Documente Academic

Documente Profesional

Documente Cultură

Microsoft Word Mecvina

Încărcat de

Ram RamirezDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Microsoft Word Mecvina

Încărcat de

Ram RamirezDrepturi de autor:

Formate disponibile

MECHANICS OF DEFORMABLE BODIES

MECHANICS OF DEFORMABLE BODIES- Study of the relationship between externally

applied loads and their internal effects on deformable bodies.

RIGID BODY Bodies which neither change in shape and size after the application of forces

FREE BODY DIAGRAM Sketch of the isolated body showing all the forces acting on it.

THREE MAJOR DIVISIONS OF MECHANICS

1. Mechanics of Rigid Bodies Engineering Mechanics

2. Mechanics of Deformable Bodies Strength of Materials

3. Mechanics of Fluids Hydraulics

SIMPLE STRESS TENSILE STRESS AND COMPRESSIVE STRESS

STRESS unit strength of the body

Where:

S Uniform internal stress

P Axial force

A Uniform cross-sectional

area

P

S=

A

Perpendicular

Passing through the centroid

P

Compressive stress

Tensile stress

Which bar is stronger A or B?

Assume that the given loads are the maximum loads each can carry.

BAR A

BAR B

A=20mm2

A=50mm2

1000N

500N

1/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

PROBLEMS ON SIMPLE STRESS

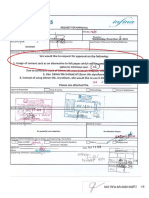

1. Determine the weight of the heaviest traffic lighting system that can be carried by the

two wires shown if the allowable stress on wire AB is 90MPa and on wire AC is 110MPa

given that the cross sectional areas of wire AB is 50mm2 and that of AC is 80 mm2.

B

C

70

35

2. Determine the required cross sectional areas of members BE, CD and CE of the given

truss shown, if the allowable stress in tension is 120MPa while in compression is

105MPa. A reduced allowable stress in compression is given to reduce the danger of

buckling.

D

C

G

4m

3m

B

A

3m

E

3m

3m

50KN

75KN

3m

F

3m

50KN

3. An bronze rod is rigidly attached between a aluminum rod and a steel rod as shown.

Axial loads are applied at the positions indicated. Find the maximum value of P that will

not exceed a stress in steel of 140MPa, in aluminum of 90MPa or in bronze of 100MPa.

Aluminum

A= 500mm2

3P

L alum= 3.5m

Bronze

Steel

A= 200mm2 A= 150mm2

P

2P

L br = 2m L st = 1.2m

2/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

8m

4. Determine the weight of the heaviest cylinder that can be

supported by the structure shown if the cross sectional

of the cable is 120mm2 and its allowable stress is 80MPa.

9m area

3m

5. The figure shows the landing gear of a light

airplane. Determine the compressive stress in

strut AB caused by the landing reaction R=30KN.

Neglect the weights of the members. The strut is

a hollow tube, with 40mm outside diameter and of

uniform thickness of 7mm.

A

B

200mm

55

600mm

6. In the recently opened World Trade Center, a

showcase of designers work is being

featured. There is a piece of marble table

which is just supported by three legs. If the

weight of the table is 500N, find the stress in

each leg if its cross-sectional section is

50mmx50mm.

5m

C

9m

3m

7. The tripod shown supports the total station

which weighs 10N. Find the required diameter of

the leg if the maximum allowable stress in each

leg is 25MPa.

8m

C

4m

3m

3m

B

6m

3/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

SHEARING STRESS This arises whenever the applied loads cause one section of the body

to slide past its adjacent section. The force acts parallel to the area.

Where:

Ss Shearing stress

P Force acting parallel to the area

A Surface area

P

Ss =

A

Shearing area

parallel to the load

TYPES OF SHEARING STRESS

1. SINGLE SHEAR

LAP JOINT

P

Rivet under Single shear

t

P

Width

of plate

130mm

Rivet under Double Shear

2. DOUBLE SHEAR

BUTT JOINT

P/2

tSPLICE

t MAIN PLATE

P/2

tSPLICE

4/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

3. PUNCHING SHEAR

4. INDUCED SHEAR

SHEARED

AREA

P

SHEARED

AREA

BEARING STRESS

Contact pressure exerted by one body upon another body. Also know as end stress. The

force acts perpendicular to the area.

LAP JOINT

P

t

P

Width

of plate

130mm

LAP JOINT

P

t

P

5/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

Width

of plate

130mm

ENLARGEMENT OF THE

RIVET HOLES

DIAMETER

OF THE PLATE

PROBLEMS ON SHEARING STRESS AND BEARING STRESS

8. A circular hole is to be punched out of a plate that has a shear strength of 40ksi The

working compressive stress in the punch is 50ksi. Compute the maximum thickness of

a plate in which a hole 2.5in in diameter can be punched. B) If the plate is 0.25in thick,

determine the smallest diameter that can be punched.

9. The lap joint is connected by three 20mm diameter

rivets. Assuming that the axial load P = 50KN is

distributed equally among the three rivets, find a)

the shearing stress in each rivet; b) bearing stress

between the plate and a rivet and c) the maximum

average tensile stress in each plate.

t=25mm

130mm

10. Determine the maximum force P that the top chord can carry if the allow shearing stress

is 50MPa, bearing stress is 60MPa and tensile stress is 85MPa of the connection

shown

P

a

b

c

d

q

b

q

a

6/37

200mm

120mm

40mm

75mm

30

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

11. A 25.6 mm diameter bolt having a diameter at the root of the threads of 21.7mm is

used to faster two timbers as shown. The nut is tightened to cause a tensile force of

34KN in the bolt. Determine the shearing stress developed in the head of the bolt and

the threads. Also determine the outside diameter of the washer if the inside diameter is

30mm and the bearing stress is limited to 0.9MPa.

15mm

17mm

12. The bracket is supported by inch

diameter pins at A and B (the pin at B fits

in the 45 slot in the bracket).

Neglecting friction, determine the shear

stresses in the pins, assuming single

shear.

45

200lb

12in

B

36in

C

10

7/37

13. Compute the maximum force P

that can be applied to the foot pedal. The

inch diameter pin at B is in single

shear, and its working shear stress is

40000psi. The cable attached at C has a

diameter of 1/8 inch and a working

normal stress of 20,000psi.

