Documente Academic

Documente Profesional

Documente Cultură

1 s2.0 S2211812814005574 Main

Încărcat de

thasarathanr1993_939Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

1 s2.0 S2211812814005574 Main

Încărcat de

thasarathanr1993_939Drepturi de autor:

Formate disponibile

Available online at www.sciencedirect.

com

ScienceDirect

Procedia Materials Science 6 (2014) 1187 1196

3rd International Conference on Materials Processing and Characterisation (ICMPC 2014)

Application of Value Stream Mapping for Reduction of Cycle Time in a

Machining Process

K. Venkataramana*, B.Vijaya Ramnathb , V.Muthu Kumarc , C.Elanchezhiand

a

Research Scholar, Vels University, Chennai, 600 117 , India

Professor, Department of Mechanical Engineering, Sri Sai Ram Engineering College, Chennai, 600044, India

c

Professor, Department of Mechanical Engineering, Saveetha Engineering College, Chennai, 600024, India

d

Professor, Department of Mechanical Engineering, Sri Sai Ram Engineering College, Chennai, 600044, India

Abstract

Lean manufacturing initiative is being followed by various organizations in the recent years which mainly focuses on improving the efficiency

of operations by eliminating and reducing wastes. This paper aimed to explain the implementation of lean manufacturing techniques in the

crankshaft manufacturing system at an automotive manufacturing plant located in south India.. A multi criteria decision making model,

analytical hierarchy process is applied to analyze the decision making process in the manufacturing system. The objective of the case industry

was to increase the export sales. Lean manufacturing system was selected to meet the companys quality, cost and delivery targets. Crankshaft

was manufactured in a single piece flow system with the low cost machines developed indigenously and the results are that the crankshafts

have passed the testing, validation and approval by the customer to produce any variant in the company. After implementing lean

manufacturing system, the manufacturing lead time reduced by forty percent, defects were reduced, higher process capability achieved, quick

response to the customer demand in small lots were achieved.

2014

2014 Elsevier

The Authors.

Published

by Elsevier

Ltd. This

is an open

access Ltd.

article under the CC BY-NC-ND license

Selection and peer-review under responsibility of the Gokaraju Rangaraju Institute of Engineering and Technology (GRIET).

(http://creativecommons.org/licenses/by-nc-nd/3.0/).

Selection and peer review under responsibility of the Gokaraju Rangaraju Institute of Engineering and Technology (GRIET)

Keywords: lean; value stream; Analytical Hierarchy Process; kaizen; production cost

1. Introduction

This Paper is a case study explaining about the successful implementation of lean manufacturing tools and techniques in the

development and implementation of crankshaft manufacturing system at the case industry plant.

Crankshaft manufacturing is a critical process and it involves 13 operations starting from facing and centering, where the

datum is created to finish grinding of journal diameter and pin diameter, washing and oiling. The vision of the company was to

increase the export sales by 30 %. The project findings are that the entire crankshaft manufacturing system was established using

lean manufacturing tools.

In 1990 a book appeared by the title, The Machine that Changed the World, often referred to as the "MIT study", describes

the principles of LP and opens new areas for leanness. Womack J.P et al. (1990). The concept of lean manufacturing was

introduced in the Toyota production system and it was the first to use lean practices. Lean manufacturing enhances production

processes and boosts the employees job satisfaction Singh, Garg, Sharma , & Grewal (2010). Lean manufacturing believes the

simple fact that customers will pay for the value of services they receive, but will not pay for mistakes Rawabdeh (2005).

* Corresponding author. Tel.: 91-996-255-3442; fax: 044-22512229.

E-mail address: venkat.mech@sairam.edu.in

2211-8128 2014 Elsevier Ltd. This is an open access article under the CC BY-NC-ND license

(http://creativecommons.org/licenses/by-nc-nd/3.0/).

Selection and peer review under responsibility of the Gokaraju Rangaraju Institute of Engineering and Technology (GRIET)

doi:10.1016/j.mspro.2014.07.192

1188

K. Venkataraman et al. / Procedia Materials Science 6 (2014) 1187 1196

Saurin and Ferreira (2009) have presented guidelines for assessing lean production impacts on working conditions either at a

plant or a departmental level, which were tested on a harvester assembly line in Brazil. Narahari et al (1999) explored how the

lead times can be reduced using scheduling, input control, load balancing and variability reduction. The models are based on

single class and multiclass queuing networks and capture important facts of a product development organisation such as

concurrent execution of multiple projects, contention for resources, feedback and reworking of project tasks and variability of the

new project initiations and task execution times. McDonald et al (2000) explained wasteful steps that have to be eliminated and

flow can be introduced in the remaining value-added processes. The concept of flow is to make parts ideally one piece at a time

from raw materials to finished goods and to move them one by one to the next workstation with no waiting time in between. Pull

is the notion of producing at the rate of the demand of the customer. Perfection is achieved when people within the organization

realize that the continuous improvement process of eliminating waste and reducing mistakes while offering what the customer

actually wants becomes possible. Khaswala et al (2001) explained the basic concepts of Value stream mapping and how to

implement them in case of multiple flow value stream mapping that merge in case of a complex product. Abdulmalek and

Rajagopal (2006) presented lean manufacturing principles being applied to a steel mill. The lean manufacturing tool of value

stream mapping has been used to map the scenarios. The paper also described simulation models which were developed using

lean manufacturing principles and also analyzed the possible benefits.

