Documente Academic

Documente Profesional

Documente Cultură

FAC of Palm Oil Palm Olein and Palm Stearin

Încărcat de

Anonymous DJrec2Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

FAC of Palm Oil Palm Olein and Palm Stearin

Încărcat de

Anonymous DJrec2Drepturi de autor:

Formate disponibile

Journal of Oleo Science

Copyright 2008 by Japan Oil Chemists Society

J. Oleo Sci. 57, (5) 275-285 (2008)

Development of Palm-Based Reference Materials

for the Quantification of Fatty Acids Composition

Azmil Haizam Ahmad Tarmizi, Siew Wai Lin and Ainie Kuntom

Analytical and Quality Development Unit, Malaysian Palm Oil Board (6, Persiaran Institusi, Bandar Baru Bangi, 43000 Kajang, Selangor,

MALAYSIA)

Abstract: Characterisation of fatty acids composition of three palm-based reference materials was carried

out through inter-laboratory proficiency tests. Twelve laboratories collaborated in these tests and the

fatty acids compositions of palm oil, palm olein and palm stearin were determined by applying the MPOB

Test Methods p3.4:2004 and p3.5:2004. Determination of consensus values and their uncertainties were

based on the acceptable statistical agreement of results obtained from the collaborating laboratories. The

consensus values and uncertainties (%) for each palm oil reference material produced are listed as follows :

0.20% (C12:0), 1.660.05% (C14:0), 43.39 0.39% (C16:0), 0.140.06% (C16:1), 3.90 0.11% (C18:0),

40.95 0.23% (C18:1), 9.68 0.21% (C18:2), 0.16 0.07% (C18:3) and 0.31 0.08% (C20:0) for fatty

acids composition of palm oil; 0.23 0.04% (C12:0), 1.020.04% (C14:0), 39.66 0.19% (C16:0), 0.18

0.07% (C16:1), 3.81 0.04% (C18:0), 44.01 0.08% (C18:1), 10.73 0.08% (C18:2), 0.20 0.06%

(C18:3) and 0.34 0.04% (C20:0) for fatty acids composition of palm olein; and 0.20% (C12:0), 1.14

0.05% (C14:0), 49.42 0.25% (C16:0), 0.16 0.08% (C16:1), 4.15 0.10% (C18:0), 36.14 0.77%

(C18:1), 7.95 0.29% (C18:2), 0.110.07% (C18:3) and 0.300.08% (C20:0) for fatty acids composition

of palm stearin.

Key words: characterisation, palm-based reference materials, fatty acids composition, MPOB Test Methods p3.4:2004 and

p3.5:2004, consensus values, uncertainties

1 INTRODUCTION

Oils and fats consist mainly of fatty acid triesters and

glycerol or well-known as triglycerides. They are recognised as essential nutrients and source of energy in both

human and animal diets1). Oils and fats also enhanced the

functionality of food products, as they act as heating medium, tenderising agents, flavour and colour carriers, facilitate aeration and others.

Functionality of food products depends on physicochemical properties such as fatty acids composition (FAC),

which is often used to characterise oils and fats2). FAC is

defined as weight percentage of individual fatty acids in

their methyl ester forms after esterification of triglyceride

molecules. Boyaci and colleagues3) emphasised that the

physical properties of oils and fats are dependent on the

distribution of fatty acids on the glycerol backbones, chain

length and degree of unsaturation. FAC is said to be the

most useful chemical feature as many of the chemical tests

for oil identification can be related to that property4). Thus,

FAC is widely used in establishing authenticity of oils and

fats. FAC provides information on the total content of saturated and unsaturated fatty acids, which is often used as

health indicators. FAC can be also used as one of the indicator to determine the oxidative stability of oils and fats1).

In 1987, the Community Bureau of Reference (BCR),

Commission of the European Communities produced two

lipid reference materials of soya-maize oil blend (CRM No.

162) and beef-pig fat blend (CRM No. 163) and the certification of their FAC5). The certification programmes, which

involved 13 European laboratories, were required to determine principal (major) fatty acids of C16:0, C18:0, C18:1,

C18:2 and C18:3 in both CRM No. 162 and CRM No. 163 and

additional fatty acids of C14:0 and C16:1 in CRM No. 163.

Fatty acid levels of less than 1 % (mass fraction) were

defined as minor fatty acids.

Some research works that correlate FAC with other

Correspondence to: Azmil Haizam Ahmad Tarmizi, Analytical and Quality Development Unit, Malaysian Palm Oil Board, 6, Persiaran

Institusi, Bandar Baru Bangi, 43000 Kajang, Selangor, MALAYSIA

E-mail: azmil_haizam@mpob.gov.my

Accepted February 22, 2008 (received for review January 25, 2008)

Journal of Oleo Science ISSN 1345-8957 print / ISSN 1347-3352 online

http://www.jstage.jst.go.jp/browse/jos/

275

A.H. Ahmad Tarmizi, W.L. Siew and A. Kuntom

properties of oils and fats have been reported. Boyaci et

al. 3) investigated the relationship between slip melting

point (SMP) and FAC of forty-four vegetable oil blends

before and after interesterification. Boyaci and colleagues6)

developed an equation for simple and rapid viscosity estimation based on the FAC of seven vegetable oils. This

study represented a model for viscosity predictions of vegetable oils (primary form) and their binary mixtures

(blends) that have different FAC. Furthermore, Rabelo et

al.7) related viscosities of oleic acid, canola oil and model

fatty systems based on their FAC. Apart from that, the liquid specific heat capacity of fatty acids can be estimated

through correlation with FAC8). The researchers applied

the Rowlinson-Bondi equation to determine the specific

heat capacity for pure fatty acid components. Halvorsen, et

al.9) estimated the density of fatty acids and vegetable oils

based on their FAC. The model was developed through

modification of Rackett equation, which was applied over a

wide range of temperature.

The importance of FAC measurement of oils and fats has

initiated the Malaysian Palm Oil Board (MPOB) to develop

and characterise palm-based reference materials through

inter-laboratory proficiency tests. The unavailability of reference materials from palm oil products was also taken

into account to cater to the needs of oils and fats industry,

especially the palm oil sector. Reference materials provide

convenient means of calibrating and validating analytical

measurements and to assess the analysts capability in performing the measurements.

This paper presents the results of an inter-laboratory

proficiency test performed prior to the characterisation of

the reference materials from palm oil, palm olein and palm

stearin for FAC quantification. These reference materials

were evaluated based on nine fatty acids. Stability test of

the reference materials produced was also conducted and

reported in this paper.

2 EXPERIMENTAL

2.1 Preparation of the reference materials

Refined palm oil, palm olein and palm stearin were purchased from Golden Jomalina Food Industries Sdn. Bhd.

The oils were heated gently until completely liquid before

being dissolved with 0.02 % tert-butylhydroquinone (97 %

purity, Sigma-Aldrich, Steinheim, Germany) and stirred to

ensure homogeneity. Portions of 5 mL of the homogenised

oil were dispersed in 5-mL dark amber glass ampoules

(Scherf Praezision, Meiningen-Dreissigacker, Germany),

flushed with nitrogen and flame-sealed at the ampoule

sealing workbench. The utilisation of such glass ampoules

will help to prevent photo-oxidation and colour changes

during storage. The oil standards were labelled, packed in

fabricated boxes and stored at -20 until dispatch.

