Documente Academic

Documente Profesional

Documente Cultură

422 Makita Manual

Încărcat de

Jesus QuiñonezTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

422 Makita Manual

Încărcat de

Jesus QuiñonezDrepturi de autor:

Formate disponibile

A worlds leading manufacturer of power tools

How To

Cut Metal Effectively

Why Makita Carbide-tipped Metal Cutting saw VS. Abrasive Cutting Saw

Carbide-Tipped Blades make Virtually

Spark-Free Cuts

Abrasive Blades make Cuts with Sparks

Makitas Carbide-Tipped Metal Blades Cuts Cleaner

Tubing

Makita

Abrasive

Carbide-Tipped Blade Blade

Threaded Rod

UNISTRUT

Angle Iron

Pipe

Makita

Abrasive

Carbide-Tipped Blade Blade

Makita

Abrasive

Carbide-Tipped Blade Blade

Makita

Abrasive

Carbide-Tipped Blade Blade

Makita

Abrasive

Carbide-Tipped Blade Blade

Carbide-Tipped Metal Blades for Many Applications

Applications

Excellent

Good

Fair

Not Applicable

Size (mm)

Tip thickness

Part No.

Angle

Tubing

Channel

Nominal thickness 6 mm 4 mm 3 mm 4.5 mm 2.3 mm 3.2 mm

305 x 60T (Mild steel)

2.1 mm

A-87242

305 x 60T (Mild steel)

2.5 mm

A-81860

Mild steel

305 x 60T (Lessend

noise) 2.4 mm

A-86723

305 x 78T (Thin steel)

2.3 mm

A-87127

305 x 76T (Staianless) 1.95 mm

A-87579

Round

Pipe

3.8 mm

Stainless Stainless

Angle

Tubing

4 mm

1.5 mm

Metal Cutting Process

Carbide-Tipped Metal Blade Cutting Tips

Metal Cutting Process

Always wear safety glasses, gloves, protective equipment and

follow instructions provided with power tool

Square &

Rectangle Tubing

Do not apply excessive pressure on the handle when cutting as

damage to the carbide-tips can be a result

(use block spacer)

Too little or too much pressure on the handle may result in

more sparks and premature blade wear

Channels &

UNISTRUT

Use block spacers when cutting square/rectangle tubing as

well as channel and UNISTRUT for longer blade life

(use block spacer)

When cutting long pieces of metal always use support blocks

on both sides so the metal will be level with the saw base

Do not touch blade or metal immediately after cut

Angle

Carbide-Tipped Metal Blade Cutting Process

1 Ensure metal is properly placed on saw base and firmly

secured in the saw

Round Pipe

2 Hold the saw handle firmly and wait until full speed is obtained

3 Lower the handle gently to bring the blade close to the metal

4 Gently ease the blade into the metal and add minimal pressure

(reduce pressure if sparks appear)

Threaded Rod

5 After completed cut, turn off power tool and wait until blade

has come to a complete stop then raise the handle back

(if handle is raised back with blade still rotating then the

blade may be caught)

Block Spacer Reference Chart

Applications

Square & Rectangle Tubing

Round Pipe

The height of material

Up to 75 mm Up to 100 mm

90 Degree Cutting

Material

B

(mm)

Up to 85 mm

25

125

25

75

25

90

25

60

25

65

50

100

50

50

50

65

50

35

50

40

75

75

75

25

75

40

75

10

75

15

100

50

100

100

15

85

90

125

25

115

* 150

45 Degree Cutting

Block Spacer

Square &

Rectangle Tubing Round Pipe

* Hint: Block Spacer should be determined by subtracting the metal width from 150 mm.

Metal Cutting Saw 305 mm (12) Model LC1230

Specifications

Blade diameter

Max. cutting capacities

at 90

Large D-Handle with

Two Finger Trigger

and Lock-off Button

at 45

No load speed

Overall dimensions

(mm)

Net weight

External Accessible Brushes

for easy maintenance

305 mm (12)

115 mm

75 mm x 150 mm

90 mm

85 mm x 85 mm

1,300 min-1 (rpm)

516 x 603 x 306

(L x H x W)

19 kg (41.9 lbs)

Standard Equipment

Carbide-Tipped Saw Blade

(for mild steel)