Ward (2007) addressed the confusion and inconsistency associated with lean manufacturing concept to clarify the semantic

confusion surrounding lean production by conducting an extensive literature review using a historical evolutionary perspective in

tracing its main components. Rother (1990) described how Toyota manages continuous improvement, human ingenuity, through

its improvement kata and coaching kata. He also explains why typical companies fail to understand the core of lean and make

limited progress. The two metrics are the lead time and Percentage value added work. William et al (2011) presented the use of

value stream mapping tool in identifying, quantifying and minimizing major wastes in a bread manufacturing set-up. The case

study shows how the VSM tool was used to identify and reduce defects, unnecessary inventory, and motion. Gurumurthy and

kodali (2011) presented simulation of models which have been modified by using Lean manufacturing principles and elements.

The impact of implementation of lean manufacturing elements on the companys performance was also analyzed.

Tapping et al (2000) wrote a book on value sream management system and how it simplifies the planning process for lean

Ron Moore (2002) wrote a book on selecting the right

implementation, ensuring quick deployment and greater success.

manufacturing improvement tools and showed how these tools can be implemented and supported. It also relates to one another

and compares their strengths and weaknesses. It also provides an excellent review of the most popular improvement tools and

strategies - Lean Manufacturing, Kaizen etc. Salomon et al. (2007) used multiple decision making for supplier selection of

assembly line equipments in an automotive industry. Kull and Tallurai (2008) proposed a combination of analytical hierarchical

process and goal programming as a decision tool for supplier in the presence of risk measures and product life cycle

considerations. The efficiency of the model is tested at a mid sized, second tier automotive supplier. Scherrer Rathje et al.

(2009) identified the major criteria and conditions that lead to either lean success or failure. They found the sources to failure like

the lack of senior management commitment, lack of interest and low acceptability of workers for changes. The sources of

success are employee autonomy to make decisions, information transparency, etc.

2. Problems in existing system

The following wastages were identified in the current system of crankshaft production process;

x High additional processing time.

x More number of workers.

x Consumes more resources.

x More inventory.

x More scrap and

x High Cycle time.

3. Methodology

The identified research work was taken for preparation of future state value stream map from the current state value

stream map, tools and techniques of Lean Production System were used to establish the single piece flow in the line, by

implementing kaizen. Analytic hierarchical process was taken as an aid for justifying the decision taken in the Kaizen

improvement and ultimately the required objectives were obtained. Several kaizen were implemented for reducing cycle time,

number of workers, inventory and scrap. However only 3 important kaizen are discussed in this paper.

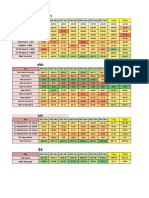

4. Value Stream Mapping

Value stream mapping is a method of lean manufacturing which uses symbols, metrics and arrows to show and improve

the flow of inventory and information required to produce a product or service which is delivered to a consumer. A value stream

map is a visual representation which enables one to determine where the waste occurs. Value stream maps are utilised to assess

current manufacturing processes (figure 1) and create ideal and future state processes Value stream mapping is a tool which

enables a company to map the process flow that helps in identifying various factors like;

x Value added time (time taken for producing the end product),

x Non Value added time (time taken which do not contribute to the production of end product),

x Cycle time (time required to perform a process) and

x Changeover time (time required to change tool and programming etc.).

This helps in identifying and eliminating muda (waste), thereby implementing lean principles.

K. Venkataraman et al. / Procedia Materials Science 6 (2014) 1187 1196

1189

After identifying the non value added steps in the current state, a future state value stream map is developed (Figure 2) which

acts as blueprint for lean activities. The future state value stream map often represents a significant change compared to the way

the company currently operates. The value stream map team thus develops a step by step implementation strategy to make the

future state a reality.