2.2 Inter-iaboratory proficiency tests

Twelve laboratories collaborated in the inter-laboratory

proficiency tests which include the Analytical and Quality

Development Unit, Malaysian Palm Oil Board, Selangor,

Malaysia; Advance Oleochemicals Technology Division,

Malaysian Palm Oil Board, Selangor, Malaysia; Golden

Hope Research Sdn. Bhd., Selangor, Malaysia; PGEO Edible Oils Sdn. Bhd., Johor, Malaysia; Edtech Associates Sdn.

Bhd., Penang, Malaysia; Southern Edible Oil Industry (M)

Sdn. Bhd., Selangor, Malaysia; Pan-Century Edible Oils

Sdn. Bhd., Johor, Malaysia; Biochem Laboratories Sdn.

Bhd., Penang, Malaysia; IOI Edible Oils Sdn. Bhd., Sabah,

Malaysia; Chemara Lab Sdn. Bhd., Negeri Sembilan,

Malaysia; Lotus Laboratory Services Sdn. Bhd., Johor,

Malaysia; ITS Testing Services Sdn. Bhd., Selangor,

Malaysia.

Each collaborator was provided with four ampoules of

each oil standard representing four replications. The measurement (FAC) should be carried out in accordance to

MPOB Test Methods p3.4:2004 and p.3.5:2004 10) . These

methods are based on the procedure of ISO 5508:1990 Animal and vegetable fats and oils - Analysis by gas chromatography (GC) of the methyl esters of fatty acids11).

The oil sample was firstly dissolved in n-hexane (Merck,

Darmstadt, Germany) prior to methylation using sodium

methoxide (Merck, Darmstadt, Germany). The mixture was

then diluted with distilled water and allowed to settle and

separate into two distinct layers. The upper clear supernatant, fatty acids methyl ester (FAME) layer was decanted

and injected into a GC, which was fitted with a fused silica

capillary column (DB-23, 60 m 0.25 m, i.d. 0.25 mm film) (J

and W Scientific, Folsom, USA). The flame ionisation

detector (FID) and injector temperatures were set at 240.

The carrier gas (helium) was positioned at 0.8 mL/min as

the column temperature was isothermal at 185. FAME

was quantified via the retention time and peak areas. The

FAC is represented as a percentage of each fatty acid in

terms of mass fractions. FAC is expressed as grams of

individual FAME per 100 grams of total FAME.

The FAC analysis had to be carried out within two

months upon receiving the oil standards. Reporting cards

were provided to the collaborators to compute their analysis results. In addition, each collaborator was supplemented with detailed instruction and study protocol of the proficiency tests.

2.3 Data evaluation

Data from the inter-laboratory tests were evaluated

using the SoftCRM 1.2.0 software, which was developed by

the European Commission of Standards, Measurements

and Testing Programmes12). The software is specifically

meant for statistical evaluation of the reference materials

data and documentation of the quality of the reference

276

J. Oleo Sci. 57, (5) 275-285 (2008)

Palm-Based Reference Materials for Fatty Acids Composition

materials produced. Consensus values (percentage of individual fatty acids) of each oil standard were generated with

95 % confidence interval (CI). Outlying data (extreme values) were detected by Grubb and Cochran tests. Grubb test

identifies outlying mean values (variability) among laboratories whereas Cochran test determines data variability

within laboratories5,13).

Repeatability relative standard deviation, RSDr (relative

standard deviation within laboratory) and reproducibility

relative standard deviation, RSDR (relative standard deviation between laboratories) were determined for each fatty

acid measured according to ISO 5725-213). RSDr is determined from data produced under repeatability conditions

of the same method on identical test items in the same laboratory by the same operator using the same instrumentation within short intervals of time whereas RSDR identified

from data generated under reproducibility conditions,

which the data are produced using the same method on

identical test items in different laboratories, operators and

instrumentations14).

2.4 Stability test

Stability test of the palm-based reference materials produced were carried out for 12 months at four storage temperatures of -20, 0, 4 and 24 (ambient temperature). Periodically, the oil samples were randomly selected

and analysed for their FAC as well as other general stabili-

Table 1

ty markers such as free fatty acid (FFA) and totox value

(TV).

FFA was analysed through titration according to the

AOCS Official Method Ca 5a-40 and expressed as a percentage of palmitic acids15). FFA is used to determine the

hydrolytic behaviour of oil standards upon storage.

Totox value is defined as TV = 2PV + AnV. Peroxide

value (PV) was determined based on iodometric titration

according to the AOCS Official Method Cd 8b-9015). Anisidine value (AnV) was measured according to the IUPAC

2.50416). PV and AnV measured the primary oxidation and

secondary decomposition products, respectively and were

determined throughout the storage period.

3 RESULTS AND DISCUSSION

3.1 Assessment of statistical data

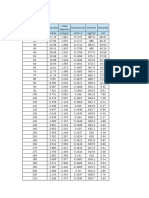

Statistical evaluations for palm oil, palm olein and palm

stearin are summarised in Table 1, Table 2 and Table 3,

respectively. The consensus values (percentage of individual fatty acids) were calculated at 95 % CI using the SoftCRM 1.2.0 software. Repeatability relative standard deviation (RSDr) of the quantified FAC in palm oil ranged from 0 %

to 9.24 % while reproducibility relative standard deviation

(RSDR) ranged from 0 % to 60.38 % (Table 1). Within-laboratory variation (RSDr) of less than 10 % for all fatty acids

Statistical Evaluation of FAC in Palm Oil.

FAa

Pb

Nc

Consensus Value

(Uncertainty)d

sre

RSDrf

rg

SRh

RSDRi

Rj

C12:0

C14:0

C16:0

C16:1

C18:0

C18:1

C18:2

C18:3

C20:0

7

11

9

10

11

8

9

10

12

28

44

36

40

44

32

36

40

48

0.20 ( )

1.66 (0.05)

43.39 (0.39)

0.14 (0.06)

3.90 (0.11)

40.95 (0.23)

9.68 (0.21)

0.16 (0.07)

0.31 (0.08)

0

0.04

0.19

0

0.08

0.12

0.09

0

0.03

0

3.64

0.43

0

2.09

0.30

0.89

0

9.24

0

0.11

0.52

0

0.23

0.35

0.24

0

0.08

0

0.07

0.53

0.08

0.18

0.29

0.29

0.10

0.13

0

7.17

1.23

60.23

4.58

0.71

2.97

60.38

42.33

0

0.21

1.49

0.24

0.50

0.82

0.81

0.27

0.37

Fatty acid (FA) measurement using capillary column GC

Number of laboratories retained after eliminating outliers

c

Number of accepted test results (replicates)

d

Consensus value and uncertainty (%) generated as 95% CI

e

Repeatability standard deviation

f

Repeatability relative standard deviation

g

Repeatability limit

h

Reproducibility standard deviation

i

Reproducibility relative standard deviation

j

Reproducibility limit

b

277

J. Oleo Sci. 57, (5) 275-285 (2008)

A.H. Ahmad Tarmizi, W.L. Siew and A. Kuntom

Table 2

Statistical Evaluation of FAC in Palm Olein.