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

14. The figure shows a roof truss and the detail of the connection at joint B. Members BC

and BE are angle sections with thickness shown in the figure. The working stresses are

70MPa for shear in rivet and 140MPa for bearing stress due to the rivets. How many

19-mm diameter rivets are required to fasten the said members to the gusset plate

D

A

4m

6m

G

4m

4m

96KN

DETAIL OF JOINT B

200K

N

10mm

GUSSET PLATE

75X75X13

H

4m

96KN

75X75X6

P BE

P BC

THIN WALLED CYLINDERS

LONGITUDINAL

JOINT

CIRCUMFERENTIAL

JOINT

SCIRCUMFERENTIAL =

r D

2t

SLONGITUDINAL =

r D

4t

PROBLEMS ON THIN WALLED CYLINDERS

15. A cylindrical tank 8m in diameter is 12m high. If the tank is completely filled with water,

determine the required thickness of tank plating if the allowable stress is 40MPa.

16. The tank shown in the figure is fabricated from

steel plate. Determine the minimum thickness of

the tank plating if the internal pressure is 1.5MPa

400mm

and the allowable stress is 40MPa.

600mm

8/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

17. A large pipe called a penstock in hydraulic work is 1.5m in diameter. Here it is

composed of wooden staves bound together by steel hoops, each 300mm2 in crosssectional area, and is used to conduct water from a reservoir to a power house. If the

maximum tensile stress permitted in the hoops is 130MPa, what is the spacing between

hoops under a head of water of 30m?

18. A spiral-riveted penstock 1.5m in diameter is made of steel plate 10mm thick. The pitch

of the spiral or helix is 3m. the spiral seam is a single-riveted lap joint consisting of 20mm diameter rivets. Using SS=70Mpa and Sb=140MPa, determine the spacing of the

rivets along the seam from a water pressure of 1.25MPa. Neglect end thrust. What is

the circumferential stress?

SIMPLE STRAIN

STRESS- STRAIN DIAGRAM

Actual Rupture Strength

STRESS

Ultimate Strength

Rupture Strength

Yield Point

Elastic limit

Proportional limit

STRAIN

9/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

The strength of the material is not only the criterion that must be considered in

designing a structure. The stiffness of a material is frequently of equal importance.

Hookes Law states that up to the proportional limit, the stress is proportional to strain.

The constant of proportionality based from experiment is the modulus of elasticity.

STRESS a d STRAIN

S=

P

A

S a d

d AXIAL =

e=

d

L

PL

AE

PROBLEMS ON SIMPLE STRAIN

19. During a stress-strain test, the unit deformation at a stress of 35MPa was

observed to be 167x10-6 m/m and at a stress of 140MPa it was 667x10-6. If the

proportional limit was 200MPa, what is the modulus of elasticity? Would these

results be valid if the proportional limit were 150MPa? Explain.

20. The compound bar containing steel bronze and aluminum segments carries the

axial loads shown in the figure. The properties of the segments and the working

stresses are listed in the table. Determine the maximum allowable value of P if

the change in length of the entire bar is limited to 0.08in and the working stresses

are not to be exceeded.

A (in2)

Steel

0.75

Bronze

1.00

Aluminm 0.50

E (psi)

30 x 106

12 x 106

10 x 106

S (psi)

20000

18000

12000

Aluminum

6

E=10x10 psi

L=3ft

2

A= 0.75 in

B

2ft

3m

Bronze

6

E=12x10 psi

L=4ft

2

A= 0.25 in

D

10/37

Engr. Divina R. Gonzales

2ft

2ft

P

MECHANICS OF DEFORMABLE BODIES

21. The rigid bars AB and CD are supported by pins at A and D. The vertical rods are

made of aluminum and

Bronze

Aluminum

Steel

bronze. Determine the

4 ft

3 ft

2 ft

vertical displacement of the

P

3P

4P

point where the force P

=10kips is applied. Neglect

the weight so the member.

22. Two steel bars AB ad BC

support a load P=30KN as shown. Area of

AB=300mm2 and BC= 500mm2. If E =

200GPA, compute the horizontal and vertical

components of the movement of B.

L=5m

q=30

B

L=4m

P= 30KN

d=

4P L

p E Dd

23. A round bar of length L tapers uniformly from a diameter D at one end to a

smaller diameter d at the other end. Determine the elongation caused by an

axial tensile load P if E is its modulus of elasticity.

24. The rigid bars shown are separated by a roller at C and pinned at A and D. A

steel rod at B helps support the load of 50KN. Compute the vertical displacement

of the roller at C. Answer: 2.82mm

STEEL

E=200x10 6 N/m2

L=3m

A= 300 mm2

A

P= 30KN

D

B

C

11/37

Engr. Divina R. Gonzales

2P

MECHANICS OF DEFORMABLE BODIES

25. The rigid bars AB and CD are supported by pins at A and D. The vertical rods

are made of aluminum and bronze. Determine the vertical displacement of the

point where the force P=10kips is applied. Neglect the weights of the member.

Answer: 0.115 in

Aluminum

L=3ft

2

A=0.75in

6

E=10x10 psi

2 ft

3ft

Bronze

L=4ft

2

A=0.25in

6

E=12x10 psi

2ft

2ft

12/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

STATICALLY INDETERMINATE MEMBERS

Static indeterminacy does not imply that the problem cannot be solved; it simply means

that the solution cannot be obtained from the equilibrium equations alone. A statically

indeterminate problem always has geometric restrictions imposed on its deformation.

The mathematical expressions of these restrictions, known as the compatibility

equations, provide us with the additional equations needed to solve the problem (the

term compatibility refers to the geometric compatibility between deformation and the

imposed constraints). Because the source of the compatibility equations is deformation,

these equations contain as unknowns either strains or elongations. We can, however,

use Hookes law to express the deformation measures in terms of stresses or forces.

The equations of equilibrium and compatibility can then be solved for the unknown

forces.

PROBLEMS ON STATICALLY INDETERMINATE MEMBERS

26. The figure shows a copper rod that is placed in an aluminum sleeve. The rod is

0.005 inch longer than the sleeve. Find the maximum safe load P that can be

applied to the bearing plate, using the following data: Answer:

Bearing60.3kips

plate

Area (in )

E (psi)

S (ksi)

COPPER

2

6

17x10

20

ALUMINUM

3

6

10x10

10

0.005

10 in

alum

copper

27. A reinforced concrete column 250mm in diameter is designed to carry an axial

compressive load of 400KN. Using the allowable stress in concrete of Sconc

=6MPa and S steel = 120MPa, determine the required area of reinforcing steel.

Assume Econc=14GPa and Esteel = 200GPa. Answer: 1320mm2

28. A rigid block of mass M is supported by

three symmetrically spaced rods as shown.

Each copper rod has an area of 900mm2

Ecopper =120GPa and the allowable stress is

70MPa. The steel rod has an area of

1200mm2, Esteel=200GPa and allowable

stress of 140MPa. Determine the largest

mass M which can be supported.

