Documente Academic

Documente Profesional

Documente Cultură

Truss Design NS Negi

Încărcat de

Sushmit SharmaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Truss Design NS Negi

Încărcat de

Sushmit SharmaDrepturi de autor:

Formate disponibile

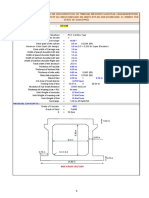

DESIGN OF STEEL TRUSS

Width of Bldg. =

Length of Bldg.=

Height of eaves=

Number of bayes =

Angle of trust (Alfa) =

Spacing of truss(assumption) =

8

16.5

7.4

4

30

4.05

m c/c

m

m

Deg.

m

Height of truss =

Incline length =

Each incline length =

Horizontal length =

2.309

4.619

1.540

1.333

m

m

m

m

0.35

0.40

0.27

KN/m2

KN/m2 (horizontal area)

KN/m2 (horizontal area)

Impose loads:

Imposed load =

For purlin =

For truss members =

350.00

402.50

268.33

N/m2

N/m2

N/m2

Wind loads:

Take basic wind speed(Vb) =

50

cum (Assume)

F = (Cpe - Cpi) X A X Pz

Cpe & Cpi = Force coefficient for exterior & interrior of building. (Ref: Table B7 and Table B9 ;( " BOOK = Design of steel structure, second edition, LS Negi", pg:309 & 311)

A = Effective area of the structure.

Pz = Design wind pressure.= 0.6Vz^2

Where,

Design wind speed , Vz = Vb x K1 x K2 x K3

Accroading to the IS:875(part3);

Risk factor, K1 =

1.08

ref; Table B-11, Risk Coefficient K1;( " BOOK = Design of steel structure, second edition, LS Negi", pg:312)

Height and size factor, K2 =

0.91

ref; Table B-12, K2 factor;( " BOOK = Design of steel structure, second edition, LS Negi", pg:312)

Topography factor, K3 =

1

K3 = 1 for upward slope < 3; K3 = 1 to 1.36 for upwind slope > 3

Therefore, Vz =

49.14

m/sec.

Design wind pressure (Pz) =

1448.84

N/m2

Now,

Height of bldg., h =

9.709

m

Width of bldg., w =

8

m

Length of bldg., L =

16.5

m

h/w =

1.21

L/w =

2.06

Internal air pressure coefficient for normal permeability, Cpi = 0.2

Total pressure =(Cpe -Cpi) x Pd

Cpi =

0.2

Downward

Wind normal to ridge :

-724.422

Cpi =

-0.2

Uplift

-144.884

Wind ward Cpe =

-0.3

Lee ward Cpe =

-0.4

-869.306

-289.769

-0.8

-1448.844

-869.306

-1159.075

-579.538

Wind parallel to ridge

Wind ward Cpe =

Lee ward Cpe =

Max.wind load for design =

Max.wind load for design =

-0.6

869.31

-1448.84

N/m2 (downward)

N/m2 (Uplift)

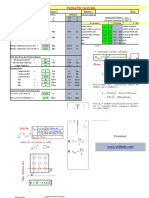

Design of purlins

Spacing of purlins =

Weigth of 20gauge CGI sheets =

Size of CGI sheet=

1.540

112.7

1.8*0.9

m c/c

N/m2 (Assume)

m*m

173.513

10

100

N/m

kgf/m

N/m

Load on purlins per meter length

Weight of sheeting =

Weight of purlin (Assuming) =

Total dead load =

Impose load =

Wind load =

273.513

536.667

-2230.641

N/m

N/m

N/m

Dead load + impose load =

Dead load + wind load =

810.180

-1957.128

N/m

N/m

When wind load is consider permissible stress is increased by 33.33%,

Therefore, dead load + wind load may be considered 33.33% less effective;

Design wind load =

-1471.525

N/m;

Maximum bending moment in the purlin =

Yield stress(fy) =

Permissible bending stress =

2413.668

250

165

Nm

N/mm2

N/mm2

Therefore, section modulus (Zx) =

14628.294

14.63

mm3

3

Cm

combination of dead & wind load is critical

Required tubular purlin (as per common steel sections)