FAa

Pb

Nc

Consensus Value

(Uncertainty)d

sre

RSDrf

rg

SRh

RSDRi

Rj

C12:0

C14:0

C16:0

C16:1

C18:0

C18:1

C18:2

C18:3

C20:0

12

10

9

12

10

10

8

12

9

48

40

36

48

40

40

32

48

36

0.23 (0.04)

1.02 (0.04)

39.66 (0.19)

0.18 (0.07)

3.81 (0.04)

44.01 (0.08)

10.73 (0.08)

0.20 (0.06)

0.34 (0.04)

0.03

0.03

0.22

0

0.11

0.16

0.08

0.03

0

14.48

3.37

0.55

0

2.86

0.37

0.73

12.63

0

0.09

0.10

0.61

0

0.31

0.46

0.22

0.07

0

0.06

0.06

0.31

0.11

0.11

0.53

0.12

0.11

0.05

28.82

5.86

0.79

60.80

2.86

1.21

1.08

53.21

15.27

0.18

0.17

0.87

0.31

0.31

1.49

0.32

0.29

0.15

Fatty acid (FA) measurement using capillary column GC

Number of laboratories retained after eliminating outliers

c

Number of accepted test results (replicates)

d

Consensus value and uncertainty (%) generated as 95% CI

e

Repeatability standard deviation

f

Repeatability relative standard deviation

g

Repeatability limit

h

Reproducibility standard deviation

i

Reproducibility relative standard deviation

j

Reproducibility limit

b

Table 3 Statistical Evaluation of FAC in Palm Stearin.

FAa

Pb

Nc

Consensus Value

(Uncertainty)d

sre

RSDrf

rg

SRh

RSDRi

Rj

C12:0

C14:0

C16:0

C16:1

C18:0

C18:1

C18:2

C18:3

C20:0

11

13

9

13

11

11

12

12

12

44

52

36

52

44

44

48

48

48

0.20 ( )

1.14 (0.05)

49.42 (0.25)

0.16 (0.08)

4.15 (0.10)

36.14 (0.77)

7.95 (0.29)

0.11 (0.07)

0.30 (0.08)

0

0.04

0.26

0.03

0.09

0.13

0.09

0

0.04

0

3.84

0.53

17.15

2.17

0.36

1.10

0

11.79

0

0.12

0.74

0.07

0.25

0.36

0.25

0

0.10

0

0.08

0.40

0.11

0.17

1.08

0.39

0.09

0.12

0

6.73

0.80

73.99

4.00

2.98

4.81

83.52

41.32

0

0.21

1.11

0.32

0.47

3.01

1.08

0.26

0.37

Fatty acid (FA) measurement using capillary column GC

Number of laboratories retained after eliminating outliers

c

Number of accepted test results (replicates)

d

Consensus value and uncertainty (%) generated as 95% CI

e

Repeatability standard deviation

f

Repeatability relative standard deviation

g

Repeatability limit

h

Reproducibility standard deviation

i

Reproducibility relative standard deviation

j

Reproducibility limit

b

278

J. Oleo Sci. 57, (5) 275-285 (2008)

Palm-Based Reference Materials for Fatty Acids Composition

signified that the FAC measurement was within the

acceptable variability. However, between-laboratory variation (RSDR) for C16:1, C18:3 and C20:0 were found to be

60.23 %, 60.38 % and 42.33 %, respectively. This is due to

the small percentage of these fatty acids, which generally

demonstrated large run-to-run variations between laboratories. Higher RSDR may be contributed by variations in

the instrument sensitivity, change of environmental conditions or uncontrolled change of instrument parameters17).

Such effects play a role, which may influence RSDR when

the samples are measured by different laboratories. Thus,

the measurement is still considered acceptable.

Table 2 highlights the statistical evaluation of FAC

quantification in palm olein. The RSDr was found to be in

the range from 0 % to 14.48 %, which is acceptable in

terms of variability of fatty acids measured. As expected,

the RSDR varied from 0.79 % to 60.80 %, where some of the

fatty acids (C12:0, C16:1 and C18:3) showed large run-torun variations due to their low contents of less than 0.5 %.

Results of the FAC quantification in palm stearin are tabulated in Table 3. The RSDr was found to be good, ranging

from 0 % to 17.15 %. The RSDR, however, varied from 0 %

to 83.52 %. This trend was similar to that in palm oil,

where C16:1, C18:3 and C20:0 contributed to the high RSDR

of 73.99 %, 83.52 % and 41.32 %, respectively.

In some cases, both RSDr and RSDR are calculated to be

0 %. This may be caused by two circumstances, where the

repeatability standard deviation (sr) of each individual laboratory retained after outliers elimination is observed to be

zero (0) or all the individual laboratory means are found to

be similar, thus resulting in the same overall laboratory

mean value. These conditions apply for C12:0 in both palm

oil (Table 1) and palm stearin (Table 3). In other cases, only

the RSDr is encountered to be 0 %. Although the sr of each

individual laboratory is zero, but the individual laboratory

means differ. This can be observed in C16:1 and C18:3 in

palm oil (Table 1), C16:1 and C20:0 in palm olein (Table 2)

and C18:3 in palm stearin (Table 3).

The FAC quantification of palm oil (Table 1), palm olein

(Table 2) and palm stearin (Table 3) may also be expressed

in the form of bar graph. Example of intra- and inter-laboratory variability of FAC measurement (C16:0 in palm oil) is

illustrated in Fig. 1. The bar graph consists of laboratory

codes with their individual means and standard deviations.

From that, the overall mean of all laboratory means with

its standard deviations were generated at 95 % CI after

outliers were eliminated through Cochran and Grubb tests.

These values were calculated according to ISO Guide 3518).

Pocklington and Wagstaffe5) reported that certification of

FAC in soya-maize oil blend (CRM No. 162) and beef-pig fat

blend (CRM No. 163) was only restricted to major fatty

acids since the determination of minor fatty acids (less

than 1 % of mass fraction) could not be undertaken to an

unacceptable degree of accuracy. They observed that the

Fig. 1 Example of Bar Graph for Quantifying C16:0 in Palm Oil.

The results plotted corresponded to four replications. Mean

of means indicate the average results of total individual

laboratory means.

279

J. Oleo Sci. 57, (5) 275-285 (2008)

A.H. Ahmad Tarmizi, W.L. Siew and A. Kuntom

measurement of minor fatty acids produced a wide range

of results and no attempt was made to attribute the uncertainties of those results. Therefore, the fatty acids measured were treated as indicative and expressed in terms of

arithmetic means.

3.2 Stability

Stability of the palm-based reference materials produced

was investigated with respect to their FAC and other general stability indicators such as FFA and TV. The test

results of four storage temperatures (-20, 0, 4 and

24) were compared with the reference materials that was

immediately ampoule-sealed and stored at -20 (t = 0).

Table 4, Table 5 and Table 6 summarise the one-year

storage stability of each individual fatty acid in palm oil,

palm olein and palm stearin. No detectable changes in the

relative proportions of fatty acids were perceived, even at

ambient temperature (24). Therefore, the stability (shelflife) of the reference materials produced for FAC measurement could be extended for more than a year.