Answer: 22.3x103Kg

13/37

Copper

160mm

Steel

240mm

Copper

160mm

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

29. Before the 400KN load is applied,

the rigid platform rests on two steel

bars each of cross-sectional area of

1200mm2, as shown. The crosssectional area of copper is

250mm

2400mm2. . Compute the stress in

each rod after the 400KN load is

applied. Neglect the weight of the

platform. Esteel =200GPa Ealuminum =70GPa.

400KN

0.1mm

steel

aluminum steel

30. The composite bar is firmly attached to unyielding supports. Compute the stress

in each material caused by the application of the axial load P=50kips. b) If the

maximum allowable stress in each material is Salum=22psi and Ssteel=40psi, find

the maximum P that the structure can support.

Aluminum

A=3.25 in2

E=10x106psi

Steel

A=5.5 in2

E= 29x106psi

P

12in

25in

31. The rigid beam is supported by the two bars shown in a horizontal position before

the load P is applied. If P=200KN, determine the stress in each rod after its

application. B) Find the vertical movement of P. c) If the allowable stress in

aluminum is 80MPa and steel is 120MPa, find the maximum load P that the

system can carry

L=6 m

aluminum

3m

steel

A in mm

E in GPa

L=4.5 m

3m

Aluminum

600

70

Steel

800

200

3m

14/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

THERMAL STRESS

It is well known that changes in temperature cause dimensional changes in a

body. An increase in temperature results in expansion, whereas a temperature

decrease produces contraction.

The thermal deformation is:

The thermal stress is:

d = a L DT

TS = a E DT

Where a = coefficient of thermal expansion and

DT= change in temperature.

PROBLEMS ON THERMAL STRESS AND THERMAL

DEFORMATION

33. A steel rod with a cross-sectional area of 150mm2 is stretched between two fixed

points. The tensile load at 20C is 5000N. What will be the stress at -20C? At

what temperature will the stress be zero? asteel = 11.7x10-6/C and E=200GPa.

Answer=127MPa ; T= 34.2C

34. Two identical steel bars 500mm long support the rigid beam shown. An

aluminum bar is placed exactly in between them, that is 0.1mm shorter. a) If the

rigid beam is weightless determine the change in temperature for the middle bar

to just touch the beam. b) If the beam weighs 300KN, find the stress in each bar.

c) If the beam weighs 250KN, determine the stress in each bar when the

temperature raises 35C d) If the beam weighs 320KN, determine the stress in

each bar when the temperature drops 25C.

0.1mm

500mm

steel

aluminum

steel

A in mm

6

a in x 10- /C

E in GPa

15/37

Aluminum

2400

23

70

Steel

1200

11.7

200

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

35. The composite bar is firmly attached

to unyielding supports. The initial

temperature is 80F when the load P

= 20kips is applied, compute the

stress in when the temperature is

150F and when the temperature is

5F.

Aluminum

A=3.25 in2

E=10x106psi

a= 12.8x10-6/F

Steel

A=5.5 in2

E= 29x106psi

a= 12.8x10-6/F

P

12in

25in

36. The rigid beam is supported by the two bars shown in a horizontal position before

the load P is applied. If P=200KN, determine the stress in each rod after an

increase in temperature of 40C B) drop of 65C.

L=6 m

aluminum

3m

A in mm

6

a in x 10- /C

E in GPa

steel

L=4.5 m

3m

Aluminum

600

23

70

Steel

800

11.7

200

3m

16/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

BEAMS

It is a structure usually horizontal acted upon by transverse loads (forces that acts

perpendicular to the plane containing the longitudinal axis of the beam)

axis beam

N/m

N/m

I. Statically Determinate

Beams supported such that the number of reacting forces equals the number of available

equations static equilibrium conditions,

P

a. Simply Supported

b. Cantilever Beams

c. Beams with Overhang

17/37

N/m

N/m

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

II. Statically Indeterminate Beams

Beams Supported such that the number of reacting forces exceeds the number of

equations of static. The analysis requires the use of elastic deformations

a. Propped Beam

N/m

b. Continuous Beams

P

c. Restrained Beams

N/m

N/m

18/37

N/m

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

TYPES OF LOADS

1. Concentrated Loads

2. Distributed Loads

a. Uniformly Distributed

N/m

b. Uniformly Varying

Triangular

Trapezoidal

W1

N/m

W2

N/m

c. Parabolic Loads

N/m

N/m

d. Moving Loads

19/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

The fundamental definitions of shear and bending moments are expressed by

V =

( F )

y left

and

M = ( M left ) = ( M right )

in which upward acting forces or loads cause positive effects. The shearing force V should be

computed only in terms of the forces to the left of the section being considered: the bending

moment M may be computed in terms of the forces to either the left or the right of the section

depending on which requires less arithmetical work.

Relations between load, shear moment are given by:

w=

dv

dx

v=

dM

dx

slope of the shear diagram

= slope of the moment diagram

These relations are amplified to provide a semi graphical method of computing shear and

moment which supplements the equations

V =

( F )

y left

and

M = ( M left ) = ( M right )

V2 = V1 + Aload - diagram

M 2 = M 1 + AShear - daigram

A summary of the principles presented suggests the following procedure for the construction of

shear and moment diagrams

1. Compute the reactions

2. Compute the values of shear at the change of load points using V2 = V1 + Aload - diagram

3. Sketch the shear diagram, drawing the correct shape and concavity of the shear diagram.

4. Locate the points of zero shear.

5. Compute values of bending moment at the change of load points and the points of zero

shear using M 2 = M 1 + AShear - daigram

6. Sketch the moment diagram

20/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

PROPERTIES OF THE SHEAR DIAGRAM

1. At every change of loading we have to investigate our shear.

2. For concentrated loads or reactions the left and right portion of the point where they are

acting must be investigated

3. Whenever we have a concentrated load or reaction there will always be a vertical line in the

shear diagram

4. The shear diagram is one degree higher than the load diagram

5. Reference of the Concavity of the Shear Diagram

Concavity of the circle corresponds to

the concavity of the shear diagram

Positively

decreasing load

Negatively

increasing load

Negatively

decreasing load

Note: When M=0

of beam.

Positively

increasing load

( point of inflection) there is a change of the concavity of the elastic curve

PROPERTIES OF THE MOMENT DIAGRAM

1. For every change in shear diagram, the moment must be investigate

2. Consider only the moment at any point and not the left and the right portion of the point

except when we have a moment load or reaction

3. Analyze the point where the shear intersects the reference line (V=0) since when shear is

zero moment is maximum or minimum

4. Vertical line will only be observed in the moment diagram whenever we have a moment

load or reaction

5. The concavity of the moment diagram depends upon the load: if the load is downward,

moment diagram is downward

6. The moment diagram is one degree higher than the shear diagram

21/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

SHEAR AND MOMENT DIAGRAMS

Determine the shear and moment diagrams of the following beams loaded as shown

100 KN

1.