The key elements of the value stream map are shown ;

x The Customer and his requirements.

x Process steps.

x Process Metrics.

x Inventory.

x Supplier with material flows.

x Information and Physical flows.

x Total lead time and Takt time

The cycle time in the figure 3 refers to the time it takes an operator to go through all of their work elements before

repeating them. The value added time is the time of those work elements that actually transforms the product in a way that the

customer is ready to pay for. The lead time refers to the time it takes one piece to move all the way through the process from start

to finish. It is total of all value added time and non value added time. The process ratio is the ratio between the value added

times to the production lead time of the process. The takt time is equal to the ratio of effective operating time per shift and the

quantity customer requires per shift.

Crankshaft for the domestic market is being produced in batch mode starting with the facing and turning operation to

journal rough turning and pin rough operation in turning cell and the turned crankshafts are then moved to oil hole drilling

operation and finally the drilled crankshafts are then moved to the oil hole drilling cell for oil hole drilling operation and finally

the drilled crankshafts are moved in batches to the grinding cell for finish journal grinding and pin grinding operations. Mapping

starts from the customer requirements.

The customer requirement is 12000 numbers per month. The takt time for the demand of 12000 numbers is 126 seconds

and the daily requirement is 545 numbers per day. Once the customer informs the 3 months firm schedule requirements through

mail, the marketing department informs the production department to plan for the next months production. The production

department informs the forging supplier to plan for the raw material and sends the schedule for the supply of forgings. The

production department also informs the value stream in charge of the crankshaft line to plan for the resources including

manpower and consumables. The forgings from the supplier arrive at the incoming inspection area and after the sample for

inspection the crankshaft forgings are then moved to the turning cell.

Earlier the crankshaft was manufactured at 3 different locations, namely turning cell, oil hole drilling cell and grinding

cell. In turning cell, all the turning machines are placed and the movement of material was in zigzag as shown in the figure 1.

There was an inventory of 10 numbers in between the machines and 1000 numbers was stored at the end of the cell. There were 2

operators in the turning cell. The turned crankshaft was moved in batches of 1000 numbers to oil hole drilling cell placed at a

distance of 10 meters away. Oil drilling machine was operated by one person with the same inventory and storage. The grinding

cell was operated by 2 operators and it was 25 metres away from oil drilling machine. The crankshafts movement was in zigzag

pattern. An inventory of 10 numbers was maintained and a batch of 1000 crankshafts was moved to the warehouse. The pitfalls

were at any point of time, there was an inventory of 1000 numbers maintained between the cells. The rejection rate was high and

there was no communication between the turning, oil hole drilling and grinding machine operators to correct the defects. The

work content of the operators was not balanced and 5 operators were used as shown in the figure 1

1190

K. Venkataraman et al. / Procedia Materials Science 6 (2014) 1187 1196

Fig. 1. Turning, Oil hole drilling and grinding cell layout

In the export crankshaft manufacturing cell, the process starts from crankshaft forging receipt at the incoming stores and it is

moved in a trolley containing 98 numbers to the facing and centring machine. The datum is created at both the ends of the

crankshaft in facing & centring machine and single piece flow transfer to the grooved end journal turning machine, thread end

journal turning machine, grooved end pin turning machine, threaded end pin turning machine, oil hole drilling machine, dia 5mm

hole drilling machine, deburring, grooved end journal finish grinding machine, thread end journal finish grinding machine,

grooved end pin grinding machine, thread end pin grinding machine, deburring, washing and oiling station with a single piece in

between the machines. The zigzag flow is eliminated and a unidirectional flow is established as shown in the figure 2. Only 3

operators are used when compared to 5 operators when the crankshaft machining was done in batch mode. The material

travelling distance reduced from 98 meters to 50 meters

Fig. 2. Crankshaft manufacturing cell

1191

K. Venkataraman et al. / Procedia Materials Science 6 (2014) 1187 1196

Value Stream mapping

CURRENT STATE MAP Domestic Crankshaft

Month/weekly/daily plan

Production

Control

Marketing

Monthly/Weekly

Fax

Monthly schedule

Daily

Customer

Supplier

Elforge

Takt time

2X

Weekly

Drilling cell

Turning cell

C/T=202s

C/T=110s

Facing mill

& Center

CO=1800s

Uptime=85%

C/T=135s

C/T=2000s

CO=0

3 shifts

2 shifts

C/T=142s

C/T=201s

C/T=202s

I CO=3600s

Uptime=85%

10

I CO=3600s

Uptime=85%

10

3 shifts

3 shifts

0.18

3.66

C/T=103s

I

CO=7200s

1000

CO=7200s

Uptime=85%

Uptime=85%

98 S

C/T=36s

3 shifts

Uptime=100%

0.18

Packing

1(shared)