Table 7 shows the average TV of the reference materials

over a 12-month storage period. Palm oil experienced

almost no increase of TV at -20, where TV was averaging

at 1.8 unit throughout the storage study. Similar pattern is

observed at 0, where TV was hovering at 1.7 unit to 2.2

unit. However, at 6 and 24, there were slight increases

of TV up to 2.5 unit and 3.1 unit, respectively.

Palm olein demonstrated a higher formation of TV at all

storage temperatures compared to palm oil (Table 7).

There was a slight increase of TV at -20 and 0 at 2.2

unit for both storage conditions. As expected, TV rose

from 1.7 unit to an average of 2.5 unit at 6 and 2.8 unit at

24. Similar trends were also observed in palm stearin. At

-20, 0 and 6, TV was doubled from its initial state,

whereby it increased up to 4-fold at 24 after one year

storage (Table 7).

The formation of TV during storage, especially at high

temperatures is expected. Peroxides are initially developed

and may break down into secondary products such as

hydrocarbons, aldehydes, ketones and small amount of

epoxides and alcohols1). In spite of the TV increase, the

maximum TV of all storage conditions were considered low

and acceptable within stability requirements of reference

materials. However, storage temperatures of -20 to 0

were preferable so as to ensure that the oxidation rate of

the reference materials could be minimised. Addition of

tert-butylhydroquinone, nitrogen flushing prior to sealing

and usage of dark amber glass ampoules will also help to

control the oxidation rate of the reference materials produced.

Triglyceride hydrolysis during storage would be accompanied by FFA development1). No FFA increase was detected at all temperatures in palm oil and palm olein after a 12month storage period (Table 8). Palm stearin demonstrated

a very small FFA increase at all storage temperatures.

This signified that the hydrolytic behaviour of the reference materials produced could be minimised and controlled.

4 CONCLUSION

Development of palm-based reference materials for fatty

acids composition has been achieved through inter-laboratory proficiency tests. Establishment of the consensus values (percentage of individual fatty acids) and their uncertainties at an acceptable level of 95 % confidence interval

have been attained using the SoftCRM 1.2.0 software.

ACKNOWLEDGEMENTS

The authors thank the Director-General of MPOB for

permission to publish this work; Director of Product Development and Advisory Services Division and Head of the

Analytical and Quality Development Unit for their suggestions and recommendations; collaborators of the inter-laboratory proficiency tests for their support and laboratory

technicians of the Analytical and Quality Development

Unit for their assistance.

References

1. Institute of Shortening and Edible Oils. Food fats and

oils. 9th edn., Washington D.C. (2006).

2. Ping, T.G. Analytical characteristics of crude and

refined palm oil and fractions. Eur. J. Lipid Sci. Technol. 109, 373-379 (2007).

3. Boyaci, I.K.; Karabulut, I.; Turan, S. Slip melting point

estimation of fat blends before and after interesterification based on their fatty acid compositions. J. Food

Lipids 10, 193-202 (2003).

4. Tan, Y.A. Quality monitoring (chemical and instrumental techniques). Proceeding of the 27 th Palm Oil

Familiarisation Programme (2007).

5. Pocklington, W.D.; Wagstaffe, P.J. The certification of

the fatty acid profile of two edible oil and fat materials.

BCR Information Reference Materials, Report EUR

11002 EN, Belgium (1987).

6. Boyaci, I.K.; Tekin, A.; Melih, .; Javidipour, I. Viscosity estimation of vegetable oils based on their fatty acid

composition. J. Food Lipids 9, 175-183 (2002).

7. Rabelo, J.; Batisha, E.; Cavaleri, F.V.W.; Meirelles,

A.J.A. Viscosity prediction for fatty systems. J. Am.

Oil Chem. Soc. 77, 1255-1262 (2000).

8. Morad, N.A.; Mustafa Kamal, A.A.; Panau, F.; Yew, T.W.

Liquid specific heat capacity estimation for fatty acids,

280

J. Oleo Sci. 57, (5) 275-285 (2008)

Palm-Based Reference Materials for Fatty Acids Composition

Changes of Individual Fatty Acids in Palm Oil.

Table 4

FAa

Tb ()

Storage Period (month)c

0

10

12

Mean

SDd

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.30

0.25

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.22

0.21

0

0

0.04

0.02

1.10

1.10

1.10

1.10

1.10

1.10

1.20

1.10

1.10

1.10

1.10

1.10

1.10

1.10

1.10

1.10

1.10

1.05

1.10

1.10

1.10

1.09

1.12

1.10

0

0.02

0.04

0

C12:0

-20

0

6

24

C14:0

-20

0

6

24

1.10

1.10

1.10

1.10

1.10

C16:0

-20

0

6

24

43.38

0.10

43.15

43.15

43.15

43.20

43.20

43.20

43.20

43.20

43.80

43.95

44.10

43.95

42.75

43.15

43.10

42.80

43.55

43.70

43.60

43.70

43.50

43.65

43.60

43.40

43.33

43.47

43.46

43.38

0.37

0.34

0.39

0.41

C16:1

-20

0

6

24

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.15

0.10

0.10

0.20

0.20

0.15

0.15

0.15

0.20

0.20

0.20

0.20

0.15

0.10

0.10

0.20

0.18

0.16

0.17

0.19

0.03

0.05

0.04

0.02

C18:0

-20

0

6

24

4.00

4.00

3.95

4.00

4.00

4.00

4.00

4.00

4.00

4.00

3.95

3.95

3.90

3.80

3.85

3.75

3.80

4.05

4.00

4.00

4.05

3.35

3.45

3.70

4.00

3.87

3.85

3.90

3.96

0.27

0.22

0.14

0.09

C18:1

-20

0

6

24

40.65

0.06

40.60

40.50

40.60

40.65

40.75

40.80

40.80

40.80

40.40

40.40

40.85

40.40

41.25

41.10

41.30

41.30

40.30

40.30

40.30

40.30

41.40

41.40

41.15

40.85

40.78

40.75

40.83

40.72

0.45

0.43

0.36

0.35

C18:2

-20

0

6

24

9.78

0.05

9.90

9.90

9.85

9.85

9.90

9.90

9.90

9.90

9.80

9.70

9.65

9.70

10.10

10.00

10.05

10.05

9.90

9.90

9.90

9.85

9.75

9.65

9.65

9.80

9.89

9.84

9.83

9.86

0.12

0.14

0.16

0.12

C18:3

-20

0

6

24

0.20

0.20

0.20

0.20

0.25

0.10

0.10

0.10

0.10

0.20

0.15

0.15

0.15

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.15

0.15

0.15

0.18

0.17

0.17

0.18

0.04

0.04

0.04

0.05

C20:0

-20

0

6

24

0.38

0.05

0.35

0.35

0.35

0.35

0.30

0.30

0.30

0.30

0.30

0.30

0.15

0.15

0.40

0.25

0.10

0.35

0.40

0.40

0.40

0.40

0.30

0.30

0.25

0.30

0.34

0.32

0.26

0.31

0.05

0.05

0.12

0.09

Fatty acid

Storage temperature

c

Mean of duplicate

d

Standard deviation

b

281

J. Oleo Sci. 57, (5) 275-285 (2008)

A.H. Ahmad Tarmizi, W.L. Siew and A. Kuntom

Table 5

FAa

Tb ()

Changes of Individual Fatty Acids in Palm Olein.

