Documente Academic

Documente Profesional

Documente Cultură

IJSRDV3I1471

Încărcat de

Matthew Smith0 evaluări0% au considerat acest document util (0 voturi)

58 vizualizări4 paginihgghf

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documenthgghf

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

58 vizualizări4 paginiIJSRDV3I1471

Încărcat de

Matthew Smithhgghf

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 4

IJSRD - International Journal for Scientific Research & Development| Vol.

3, Issue 01, 2015 | ISSN (online): 2321-0613

Design and Analysis of Composite Drive Shaft- A Review

Pankaj K. Hatwar 1 Dr. R.S. Dalu2

1,2

Department of Mechanical Engineering

1,2

Government College of Engineering, Amravati, India

Abstract Polymeric materials reinforced with synthetic

fibres such as glass, carbon, and aramid provide advantages

of high stiffness and strength to weight ratio as compared to

conventional construction materials, i.e. wood, concrete, and

steel. Despite these advantages, the widespread use of

synthetic fibre-reinforced polymer composite has a tendency

to decline because of their high-initial costs, their use in

non-efficient structural forms and most importantly their

adverse environmental impact. In the recent days, there is a

huge demand for a light weight material such as fiber

reinforced polymer composites seems to be a promising

solution to this arising demand. These materials have gained

attention due to their applications in the field of automotive,

aerospace, sports goods, medicines and household

appliances. The overall objective of this work is to analyze a

composite drive shaft for power transmission. This work

deals with the replacement of conventional steel drive shafts

composite drive shaft for an automotive application.

Key words: Automotive, Composite, Cost, Drive Shaft,

Fiber, Weight

I. INTRODUCTION

Over the last thirty years composite materials, Plastics and

ceramics have been the dominant emerging materials. The

volume and number of applications of composite materials

have grown steadily, penetrating and conquering new

markets relentlessly. Modern composite materials constitute

a significant proportion of the engineered materials market

ranging from everyday products to sophisticated niche

applications. While composites have already proven their

worth as weight-saving materials, the current challenge is to

make them cost effective. The most widely used meaning is

the following one, which has been stated by Jartiz

Composites are multifunctional material systems that

provide characteristics not obtainable from any discrete

material. They are cohesive structures made by physically

combining two or more compatible materials, different in

composition and characteristics and sometimes in form.

A driveshaft is a rotating shaft that transmits drive

to wheels. Driveshaft must operate through constantly

changing angles between the transmission and axle. High

quality steel (Steel SM45) is a common material for

construction. Steel drive shafts are usually manufactured in

two pieces to increase the fundamental bending natural

frequency because the bending natural frequency of a shaft

is inversely Proportional to the square of beam length and

Proportional to the square root of specific modulus. The two

piece steel drive shaft consists of three universal joints, a

cross center supporting bearing and a bracket, which

increase the total weight of a vehicle. Power transmission

can be improved through the reduction of inertial mass and

light Hooks weight. The application of composite materials

started first at the aerospace industry in 1970s, but

nowadays after only three decades, it has been developed in

most industries. Meanwhile, the automotive industry,

considered as a pioneer in every country, has been benefited

from the properties and characteristics of these advanced

materials For automotive applications, the first composite

drive shaft was developed by the Spicer U-Joint division of

Dana Corporation for Ford econoline van models in 1985

[1]. Also, composite materials typically have a lower

modulus of elasticity. As a result, when torque peaks occur

in the driveline, the driveshaft can act as a shock absorber

and decrease stress on part of the drive train extending life.

II. LITERATURE SURVEY

Dai Gil Lee, Hak Sung Kim, Jong Woon Kim and Jin Kook

Kim [2] use hybrid aluminum/composite for making

automotive drive shaft. In this work, one-piece automotive

hybrid aluminum/composite drive shaft was developed with

a new manufacturing method, in which a carbon fiber epoxy

composite layer was co-cured on the inner surface of an

aluminum tube rather than wrapping on the outer surface to

prevent the composite layer from being damaged by external

impact and absorption of moisture. From experimental

results, it was found that the developed one-piece

automotive hybrid aluminum/composite drive shaft had 75%

mass reduction, 160% increase in torque capability

compared with a conventional two-piece steel drive shaft. It

also had 9390 rpm of natural frequency which was higher

than the design specification of 9200 rpm.