C/T=6000s

CO=0

Uptime=100%

36 S

2 shifts

I C/T=78s

10 CO=1800s

I

6000

Uptime=85%

3 shifts

0.18

135 S

3 shifts

Shipping

Washing and

oiling

0.18

138 S

C/T=86s

I CO=1800s

I CO=0s

Uptime=85%

Uptime=100%

10

10

86 S

3 shifts

0.18

Deburring

0.18

I C/T=24s

10 CO=0s

3 shifts

0.18

0.18

103 S

Uptime=85%

3 shifts

3 shifts

1.83

I

10 CO=7200s

Dia. 5 hole

drilling

110 S

Deburring

C/T=135s

Uptime=85%

Uptime=85%

3 shifts

3 shifts

1.83

202 S

T.E.Pin

grinding

I C/T=138s

10 CO=7200s

I C/T=98s

10 CO=7200s

3 shifts

0.18

G.E. Pin

grinding

T.E.Journal

grinding

C/T=110s

CO=1800s

I

Uptime=85%

1000

3 shifts

201 S

142 S

G.E.Journal

grinding

2

C/T=138s

0.18

140 S

Grinding cell

3 shifts

0.18

135 S

2000 S

Oil hole

drilling

I CO=1800s

10 Uptime=85%

C/T=140s

I

CO=1800s

I CO=1800s

2000 Uptime=85%

10 Uptime=85%

Uptime=100%

T.E.Pin

rough grind

G.E.Pin

rough grind

1X 15 days

545 nos /day

3 shifts

T.E.Journal

Turning

G.E.Journal

Turning

Demand/month

12000

CO=3600s

Uptime=85%

3 shifts

Inspection

stores

126 Sec.

11

24 S

Process Ratio

78 S

6000 S

9627s

Value added Time

=

=

Production lead time

1644300s

0.60%

Fig. 3. Current state value stream mapping

Step 1

Month/weekly/daily plan

Production

Control

Supplier

Elforge

1X

Daily

Process scrap

reduction

C/T=2000s

CO=0

Facing &

Centering

C/T=91s

CO=1800s

600 Uptime=85%

1.1

600 S

Poka yoke

introduction

Standardised work

introduction

Combine

operations

Demand/month

12000

CO=7200s

Uptime=85%

C/T=111s

I CO=1800s

1 Uptime=85%

C/T=105s

C/T=114s

I CO=3600s

1 Uptime=85%

I CO=1800s

1 Uptime=85%

3 shifts

3 shifts

3X weekly

545 nos /day

G.E. & T.E

Journal Grind

C/T=121s

CO=7200s

Uptime=85%

121S

C/T=101s

1 Uptime=85%

3 shifts

T.E.Pin

grinding

C/T=114s

C/T=111s

CO=7200s

114 S

CO=7200s

I Uptime=85%

1 3 shifts

0

111S

CO=7200s

Uptime=100%

3 shifts

C/T=78s

I

1

CO=1800s

Uptime=85%

36 S

Process Ratio

Fig. 4. Future state value stream mapping

I

1100

Push to

pull and

frequent lot

transfer

78 S

1100 S

Value added Time

Production lead time

Shipping

Packing

1(shared)

C/T=1100s

CO=0

Uptime=100%

3 shifts

0Output

36 S

Washing and

oiling

C/T=98s

CO=1800s

101 S

Deburring

C/T=36s

1 Uptime=100% I

1

3 shifts

Uptime=85%

114 S

CO=1800s

3 shifts

101 S

Deburring

C/T=101s

I

1

CO=1800s

3 shifts

G.E. Pin

grinding

I Uptime=85%

1 3 shifts

Dia. 5 hole

drilling

C/T=114s

105 S

114 S

Oil hole

drilling

I CO=3600s

1 Uptime=85%

3 shifts

111S

T.E.Pin rough

turning

G.E.Pin rough

turning

Date - 23.11. 2010

126 Sec.

Replace with pin

Turning m/c

T.E.Journal

Turning

3 shifts

Introduce hydraulic

clamping

Takt time

Machining

cell

3 shifts

Input 0

91S

Customer

C/T=202s

Reduce cutting time

G.E.Journal

Turning

3 shifts

2 shifts

Daily

TPM introduction

Single piece flow

introduction

Productivity

improvement

Eliminate face

milling

Monthly/Weekly

Fax

Monthly schedule

Marketing

Cell

manufacturing

Line balancing

Cycle time

reduction

Inspection

stores

Value stream mapping

FUTURE STATE MAP Export crankshaft cell

2 shifts

2933s

251100s

1.17%

1192

K. Venkataraman et al. / Procedia Materials Science 6 (2014) 1187 1196

Fig. 5 Cycle time details

Fig. 6. Identifying the Opportunities for improvement

KAIZEN 1: Implement the Modified Process by eliminate and combine operations (figure 7)