Storage Period (month)c

SDd

10

12

Mean

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0

0

0

0

1.10

1.10

1.10

1.05

1.00

1.10

1.00

1.05

1.00

1.00

1.00

1.00

1.10

1.10

1.10

1.10

1.10

1.05

1.10

1.10

1.07

1.08

1.07

1.08

0.05

0.04

0.05

0.03

C12:0

-20

0

6

24

C14:0

-20

0

6

24

1.00

1.00

1.10

1.10

1.10

C16:0

-20

0

6

24

39.88

0.10

40.30

40.00

39.90

39.80

40.05

40.00

39.90

39.95

40.25

40.35

40.25

40.30

39.90

39.45

39.40

39.35

40.00

40.20

40.20

40.10

41.05

40.70

40.45

40.55

40.26

40.12

40.02

40.01

0.42

0.42

0.37

0.42

C16:1

-20

0

6

24

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.25

0.20

0.15

0.20

0.20

0.20

0.19

0.20

0.21

0.20

0.02

0

0.02

0

C18:0

-20

0

6

24

3.90

3.70

3.80

3.80

3.75

3.70

3.70

3.70

3.80

3.80

3.80

3.80

3.80

3.55

3.55

3.70

3.55

3.90

3.90

3.80

3.85

3.60

3.50

3.70

3.70

3.71

3.71

3.75

3.74

0.13

0.16

0.05

0.11

C18:1

-20

0

6

24

43.38

0.05

42.90

43.20

42.70

42.55

43.20

43.30

43.40

43.20

43.05

42.95

43.05

43.00

43.20

43.80

43.60

44.05

43.45

43.30

43.25

43.30

43.10

43.45

43.35

43.30

43.15

43.33

43.23

43.23

0.18

0.28

0.31

0.49

C18:2

-20

0

6

24

10.68

0.05

11.00

11.00

11.05

10.90

10.90

10.90

10.90

10.80

10.70

10.80

10.70

10.75

11.15

11.05

11.10

11.00

10.55

10.50

10.60

10.55

10.35

10.40

10.55

10.45

10.78

10.78

10.82

10.74

0.30

0.27

0.23

0.21

C18:3

-20

0

6

24

0.20

0.30

0.30

0.35

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.25

0.25

0.30

0.25

0.20

0.20

0.20

0.20

0.15

0.20

0.20

0.20

0.22

0.23

0.24

0.21

0.05

0.04

0.07

0.02

C20:0

-20

0

6

24

0.40

0.30

0.30

0.40

0.30

0.30

0.30

0.30

0.30

0.40

0.30

0.35

0.35

0.35

0.35

0.50

0.30

0.40

0.40

0.40

0.40

0.30

0.30

0.30

0.30

0.34

0.33

0.38

0.33

0.05

0.04

0.08

0.04

Fatty acid

Storage temperature

c

Mean of duplicate

d

Standard deviation

b

282

J. Oleo Sci. 57, (5) 275-285 (2008)

Palm-Based Reference Materials for Fatty Acids Composition

Table 6

FAa

Tb ()

Changes of Individual Fatty Acids in Palm Stearin.

Storage Period (month)c

SDd

10

12

Mean

C12:0

-20

0

6

24

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0

0

0

0

C14:0

-20

0

6

24

1.15

0.06

1.20

1.20

1.20

1.20

1.20

1.20

1.20

1.20

1.25

1.20

1.10

1.20

1.20

1.20

1.20

1.20

1.20

1.20

1.20

1.20

1.15

1.15

1.15

1.15

1.20

1.19

1.18

1.19

0.03

0.02

0.04

0.02

C16:0

-20

0

6

24

49.50

0.20

49.40

49.50

49.35

49.45

49.40

49.40

49.40

49.40

50.60

50.55

50.55

50.25

49.15

49.00

49.00

49.00

49.80

49.60

49.65

49.60

50.05

50.20

50.05

51.10

49.73

49.71

49.67

49.63

0.53

0.57

0.56

0.47

-20

0

6

24

0.18

0.05

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.20

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.15

0.10

0.10

0.10

0.10

0.15

0.15

0.13

0.14

0.05

0.05

0.05

0.05

C18:0

-20

0

6

24

4.23

0.10

4.20

4.20

4.15

4.20

4.20

4.20

4.20

4.20

3.95

4.10

4.10

4.15

4.10

4.10

4.10

4.10

4.20

4.20

4.20

4.20

3.80

3.80

3.85

3.90

4.08

4.10

4.10

4.13

0.17

0.15

0.13

0.12

C18:1

-20

0

6

24

35.95

0.17

35.75

35.75

35.80

35.70

36.00

36.00

36.00

36.00

35.55

35.30

35.55

35.35

36.50

36.50

36.50

36.50

35.75

36.10

36.20

36.10

36.30

36.25

36.25

36.15

35.98

35.98

36.05

35.97

0.36

0.42

0.34

0.40

C18:2

-20

0

6

24

8.28

0.10

8.25

8.30

8.30

8.25

8.30

8.30

8.30

8.30

8.05

7.90

7.90

8.00

8.35

8.40

8.40

8.40

8.20

8.10

7.95

8.05

7.95

7.95

7.90

7.90

8.18

8.16

8.13

8.15

0.15

0.21

0.23

0.19

C18:3

-20

0

6

24

0.10

0.20

0.20

0.15

0.20

0.10

0.10

0.10

0.10

0.05

0.10

0.15

0.25

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.15

0.20

0.11

0.12

0.13

0.16

0.05

0.04

0.03

0.07

C20:0

-20

0

6

24

0.40

0.25

0.20

0.25

0.35

0.30

0.30

0.30

0.30

0.05

0.20

0.20

0.20

0.30

0.35

0.40

0.40

0.30

0.30

0.30

0.30

0.25

0.20

0.35

0.30

0.24

0.28

0.31

0.34

0.10

0.06

0.06

0.10

C16:1

Fatty acid

Storage temperature

c

Mean of duplicate

d

Standard deviation

b

283

J. Oleo Sci. 57, (5) 275-285 (2008)

A.H. Ahmad Tarmizi, W.L. Siew and A. Kuntom

Table 7 Changes of TV in Palm-Based Reference Materials.

Reference

Materials

a

b

Ta ()

Palm Oil

-20

0

6

24

Palm Olein

-20

0

6

24

Palm Stearin

-20

0

6

24

Storage Period (month)b

0

10

12

1.5

1.7

1.9

2.2

2.4

2.2

1.9

2.4

2.8

2.1

2.2

2.4

3.0

1.7

1.7

2.0

3.1

1.8

1.7

1.7

2.8

1.6

2.0

2.5

2.6

1.7

2.5

2.5

2.7

2.9

2.4

2.4

2.6

3.2

2.7

2.4

2.8

3.2

2.0

2.0

2.2

3.6

1.9

2.1

2.8

2.8

1.8

2.4

2.2

3.1

1.0

1.7

1.6

2.3

2.4

2.3

1.5

2.5

2.9

2.2

2.0

2.3

3.1

1.9

2.0

2.2

3.8

2.0

1.6

2.3

3.3

1.7

1.9

1.7

3.7

Storage temperature

Mean of triplicate

Table 8 Changes of FFA in Palm-Based Reference Materials.