Zx =

Outside Diameter =

Nominal Bore =

Class =

Thickness =

Weight =

Area of X-section =

14.4

76.1

65

Medium

3.65

6.53

8.31

Cm

mm

mm

mm

kg/m

Cm2

Design Load for roof truss

Loads:

1) Dead loads:

Length along the sloping roof =

Self weight of the truss =

Gauge of CGI sheet =

weight of roofing material =

No. of purling =

Weight of purling =

4.619

100

20

112.7

8

65.3

m

N/m2 (Assume @100 N/m2 horizontally)

N/m2

N/m2

Therefore;

Load due to :

Self weight of truss =

Roofing material (CGI sheet) =

Purlins =

Total =

3240.00

4216.37

2115.72

9572.086

N

N

N

N

No. of panels =

Load acting on intermediate panel point =

6

1595.35

Dead load acting on node =

Dead load acting on shoe =

1595.35

797.67

N

N

Miscellaneouse load (Live loads) =

Total live load =

Load acting on intermediat panel point =

0.2

8724.48

1454.08

N/m2 (Assume)

N

N

Live load acting 0n node =

Live load acting on shoe =

1454.08

727.04

N

N

1448.84

9034.10

4517.05

N

N

2) Imposed loads:

3) Wind loads:

Total wind load =

Wind load acting on one intermediat panel =

Wind load acting on shoe =

S-ar putea să vă placă și

- Asset Management Council 1205 TheAsset0602 PDFDocument48 paginiAsset Management Council 1205 TheAsset0602 PDFSushmit SharmaÎncă nu există evaluări

- Design of Circular Base Plate Under Large Bending MomentDocument5 paginiDesign of Circular Base Plate Under Large Bending MomentAntonioMonteroÎncă nu există evaluări

- Spreadsheets To BS 8110: Henry Level - 1 Base B1 RMW 113Document1 paginăSpreadsheets To BS 8110: Henry Level - 1 Base B1 RMW 113ojok100% (1)

- Steel Bridge DesignDocument24 paginiSteel Bridge DesignVarun ShastryÎncă nu există evaluări

- Structural Design-Part One-Board ProblemsDocument10 paginiStructural Design-Part One-Board ProblemsaivanÎncă nu există evaluări

- Footing Type Lf1: Step 1 - Check Soil PressureDocument3 paginiFooting Type Lf1: Step 1 - Check Soil PressureseyfeÎncă nu există evaluări

- Building Construction Department (BCD) Edmac Engineering Consultant (I) Pvt. LTDDocument20 paginiBuilding Construction Department (BCD) Edmac Engineering Consultant (I) Pvt. LTDIrfan Khan100% (1)

- Estimate-7420 (Sor 29-08-2017)Document37 paginiEstimate-7420 (Sor 29-08-2017)ankit hardahaÎncă nu există evaluări

- Pile cap design for column load of 1000 KNDocument8 paginiPile cap design for column load of 1000 KNsnehar redkarÎncă nu există evaluări

- RCC Box Culvert DesignDocument27 paginiRCC Box Culvert DesignPraveen Cyssan0% (1)

- Design of Flexible Pavement CalculationDocument2 paginiDesign of Flexible Pavement CalculationbharatÎncă nu există evaluări

- Design of Deck Slab 3Document35 paginiDesign of Deck Slab 3Allan MarbaniangÎncă nu există evaluări

- Slab Design Excel FileDocument4 paginiSlab Design Excel FileSuman Resolved NeupaneÎncă nu există evaluări

- PDF - Significant Change Seismic Provision ASCE 7-10Document9 paginiPDF - Significant Change Seismic Provision ASCE 7-10MIKHA201467% (3)

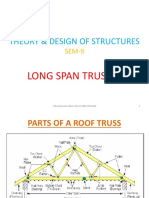

- Long Span TrussesDocument26 paginiLong Span TrussesAshish Gokawar100% (1)

- Slab Bridge Final KPJDocument73 paginiSlab Bridge Final KPJvinoraamÎncă nu există evaluări

