishanpragati100% (2)

- Internal Control QuestionnaireDocument10 paginiInternal Control QuestionnaireNaeemRahmanÎncă nu există evaluări

- Purchasing, Inventory, and Cash Disbursements: Common Frauds and Internal ControlsDe la EverandPurchasing, Inventory, and Cash Disbursements: Common Frauds and Internal ControlsEvaluare: 5 din 5 stele5/5 (1)

- Canias System Analysis TemplateDocument17 paginiCanias System Analysis TemplateDickson AllelaÎncă nu există evaluări

- Accounting Information System For Merchandising BusinessDocument14 paginiAccounting Information System For Merchandising BusinessJubert Ng0% (1)

- Preliminary Controls Assessment Questionnaire - Billing, Accounts Receivable, Credit and CollectionsDocument13 paginiPreliminary Controls Assessment Questionnaire - Billing, Accounts Receivable, Credit and CollectionsABDULKARIM HAJI YOUSUFÎncă nu există evaluări

- General Ledger / Budgeting / Bank ModuleDocument3 paginiGeneral Ledger / Budgeting / Bank ModuleMohamed SallamyÎncă nu există evaluări

- Aung Kyaw Moe-Task (9) - Unit (2) Warehouse and InventoryDocument5 paginiAung Kyaw Moe-Task (9) - Unit (2) Warehouse and InventoryAung Kyaw Moe100% (1)

- AIS - MerchandisingDocument2 paginiAIS - MerchandisingJubert NgÎncă nu există evaluări

- Tutorial 1Document2 paginiTutorial 1唄Încă nu există evaluări

- Inventory MemoDocument3 paginiInventory MemoBryan Ramos57% (7)

- Income Tax - 3-28-12 Ganer FinalDocument85 paginiIncome Tax - 3-28-12 Ganer Finaljeromie163Încă nu există evaluări

- AP Solutions 2013Document7 paginiAP Solutions 2013Rod Lester de GuzmanÎncă nu există evaluări

- 5769 - Toa Test Bank 74Document12 pagini5769 - Toa Test Bank 74Rod Lester de GuzmanÎncă nu există evaluări

- 13 x11 Financial Management A Financial Planning & StrategiesDocument9 pagini13 x11 Financial Management A Financial Planning & StrategiesRod Lester de GuzmanÎncă nu există evaluări

- Topic Outline Date of Approval, Presentation, Submission Quizzes Date Seat Works DateDocument1 paginăTopic Outline Date of Approval, Presentation, Submission Quizzes Date Seat Works DateRod Lester de GuzmanÎncă nu există evaluări

- Revques t3 Sub 2011Document37 paginiRevques t3 Sub 2011Rod Lester de GuzmanÎncă nu există evaluări

- Auditing TheoryDocument9 paginiAuditing TheoryYenelyn Apistar CambarijanÎncă nu există evaluări

- Responsibility Accounting and Transfer PricingDocument7 paginiResponsibility Accounting and Transfer PricingRod Lester de Guzman100% (6)

- Auditing Problems TheoryDocument40 paginiAuditing Problems TheoryRod Lester de Guzman100% (2)

- LIVING IN THE IT ERA (Introduction)Document9 paginiLIVING IN THE IT ERA (Introduction)johnnyboy.galvanÎncă nu există evaluări

- A330 Tire Inspn PDFDocument21 paginiA330 Tire Inspn PDFRithesh Ram NambiarÎncă nu există evaluări

- Quotation For Blue Star Printek From Boway2010 (1) .09.04Document1 paginăQuotation For Blue Star Printek From Boway2010 (1) .09.04Arvin Kumar GargÎncă nu există evaluări

- Econ 103 - 01Document3 paginiEcon 103 - 01perrerÎncă nu există evaluări

- White Products CatalogDocument49 paginiWhite Products CatalogjesusÎncă nu există evaluări

- SKANDIX - Order EditDocument2 paginiSKANDIX - Order EditmehÎncă nu există evaluări

- CMA Building Foundation Beams PDFDocument13 paginiCMA Building Foundation Beams PDFRegie NojaldaÎncă nu există evaluări

- Data CenterDocument108 paginiData CenterKhanh Nato100% (5)

- Modelling and Simulation of Absorption Solar Air Conditioning SystemDocument20 paginiModelling and Simulation of Absorption Solar Air Conditioning SystemShadi KarkabaÎncă nu există evaluări

- Kv2ci Oi PDFDocument142 paginiKv2ci Oi PDFJethro AbanadorÎncă nu există evaluări

- SWIFT Case Study Accord EADS 200808Document3 paginiSWIFT Case Study Accord EADS 200808maheshbendigeri5945Încă nu există evaluări

- Compressor Service ProcedureDocument22 paginiCompressor Service ProcedureFriget Rusianto100% (2)

- ICT Css NotesDocument11 paginiICT Css NotesWinnie OoiÎncă nu există evaluări

- UM M Series Air-Cooled Type A4 enDocument172 paginiUM M Series Air-Cooled Type A4 enTuấn LiuÎncă nu există evaluări

- Radios of America in EnglishDocument3 paginiRadios of America in Englishvitor_pedroÎncă nu există evaluări

- Graphics Display Resolution - Wikipedia, The Free EncyclopediaDocument15 paginiGraphics Display Resolution - Wikipedia, The Free EncyclopediaKarun KumarÎncă nu există evaluări

- Presentation On Market Potential of Tag TasteDocument10 paginiPresentation On Market Potential of Tag TasteRajaÎncă nu există evaluări

- Product Handling: Complete Solutions From A Single SourceDocument24 paginiProduct Handling: Complete Solutions From A Single Sourcemarciojunk100% (1)

- UntitledDocument32 paginiUntitledAnimeFreak930901Încă nu există evaluări

- CMD LinecommandsDocument14 paginiCMD LinecommandsdesideriuÎncă nu există evaluări

- CL Fuses 8KV-15KV-23KV-38KV Data SheetDocument9 paginiCL Fuses 8KV-15KV-23KV-38KV Data SheetSamer Abdulaziz SadaqaÎncă nu există evaluări

- Phase ShifterDocument7 paginiPhase ShifterNumanAbdullahÎncă nu există evaluări

- Pre-Stressed Elective EngineeringDocument7 paginiPre-Stressed Elective EngineeringJonas FernandezÎncă nu există evaluări

- 9500MPR - MEF8 Circuit Emulation ServicesDocument5 pagini9500MPR - MEF8 Circuit Emulation ServicesedderjpÎncă nu există evaluări

- Bill of Materials SampleDocument31 paginiBill of Materials SampleOcsi YeahÎncă nu există evaluări

- InternshipDocument14 paginiInternshipMohammed Shaheeruddin0% (1)

- Electricalprep Com Transformers More 5Document16 paginiElectricalprep Com Transformers More 5gokulchandruÎncă nu există evaluări

- Characteristics of Responsible Users and Competent Producers of Media and InformationDocument83 paginiCharacteristics of Responsible Users and Competent Producers of Media and InformationMarson B. GranaÎncă nu există evaluări

- INDUSTRIAL LUBRICANTS-misr Petroleum PDFDocument17 paginiINDUSTRIAL LUBRICANTS-misr Petroleum PDFIslam FawzyÎncă nu există evaluări

- Rotation Gearbox Component Fig 1Document2 paginiRotation Gearbox Component Fig 1Mohamed RashedÎncă nu există evaluări