Reference

Materials

a

b

Ta ()

Palm Oil

-20

0

6

24

Palm Olein

-20

0

6

24

Palm Stearin

-20

0

6

24

Storage Period (month)b

0

10

12

0.04

0.04

0.04

0.03

0.04

0.04

0.04

0.03

0.04

0.03

0.04

0.03

0.04

0.03

0.03

0.02

0.03

0.03

0.03

0.02

0.03

0.05

0.04

0.04

0.03

0.07

0.06

0.06

0.07

0.07

0.06

0.06

0.07

0.08

0.06

0.06

0.06

0.07

0.06

0.06

0.07

0.08

0.06

0.06

0.07

0.08

0.06

0.08

0.08

0.10

0.02

0.04

0.03

0.04

0.03

0.03

0.03

0.03

0.03

0.03

0.03

0.03

0.03

0.05

0.03

0.03

0.03

0.03

0.03

0.04

0.04

0.04

0.04

0.05

0.03

Storage temperature

Mean of triplicate

triacylglycerols and vegetable oils based on their fatty

acid composition. J. Am. Oil Chem. Soc. 77, 1001-1005

(2000).

9. Halvorsen, J.D.; Mammel Jr, W.C.; Clements, L.D. Density estimation for fatty acids and vegetable oils based

on their fatty acid composition. J. Am. Oil Chem. Soc.

70, 875-880 (1993).

10. Ainie, K.; Siew, W.L.; Tan, Y.A.; Nor Aini, I.; Mohtar, Y.;

Tang, T.S.; Nuzul Amri, I. MPOB test methodsA compendium of test on palm oil products, palm kernel

products, fatty acids, food related products and others. Malaysian Palm Oil Board (2004).

11. ISO 5508:1990. Animal and vegetable fats and oils

Analysis by gas chromatography (GC) of the methyl

284

J. Oleo Sci. 57, (5) 275-285 (2008)

Palm-Based Reference Materials for Fatty Acids Composition

12.

13.

14.

15.

esters of fatty acids. International Organization for

Standardization (1990).

Bonas G. SoftCRM version 1.2.0. Funded by Standards, Measurements and Testing Programmes (1997).

ISO 5725-2. Accuracy (trueness and precision) of measurement methods and results -Part 1 :Basic method

for the determination of repeatability and reproducibility of a standard measurement method. 1st

edn., International Organization for Standardization

(1994).

ISO 3534-1. Statistics, vocabulary and symbols-Part

1:Probability and general statistical terms. 1st edn.,

International Organization for Standardization (1993).

Firestone, D. Official methods and recommended

practices of the AOCS. 5th edn., Am. Oil Chem. Soc.,

Champaign (1998).

16. Dieffenbacher, A.; Pocillinton, W.D. Standard methods

for the analysis of oils, fats and derivatives. 7th edn.,

International Union and Pure Applied Chemistry,

Oxford (2002).

17. Azmil Haizam, A.T.; Elina, H.; Siew, W.L.; Ainie, K. and

Ooi, C.K. Commercialisation of standard reference

materials from palm oil products. MPOB 117th VIVA

Committee Meeting, VIVA Report No. 391/2007 (07),

Malaysian Palm Oil Board (2007).

18. ISO Guide 35. Certification of reference materials

General and statistical principle. 2nd edn., International Organization for Standardization, Switzerland

(1989).

285

J. Oleo Sci. 57, (5) 275-285 (2008)

S-ar putea să vă placă și

- Foundation Code 2004Document64 paginiFoundation Code 2004Patie Zheng100% (2)

- Foundation Code 2004Document64 paginiFoundation Code 2004Patie Zheng100% (2)

- Motor Load and Efficiency PDFDocument16 paginiMotor Load and Efficiency PDFwfjerrÎncă nu există evaluări

- Waste Oil Distillation MachineDocument12 paginiWaste Oil Distillation Machinenazif100% (1)

- Carboxylic AcidDocument21 paginiCarboxylic AcidShalsabila NHÎncă nu există evaluări

- Strobe Rocket Spindle For Other Rocket TypesDocument1 paginăStrobe Rocket Spindle For Other Rocket TypeseskawitzÎncă nu există evaluări

- Cbse Sample Papers For Class 11 Chemistry Download PDFDocument4 paginiCbse Sample Papers For Class 11 Chemistry Download PDFPIPARIYAÎncă nu există evaluări

- Ethanol Production From GrainDocument21 paginiEthanol Production From Grainrenger20150303Încă nu există evaluări

- Accounting Finance For EngineersDocument16 paginiAccounting Finance For EngineersSubashiиy PяabakaяaиÎncă nu există evaluări

- Accounting Finance For EngineersDocument16 paginiAccounting Finance For EngineersSubashiиy PяabakaяaиÎncă nu există evaluări

- 3 - Shortenings - Science and TechnologyDocument41 pagini3 - Shortenings - Science and TechnologyJulesÎncă nu există evaluări

- PRODUCTIONOF60000MTPAOFOLEOCHEMICALMETHYLESTERFROMRBDPALMKERNELOILDocument586 paginiPRODUCTIONOF60000MTPAOFOLEOCHEMICALMETHYLESTERFROMRBDPALMKERNELOILKevin Fernando PratamaÎncă nu există evaluări

- 5.pondasi FFB Conveyor & SterilzerDocument6 pagini5.pondasi FFB Conveyor & SterilzerSuhandra HendraÎncă nu există evaluări

- 4 - Technical Specifications For Piling Works - Pile Foundation For Tanks - ParadeepDocument48 pagini4 - Technical Specifications For Piling Works - Pile Foundation For Tanks - Paradeepvignesh_freeboterÎncă nu există evaluări

- Environmental Fact Sheet (# 33) Crude Palm Kernel Oil (CPKO)Document6 paginiEnvironmental Fact Sheet (# 33) Crude Palm Kernel Oil (CPKO)eefgtgÎncă nu există evaluări

- Blending of Thermal Coals: Section ContentsDocument17 paginiBlending of Thermal Coals: Section ContentsWulan Dwikusuma AsihÎncă nu există evaluări

- Bio Energy Presentation of Bio FuelDocument31 paginiBio Energy Presentation of Bio FuelDeep GreyÎncă nu există evaluări

- Experiment 1 Qualitative Analysis of CarbohydratesDocument14 paginiExperiment 1 Qualitative Analysis of CarbohydratesEko Nevrian90% (10)

- Palm Oil & Saturated Steam PropertiesDocument4 paginiPalm Oil & Saturated Steam PropertiesStefanusÎncă nu există evaluări

- Crude Palm OilDocument19 paginiCrude Palm OilmarpadanÎncă nu există evaluări

- LOTTE E&C - IntroduceDocument14 paginiLOTTE E&C - Introducemyusuf123Încă nu există evaluări

- Cornstarch ProjectDocument44 paginiCornstarch ProjectpadhaiÎncă nu există evaluări

- Chloride in Palm OilDocument4 paginiChloride in Palm OilFebrian IsharyadiÎncă nu există evaluări

- Dry FractionationDocument12 paginiDry FractionationRinovetz AlexandruÎncă nu există evaluări

- Reaction List v002Document5 paginiReaction List v002cecil3414Încă nu există evaluări