Bhirud Pankaj Prakash and Bimlesh Kumar Sinha

[3] use Kevlar/epoxy or E glass polythene resin composite

automotive drive shaft. The intention of work is to minimize

the weight of drive shaft. In this work an attempt has been to

estimate the deflection, stresses, and natural frequencies

under subjected loads using FEA. Further comparison

carried out for both loads using FEA. Further comparison

carried out for both optimized and stress intensity factor

found for both Steel and composite drive shafts. The

presented work was aimed to reduce the fuel consumption of

the automobile in the particular or any machine, which

employs drive shafts; in general it is achieved by using light

weight composites like Kevlar/Epoxy. By taking into

considerations the weight saving, deformation, shear stress

induced and resonant Frequencies it is evident that

Kevlar/Epoxy composite has the most encouraging

properties to act as replacement for steel out of the

considered two materials.

Sagar R dharmadhikari, sachin G mahakalkar,

jayant P giri and nilesh D khutafale [4] work on Design of

composite drive shaft, Analysis of composite drive shaft

using ANSYS, Design optimization using genetic algorithm

(GA) by Modeling and simulation. In this they found that

the replacement of conventional drive shaft results in

reduction in weight of automobile. The finite element

analysis is used in this work to predict the deformation of

shaft. The deflection of steel, HS carbon / epoxy and HM

carbon / epoxy shafts was 0.00016618, 0.00032761 and

0.0003261 mm respectively. The frequency calculated by

bernoulli euler theory is high because it neglects the effect

of rotary inertia & transverse shear. Hence the single piece

All rights reserved by www.ijsrd.com

1294

A Prototype of Assistive Text Label Reading System for Blind An Overview

(IJSRD/Vol. 3/Issue 01/2015/341)

high strength carbon / epoxy composite drive shaft has been

proposed to design to replace the two piece conventional

steel drive shaft of an automobile.

M.R. Khoshravan and A. Paykani [5] work on

Design of a composite drive shaft, Modal analysis of

composite drive shaft using ANSYS, The weight

comparison between composite and steel drive shafts

Modeling and simulation. In this they found that Mechanical

properties for each Lamina of the laminate. Load carrying

capacity, lateral bending natural frequency lateral bending

natural frequency, buckling torque, effect of fiber angle.

R. P. Kumar Rompicharla and Dr. K. Rambabu [6]

use Kevlar /Epoxy composite material and The drive shaft

of Toyota Qualis was chosen for determining the

dimensions, which were used then used for the material

properties of composites were used the stability of drive

shaft is ensured by limiting the include values with in the

permissible range in ANSYS 12.0. The stress intensity value

at crack tip is observed for composite driveshaft is low.

D.dinesh and F. anand raju [7] work on optimum

design and analysis of a composite drive shaft for an

automobile by using genetic algorithm and ANSYS. In this

they found that the deflection of steel, e glass/ epoxy, high

strength carbon/epoxy and high modulus carbon/epoxy

shafts were equal to 0.012407, 0.025262, 0.019288 and

0.012919 mm respectively. The fundamental natural

frequency of steel, e glass/ epoxy, high strength

carbon/epoxy and high modulus carbon/ epoxy shafts were

9319.98, 6514.56, 7495.42 and 9270.28 rpm respectively.

The torsional buckling capacity of steel, e glass/epoxy,

high strength carbon/ epoxy and high modulus carbon/epoxy

shafts were 43857.96, 29856.45, 3772.11 and 3765.75 n-m

respectively.

Bhushan K. Suryawanshi and Prajitsen G.Damle

[8] presented work on hybrid aluminium/composite drive

shaft and found that a press fit joining method between the

steel yoke with protrusions on its surface and the aluminium

tube was developed to increase the reliability of joining and

to reduce manufacturing cost.

Harshal Bankar, Viraj Shinde and P. Baskar [9]

chose Steel, Boron/Epoxy Composite, Kevlar/Epoxy

Composite, Aluminum Glass/Epoxy Hybrid, Carbon

Glass/Epoxy Hybrid. The analysis was carried out for three

different ply orientations of the composites in order to

suggest the most suitable ply orientation of the material that

would give the maximum weight reduction while

conforming to the stringent design parameters of passenger

cars and light commercial vehicle. The stress distribution

and the maximum deformation in the shaft are the functions

of the stacking of material. The optimum stacking of

material layers can be used as the effective tool to reduce

weight and stress acting on the drive shaft.