Socket Wrench

Safety Goggles

Powerful Motor

305 mm x 60T Carbide-Tipped Blade

for virtually burr and spark free cuts

Quick Release Vise

for fast stock retention and cut-offs

Large Cast

Aluminum Base

for stability

Quick Release Vise

for fast stock retention

and cut-offs

Large cutting capacity; cuts 115mm

at 90 and 90mm at 45

Quick release vise for fast repent

cut-offs

Large D-handle with two finger

trigger and lock-off button

Tool-less guide plate adjustment

for 0 - 45 miter cuts

Makita Corporation

3-11-8 Sumiyoshi-cho, Anjo, Aichi 446-8502 Japan

PRINTED IN JAPAN Z23118-2 2003-12

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- ESPN Fantasy Baseball 5x5 RankingsDocument1 paginăESPN Fantasy Baseball 5x5 RankingsactÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- v850h TroubleshootingDocument2 paginiv850h Troubleshootingjoaquin ferÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- A.S.K.O. Wado-Ryu Karate ClubDocument39 paginiA.S.K.O. Wado-Ryu Karate ClubRobert johnsonÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Most Famous Singer in The World Right Now, Ranked by FansDocument1 paginăThe Most Famous Singer in The World Right Now, Ranked by Fanshee heeÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Extra Secrets For Rime of The FrostmaideDocument3 paginiExtra Secrets For Rime of The FrostmaideUranuzÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Viva La Vida Coldplay String Quartet Sheet MusicDocument5 paginiViva La Vida Coldplay String Quartet Sheet MusicNilton Luiz25% (4)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- C 400Document14 paginiC 400Bondan Raharjo0% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Audition Songs 2021Document5 paginiAudition Songs 2021Steven Kramer100% (1)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Jazz Covers PopDocument4 paginiJazz Covers Popmaria22mazaÎncă nu există evaluări

- LINEAR SLOT DIFFUSER - SLSD - Submittal1Document1 paginăLINEAR SLOT DIFFUSER - SLSD - Submittal1XAARISÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- RDT Routine ServiceDocument26 paginiRDT Routine ServiceAnonymous 340A7vnwV1100% (1)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Trapstar Shooters Hooded Tracksuit Men Woman Tiger Towel Embroidery Pullover High Quality Fleece Sweatshirts Streetwear HoodieDocument1 paginăTrapstar Shooters Hooded Tracksuit Men Woman Tiger Towel Embroidery Pullover High Quality Fleece Sweatshirts Streetwear Hoodiekelake.23 juniorÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Brief: Integrated Gigabit Ethernet and Memory Card Reader ControllerDocument2 paginiBrief: Integrated Gigabit Ethernet and Memory Card Reader ControllerYan AzmyÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Lesson 2 MusicDocument10 paginiLesson 2 MusicAbby shanti NocasaÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- HerakalesDocument16 paginiHerakalesWesley MuhammadÎncă nu există evaluări

- Standard Installation MTS9304A-HD2002 PDFDocument19 paginiStandard Installation MTS9304A-HD2002 PDFDony MauridsÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Topic 7 Cardiorespiratory Adaptations To TrainingDocument26 paginiTopic 7 Cardiorespiratory Adaptations To TrainingCikguAmelia100% (1)

- Chapter 2 Marketing Strategy PlanningDocument33 paginiChapter 2 Marketing Strategy PlanningĐặng Ngọc Yến TrâmÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Die FormingDocument4 paginiDie FormingMohit KambojÎncă nu există evaluări

- 5fcefef774277f6f7072b753 - HP LaserJet E62655 SeriesDocument4 pagini5fcefef774277f6f7072b753 - HP LaserJet E62655 SeriesOCIN GOTTONÎncă nu există evaluări

- Love Systems Insider: Braddock & Savoy On Text GameDocument9 paginiLove Systems Insider: Braddock & Savoy On Text GameLove SystemsÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Transmission Lines and WaveguidesDocument109 paginiTransmission Lines and WaveguidesdhruvaaaaaÎncă nu există evaluări

- Rusticucina MenuDocument3 paginiRusticucina MenuEaterSDÎncă nu există evaluări

- Past SimpleDocument14 paginiPast SimpleBetty Huaman PurihuamanÎncă nu există evaluări

- SerialxpDocument3 paginiSerialxpreisstyleÎncă nu există evaluări

- Street Smart Dating EbookDocument139 paginiStreet Smart Dating Ebookchris75paris63% (8)

- Portrayal of Women in Siswati Drama. Khulisile Judith NkunaDocument146 paginiPortrayal of Women in Siswati Drama. Khulisile Judith NkunaBuhleÎncă nu există evaluări

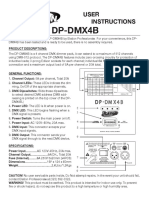

- Dp-Dmx4B: User InstructionsDocument1 paginăDp-Dmx4B: User InstructionsTito Estrada AmadorÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Selfish Giant (With Phonetics)Document4 paginiThe Selfish Giant (With Phonetics)Marcela MORALESÎncă nu există evaluări

- Vipac Roller SpecificationsDocument2 paginiVipac Roller SpecificationsMuhaimin100% (2)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)