2m

80 KN

40KN/m

1m

20 KN/m

3m

7m

2.

60 KN

120KN-m

40 KN/m

1m

3.

3m

1m

1m

40 KN/m

3m

w1 KN/m

2m

w2 KN/m

5m

40 KN

80 KN

20 KN/m

4.

2m

2m

1m

20 kN

2m

5.

2m

1m

20 KN/m

w KN/m

1m

10kN/m

1m

2m

25 kN

6.

3m

2m

1m

Hinge

22/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

2m

80 KN

Hinge

40 KN/m

7.

4m

R1

20 KN/m

1m

1m

50KN-m

20 KN/m

8.

1m

R3

6m

R2

1m

2m

3m

120KN-m

10KN/m

9.

2m

2m

1m

10. Determine P so that the moment at each support is equal to the moment at midspan.

P KN

P KN

10 KN/m

1m

1m

6m

23/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

II SHEAR AND MOMENT DIAGRAMS OF BEAMS WITH

TRIANGULAR LOADINGS

1.

12 KN/m

12 KN

1m

4m

9m

1m

w KN/m

80KN/m

2.

MAX M=80KN-m

40 KN/m

2m

3.

2m

1m

3m

60KN/m

40 KN

3m

1m

2m

40KN

120KN/m

4.

40 KN/m

3m

2m

20 KN/m

MAX M=160KN-m

2m

80KN/m

5.

MAX M=137.5KN-m

1m

3m

24/37

1m

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

6.

120KN/m

120KN/m

3m

7.

MAX M=-450KN-m

3m

3m

3m

12KN/m

18KN/m

MAX M=49.5KN-m

3m

6m

8. The shear diagram is shown in the figure, determine the moment and load diagrams.

2m

2m

1m

1m

45KN

45KN

-15KN

105KN

9.

1m

20KN

-10KN

2m

2m

-30KN

-20KN

10.

-10KN

-2KN

3m

-8KN

1m

25/37

1m

2m

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

DESIGN FOR FLEXURAL STRESS

1. A cantilever beam, 75mm wide by 200 mm high and 6m long carries a load that varies

uniformly from zero at the free end to 1500 N/m at the wall. (a) Compute the magnitude

and location of the maximum flexural stress (b) Determine the type and magnitude of the

stress in a fiber 25mm from the top of the beam at section 2.5m from the free end.

b

3m

5000N

2. Determine the minimum width b

2000N/m

200mm

of the beam shown if the flexural

stress is not to exceed 10Mpa.

3m

1m

3. A 2 diameter bronze bar is used as a simply supported beam 8ft long. Determine the

largest uniformly distributed load, which can be, applied over the right half of the beam if

the flexural stress is limited to go 10ksi?

4. A simply supported rectangular yacal beam, 75mm wide by 150mm deep, carries a

uniformly distributed load of 2250 N / m over its entire length. What is the maximum

length of the beam if the flexural stress is limited to 18 Mpa?

5. A simply supported beam 6m long is composed of two C 200x28 channels riveted back

to back. What uniformly distributed load can be carried, in addition to the weight of the

beam, without exceeding a flexural stress of 125 MN/m2 if (a) the webs are vertical and

(b) the webs are horizontal. Refer to Appendix B for channel properties.

6. A beam with a S380 x 74 section is simply supported at the ends. It supports a central

concentrated load of 40 kN and a uniformly distributed load of 15 kN/m over its entire

length, including the weight of the beam. Determine the maximum length of the beam if

the flexural stress is not to exceed 130 Mpa. Refer to Appendix B for properties of S

shapes.

7. A beam 15 m long is simply supported 2 m from each end. It is a

built

up made of four angle bars 100x75x13, with long legs horizontal

(see

Table B-6) welded to a flat bar 25mmx300mm as shown in the

figure. Determine the total uniformly distributed load that can be

carried along its entire length without exceeding a flexural stress of

120

MPa.

8. A beam with a W2360x33section (see Table B-2) is used as a cantilever beam 7.5 m

long. Find the maximum uniformly distributed load which can be applied over the entire

length of the beam, in addition to the weight of the beam, if the flexural stress is not to

exceed 140 MN / m2

9. A 12-m beam simply supported at the ends carries a uniformly distributed load of 20kN / m over

its entire length. What is the lightest W shape beam that will not exceed a flexural stress of

120MPa ? What is the actual stress in the beam selected?

10. A simply supported steel beam 10m long carries a uniformly distributed load of 18kn/m load

over the entire length and a central concentrated load of 25Kn. Determine the lightest Wide

flanged section that can be used to support the load. What is the actual resulting stress in the

beam selected.

50K

11. A cantilever wooden beam is composed of two

segments with rectangular cross sections. The width

of each section is 75mm but their depths (150mm

1.5m

and 250mm) are different, as shown in the figure.

2m

Determine the maximum bending stess in each beam.

26/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

UNSYMMETRICAL SECTION DESIGN

FOR BENDING STRESS

The previous discussions are all about beams symmetric with respect to the neutral axis.

Because flexural stress vary directly with distance from the neutral axis of symmetric beams,

which is the centroidal axis, such beam sections are desirable for materials that are equally

strong in tension and compression. However, for materials relatively weak in tension and

strong in compression such as cast iron, it is desirable to use beams that are unsymmetrical

with respect to the neutral axis. With such a cross section, the stronger fibers can be located

at a greater distance from the neutral axis than the weaker fibers. The ideal treatment for such

materials is to locate the centroidal or neutral axis in such a position that the ratio of the

distances from it to the fivers in tension and in compression is exactly the same as the ratio of

the allowable stresses in tension and in compression. The allowable stresses thus reach their

permitted values simultaneously.

1. A cast-iron beam carries a uniformly distributed load on a simple span. Compute the

flange width b of the inverted T section so that the allowable stresses fb(tension)=30MPa and

fb(compression)=90MPa reach their limits simultaneously.

20mm

W N/m

yc

120mm

L

NA

yt

20mm

b

2. Compute the maximum tensile and compressive stresses developed in the beam that is

loaded and has the cross-sectional properties shown.

8KN

30mm

10KN/m

4m

1m

125mm

25mm

100mm

3. Determine the maximum safe value of W that can be carried by the beam shown if

the following allowable stresses fb(tension)=60MPa and fb(compression)=90MPa

6W KN

given

80mm

20mm

20mm

35mm

120mm

2m

8m

2m

27/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

DESIGN FOR SHEARING STRESS

The vertical shear sets up numerically equal shearing stresses on longitudinal and

transverse sections, which are determined from:

VQ

;

Ib

fv =

Q=AB in which A is the partial area of the cross section above a line drawn through the point

at which the shearing stress is desired. Q=Ay is the static moment about the NA of this area

(or of the area below this line).