M.A.K. Chowdhuri and R.A. Hossain [10]

proposed two different designs are, one is purely from

Graphite/Epoxy lamina and other is using Aluminum with

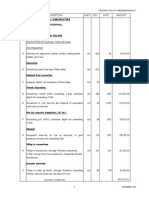

Sl.n

o

Property

Symbo

l

Unit

Carbon/Epox

y

Graphite/Epoxy. The basic requirements considered here are

torsional strength, torsional buckling and bending natural

frequency. An optimum design of the draft shaft is done,

which is cheapest and lightest but meets all of the above

load requirements. Progressive failure analysis of the

selected design is also done.

V. S. Bhajantri, S. C. Bajantri, A. M. Shindolkar

and S. S. Amarapure [11] use Carbon Epoxy Composite

automotive drive shaft. The design procedure is studied and

along with finite element analysis some important parameter

are obtained. The composite drive shaft made up of HM

carbon / epoxy multilayered composites has been designed.

The results reveal that the orientation of fibres has great

influence on the static characteristics of the composite shafts

and offers advantages such as Lower weight, Higher

strength, Progressive failure mechanism (offers warning

before failure) , Lower power consumption.

Arun Ravi [12] uses HS Carbon/Epoxy and HM

Carbon/ Epoxy Composite automotive drive shaft and

analyses it by using ANSYS. . In this he found that the

weight savings of the HS Carbon is 24 %( 100-50 & Solid)

compared to same dimensions of steel shaft and the

deflection of Steel and High Strength Carbon.

Ghatage K.D and Hargude N.V [13] optimize

design of automotive composite drive shaft with genetic

algorithm as optimization tool. About 15.75% weight saving

is achieved with Glass-carbon/Epoxy composite shaft with

increase in critical speed enabling manufacturing of shaft of

length 1.7 m to 2m; as compared to steel shaft; by

experimentation. The results reveal that the orientation of

fibers has great influence on the dynamic characteristics of

the composite material shafts in a positive direction. Genetic

Algorithm is suggested as an effective optimization tool.

R. Srinivasa Moorthy, Yonas Mitiku and K.

Sridhar [14] design automobile driveshaft using

carbon/epoxy and kevlar/epoxy composites. This work relies

purely upon analytical calculations and use of ply

distribution tables/graphs pertaining to 60% volume fraction

and 0.13 mm ply thickness. This approach throws light upon

ply distribution in standard orientations of 0, 90, +45 and

-45 for the composite considered. The effect of varying ply

staking sequence on the performance of composites can be

found by using computational software. Moreover,

considering the material and manufacturing cost will give

better grounds to compare the overall efficacy, thus resulting

in an appropriate selection of the best fibre/matrix

combination for making automotive driveshaft.

Parshuram D and Sunil Mangsetty [15] Design and

Analysis Composite/Hybrid Drive Shaft for Automotive.

The modeling of the drive shaft assembly was done using

CATIA software. A shaft has to be designed to meet the

stringent design requirements for automotive. In this work

an attempt has been to estimate deflection, stresses under

subjected loads & natural frequencies using FEA.

Aluminu

m

Crowfoo

t satin

woven

glass

ber

epoxy

Steel

E glass

polyeste

r resin

Kevlar

/

Epoxy

Boron/epox

y

All rights reserved by www.ijsrd.com

1295

A Prototype of Assistive Text Label Reading System for Blind An Overview

(IJSRD/Vol. 3/Issue 01/2015/341)

1

2

3

4

5

6

7

8

Longitudin

al modulus

Transverse

modulus

Shear

modulus

Poissons

ratio

Density

Longitudin

al tensile

strength

Transverse

tensile

strength

Shear

strength

E11

Gpa

190

E22

Gpa

7.7

G12

Gpa

4.2

-----

0.3

Kg/m

3

1600

St1

Mpa

870

St2

Mpa

540

Ss

Mpa

30

72.0

35.5

72.0

17.2

27.0

3.5

0.33

0.22

2700

2050

270

600

207.