- PCI Parking BuildingDocument125 paginiPCI Parking BuildingProfessor Dr. Nabeel Al-Bayati-Consultant EngineerÎncă nu există evaluări

- College Building DBRDocument171 paginiCollege Building DBRchetanchintaÎncă nu există evaluări

- Design of Cantilever Slab (Balconey)Document11 paginiDesign of Cantilever Slab (Balconey)Engineeri TadiyosÎncă nu există evaluări

- DEEP BEAM DesignDocument2 paginiDEEP BEAM DesignmangeshÎncă nu există evaluări

- Types of FoundationDocument23 paginiTypes of FoundationemmanuelÎncă nu există evaluări

- Useful Data From IS456 & Is-13920Document29 paginiUseful Data From IS456 & Is-13920MayurÎncă nu există evaluări

- Purlin, Runner - R1 - 1Document7 paginiPurlin, Runner - R1 - 1MadhurimaMitra100% (1)

- GIS Tutorial 1 Basic WorkbookDocument417 paginiGIS Tutorial 1 Basic WorkbookJuan95% (21)

- Ductile Detailing As Per 13920Document4 paginiDuctile Detailing As Per 13920Gautam DuttaÎncă nu există evaluări

- CH 27Document25 paginiCH 27hemant_durgawaleÎncă nu există evaluări

- Truss Design NS NegiDocument23 paginiTruss Design NS NegiSushmit Sharma100% (1)

- Proposed Residential Development: Thirty Stars Investment Group Ltd. Base B1 AMG 1Document1 paginăProposed Residential Development: Thirty Stars Investment Group Ltd. Base B1 AMG 1patrick chegeÎncă nu există evaluări

- Slab DesignDocument6 paginiSlab DesignThea DoradoÎncă nu există evaluări

- HCF PDFDocument68 paginiHCF PDFSushmit SharmaÎncă nu există evaluări

- STeelDesign - I by N. PrabhakarDocument36 paginiSTeelDesign - I by N. Prabhakarrajasekhar.cheruvu8635Încă nu există evaluări

- Construction ScheduleDocument1 paginăConstruction Schedulenasiramzan0% (1)

- Structural design analysis of Manahari rural office buildingDocument41 paginiStructural design analysis of Manahari rural office buildingPraveen Bhandari100% (1)

- Stair Case One Way SlabDocument3 paginiStair Case One Way SlabPiyush Machhi0% (1)

- Structure and Architecture - Case StudiesDocument29 paginiStructure and Architecture - Case Studiesharish v100% (2)

- A Holistic Approach To Asset Management in The NetherlandsDocument10 paginiA Holistic Approach To Asset Management in The NetherlandsSushmit SharmaÎncă nu există evaluări

- One Way Two Way Slab S6Document1 paginăOne Way Two Way Slab S6manishnparmarÎncă nu există evaluări

- What Is New in PMBOK Guide 6th EdDocument130 paginiWhat Is New in PMBOK Guide 6th EdMikiRoniWijaya94% (16)

- RCCDocument16 paginiRCCSyed Sirajul HaqÎncă nu există evaluări

- CribDocument1 paginăCribskumarsrÎncă nu există evaluări

- 14 M Steel Bridge - Design Review of Cross Beam & End ConnectionDocument4 pagini14 M Steel Bridge - Design Review of Cross Beam & End ConnectionvibishnanÎncă nu există evaluări

- Two Way Slab Design: Panal Size 6.50 3.70 25 500 30 MM Lg. Span (L) Sh. Span (L) N/MM N/MMDocument2 paginiTwo Way Slab Design: Panal Size 6.50 3.70 25 500 30 MM Lg. Span (L) Sh. Span (L) N/MM N/MMmoha abidÎncă nu există evaluări

- Two-way Restrained Slab Design CheckDocument3 paginiTwo-way Restrained Slab Design CheckBasandharaAdhikariÎncă nu există evaluări

- Summary of Loads-Left Bank Abutment: Sukhaura River Motorable Bridge, Makwanpur Abutment Design IDD, ChitwanDocument26 paginiSummary of Loads-Left Bank Abutment: Sukhaura River Motorable Bridge, Makwanpur Abutment Design IDD, ChitwanPoshan DhunganaÎncă nu există evaluări