Maximum shearing stresses occur at the section of maximum V and usually at the NA.

For rectangular beams, the maximum shearing stress is

Max . f v =

3V

.

2bh

1. Draw the shearing stress distribution for a rectangular beam 75mmx200mm which is

simply supported on a 10m beam with a load of 20KN/m over the entire length.

2. Determine the maximum and minimum shearing stress in the web of the wide flange

section if V=120KN.

3. The distributed load shown is supported by a box beam shown. Determine the

maximum safe value of w that will not exceed a flexural stress of 10 MPa or a shearing

stress of 1MPa.

3m

1m

4. The distributed load shown is supported by a wide-flange section W 360x45 of the given

dimensions. Determine the maximum safe w that will not exceed a flexural stress of

140 MPa or a shearing stress of 75 MPa.

2m

4m

28/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

DESIGN FOR FLEXURE AND SHEAR

In heavily loaded short beams the design is usually governed by shearing stress; but in longer

beams the flexure stress generally governs because the bending moment varies with both the

load and length of beam. Shearing is more important in timber beams than in steel beams

because of the low shearing strength of wood.

1. A box beam supports the loads shown. Compute the maximum value of P that will not

exceed a flexural stress fb(flexure)=8MPa and fv(shearing)=1.2MPa for section between the

20mm

20mm

support.

160mm

4000 N

P

2m

2m

2m

200mm

160mm

2. A simply supported beam L meters long carries a uniformly distributed load of 16KN/m

over its entire length and has the cross section shown . Find L to cause a maximum

flexural stress of 40MPa. What maximum shearing stress is then developed?

140mm

20mm

20mm

160mm

3. The wide flenage beam shown in the fig supports the concentrated load W and a total

uniformly distributed load 2W KN. Determine the maximum safe value of W if

fb(flexure)=10MPa and fv(shearing)=1.4MPa

200mm

W

2W

220mm

20mm

2m

1m

180mm

2m

29/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

DEFLECTION IN BEAMS

Frequently the design of a beam is determined by its rigidity rather than by its strength.

Several methods are available for determining beam deflections. Although based on the same

principles, they differ in technique and in their immediate objective. We consider first a

variation of the double-integration method that greatly broadens and simplifies its application.

Another method, the area-moment method, is thought to be the most direct of any, especially

when the deflection at a specific location is desired.

DOUBLE INTEGRATION METHOD

A mathematical approach in solving for the deflection at any portion of the beam involve a

complete determination of the moment, slope and deflection equation for the entire beam:

d2y

Moment Equation EI dx 2 = M

d2y

Slope Equation EI 2 =

dx

Deflection Equation

Mdx + C

d2y

EI 2 = Mdxdx + C1 x + C 2

dx

The constants of integration will become zero if the origin of axes is selected at a position

where the slope and deflection are known to be zero, as at a perfectly restrained end or at the

center of a symmetrically loaded beam.

1. Determine the midspan deflection of a simply supported beam carrying a

a) uniformly distributed load over the entire length of the beam.

b) central concentrated load.

2. Determine the free end deflection of a cantilever beam carrying a

a) uniformly distributed load over the entire length of the beam.

b) free end concentrated load.

3. Find the value of EIy at the position midway between the supports and at the overhanging

end for the beam shown and also determine the location of maximum deflection.

400N/m

1m

3m

600N

2m

2m

30/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

AREA-MOMENT METHOD

Theorem I: The change in slope between tangents drawn to the elastic curve at any two points

A and B is equal to the product of 1/EI multiplied by the area of the moment diagram between

these two points.

1

( AREA)AB

EI

q AB =

Theorem II: The deviation of any point B relative to a tangent drawn to the elastic curve at

any other point A, in a direction perpendicular to the original position of the beam, is equal to

the product of 1/EI multiplied by the moment of area about B of that part of the moment

diagram between points A and B.

tB / A =

1

( area ) BA x B

EI

The product EI is called flexural rigidity. In two theorems, (area)AB is the area of the moment

diagram between points A and B, and x B is the moment arm of this area measured from B.

When the area of the moment diagram is composed of several parts, the expression (area)AB

includes the moment of the area of all such parts. The moment of the area is always taken

about an ordinate through the points at which the deviation is being computed.

One rule is very important: The deviation at any point is positive if the point lies above the

reference tangent from which the deviation is measured and negative if the point lies below the

reference tangent.

B

A

tB/A

tB/A

Negative deviation: B located

below reference tangent

Positive deviation: B located above

reference tangent

1. Determine the midspan deflection of a simply supported beam carrying a

a) uniformly distributed load over the entire length of the beam.

b) central concentrated load.

2. Determine the free end deflection of a cantilever beam carrying a

a) uniformly distributed load over the entire length of the beam.

b) free end concentrated load.

3. Find the value of EIy at the position midway between the supports and at the overhanging

end for the beam shown and also determine the location of maximum deflection.

400N/m

1m

3m

600N

2m

31/37

2m

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

PROBLEM SET

1. Compute the value of EId at midspan for the beam loaded as shown. If E=10GPa, what

value of I is required to limit the midspan deflection to 1/360 of the span?

300N/m

2m

Answer=EId=5000N-m3;

2

2. Compute the value of EId at midspan for the beam loaded as shown.

1.5m

300N/m 0.5m

4m

Answer: EId=657N-

3. Compute the value of EId at the right end of the beam loaded as shown.

400N/m

1m 1

4m

400

Answer: EId=195N-

4. Compute the value of EIy midway between the supports for the overhanging beam

shown.

4kN

2kN/m

2kN/m

2m

Answer: EId=-4.66kN-

32/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

TORSION

Torsion is a variable shearing stress experienced by solid or hollow circular shafts subjected to

moment or torque. This shearing stress varies directly with the radial distance from the center

of the cross section and is expressed by

~ Tr

. The radial distance r becomes r for maximum torsional shearing stress. For

T =

J

~ 16T

maximum torsional shearing stress in solid shafts of diameter d becomes T = 3

pd

The angular deformation in a length L

is expressed in radians by q =

TL

.

JG

III. Flanged Bolt Coupling Connection

A commonly used connection between two shafts is a flanged bolt coupling. It cobnsists of

flanges rigidly attached to the ends of the shafts and bolted together. The torque is transmitted

by the shearing force P created in the bolts.

P=SA

pd 2

SRn .