0

34

95.71

169.6

6.53

10.45

7.29

80.0

2.433

25.08

4.625

0.3

0.287

0.34

0.29

7600

2100

1402

2100

370

700

200

60

275

420

Frequency

Hz

169.64

156.5

3.76

1.238

2.04

92.72

10

Mass

reduction

(%)

72

25

29

24

29

11

Deflection

Mm

0.3276

17.38

7.49

9.039

12

Stress

Mpa

143.7

50.05

48.56

54.118

6,14

Paper no.

4,7,11,12

0.54

6

58.5

9

8,10,15

All

Table 1: Findings from Literature

III. CONCLUSION

By studying all above publish paper we found the following

conclusions:

1) A two-piece steel drive shaft was considered to be

replaced by a one-piece composite drive shaft.

2) The usage of composite materials has resulted in

considerable amount of weight saving in the range

of 81% to72% when compared to conventional

steel drive shaft.

3) Apart from being lightweight, the use of

composites also ensures less noise and vibration.

4) Shaft with increase in critical speed enabling

manufacturing of shaft of length 1.7 m to 2m; as

compared to steel shaft; by experimentation.

5) The results reveal that the orientation of fibers has

great influence on the dynamic characteristics of

the composite material shafts in a positive

direction.

6) Genetic Algorithm is suggested as an effective

optimization tool.

7) The torque transmission capacity of the composite

drive shafts has been calculated by neglecting and

considering the effect of centrifugal forces and it

has been observed that centrifugal forces will be

reducing the torque transmission capacity of the

shaft.

8) Natural frequency using Bernoulli Euler and

Timoshenko beam theories was compared. The

frequency calculated by using the Bernoulli Euler

beam theory is high, because it neglects the effect

of rotary inertia & transverse shear.

IV. FUTURE SCOPE

1) This study leaves wide scope for future

investigations. It can be extended to newer

composites using other reinforcing phases and the

resulting experimental findings can be similarly

analyzed.

2) Tribological evaluation of glass/carbon fiber

reinforced epoxy resin composite has been a much

less studied area. There is a very wide scope for

future scholars to explore this area of research.

Many other aspects of this problem like effect of

fiber orientation, loading pattern, weight fraction of

ceramic fillers on wear response of such

composites require further investigation

REFERENCES

[1] P.K. Mallick, S. Newman, Composite materials

technology. Hanser Publishers. pp. 206-10, 1990.

[2] D.G. Lee, Hak Sung Kim, Jong Woon Kim, Jin

Kook Kim, Composite Structures 63 (2004) pp.87

99.

[3] Bhirud Pankaj Prakash, Bimlesh Kumar Sinha,

International Journal of Mechanical and Production

Engineering, ISSN: 2320-2092, Volume- 2, Issue2, Feb.-2014, pp.2429.

[4] Sagar R dharmadhikari, sachin G mahakalkar,

jayant P giri,nilesh D khutafale. International

journal of modern engineering research, vol.3,

issue.1, jan-feb.2013, pp.490-496.

All rights reserved by www.ijsrd.com

1296

A Prototype of Assistive Text Label Reading System for Blind An Overview

(IJSRD/Vol. 3/Issue 01/2015/341)

[5] M.R. Khoshravan, A. Paykani, Journal of applied

research and technology, vol. 10, December 2012

/pp.826834.

[6] R. P. Kumar Rompicharla, Dr. K. Rambabu,

International Journal of Modern Engineering

Research, ISSN: 2249-6645 Vol.2, Issue.5, SepOct. 2012 pp.3422-3428.

[7] D.dinesh, F.anandraju, International journal of

engineering research and applications, issn: 22489622, vol. 2, issue4, July-august 2012, pp.18741880.

[8] Bhushan K. Suryawanshi, Prajitsen G.Damle,

International Journal of Innovative Technology and

Exploring Engineering, ISSN: 2278-3075, Volume2, Issue-4, March 2013 pp-259-266.

[9] Harshal Bankar, Viraj Shinde, P. Baskar, IOSR

Journal of Mechanical and Civil Engineering, eISSN: 2278-1684, p-ISSN: 2320-334X, Volume

10, Issue 1 (Nov. - Dec. 2013), pp. 39-46.

[10] M.A.K. Chowdhuri, R.A. Hossain, International

Journal of Engineering and Technology Vol.2,

2010, pp. 45-48.

[11] S. Bhajantri S. C. Bajantri, A. M. Shindolkar, and

S. S. Amarapure, International Journal of Research

in Engineering and Technology, Volume: 03

Special Issues: 03, May-2014, pp. 2321-7308.