In facing and centring machine, the cycle time was 135 seconds because milling head and drilling head were used for face

milling and drilling operation. The sequence of operation was that the milling head will traverse in y axis to first mill the journal

end face and then the drilling head will move in to drill. By developing a special tool with cartridges fitted with inserts mounted

on the tool face and a centre drill mounted on the tool centre as shown in the figure 4, the plunge facing and centering operation

was completed on both sides of the journal. By this the facing operation was eliminated and plunge facing, facing and centre

drilling operations were combined. Due to this kaizen, the cycle time reduced from 135 seconds to 70 seconds and the capital

investment for the milling head was also eliminated resulted in a saving of Rs. 0.15 million

Fig. 7. Eliminate and combined operations

Fig. 8 Optimizing Machining Parameter

KAIZEN 2: Implement the modified process by optimizing the process parameters

The existing process parameters for roughing operation and finishing operation were studied and based on the cutting force

K. Venkataraman et al. / Procedia Materials Science 6 (2014) 1187 1196

1193

calculation; the process parameters speed and feed were optimized for roughing and finishing operations. There was no

deterioration on the tool life due to increasing speed and feed. The cycle time reduced from 140 seconds to 111 seconds and there

was no side effect on quality. (fig 8)

KAIZEN 3: Implement the modified process by tooling improvement and introduce CNC lathe Historically the crankshaft

pin roughing operation was done on a grinding machine to remove material from forging stage to the roughing stage for material

removal of 2.5 mm diametrically. As grinding operation is a slow process, the cycle time was also more. Since the pin diameter

is eccentric by 25 mm, a special eccentric collet chuck to centralize the pin diameter to the CNC lathe (fig. 10)spindle axis was

designed and developed to turn the diameter from the forging stage to the roughing stage by using special new generation

neutral, left hand and right hand tool. Due to this the cycle time reduced from 201 seconds to 105 seconds and the capital

investment for the groove end pin turning operation also reduced from Rs. 4.57 million to Rs. 2.5 million. There was no

compromise on quality.

The cycle time details of the improved processes are shown in figure 9.

Fig 9. Cycle Time details

Fig. 10. CNC Lathe Introduction

5. Analytic Hierarchical Process (AHP) for KAIZEN 3

AHP is one of the Multi criteria Decision making methods developed by Saaty (1999, 2008). The basic framework of

AHP is based on the innate human ability to make sound judgement for small problems. AHP is a structured technique for

complex problems. By using AHP, the decision making will become easy and the decision makers will gain confidence for the

selection of suitable assembly method for their company by Vijayaramnath et al. (2010)

Various manufacturing methods were used to achieve the above goals. The most practical method to improve the

productivity was selected using analytical hierarchical process. The overall performance matrix, relative value factor are given

below, using them overall priority vector is found .

5.1 AHP algorithm

The step by step procedure to carryout AHP is given below (fig 11)

Step 1: Setting up hierarchy.

Step 2: Pair wise comparison of characteristics

Step 3: Establish priority vector

Step 4: Comparison of alternatives

Step 5: Calculate priority vector for alternatives (for various factors considered)

Step 6: Obtain the overall priority vector

The above steps were calculated using AHP, and the values are shown in the following table 1, table 2, and table 3.

1194

K. Venkataraman et al. / Procedia Materials Science 6 (2014) 1187 1196

Table 1: comparison of characteristics of different machining equipment

SP

OP

PQ

IMP

RO

CO

Old grinding machine

0.09

0.08

0.15

0.15

0.35

0.10

Machining with special purpose 0.15

0.48

0.23

0.20

0.12

0.47

machine

In-house development of existing CNC 0.44

0.25

0.09

0.12

0.20

0.24

machine

Turning with conventional machine 0.08

0.06

0.41

0.43

0.13

0.06

modified

New CNC machine with modified 0.24

0.12

0.11

0.09

0.20

0.14

tooling

LC

0.27

0.06

TI

0.15

0.23

0.13

0.12

0.46

0.44

0.07

0.06

Fig. 11. Hierarchical structure of AHP model

Table 2: Relative value factor

Speed of production (SP)

Optimizing parameters (OP)

Part quality (PQ)

Investment for mass production (IMP)

Reducing operations (RO)

Combining operations (CO)

Labour cost (LC)

Tooling improvement (TI)

0.33

0.19

0.16

0.12

0.08

0.05

0.04

0.03

Table 3: Overall priority factor

Existing Manufacturing Processes

Overall Priority vector %

Rank

Old grinding machining

13.52

5

Machining with special purpose machine

24.39

2

1

In house development of the existing CNC m/c

25.83

with special tooling

3

Turning with conventional m/c with modified tooling

20.0

4

New CNC machine with modified tooling

15.8

From the analytical hierarchy process, it can be concluded that the In-House development of the existing CNC machine with

special tooling is best method for machining the crankshaft. Hence the statistical tool supports the real time analysis of obtaining

the desired production rate.