T=PRn or T = PRn =

4

Occasionally a coupling has two concentric rows of bolt. Letting the subscript 1 refer to bolts

on the outer circle and subscript 2 refer to bolts on the inner circle, the torque capacity of the

coupling is T=P1R1n1+P2R2n2. The relation between P1 and P2 can be determined from the

fact that the comparatively rigid flanges cause shear deformations in the bolts which are

proportional to their radial distances from the shaft axis. Using Hookes Law for shear,

P1

P2

A1

A2

=

G1R1 G2 R21

33/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

TORSION PROBLEMS

1. What is the minimum diameter of a solid steel shaft that will not twist through more than

3 in a 6m length when subjected to a torque of 14KN-m? What maximum shearing

stress is developed? Use G=83Gpa.

2. A stepped steel shaft consists of a hollow shaft 2m long, with an outside diameter of

100 mm and an inside diameter of 70mm, rigidly attached to a solid shaft 1.5m long,

and 70mm in diameter. Determine the maximum torque that can be applied without

exceeding a shearing stress of 70MPa or a twist of 2.5 in a 3.5 m

length. Use G=83Gpa

3. A solid steel shaft is loaded as shown. Using G=83Gpa, determine the

required diameter of the shaft if the shearing stress is limited to 60MPa

and the angle of rotation at the free end is not to exceed 4.

4. A flanged bolt coupling consists of eight steel 20-mm bolts spaced evenly around a bolt

circle of300mm in diameter. Determine the torque capacity of the coupling if the

allowable shearing stress in the bolts is 40MPa.

5. A flange bolt coupling consists of 6-10mm diameter steel bolts on a bolt circle 300mm in

diameter and 4-10mm diameter steel on a concentric bolt circle 200mm in diameter.

What torque can be applied without exceeding a shearing stress of 60MPa in the bolts?

B) Determine the number of 10mm steel bolts that must be used on the 300mm bolt

circle of the coupling to increase the torque capacity to 8KN-m.

a. ECCENTRICALLY LOADED RIVETED CONNECTIONS

34/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

6. The connection of 12 rivets shown, the load P = 200kN passes through the center of

rivet C and has a slope of 4/3. Determine the resultant load on the most heavily loaded rivet.

Y

A

100

mm

c.g.

CCC

100

mm

80 mm

80 mm

80 mm

7. Determine the most and least heavily loaded 16mm diameter rivet in the connection shown.

Note that rivets B and C were not properly driven that they do not carry any load.

90 mm

90 mm

120 mm

P=50KN

120 mm

35/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

8. Rivets 22 mm in diameter are used in the connection shown in the figure. If P = 90 kN,

what thickness of plate is required so as not to exceed a bearing stress of 140 MPa?

P

80 mm

80 mm

100 mm

9. In the gusset plate connection shown in the figure, if P = 60 kN, determine the

shearing stress in the most heavily loaded of the four 22-mm rivet.

100 mm

100 mm

200 mm

150 mm

36/37

Engr. Divina R. Gonzales

MECHANICS OF DEFORMABLE BODIES

10. For the connection shown in the figure, determine the shearing stress in the most

heavily loaded of the three 22-mm rivets.

80 mm

80 mm

90 mm

100 mm

3

60 kN

11. A gusset plate is riveted to a larger plate by four 22mm rivets arranged and

loaded as shown. Determine the minimum shear stress developed in the rivets.

80

mm

80 80

mm mm

100

mm

P=40KN

37/37

Engr. Divina R. Gonzales

S-ar putea să vă placă și

- SOM Two Marks Q&ADocument22 paginiSOM Two Marks Q&AthandialÎncă nu există evaluări

- Ce161p A88 q1 MakeupDocument1 paginăCe161p A88 q1 MakeupRam RamirezÎncă nu există evaluări

- Carbon-Carbon Composites A Summary of Recent Developments and ApplicationsDocument5 paginiCarbon-Carbon Composites A Summary of Recent Developments and Applicationsdroessaert_stijn100% (1)

- C E D C A E: Ollege of Ngineering Epartment of Ivil & Rchitectural NgineeringDocument27 paginiC E D C A E: Ollege of Ngineering Epartment of Ivil & Rchitectural Ngineeringhend mahmoudÎncă nu există evaluări

- Mechanics of Solids CE 1201Document12 paginiMechanics of Solids CE 1201G Sri SoumyaÎncă nu există evaluări

- CE 6306 Strength of Materials Two MarksDocument8 paginiCE 6306 Strength of Materials Two MarksGokulraju Rangasamy100% (2)

- Strength of Metirials QUSDocument5 paginiStrength of Metirials QUSraviÎncă nu există evaluări

- Structural Theory: By: Engr. Ma. Angelica C. Avillanosa, MsceDocument32 paginiStructural Theory: By: Engr. Ma. Angelica C. Avillanosa, MsceIvy Jill Jurada100% (1)

- A. Reading Assignment: Analysis of Members With Axial Loads and MomentsDocument19 paginiA. Reading Assignment: Analysis of Members With Axial Loads and MomentsIhab El AghouryÎncă nu există evaluări

- PDF Simplified Reinforced Concrete Design 2010 NSCPDocument200 paginiPDF Simplified Reinforced Concrete Design 2010 NSCPMeverlyn RoqueroÎncă nu există evaluări

- INTRODUCTION (Cont..) : TIN 205-TIN31 Engineering MechanicsDocument47 paginiINTRODUCTION (Cont..) : TIN 205-TIN31 Engineering Mechanicsgundul paculÎncă nu există evaluări

- Distributed ForcesDocument71 paginiDistributed ForcesNOKIAÎncă nu există evaluări

- Chapter IIIDocument83 paginiChapter IIIlatendra kumar srivastavÎncă nu există evaluări

- Som PDFDocument105 paginiSom PDFanon_10845568100% (1)

- 3-Dimensional Drawings, or Photographic or Pictorial Drawings. Isometric DrawingDocument12 pagini3-Dimensional Drawings, or Photographic or Pictorial Drawings. Isometric DrawingHarshit SolankiÎncă nu există evaluări

- Review of Related LiteratureDocument5 paginiReview of Related LiteratureJay Ar GalangÎncă nu există evaluări

- Strength of Materials Objective and Conventional by S K MondalDocument434 paginiStrength of Materials Objective and Conventional by S K Mondalpadalakirankumar33% (3)

- Strength of Materials 2 Mark QuestionsDocument42 paginiStrength of Materials 2 Mark Questionssiraj100% (5)

- Ramkali Sad Sahib SinghDocument22 paginiRamkali Sad Sahib SinghAmritpal SinghÎncă nu există evaluări

- Sec 05100 - Structural SteelDocument10 paginiSec 05100 - Structural Steeltiju2005hereÎncă nu există evaluări