- Design of Dome: Type: ProjectDocument9 paginiDesign of Dome: Type: ProjectdeponkkarÎncă nu există evaluări

- Design Basic ReportDocument6 paginiDesign Basic ReportManinder ChaudharyÎncă nu există evaluări

- RCC14 Crack WidthDocument1 paginăRCC14 Crack WidthKha Phuc100% (1)

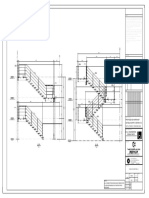

- Openwell StaircaseDocument8 paginiOpenwell StaircaseAbdul AzeemÎncă nu există evaluări

- Traffic Final Report Group 7Document86 paginiTraffic Final Report Group 7erlyn alagonÎncă nu există evaluări

- All Plug-Ins of Arc BdsDocument48 paginiAll Plug-Ins of Arc BdsAshish LoyaÎncă nu există evaluări

- Shear Wall NotesDocument22 paginiShear Wall NotesNupur BhadraÎncă nu există evaluări

- Design of V.R.BridgeDocument15 paginiDesign of V.R.BridgeNadeem HassoonÎncă nu există evaluări

- Elevated Service ReservoirDocument3 paginiElevated Service ReservoirSureshÎncă nu există evaluări

- Pile Cap Design Calculations With CSI SAFEDocument6 paginiPile Cap Design Calculations With CSI SAFEroshanÎncă nu există evaluări

- Slab Culvert Irc 21 Irc 112Document5 paginiSlab Culvert Irc 21 Irc 112Rupendra palÎncă nu există evaluări

- Grade Slab NMRCLDocument62 paginiGrade Slab NMRCLmvssrajuÎncă nu există evaluări

- Design of Stair Waist Slab: Concrete Slab Deflection CheckDocument2 paginiDesign of Stair Waist Slab: Concrete Slab Deflection CheckRathinavel VenkateshwaranÎncă nu există evaluări

- L&T TechnicalDocument5 paginiL&T TechnicalvigneshwarimahamuniÎncă nu există evaluări

- SP Is CODE Masonary DesignDocument167 paginiSP Is CODE Masonary DesignKumar PallavÎncă nu există evaluări

- Masonry Wall Design - 2Document3 paginiMasonry Wall Design - 2Michael AbandeÎncă nu există evaluări

- Handrail For Staircase-3: NotesDocument1 paginăHandrail For Staircase-3: NotesKARTHIK SGÎncă nu există evaluări

- Reinf - conc.Beams-Design Torsional&Axially LoadedDocument1 paginăReinf - conc.Beams-Design Torsional&Axially LoadedHermogenesGerardoIII OcanaÎncă nu există evaluări

- ALDECK3Document5 paginiALDECK3Mustafa ÇakırÎncă nu există evaluări

- Detailed Longitudinal Section Through RCC Deep BeamDocument1 paginăDetailed Longitudinal Section Through RCC Deep BeamShaikh ImranÎncă nu există evaluări

- Steps For RCC Design 10.01.08 PDFDocument12 paginiSteps For RCC Design 10.01.08 PDFSACHIDANANDA SÎncă nu există evaluări

- Structural Design of Bridges, Robs and UnderpassesDocument4 paginiStructural Design of Bridges, Robs and UnderpassessujupsÎncă nu există evaluări

- Load Calculation of Test PileDocument2 paginiLoad Calculation of Test PileRAJAT SHARMAÎncă nu există evaluări

- Nandyal SSE Office: Load Calculations Details of Loads 1 Floor LoadDocument1 paginăNandyal SSE Office: Load Calculations Details of Loads 1 Floor Loadravi4paperÎncă nu există evaluări

- Combined Footing For TwoDocument15 paginiCombined Footing For Twoer.praveenraj30Încă nu există evaluări

- Truss AnalysisDocument35 paginiTruss AnalysisSandip BudhathokiÎncă nu există evaluări

- SF10 and SF16Document22 paginiSF10 and SF16Shanil BussooaÎncă nu există evaluări