- Activation of Spent Bleaching Earth For Dehumidification ApplicationDocument8 paginiActivation of Spent Bleaching Earth For Dehumidification ApplicationWorld-Academic JournalÎncă nu există evaluări

- Lecture 3 PDFDocument53 paginiLecture 3 PDFCurtis Hotate100% (1)

- Bio Oil Empty Fruit BunchesDocument8 paginiBio Oil Empty Fruit Bunchesegananta100% (1)

- Thermal Conductivity of WaterDocument6 paginiThermal Conductivity of Waterhiddenkey1Încă nu există evaluări

- PolymerViscosity Lab ReportDocument14 paginiPolymerViscosity Lab ReportBrandeice Barrett100% (1)

- Contractual Methods of Analysis 2017Document11 paginiContractual Methods of Analysis 2017jaimeÎncă nu există evaluări

- IndustrialAndPreparativeResin CatalogueDocument26 paginiIndustrialAndPreparativeResin CatalogueI. Murali KrishnaÎncă nu există evaluări

- Substances Vs MixturesDocument2 paginiSubstances Vs MixturesEdelvina Lorenzo AlejoÎncă nu există evaluări

- Biodiesel Production Techniques PDFDocument4 paginiBiodiesel Production Techniques PDFatomixmanÎncă nu există evaluări

- Physico Chemical Properties of Palm StearinDocument77 paginiPhysico Chemical Properties of Palm StearinSeren VegaÎncă nu există evaluări

- FOSFA Technical Manual - Oils and FatsDocument15 paginiFOSFA Technical Manual - Oils and Fatssr51585559Încă nu există evaluări

- SNI Palm Kernel OilDocument8 paginiSNI Palm Kernel OilYouke Septiany SapanganÎncă nu există evaluări

- Biocatalysis and Agricultural Biotechnology: Garima Pande, Casimir C. Akoh, Robert L. ShewfeltDocument9 paginiBiocatalysis and Agricultural Biotechnology: Garima Pande, Casimir C. Akoh, Robert L. ShewfeltersierrasÎncă nu există evaluări

- Ruchi Soya IndustriesDocument8 paginiRuchi Soya IndustriesAkhilesh KumarÎncă nu există evaluări

- Product Spect - VPODocument2 paginiProduct Spect - VPOKomathi BalasupramaniamÎncă nu există evaluări

- Technical Manual 2021 AmendmentsDocument16 paginiTechnical Manual 2021 Amendmentslaboratorium operasionalÎncă nu există evaluări

- LP1 - Razmah Ghazali PDFDocument56 paginiLP1 - Razmah Ghazali PDFJessicalba LouÎncă nu există evaluări

- DR Seema ParohaDocument21 paginiDR Seema ParohaTEERATH RAJÎncă nu există evaluări

- Iodine Value Determination Porim Test MethodDocument2 paginiIodine Value Determination Porim Test MethodAdawiyah Ali100% (1)

- Table of Thermal Conductivity Values of Propylene Glycol and Water MixesDocument2 paginiTable of Thermal Conductivity Values of Propylene Glycol and Water MixesTung Trinh0% (1)

- Project Report On Citric Acid and Lemon Oil From LemonDocument7 paginiProject Report On Citric Acid and Lemon Oil From LemonEIRI Board of Consultants and PublishersÎncă nu există evaluări

- Exp 2-Dry FractionationDocument14 paginiExp 2-Dry FractionationFfmohamad NAdÎncă nu există evaluări

- Fuel Oil TreatmentDocument8 paginiFuel Oil TreatmentRague MiueiÎncă nu există evaluări

- AlfaLaval Corn Gluten Dewatering BrochureDocument2 paginiAlfaLaval Corn Gluten Dewatering BrochureI. Murali KrishnaÎncă nu există evaluări

- Ecoboard Spentwash PDFDocument23 paginiEcoboard Spentwash PDFMailhem Dr. Suhas GoreÎncă nu există evaluări

- Philippine Coconut Authority: Republic of The Philippines Department of AgricultureDocument12 paginiPhilippine Coconut Authority: Republic of The Philippines Department of Agricultureanthony santosoÎncă nu există evaluări

- Material BalanceDocument27 paginiMaterial BalanceJohn Bryan AldovinoÎncă nu există evaluări

- New Developments in Palm Oil FractionationDocument7 paginiNew Developments in Palm Oil FractionationALEJANDRO HERNANDEZÎncă nu există evaluări

- Technicalreport Alcoholtechnology PDFDocument0 paginiTechnicalreport Alcoholtechnology PDFAmol DeshmukhÎncă nu există evaluări

- Thermodynamics Palm Oil MillDocument9 paginiThermodynamics Palm Oil MillWilliam MansoÎncă nu există evaluări

- Afroz 2003Document7 paginiAfroz 2003Fatin AqilahÎncă nu există evaluări

- 31295019466605Document329 pagini31295019466605ctomeyÎncă nu există evaluări

- Lecture 1Document22 paginiLecture 1Curtis HotateÎncă nu există evaluări

- Palm Oil FractionationDocument2 paginiPalm Oil FractionationChiew Let Chong0% (1)

- A Direct Method For Fatty Acid Methyl Ester (FAME) SynthesisDocument40 paginiA Direct Method For Fatty Acid Methyl Ester (FAME) Synthesisanuradha.d.bhat9860Încă nu există evaluări

- Supply ChainDocument19 paginiSupply Chainmarkkishan100% (2)

- Deterioration of Bleachability of Palm Oil MillDocument5 paginiDeterioration of Bleachability of Palm Oil MillEffy SaifulÎncă nu există evaluări

- Poeb130 YosriDocument9 paginiPoeb130 YosriNa'imusyahmi Ghazali100% (1)

- Brief Refinery Write Up GRDocument11 paginiBrief Refinery Write Up GRShiv KumarÎncă nu există evaluări

- Proposal Defence - Farah Wahida Corrected Ss 2Document19 paginiProposal Defence - Farah Wahida Corrected Ss 2Farah Wahida JusohÎncă nu există evaluări

- Caustic Recovery With Hot WaterDocument1 paginăCaustic Recovery With Hot WaterNadeem NaseemÎncă nu există evaluări

- D1429-03-Test Methods For Specific Gravity of Water and BrineDocument7 paginiD1429-03-Test Methods For Specific Gravity of Water and BrinefabianÎncă nu există evaluări

- Liquid Urea-Formaldehyde Resin Manufacturing Industry-217599 - 4Document65 paginiLiquid Urea-Formaldehyde Resin Manufacturing Industry-217599 - 4Sanzar Rahman 1621555030Încă nu există evaluări

- Paradeep DFRDocument22 paginiParadeep DFRioeuserÎncă nu există evaluări

- FFB Crop ForecastDocument6 paginiFFB Crop ForecastAmeen ZennÎncă nu există evaluări

- Fatty Acid CompositionDocument5 paginiFatty Acid CompositionAnonymous MhTaJsÎncă nu există evaluări

- TAP Uleiuri False1Document12 paginiTAP Uleiuri False1Benn BennetÎncă nu există evaluări

- Standard For Essential Composition of VCO PDFDocument11 paginiStandard For Essential Composition of VCO PDFUbais AliÎncă nu există evaluări