6. Results and benefits of Lean Systems

x Single piece flow for crankshaft manufacturing system was established.

x The non-value adding activity of having inventory between the machines were eliminated

x Quick response to the customer demand to supply frequently in small lots

K. Venkataraman et al. / Procedia Materials Science 6 (2014) 1187 1196

1195

The complete export crankshaft manufacturing cell was established to meet the customer quality, cost and delivery

requirements. The results are shown in table 4.

Table 4: Results

Description

Existing

manufacturing line

Target Export crankshaft

manufacturing line

Productivity (P)

Number

of

operators

Quality (Q)

Cost (C)

Delivery (D)

Morale (M)

20/hour

5

25/hour

3

8%

Rs.1000

80% fill rate

10

suggestion/person/

month

Zero accidents

5%

Rs. 900

100% fill rate

50 suggestions / person/month

5.5 %

Rs. 875

100% fill rate

Zero accidents

Zero accidents

Safety (S)

Result Actual in Export

crankshaft

manufacturing

line

28.57/hour

3

7. Conclusion.

Lean manufacturing system implemented in this paper is done in a crankshaft manufacturing cell to eliminate the 8 nonvalue adding wastes like over production, waiting, unnecessary transport movement, defects and unused employee creativity

from the manufacturing system and also to create product mix flexibility in the manufacturing cell. The limitation in this research

is that the crankshaft manufacturing cell set-up changeover between the crankshaft variants is not within the takt time of 126

seconds and the agreement with the customer is also to produce one variant for one week and changeover to the next variant,

will not have an impact on the project. The limitations in this research is that this export crankshaft manufacturing cell can

produce only crankshaft variants and there is no flexibility of producing other critical parts of the compressor The future work is

to establish lean manufacturing systems for all compressor critical parts machining and supply assembled compressors to

customer.

References

Abdulmalek, F.W. and Rajgopal, J., 2006 Analyzing the benefits of lean manufacturing and value stream mapping via

simulation: A process sector case study, International Journal of Production Economics, Vol.107, pp. 223 236.

Don Tapping, Tom Luyster, Tom Shuker, 2002 in Value Stream Management: Eight steps to Planning, Mapping and Sustaining productivity

press, ISBN 1-56327-245-8, 2002.

Gurumurthy, A. and Kodaly, R., 2011 Design of lean manufacturing systems using value stream mapping

with simulation: A case study, Journal of Manufacturing Technology Management, Vol. 22 Issue 4, pp.444 - 473.

Khaswala, Z.N., and Irani, S.A., 2001 Value Network Mapping (VNM): Visualization and Analysis of Multiple Flows

in Value Stream Maps, Proceedings of the Lean Management Solutions Conference, St. Louis, Missouri, United states of America, pp.

47-63.

Kull J. & Talluri S., 2008 A supply risk reduction model using integrated multi criteria decision making. IEEE Transactions on Engineering

Management, 2008, 55(3), 409 - 419

McDonald, T., Van Aken, E. and Butler, R., 2000 Integration of Simulation and Value Stream Mapping in Transformation to

Lean Production, IIE Annual Conference

McGraw Womack, J.P, Jones, D.T and Roos, D., 1990 The Machine that Changed the World, 2nd ed., Harper Perennial, New York, United

states of America.

Mike Rother, Toyota Kata, Managing people for improvement, adaptiveness, and superior result, ISBN-10:0-07068346-8,

Narahari Y., Viswanadham, N. and Kumar V. K., 1999 Lead time modelling and acceleration of product design and

development, IEEE Transactions on Robotics & Automation, Vol.15 Isuue.1, pp. 882-896

Rawabdeh, I. A., 2005. A model for the assessment of waste in job shop environments. International Journal of

Operations & Production Management, 25, 800822

Rother, M. and Shook, J., 1999 Learning to See: Value Stream Mapping to Add Value and Eliminate Muda, 2 nd ed., Lean Enterprise

Institute, Brookline, Massachusetts, United states of America.

Ron Moore Selecting the right manufacturing improvement tools: Elsevier limited, ISBN 10:0-7506-7916-6, 2002

Saaty, L., 2008. Decision making with the analytic hierarchy process in international journal of services sciences, 1(1), 83-98.

Salomon A. P., Marins A. S & Duduch A., 2007 Multiple decision making applied to the supplier selection for assembly line equipments in an

automotive Industry. ISAHP, 1-5

Singh, B., Garg, S. K., Sharma, S. K., & Grewal, C. 2010. Lean implementation and its benefits to production industry. International Journal of

Lean Six Sigma, 1, 157168.

Saurin, T.A., Ferreira, C.F., 2009. The impacts of lean production on working conditions: A case study of a harvester assembly line in Brazil.