- Dindigul Bypass To Samyanallore On NH 7 in The State of Tamil Nadu Vol - II (A)Document641 paginiDindigul Bypass To Samyanallore On NH 7 in The State of Tamil Nadu Vol - II (A)harishram123456Încă nu există evaluări

- Design Loads for Sub-StructuresDocument72 paginiDesign Loads for Sub-Structuresmayank007aggarwalÎncă nu există evaluări

- Economic Design of RCC Box Culvert ThrouDocument7 paginiEconomic Design of RCC Box Culvert ThrouOscarKonzultÎncă nu există evaluări

- SchneiderElectric 111711 PDFDocument17 paginiSchneiderElectric 111711 PDFShiva Naga KumarÎncă nu există evaluări

- Section-1 Es enDocument75 paginiSection-1 Es enSushmit SharmaÎncă nu există evaluări

- Action Verbs For ResumesDocument2 paginiAction Verbs For Resumesapi-2627751040% (1)

- Decision Support For Maintenance and Refurbishment Planning of Hydropower PlantsDocument10 paginiDecision Support For Maintenance and Refurbishment Planning of Hydropower PlantsSushmit SharmaÎncă nu există evaluări

- OT3 GIS For BeginnersDocument37 paginiOT3 GIS For Beginnersmakmohit6037Încă nu există evaluări

- Labour Act, 2048 (1992) : It Came Into Force On 2054.7.18 (Nov. 3, 2000) by A Notification Published in The Nepal GazetteDocument44 paginiLabour Act, 2048 (1992) : It Came Into Force On 2054.7.18 (Nov. 3, 2000) by A Notification Published in The Nepal GazettenepalcaÎncă nu există evaluări

- PPA ProcedureDocument5 paginiPPA ProcedureSushmit SharmaÎncă nu există evaluări

- Electricity Act 2049-EnglishDocument14 paginiElectricity Act 2049-EnglishFariyad AnsariÎncă nu există evaluări

- Cement Grouted Rock Bolts PDFDocument28 paginiCement Grouted Rock Bolts PDFSushmit SharmaÎncă nu există evaluări

- Labour Act, 2048 (1992) : It Came Into Force On 2054.7.18 (Nov. 3, 2000) by A Notification Published in The Nepal GazetteDocument44 paginiLabour Act, 2048 (1992) : It Came Into Force On 2054.7.18 (Nov. 3, 2000) by A Notification Published in The Nepal GazettenepalcaÎncă nu există evaluări

- Decision Support For Maintenance and Refurbishment Planning of Hydropower PlantsDocument10 paginiDecision Support For Maintenance and Refurbishment Planning of Hydropower PlantsSushmit SharmaÎncă nu există evaluări

- EIA IEE Working Procedure 2073Document4 paginiEIA IEE Working Procedure 2073Sushmit SharmaÎncă nu există evaluări

- Hydropower Development Policy, 2049: 1. BackgroundDocument5 paginiHydropower Development Policy, 2049: 1. BackgroundRajpÎncă nu există evaluări

- Christie Burger Henk HattinghDocument28 paginiChristie Burger Henk HattinghSushmit SharmaÎncă nu există evaluări

- Crucial Role of Physical Modeling in Developing Intake ConfigurationDocument20 paginiCrucial Role of Physical Modeling in Developing Intake Configurationrelu100% (1)

- 02 Sanchez AM Overview PDFDocument20 pagini02 Sanchez AM Overview PDFSushmit SharmaÎncă nu există evaluări

- Fostering Academic Cooperation and CollaborationDocument22 paginiFostering Academic Cooperation and CollaborationSushmit SharmaÎncă nu există evaluări

- Barreiro-Trigos Octavio PDFDocument72 paginiBarreiro-Trigos Octavio PDFSushmit SharmaÎncă nu există evaluări

- Good Governance in The Public SectorDocument54 paginiGood Governance in The Public Sectorhermione_crisÎncă nu există evaluări

- Supply Chain Management Fact SheetDocument4 paginiSupply Chain Management Fact SheetYong Yang YangÎncă nu există evaluări