[12] Arun Ravi, International Review of Applied

Engineering Research. ISSN 2248-9967 Volume 4,

Number 1 (2014), pp. 21-28.

[13] Ghatage K.D, Hargude N.V, IJMET, Volume 3,

Issue 3, September - December (2012), pp. 438449.

[14] R. Srinivasa Moorthy, Yonas Mitiku & K. Sridhar,

American Journal of Engineering Research, eISSN: 2320-0847 p-ISSN: 2320-0936 Volume-02,

Issue-10, pp.173-179.

[15] Parshuram D, Sunil Mangsetty, The International

Journal of Engineering and Science, Volume2 Issue

01, 2013, pp.160-171.

All rights reserved by www.ijsrd.com

1297

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elemental Bill of Quantities For 3 Bedroom Apartment BlockDocument29 paginiElemental Bill of Quantities For 3 Bedroom Apartment BlockAliyu Shehu83% (72)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Audi Engine Management SystemsDocument185 paginiAudi Engine Management SystemsHri Vitalion100% (12)

- Cardolite Coatings Brochure PDFDocument20 paginiCardolite Coatings Brochure PDFKalyanasundaram Thirugnanasambandam100% (1)

- Time Management Conference 2019Document28 paginiTime Management Conference 2019Matthew SmithÎncă nu există evaluări

- 6Rph6Wxglhv RQ 0hfkdqlfdo 3urshuwlhv Ri (SR (/&7%1&od/ %Dvhg3Ro/Phu 1Dqrfrpsrvlwhv 31&Document8 pagini6Rph6Wxglhv RQ 0hfkdqlfdo 3urshuwlhv Ri (SR (/&7%1&od/ %Dvhg3Ro/Phu 1Dqrfrpsrvlwhv 31&Matthew SmithÎncă nu există evaluări

- C 20 MTT 1 2 SemDocument165 paginiC 20 MTT 1 2 SemMatthew SmithÎncă nu există evaluări

- Maths 3 CompressedDocument208 paginiMaths 3 CompressedMatthew SmithÎncă nu există evaluări

- C 20 MY 3 4 SemDocument80 paginiC 20 MY 3 4 SemMatthew SmithÎncă nu există evaluări

- Front-Wheel-Drive (Transaxle and CV Joint) Fundamentals: © 2012 Delmar, Cengage LearningDocument25 paginiFront-Wheel-Drive (Transaxle and CV Joint) Fundamentals: © 2012 Delmar, Cengage LearningMatthew SmithÎncă nu există evaluări

- Study of Friction and Wear of ABS/Zno Polymer Composite Using Taguchi TechniqueDocument10 paginiStudy of Friction and Wear of ABS/Zno Polymer Composite Using Taguchi TechniqueMatthew SmithÎncă nu există evaluări

- Combustion in Si EnginesDocument36 paginiCombustion in Si Enginesrgopi_83Încă nu există evaluări

- Basic Thermo 3Document65 paginiBasic Thermo 3Matthew SmithÎncă nu există evaluări

- BTD - QBDocument25 paginiBTD - QBMatthew SmithÎncă nu există evaluări

- 6 CNC PDFDocument42 pagini6 CNC PDFOgnjenOklobdzijaÎncă nu există evaluări

- Describe The Construction and Operation of Manual and Semi-Automatic Transmissions Used On Light VehiclesDocument3 paginiDescribe The Construction and Operation of Manual and Semi-Automatic Transmissions Used On Light VehiclesMatthew SmithÎncă nu există evaluări

- 1 PBDocument8 pagini1 PBMatthew SmithÎncă nu există evaluări

- Applied Thermodynamics Unit-Ic Engines Assaignment - 01: Bharath .A, Lecturer, Dsce, BangaloreDocument4 paginiApplied Thermodynamics Unit-Ic Engines Assaignment - 01: Bharath .A, Lecturer, Dsce, BangaloreMatthew Smith0% (1)

- Types of Chassis LayoutDocument8 paginiTypes of Chassis LayoutMatthew SmithÎncă nu există evaluări

- MP 3Document69 paginiMP 3Matthew SmithÎncă nu există evaluări

- Marine Fire and Gas Dampers: Type JFDDocument8 paginiMarine Fire and Gas Dampers: Type JFDTakrimi IsmailÎncă nu există evaluări