International Journal of Industrial Ergonomics, 39, 403412

Sullivan. G., McDonald, N. & Aken, E. V., 2007 Equipment replacement decisions and lean manufacturing. A Journal of robotics and

1196

K. Venkataraman et al. / Procedia Materials Science 6 (2014) 1187 1196

computer integrated manufacturing, 18, 255 -265.

Vijaya Ramnath. B, Elanchezhian. C, Kesavan. R (2010). A multi attribute decision making method for selection of optimal line, A journal of

management science letters I (2011) 65 72.

Ward, A.C., 2007, Lean Product and Process Development, 4th ed., Lean Enterprise Institute, Brookline MA.

William, M. G., Mhlanga, S. and Marecha, A., 2011 Use of the value stream mapping tool for waste reduction

in Manufacturing. Case study for bread manufacturing in Zimbabwe. Proceedings of International

Conference on Industrial Engineering and Operations Management, Kuala Lumpur, Malaysia, pp 236

S-ar putea să vă placă și

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Mba ZG537 Ec-3r First Sem 2020-2021Document2 paginiMba ZG537 Ec-3r First Sem 2020-2021thasarathanr1993_939Încă nu există evaluări

- Quality Control Assurance & Reliability: BITS PilaniDocument62 paginiQuality Control Assurance & Reliability: BITS Pilanithasarathanr1993_939Încă nu există evaluări

- Mba ZG514 Ec-3r First Sem 2020-201Document5 paginiMba ZG514 Ec-3r First Sem 2020-201thasarathanr1993_939Încă nu există evaluări

- Part A: Content Design: Birla Institute of Technology & Science, Pilani Work Integrated Learning Programmes DigitalDocument10 paginiPart A: Content Design: Birla Institute of Technology & Science, Pilani Work Integrated Learning Programmes Digitalthasarathanr1993_939Încă nu există evaluări

- 2007 SPU MOSTTechniqueDocument8 pagini2007 SPU MOSTTechniquethasarathanr1993_939Încă nu există evaluări

- BITS Pilani - MBA in MAnufacturing ManagmentDocument11 paginiBITS Pilani - MBA in MAnufacturing Managmentthasarathanr1993_939Încă nu există evaluări

- Aggregate Planning 1614614720244Document12 paginiAggregate Planning 1614614720244thasarathanr1993_939Încă nu există evaluări

- Capacitated Plant Location Model 1613647752323Document2 paginiCapacitated Plant Location Model 1613647752323thasarathanr1993_939Încă nu există evaluări

- Buffalo Memphis St. Louis Atlanta Boston Jacksonville Philadelphia New YorkDocument1 paginăBuffalo Memphis St. Louis Atlanta Boston Jacksonville Philadelphia New Yorkthasarathanr1993_939Încă nu există evaluări

- Z Z Z Z Z Waiting 1,2, 3,4, Over Production Unused Creativity Quality Defects Transportation Motion Inventory De-Burring Over ProcessDocument1 paginăZ Z Z Z Z Waiting 1,2, 3,4, Over Production Unused Creativity Quality Defects Transportation Motion Inventory De-Burring Over Processthasarathanr1993_939Încă nu există evaluări

- Automatic Car Parking System: A Mini Project Report Submitted byDocument24 paginiAutomatic Car Parking System: A Mini Project Report Submitted bythasarathanr1993_939Încă nu există evaluări

- Frequently Asked Questions About Rajya SabhaDocument21 paginiFrequently Asked Questions About Rajya Sabhathasarathanr1993_939Încă nu există evaluări

- Quality CrosswordDocument1 paginăQuality Crosswordthasarathanr1993_939Încă nu există evaluări

- 7 Team Round RobinDocument1 pagină7 Team Round Robinthasarathanr1993_939Încă nu există evaluări

- Sample For One Page ReportDocument2 paginiSample For One Page Reportthasarathanr1993_939Încă nu există evaluări

- SQC Module1 DD - DoneDocument20 paginiSQC Module1 DD - Donethasarathanr1993_939Încă nu există evaluări

- Taxi TrolleyDocument16 paginiTaxi Trolleythasarathanr1993_939Încă nu există evaluări

- Current Longest Serving G7 LeaderDocument3 paginiCurrent Longest Serving G7 Leaderthasarathanr1993_939Încă nu există evaluări

- Uproar Among Doctors Over Rajya Sabha Plan To Cap Consultation ChargesDocument1 paginăUproar Among Doctors Over Rajya Sabha Plan To Cap Consultation Chargesthasarathanr1993_939Încă nu există evaluări

- Extinct AnimalsDocument6 paginiExtinct Animalsthasarathanr1993_939Încă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Deep Security Container Protection Customer PresentationDocument42 paginiDeep Security Container Protection Customer PresentationsaurabhbectorÎncă nu există evaluări