- Mf7017 Materials Testing and Characterlation TechniquesDocument1 paginăMf7017 Materials Testing and Characterlation TechniquesSudhir Chakravarthy KatragaddaÎncă nu există evaluări

- Relationship Between Stress and StrainDocument2 paginiRelationship Between Stress and Strainbabe100% (4)

- Indetermine StructureDocument8 paginiIndetermine Structuremaloy100% (1)

- Eccentric LoadingDocument5 paginiEccentric LoadingconfederateyankeeÎncă nu există evaluări

- BFC 20903 (Mechanics of Materials) Chapter 1: Stress & StrainDocument55 paginiBFC 20903 (Mechanics of Materials) Chapter 1: Stress & StrainAfif Azhar100% (1)

- Strength of Materials by S K Mondal 4 PDFDocument34 paginiStrength of Materials by S K Mondal 4 PDFajaykrishna_99Încă nu există evaluări

- Eccentric LoadDocument6 paginiEccentric LoadAtish Kumar100% (3)

- Chap4b-Axially Loaded MembersDocument27 paginiChap4b-Axially Loaded Membersskhan247100% (1)

- Stress Strain DiagramDocument4 paginiStress Strain DiagramMartine CastroÎncă nu există evaluări

- Steel Structures Tension Members 2Document24 paginiSteel Structures Tension Members 2Nafi AykutÎncă nu există evaluări

- PDF Ch3B Couple StaticDocument43 paginiPDF Ch3B Couple StaticHaiqal AzizÎncă nu există evaluări

- 5 - Cylinders and Vessels (Part-1)Document17 pagini5 - Cylinders and Vessels (Part-1)Rubab ZahraÎncă nu există evaluări

- Module 7 Column and StrutDocument69 paginiModule 7 Column and StrutRahul SinghÎncă nu există evaluări

- Strength of MaterialsDocument101 paginiStrength of MaterialsLucksy Marcus PalloÎncă nu există evaluări

- Som VivaDocument13 paginiSom VivaDoddaBasappaKÎncă nu există evaluări

- Statics and Strength of Materials Formula SheetDocument1 paginăStatics and Strength of Materials Formula SheetRichard TsengÎncă nu există evaluări

- Strength of Materials 4th Edition by Pytel and Singer Problem 126 Page 21 GivenDocument12 paginiStrength of Materials 4th Edition by Pytel and Singer Problem 126 Page 21 Givenজাকির হোসেনÎncă nu există evaluări

- Simple Stresses and Strains PDFDocument104 paginiSimple Stresses and Strains PDFyaminiÎncă nu există evaluări

- Theories of Failure 2Document23 paginiTheories of Failure 2Nagendra Manral100% (1)

- Tension Compression and ShearDocument27 paginiTension Compression and ShearRizal Muhammad FaradayÎncă nu există evaluări

- Chapter 8 Slope and Deflection Strength of Materials - Part 1Document14 paginiChapter 8 Slope and Deflection Strength of Materials - Part 1Abhijith ShettyÎncă nu există evaluări

- Simple StrainDocument12 paginiSimple StrainChristine Mae TinapayÎncă nu există evaluări

- Mechanics of Solids Power-Point PresentationDocument38 paginiMechanics of Solids Power-Point Presentationjust_friends199Încă nu există evaluări

- Torsion 6th ChapterDocument13 paginiTorsion 6th ChapterakshatbhargavaÎncă nu există evaluări

- A. Hydrostatic Force On Plane Surface: 1. FormulaDocument20 paginiA. Hydrostatic Force On Plane Surface: 1. FormulaKim Kelley AngÎncă nu există evaluări

- Engg Mech and Strength of MaterialsDocument73 paginiEngg Mech and Strength of MaterialsClaire NecesitoÎncă nu există evaluări

- Formula Sheet For Exam 1Document1 paginăFormula Sheet For Exam 1chris ricaÎncă nu există evaluări

- Analysis of TrussesDocument2 paginiAnalysis of TrussesMelvin Esguerra50% (2)

- Strength of Materials (HE 306)Document463 paginiStrength of Materials (HE 306)Anu ParameswaranÎncă nu există evaluări

- Chapter 6 Bending: Moments Forces Perpendicular To AxisDocument13 paginiChapter 6 Bending: Moments Forces Perpendicular To AxisSumaya MahmoodÎncă nu există evaluări

- Simple Stress StrainDocument141 paginiSimple Stress Strainjs kalyana ramaÎncă nu există evaluări

- Dynamics in One Complex Variable. (AM-160): (AM-160) - Third EditionDe la EverandDynamics in One Complex Variable. (AM-160): (AM-160) - Third EditionÎncă nu există evaluări

- Lecture On Strength of Materials August 2014Document87 paginiLecture On Strength of Materials August 2014Cha Castillo100% (1)

- Lecture On Strength of Materials 2014Document87 paginiLecture On Strength of Materials 2014BatsCrazy100% (1)

- Chapter 1 - Simple StressesDocument39 paginiChapter 1 - Simple StressesJovy Notorio100% (2)

- Strength of Materials: Prepared By: Engr. Jeric P. SarteDocument30 paginiStrength of Materials: Prepared By: Engr. Jeric P. SarteGiacomo EllieÎncă nu există evaluări

- Simple StressDocument50 paginiSimple StressIvan Manalang50% (4)

- Simple Stresses 1Document21 paginiSimple Stresses 1Midas Troy VictorÎncă nu există evaluări

- STR ModuleDocument10 paginiSTR ModuleViamae Avellana CabutajeÎncă nu există evaluări

- Strength of Material Lecture ProblemsDocument11 paginiStrength of Material Lecture ProblemsLorenz ArdienteÎncă nu există evaluări

- MECH 314 Unit 1Document34 paginiMECH 314 Unit 1Tomas Otero IIIÎncă nu există evaluări

- Work Inspection Checklists (11!06!2019)Document53 paginiWork Inspection Checklists (11!06!2019)Ram RamirezÎncă nu există evaluări

- RMExtractionDocument21 paginiRMExtractionRam RamirezÎncă nu există evaluări

- Used Sack To Be Used As The Sleeve Material in The Horizontal Bar Lap Splice Instead of Felt PaperDocument8 paginiUsed Sack To Be Used As The Sleeve Material in The Horizontal Bar Lap Splice Instead of Felt PaperRam RamirezÎncă nu există evaluări

- Final Assesment: Ramirez, Charles Jon N. December 9, 2015 CE121/B2 Engr. BalmorisDocument3 paginiFinal Assesment: Ramirez, Charles Jon N. December 9, 2015 CE121/B2 Engr. BalmorisRam RamirezÎncă nu există evaluări