- Strength of MaterialsDocument6 paginiStrength of MaterialsSheryll de GuzmanÎncă nu există evaluări

- DAK 12403 - Exp 5 Head Loss Through FittingsDocument7 paginiDAK 12403 - Exp 5 Head Loss Through FittingsMuiz UdinÎncă nu există evaluări

- 6 - Geomembrane Lifetime Prediction PDFDocument27 pagini6 - Geomembrane Lifetime Prediction PDF齐左Încă nu există evaluări

- WP-01 Foundation Waterproofing LayoutDocument1 paginăWP-01 Foundation Waterproofing LayoutAqib Azad JanjuaÎncă nu există evaluări

- r05322102 Aerospace Vehicle Structures IIDocument12 paginir05322102 Aerospace Vehicle Structures IISRINIVASA RAO GANTA100% (2)

- Slab DesignDocument78 paginiSlab DesignWrishad Zia100% (26)

- DHM 6 Set: Mini Instantaneous Water Heater PRODUCT-NO.: 236452Document4 paginiDHM 6 Set: Mini Instantaneous Water Heater PRODUCT-NO.: 236452Cire Lop CastroÎncă nu există evaluări

- GATEMSM CompressedDocument13 paginiGATEMSM CompressedChaitanya Kishore ChitikenaÎncă nu există evaluări

- Sanyo ScrollDocument50 paginiSanyo ScrollBruno CoutoÎncă nu există evaluări

- Sanitation EngineeringDocument322 paginiSanitation Engineeringramesh rahulÎncă nu există evaluări

- Course Highway Engineering Course Code ECG354 Level of Openness 0Document6 paginiCourse Highway Engineering Course Code ECG354 Level of Openness 0Nurul NadhirahÎncă nu există evaluări

- Plastering Guide PDFDocument8 paginiPlastering Guide PDFStas ChirilaÎncă nu există evaluări

- Technical Folder Filtercel Cfa-W: SpecificationsDocument1 paginăTechnical Folder Filtercel Cfa-W: SpecificationsmehrezÎncă nu există evaluări

- Apollo and Apollo ATI Natural Smoke VentilatorDocument2 paginiApollo and Apollo ATI Natural Smoke VentilatoradnanÎncă nu există evaluări

- A Study On Stabilization of Black Cotton Soil Using Rice Husk AshDocument10 paginiA Study On Stabilization of Black Cotton Soil Using Rice Husk AshMuhammad ShadabÎncă nu există evaluări

- Wu - Glass Deramic Foams From Coal Ash and Waste Glass - Production and CharacterisationDocument9 paginiWu - Glass Deramic Foams From Coal Ash and Waste Glass - Production and CharacterisationArgiliathÎncă nu există evaluări

- List of Published Sans StandardsDocument7 paginiList of Published Sans StandardsBrian Galindez100% (1)

- CH412 Problems 0005Document1 paginăCH412 Problems 0005BSMK600% (1)

- Manual Lavaloza Blankelee D-18Document66 paginiManual Lavaloza Blankelee D-18christopher menesesÎncă nu există evaluări

- Oil SeparatorDocument2 paginiOil SeparatorOnofreÎncă nu există evaluări

- Design of Slab FormsDocument27 paginiDesign of Slab FormsZevanyaRolandTualaka100% (1)

- Fresh Water ModuleDocument24 paginiFresh Water Moduleanon_411130333Încă nu există evaluări

- Art Village ThesisDocument4 paginiArt Village ThesisBhanu GillÎncă nu există evaluări

- Sandvik 2RE10 - The Risk Reducer in Nitric Acid Production - Sandvik Materials TechnologyDocument5 paginiSandvik 2RE10 - The Risk Reducer in Nitric Acid Production - Sandvik Materials TechnologyAnonymous 5odj1IcÎncă nu există evaluări

- Civil Industrial TrainingDocument59 paginiCivil Industrial TrainingAbhi Ram Yuvasamrat50% (2)

- Estimating Door InfiltrationDocument11 paginiEstimating Door InfiltrationRey Regaspi TuyayÎncă nu există evaluări

- Edibon Refrigeration Cycle ManualDocument66 paginiEdibon Refrigeration Cycle Manualleo besaÎncă nu există evaluări