- Manual de Partes JCB JS200L PDFDocument99 paginiManual de Partes JCB JS200L PDFAdolfo Martinez89% (18)

- Fronius Warranty TermsDocument4 paginiFronius Warranty TermsRobertoÎncă nu există evaluări

- GSB Solar Product Catalog A4Document40 paginiGSB Solar Product Catalog A4mohamed husseinÎncă nu există evaluări

- Step-By-Step Guide For AWS Virtual TrainingDocument6 paginiStep-By-Step Guide For AWS Virtual TrainingAdmin BakamaÎncă nu există evaluări

- Chapter One: Introduction & Review of Principles of Object OrientationDocument50 paginiChapter One: Introduction & Review of Principles of Object OrientationhenokÎncă nu există evaluări

- Project Segway 3 WheelDocument26 paginiProject Segway 3 WheelMohit ChetwaniÎncă nu există evaluări

- Cordex HP 1.2kW: 1RU Integrated Shelf System With GMT DistributionDocument2 paginiCordex HP 1.2kW: 1RU Integrated Shelf System With GMT DistributionJohn WikieÎncă nu există evaluări

- Prismaflex 8.1: For Continuous Extracorporeal Blood Purification TherapiesDocument2 paginiPrismaflex 8.1: For Continuous Extracorporeal Blood Purification TherapiesIftekhar AhamedÎncă nu există evaluări

- Training ReportDocument30 paginiTraining ReportManuka DilshanÎncă nu există evaluări

- 1 2 7 P Understandingdigitaldesign RNG (1) FinishedDocument8 pagini1 2 7 P Understandingdigitaldesign RNG (1) Finishedapi-287488627Încă nu există evaluări

- Nokia.Document1 paginăNokia.kshiti ahireÎncă nu există evaluări

- Advt No.: HSCC/RECT/2019/2: 1 (A) EXECUTIVE ASSISTANT ENGINEER (Civil/Electrical/Mechanical)Document9 paginiAdvt No.: HSCC/RECT/2019/2: 1 (A) EXECUTIVE ASSISTANT ENGINEER (Civil/Electrical/Mechanical)jitu brarÎncă nu există evaluări

- Dnp3 Master Ethernet ManualDocument143 paginiDnp3 Master Ethernet ManualunnikuttanÎncă nu există evaluări

- D6NDocument47 paginiD6NRodrigo Ricardo Véliz Meza100% (3)

- OSPF Part of The CCIE EI Workbook Orhan ErgunDocument123 paginiOSPF Part of The CCIE EI Workbook Orhan ErgunYoussef Fatihi100% (1)

- CS544 - Cloud Application DevelopmentDocument3 paginiCS544 - Cloud Application DevelopmentMayur PatilÎncă nu există evaluări

- Q3. Quiz1Document2 paginiQ3. Quiz1Jinkee F. Sta MariaÎncă nu există evaluări

- Masterpieces of Piano MusicDocument562 paginiMasterpieces of Piano Musichtrung2101100% (1)

- IFSC Syllabus (GTURanker - Com)Document3 paginiIFSC Syllabus (GTURanker - Com)VARSHAÎncă nu există evaluări

- Final PPT A PRIVACY PRESERVING FRAMEWORK FOR PRESERVING MOBILE AD PDFDocument11 paginiFinal PPT A PRIVACY PRESERVING FRAMEWORK FOR PRESERVING MOBILE AD PDFlechu-92Încă nu există evaluări

- NBH DBH BBH Comparision SikarDocument21 paginiNBH DBH BBH Comparision SikarNikhil Kumar Gupta100% (1)

- An English Temne DictionaryDocument423 paginiAn English Temne Dictionary1scribe2011Încă nu există evaluări

- PHD Thesis Download Free Computer ScienceDocument4 paginiPHD Thesis Download Free Computer Sciencegingermartinerie100% (2)

- Realistic Robot SimulationDocument102 paginiRealistic Robot SimulationDraconixÎncă nu există evaluări

- DFC-90 Cirrus Config and Testing AVDFC-096Document15 paginiDFC-90 Cirrus Config and Testing AVDFC-096Anderson RamalhoÎncă nu există evaluări

- Equipment Installation Verification Procedure:: How To Use This DocumentDocument3 paginiEquipment Installation Verification Procedure:: How To Use This DocumentBasha Yazn AnjakÎncă nu există evaluări

- Iec 61724 1 2021Document15 paginiIec 61724 1 2021Loyel RoseÎncă nu există evaluări

- Magnelis Warranty C5M ENDocument2 paginiMagnelis Warranty C5M ENjames schembriÎncă nu există evaluări

- Characteristics of Digital DataDocument6 paginiCharacteristics of Digital DataArdi DiraÎncă nu există evaluări