- Academic Advising FormDocument1 paginăAcademic Advising FormRam RamirezÎncă nu există evaluări

- Course Expectation AlbaDocument1 paginăCourse Expectation AlbaRam RamirezÎncă nu există evaluări

- Course Expectation: Ramirez, Charles Jon N. October 7, 2015 CE-3 / 2013150342 Engr. BalmorisDocument1 paginăCourse Expectation: Ramirez, Charles Jon N. October 7, 2015 CE-3 / 2013150342 Engr. BalmorisRam RamirezÎncă nu există evaluări

- Ramirez, Charles Jon N. Compiled ProbsDocument5 paginiRamirez, Charles Jon N. Compiled ProbsRam RamirezÎncă nu există evaluări

- FW1Document18 paginiFW1Ram RamirezÎncă nu există evaluări

- Name: Ramirez, Charles Jon N. MEC 32-1 A2 July 28, 2015 S#: 2013150342 SNDocument2 paginiName: Ramirez, Charles Jon N. MEC 32-1 A2 July 28, 2015 S#: 2013150342 SNRam RamirezÎncă nu există evaluări

- Exp 8 10 ConmatDocument3 paginiExp 8 10 ConmatRam RamirezÎncă nu există evaluări

- LAB REPORT-Osbourne Reynolds ApparatusDocument20 paginiLAB REPORT-Osbourne Reynolds Apparatusmizizasbonkure9055% (11)

- PeerDocument1 paginăPeerRam RamirezÎncă nu există evaluări

- Mathexit 1Q1112Document8 paginiMathexit 1Q1112Ram RamirezÎncă nu există evaluări

- PHY11 Lesson 3jhb Momentum and Collisions 2Q1415Document21 paginiPHY11 Lesson 3jhb Momentum and Collisions 2Q1415Ram RamirezÎncă nu există evaluări

- Caringal - B25Document1 paginăCaringal - B25Ram RamirezÎncă nu există evaluări

- Application Form For Scholarship: Center For Scholarships and Financial AssistanceDocument3 paginiApplication Form For Scholarship: Center For Scholarships and Financial AssistanceRam RamirezÎncă nu există evaluări

- FIL11Document8 paginiFIL11Ram Ramirez0% (1)

- Antidifferentiation: MATH22-1 Calculus 2Document11 paginiAntidifferentiation: MATH22-1 Calculus 2Ram RamirezÎncă nu există evaluări

- Experimental Investigations of Buckling Behaviour of Steel ScaffoldsDocument30 paginiExperimental Investigations of Buckling Behaviour of Steel ScaffoldsMarah Husin Fadli LubisÎncă nu există evaluări

- Astm D2573 D2573M 18Document4 paginiAstm D2573 D2573M 18deptrailaikieuÎncă nu există evaluări

- DjekicDocument110 paginiDjekicРаденко ОстојићÎncă nu există evaluări

- MS8910 Instruction ManualDocument6 paginiMS8910 Instruction ManualAndre Fabiano JardimÎncă nu există evaluări

- Signal & System WB SolutionsDocument226 paginiSignal & System WB SolutionsCHANDRIMA UPADHYAYÎncă nu există evaluări

- Soudal Soudafix CA 1400 TDSDocument2 paginiSoudal Soudafix CA 1400 TDSAddisÎncă nu există evaluări

- Eaton 120641 FAZ C10 2 NA DC en - GBDocument2 paginiEaton 120641 FAZ C10 2 NA DC en - GBCarlos Garcia Jacome DarkerÎncă nu există evaluări

- Cellular Beam L 10MDocument10 paginiCellular Beam L 10MAnh KyÎncă nu există evaluări

- Characterizing Metallic Microstructure Cu-Based AlloysDocument51 paginiCharacterizing Metallic Microstructure Cu-Based AlloysjuegyiÎncă nu există evaluări

- Chapter 17 Electromagnetic Induction Notes Answers PDFDocument2 paginiChapter 17 Electromagnetic Induction Notes Answers PDFabdul halimÎncă nu există evaluări

- 4c Lab3 Heat EnginesDocument4 pagini4c Lab3 Heat EnginesAiza AliÎncă nu există evaluări

- Key Concepts in Welding EngineeringDocument4 paginiKey Concepts in Welding EngineeringXÎncă nu există evaluări

- Cired 2019 - 1606Document5 paginiCired 2019 - 1606romany allamÎncă nu există evaluări

- Skema Kertas 3Document13 paginiSkema Kertas 3rhimalinyÎncă nu există evaluări

- 2006 01 0884Document38 pagini2006 01 0884Yosra RamadhanÎncă nu există evaluări

- Mos GRPDocument53 paginiMos GRPslxanto100% (3)

- Personal Care Isostearic Acid & EstersDocument15 paginiPersonal Care Isostearic Acid & EsterssinghsachinkumarÎncă nu există evaluări

- ISO/TS 12913-2:2018 Soundscape - Part 2: Data Collection and Reporting Requirements - What's It All About?Document3 paginiISO/TS 12913-2:2018 Soundscape - Part 2: Data Collection and Reporting Requirements - What's It All About?jrlr65100% (1)

- BeerJohnson Vector Mechanics SampleDocument563 paginiBeerJohnson Vector Mechanics SampleRamkumar S100% (3)

- Energy Guide Midea - Mrc07m6aww Mrc07m6ewwDocument1 paginăEnergy Guide Midea - Mrc07m6aww Mrc07m6ewwharry HendersonÎncă nu există evaluări

- Bromhead - A Simple Ring Shear ApparatusDocument3 paginiBromhead - A Simple Ring Shear ApparatusDaniel Felipe Rodriguez RamirezÎncă nu există evaluări

- Luisa 1Document20 paginiLuisa 1Walenty JanowiczÎncă nu există evaluări

- (2006 - Tamura) Wind Resistand Design of Tall Buildings in JapanDocument20 pagini(2006 - Tamura) Wind Resistand Design of Tall Buildings in JapanDuchatteÎncă nu există evaluări

- Water Stagnant of Solar ModulesDocument6 paginiWater Stagnant of Solar ModulesNITIN MISHRAÎncă nu există evaluări

- Potential Difference WorksheetDocument2 paginiPotential Difference WorksheetDigCity DiggÎncă nu există evaluări

- Xilinx Spartan3 Device ReliabilityDocument118 paginiXilinx Spartan3 Device ReliabilityRaffi SkÎncă nu există evaluări

- Sheldon S File 3Document7 paginiSheldon S File 3NATHANIEL YACASÎncă nu există evaluări

- Ch. 9 (B) LecDocument38 paginiCh. 9 (B) LecTom UlesÎncă nu există evaluări