- 05 Supplier Selection Process PDFDocument15 pagini05 Supplier Selection Process PDFSushmit SharmaÎncă nu există evaluări

- PMI ManagingSubcontracts March2010Document25 paginiPMI ManagingSubcontracts March2010Sushmit SharmaÎncă nu există evaluări

- Multilevel Project Governance Trends and OpportunitiesDocument18 paginiMultilevel Project Governance Trends and OpportunitiesSushmit SharmaÎncă nu există evaluări

- Case Template Nuremberg-Ingolstadt FinalDocument45 paginiCase Template Nuremberg-Ingolstadt FinalSushmit SharmaÎncă nu există evaluări

- Worksheet On Marshal Mix DesignDocument1 paginăWorksheet On Marshal Mix DesignHordofa ZekeriaÎncă nu există evaluări

- Future Readymix - Original: K150 K200 Q Cost Q Cost 0.190 3.990 0.190 4.275 0.734 5.072 0.598 0.150 0.678 1.356 2 0.360Document10 paginiFuture Readymix - Original: K150 K200 Q Cost Q Cost 0.190 3.990 0.190 4.275 0.734 5.072 0.598 0.150 0.678 1.356 2 0.360Mohammed Abd ElazizÎncă nu există evaluări

- Scope of Work Design and ConstructionDocument19 paginiScope of Work Design and ConstructionThomas JohnÎncă nu există evaluări

- Earthquake Resistant Building Techniques and Construction MaterialDocument13 paginiEarthquake Resistant Building Techniques and Construction MaterialrishitaÎncă nu există evaluări

- Fatigue and CreepDocument19 paginiFatigue and CreepkhanÎncă nu există evaluări

- Software Verification: AISC-360-16 Example 004Document4 paginiSoftware Verification: AISC-360-16 Example 004alejandro mantillaÎncă nu există evaluări

- 2007 Air PDFDocument8 pagini2007 Air PDFJames FernÎncă nu există evaluări

- Sample Intellibuild EstimateDocument23 paginiSample Intellibuild EstimateRomani Noel S. Chavez Jr.Încă nu există evaluări

- RAC Lab Experiment No 1Document3 paginiRAC Lab Experiment No 1HallucinatoryÎncă nu există evaluări

- 19 - ME - 123 Shresth Sanskar Assignment 1 ES-ME401Document5 pagini19 - ME - 123 Shresth Sanskar Assignment 1 ES-ME401Shresth SanskarÎncă nu există evaluări

- Chapter 3Document34 paginiChapter 3Jeric EliveraÎncă nu există evaluări

- Assessing Vertical Lift PerformanceDocument8 paginiAssessing Vertical Lift PerformanceKader BakourÎncă nu există evaluări

- Pipe and Pipe FittingsDocument21 paginiPipe and Pipe FittingsAdamÎncă nu există evaluări

- Design of Column Base PlateDocument6 paginiDesign of Column Base PlatebuildconÎncă nu există evaluări

- Insul-Mate Aluminum JacketingDocument1 paginăInsul-Mate Aluminum JacketingПабло Рамирес РамиресÎncă nu există evaluări

- Slump TestDocument11 paginiSlump TestMuhammad asrafÎncă nu există evaluări

- 3 Codified Requirements For MORE THAN 2 LPG CYLINDERDocument5 pagini3 Codified Requirements For MORE THAN 2 LPG CYLINDERMrigank AggarwalÎncă nu există evaluări

- Revit MEPDocument6 paginiRevit MEPMohammed Hussam ShaikhÎncă nu există evaluări

- Jabatan Kerja Raya Preliminary Detailed Abstract ForDocument2 paginiJabatan Kerja Raya Preliminary Detailed Abstract ForFadzlini RamliÎncă nu există evaluări

- Design of A Pothole Repair For FijiDocument9 paginiDesign of A Pothole Repair For FijidonovanÎncă nu există evaluări

- Uttarakhand PWD Estimation for Road Improvement WorksDocument21 paginiUttarakhand PWD Estimation for Road Improvement WorksdaisyÎncă nu există evaluări