- 117 Excerpts 2004Document7 pagini117 Excerpts 2004Anonymous DJrec2Încă nu există evaluări

- The Business Model CanvasDocument1 paginăThe Business Model CanvasAnonymous DJrec2Încă nu există evaluări

- Factor of Safety On The Geotechnical Information WebsiteDocument2 paginiFactor of Safety On The Geotechnical Information WebsiteAnonymous DJrec2Încă nu există evaluări

- External Friction Angle On The Geotechnical Information WebsiteDocument2 paginiExternal Friction Angle On The Geotechnical Information WebsiteAnonymous DJrec2100% (1)

- Bearing Capacity Factors On The Geotechnical Information WebsiteDocument2 paginiBearing Capacity Factors On The Geotechnical Information WebsiteAnonymous DJrec2Încă nu există evaluări

- Cohesion On The Geotechnical Information WebsiteDocument2 paginiCohesion On The Geotechnical Information WebsiteAnonymous DJrec2Încă nu există evaluări

- 0217 PresentationDocument73 pagini0217 PresentationHector RodriguezÎncă nu există evaluări

- CFD Simulation On CFBC BoilerDocument6 paginiCFD Simulation On CFBC BoilerAnonymous DJrec2Încă nu există evaluări

- Circulating Fluidized Bed Boiler Development Situation and ProspectsDocument4 paginiCirculating Fluidized Bed Boiler Development Situation and ProspectsAnonymous DJrec2Încă nu există evaluări

- Evolution of Management ThoughtDocument17 paginiEvolution of Management ThoughtAnonymous DJrec2Încă nu există evaluări

- BEM Code of Ethics - Ir. Yim Hon WaDocument53 paginiBEM Code of Ethics - Ir. Yim Hon WaAnonymous DJrec2Încă nu există evaluări

- BEM Code of EthicsDocument11 paginiBEM Code of EthicsAbdul Hakim AbdullahÎncă nu există evaluări

- Managing A Safe Work PlaceDocument3 paginiManaging A Safe Work PlaceAnonymous DJrec2Încă nu există evaluări

- Understanding MarketingDocument5 paginiUnderstanding MarketingAnonymous DJrec2Încă nu există evaluări

- Engineers in Construction Industry - Ir. Choo Kok BengDocument22 paginiEngineers in Construction Industry - Ir. Choo Kok BengAnonymous DJrec2Încă nu există evaluări

- Power Amps Efficiency PFDocument5 paginiPower Amps Efficiency PFAnonymous DJrec2Încă nu există evaluări

- Industrial LowbayDocument8 paginiIndustrial LowbayAnonymous DJrec2Încă nu există evaluări

- Dry-Type Transformers: Codes and Standards Enhancement (CASE) StudyDocument22 paginiDry-Type Transformers: Codes and Standards Enhancement (CASE) StudyAnonymous DJrec2Încă nu există evaluări

- HarmonicsDocument7 paginiHarmonicsAnonymous DJrec2Încă nu există evaluări

- Third Quarter 2016 Investment Outlook: Asset Class SectorDocument6 paginiThird Quarter 2016 Investment Outlook: Asset Class SectorAnonymous DJrec2Încă nu există evaluări

- Sportage SL Pen-010112 PDFDocument1 paginăSportage SL Pen-010112 PDFAnonymous DJrec2Încă nu există evaluări

- Basics of Power CableDocument7 paginiBasics of Power CableAnonymous DJrec2Încă nu există evaluări

- CiMB Research Report On REITDocument6 paginiCiMB Research Report On REITAnonymous DJrec2Încă nu există evaluări

- Adoc - Pub - Pengaruh Penambahan Bahan Kimia Pada Tanah LempungDocument12 paginiAdoc - Pub - Pengaruh Penambahan Bahan Kimia Pada Tanah LempungDewi rahmawatiÎncă nu există evaluări

- Column Manual: Metrosep A Supp 4 (6.1006.XX0 / 6.01021.XX0)Document50 paginiColumn Manual: Metrosep A Supp 4 (6.1006.XX0 / 6.01021.XX0)LollipopÎncă nu există evaluări

- Tutorial 7-Chemical Equilibrium and Ionic Equilibria Part IDocument2 paginiTutorial 7-Chemical Equilibrium and Ionic Equilibria Part IRazy NicholaiÎncă nu există evaluări

- Cambridge IGCSE™: Chemistry 0620/43Document11 paginiCambridge IGCSE™: Chemistry 0620/43krishaÎncă nu există evaluări

- Inorganica Chimica ActaDocument10 paginiInorganica Chimica ActaNikhil BhoumikÎncă nu există evaluări

- Zytel LC7602 BK010Document11 paginiZytel LC7602 BK010Spu XisterÎncă nu există evaluări

- Reversible Reactions: When You Heat Copper (II) Sulfate CrystalsDocument2 paginiReversible Reactions: When You Heat Copper (II) Sulfate CrystalsShahid Ur RehmanÎncă nu există evaluări

- Program Studi Kimia F.MIPA, Universitas UdayanaDocument6 paginiProgram Studi Kimia F.MIPA, Universitas UdayanaRyu- MikaÎncă nu există evaluări

- CHMBD 449 - Organic Spectral: AnalysisDocument43 paginiCHMBD 449 - Organic Spectral: AnalysisIleana ManciuleaÎncă nu există evaluări

- l4 Separation and Identification of Group 2a CationsDocument3 paginil4 Separation and Identification of Group 2a Cationsthegr8 GÎncă nu există evaluări

- Report Expt. 1 Chemical ReactionsDocument7 paginiReport Expt. 1 Chemical ReactionsNgô BắpÎncă nu există evaluări

- June 2018 Question Paper 31 PDFDocument16 paginiJune 2018 Question Paper 31 PDFKazi Ahnaf SaadÎncă nu există evaluări

- 20 PDFDocument82 pagini20 PDFWalid EbaiedÎncă nu există evaluări

- Lecture Planner - Chemistry - MANZIL For JEE 2024Document1 paginăLecture Planner - Chemistry - MANZIL For JEE 2024Rishi NairÎncă nu există evaluări

- Formulating For Extruding AbateDocument11 paginiFormulating For Extruding Abatehossny100% (1)

- Mrs. Melendez-Beltran Pre-AICE ChemDocument98 paginiMrs. Melendez-Beltran Pre-AICE ChemTravel UnlimitedÎncă nu există evaluări

- Experiment 7 (EDTA) - Lab ManualDocument3 paginiExperiment 7 (EDTA) - Lab ManualJoseph JoeÎncă nu există evaluări

- bufferDocument51 paginibufferdiah ayu romadhaniÎncă nu există evaluări

- FBISE Chapter 6Document12 paginiFBISE Chapter 6Ch NajamÎncă nu există evaluări

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 paginăUltratech Cement: Particulars Test Results Requirements ofRajeshÎncă nu există evaluări

- Chemistry Practicals CompleteDocument22 paginiChemistry Practicals Completemoviemaza071Încă nu există evaluări

- Allopurinol PDFDocument3 paginiAllopurinol PDFGladdis Kamilah PratiwiÎncă nu există evaluări

- Safari PDFDocument18 paginiSafari PDFHussain KhanÎncă nu există evaluări